Datamax I-Class Mark II Operating manual

GPIO Option

92-2586-01 Rev.B

1

Overview

This document describes the installation and use of the General Purpose Input Output

(GPIO) option for the I-Class Mark II printer. Follow the steps to begin installing/using the

option.

CAUTION

For safety and to avoid equipment damage, turn OFF the power switch and

unplug the AC power cord from the printer before starting this installation.

Contents

This kit contains the following items:

GPIO Circuit Card Assembly

Standoff, 6mm Hex (2)

Locking Nut, 5.5mm (2)

3

1

2

Tools Required

To install this option, you will need:

Philips screwdriver

5mm Hex Driver

5.5mm Hex Driver

6mm Hex Driver

Additional Requirements

Depending on your application, you may need the following hardware to interface the card:

Cable - DB15 Male connector (e.g., StarTech C15PCM) with shielded cabling.

2

Installing the Option

If the GPIO Card is already installed in the printer, skip this section and proceed to

“Configuring the Hardware”. Otherwise, install the GPIO Card as described below:

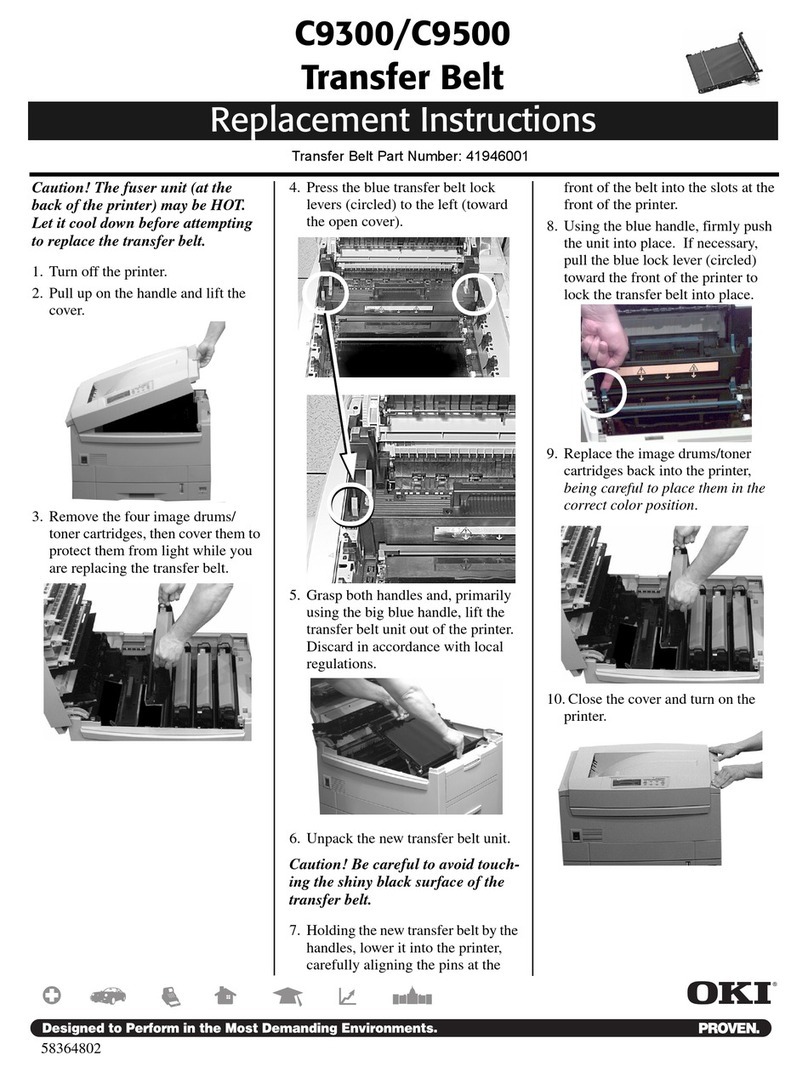

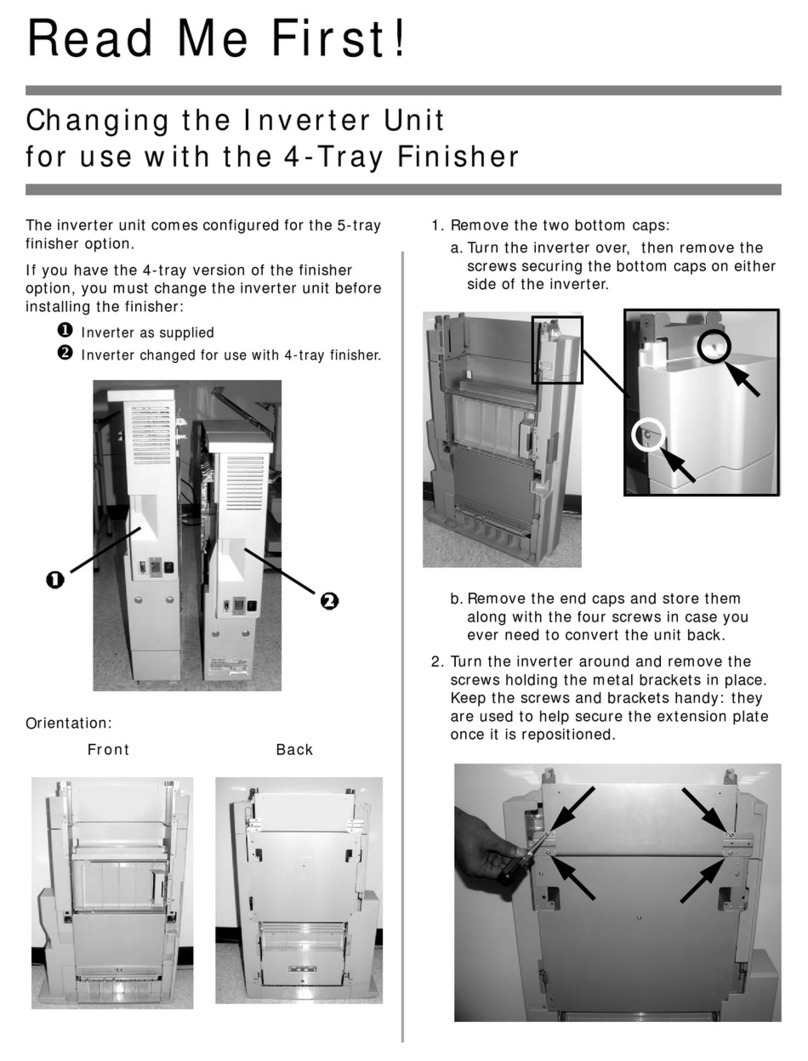

A) Turn off and disconnect the power cord from the printer. Remove the three Screws

from the left side cover of the printer.

B) Open the printer’s cover, loosen (do not remove) the two Screws on the inside of the

printer and lift the Cover Assembly up and off the printer.

Screws

Cover

Assembly

Screws

3

C) Remove the 5mm Screw and Cover

Plate from the rear of the printer.

D) Remove the two Jack Screws from

the GPIO Card, (these will be re-

installed later in the procedure).

Cover Plate

5mm Screw

Jack

Screws

E) Install the two 6mm Standoffs into the main board in the locations shown.

6mm

Standoffs

4

F) Install the GPIO Card into the printer. First insert the “Port” end into the cut-out in the

rear of the printer. Then pivot the GPIO Card onto the two Standoffs.

G) Loosely install the two previously removed Jack Screws and the two 5.5mm Nuts.

Jack

Screws

5.5mm

Nuts

H) Tighten the two Jack Screws and the two 5.5mm Nuts. Proceed to “Configuring the

Hardware” on the next page.

5

Configuring the Hardware

Configure the card to meet your interfacing requirements by arranging hardware jumpers,

as described in the following procedure:

CAUTION

Only qualified service personnel should configure of the GPIO card.

For your safety and to avoid equipment damage, always turn OFF power

and unplug the printer’s power cord before beginning this installation and

when performing service.

Always wear a wrist strap and follow standard ESD prevention measures

when handling the card.

A) Turn off and disconnect the power cord from the printer. Remove the printer’s cover if

needed.

B) Set the jumpers on the card (detailed below) to meet the requirements of your

application. Once complete re-install the printer’s cover.

Four dedicated inputs control printer functions. Designed to interface to open-

collector outputs, these inputs require no external pull-ups, while blocking diodes

allow the use of totem pole outputs from +4.5 VDC to + 26 VDC. Optical isolators

provide galvanic isolation. Two print control interface circuit examples are given on

the following page.

6

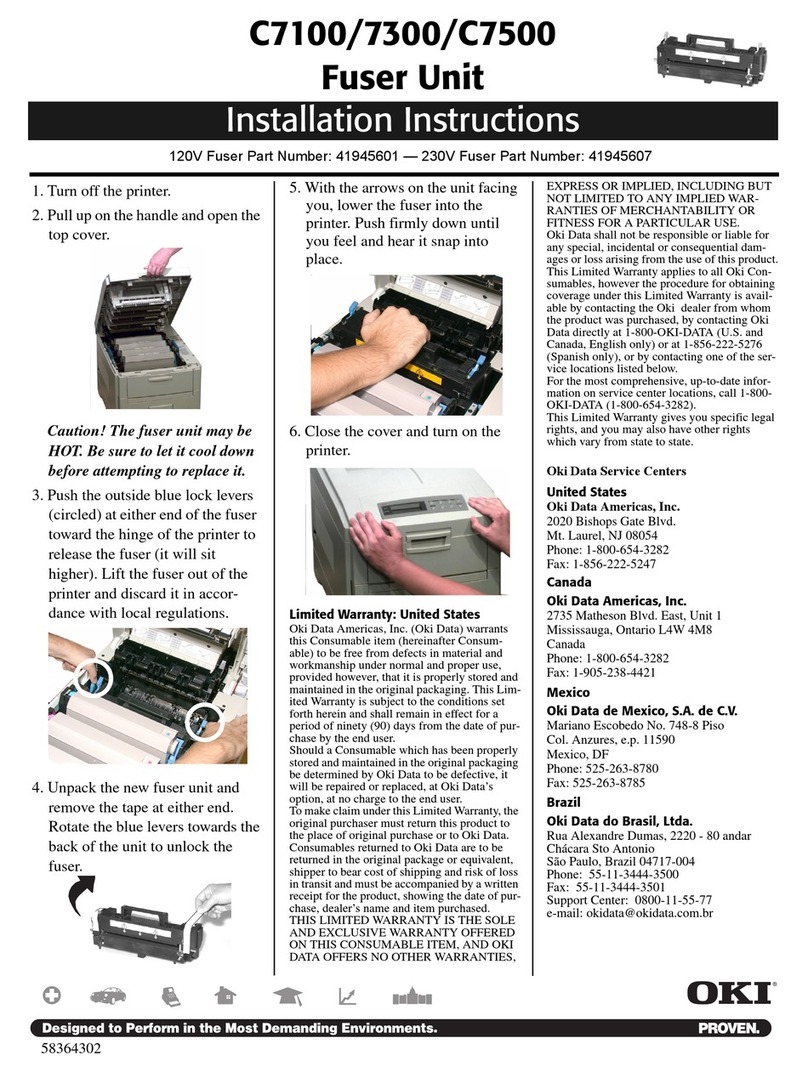

For direct inputs –

Default Configuration JMP2 and JMP3 installed.

Uses the printer’s +5VDC and Ground to

supply the devices interfacing to the GPIO

inputs (as shown in the sample circuit, right).

GPI/O A - J1

3

4

5

6

1

Start of Print

Slew Label

Toggle/Pause

Reprint

Ground

For isolated inputs –

To provide galvanic isolation for the GPIO

inputs, remove Jumper JMP 2 then supply an

external +5VDC source voltage to Pin 2.

Remove Jumper JMP 3 and supply an external

Ground (as shown this sample circuit, right).

3

4

5

6

2

Start of Print

Slew Label

Toggle/Pause

Reprint

Vcc

GPI/O A - J1

1Ground

+5 VDC

External +

Seven dedicated outputs are available for control, warning, and error functions.

These open-collector outputs have slew-limited signal-edge rise and fall times to

prevent cross talk in the cabling. Optional 10K ohm pull-up resistors, tied to a

common point for use at either +5 or +24 VDC, are available via Jumper JMP 1.

For +5VDC, on JMP1 place a jumper across pins 1 and 2. For +24VDC, on JMP1 place

a jumper across pins 2 and 3.

Note: If external pull-ups are used (that is, without Jumper JMP1 installed),

ensure that the applied external voltage does not exceed +30VDC.

The table on the following page details the GPIO port pin assignments, settings and

functions.

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

7

WARNING

Failure to properly configure the GPIO Port can result in damage to the printer and / or connected devices.

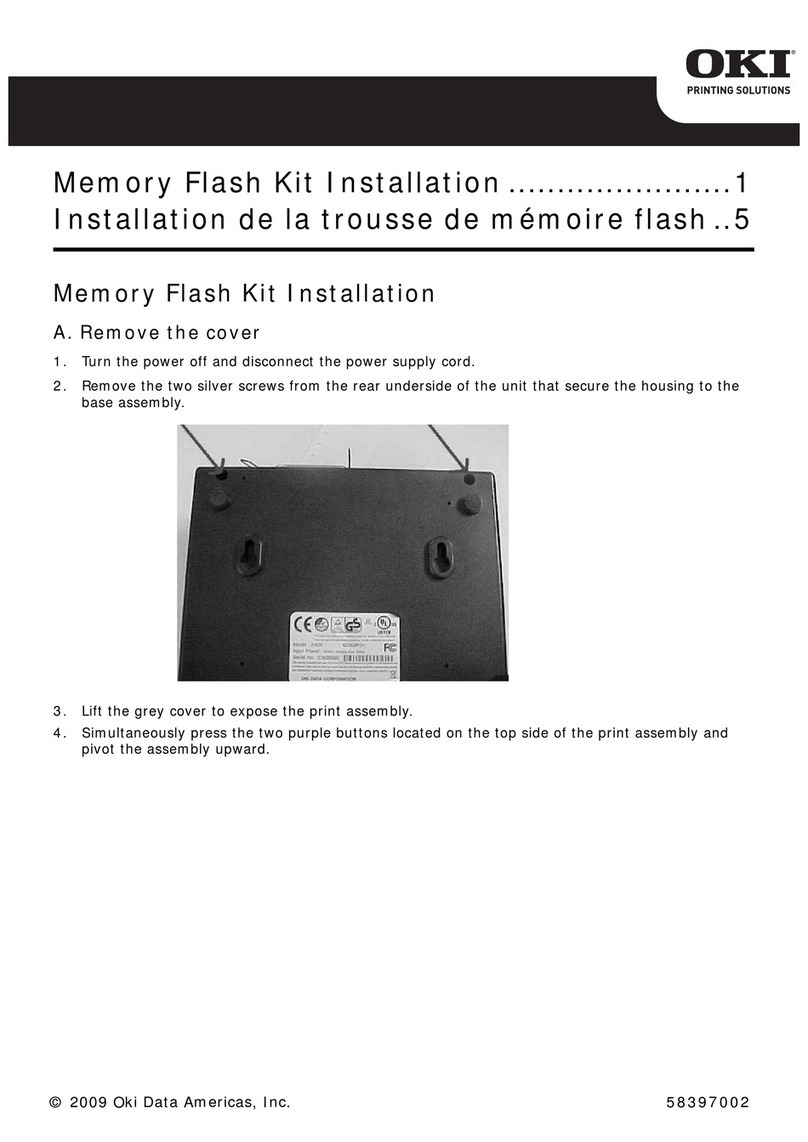

GPI/O Port A Jumper Overview

Pin Signal

Name Direction [1] Jumper Position Function / Description

Installed Printer chassis is used.

1

Ground JMP 3

Removed Ground must be supplied.

Installed

Printer +5VDC is used (.5 amp maximum)

Note: Drawing more than .5 amps can cause unreliable printer operation.

2 +5 VDC

N/A

JMP 2

Removed +5VDC must be supplied.

3 Start Of Print [2] Programmable [3]

4 Slew Label Media is advanced until the signal goes HIGH and, if not in continuous mode, the label

is positioned at the next available TOF.

5 Toggle / Pause The printer pauses when the signal is taken LOW.

6 Reprint

Input

The last label is reprinted exactly, with no increment or time stamp changes;

recommended for use during error conditions. Keeping this signal LOW produces non-

stop printing.

7 +24 VDC Printer +24 VDC (1.5 amp maximum).

8 Ground

N/A

N/A N/A

Printer chassis.

9 Ribbon Low Programmable [1]. Signifies a RIBBON LOW DIAMETER warning condition.

10 Service Required Evoked by occurrences listed under ‘Fault Messages.’[1] Active LOW.

11 End Of Print Programmable [1]. Signifies the End of Print (EOP) process.

12 Media Out Evoked during an Out of Stock condition. Active LOW.

13 Ribbon Out Evoked during an Out of Ribbon condition. Active LOW.

14 Data Ready

Evoked when a label is waiting to print. After Start of Print is received, printing will begin.

For synchronization with the print cycle, End Of Print indicates the completion of the

process. Active LOW.

15 Option Fault

Output JMP 1

When inactive, outputs will be

pulled up to a voltage

determined by this jumper

setting, where:

Pins 1 – 2 = +5VDC;

Pins 2 – 3 = +24VDC; or,

None = an external voltage

(not to exceed +30VDC) via

external pull-ups providing a

20K ohm feedback path

through any two outputs. Evoked during a Linear Scanner or RFID fault condition. Active LOW.

[1] Signal directions given relative to the printer.

[2] If active with no current print job, “WAITING FOR DATA” will be displayed. Specifying a quantity of 9999 while keeping this signal ON will cause non-stop label printing, except

in single label “Imaging Mode”, which will cause the printer to stop between labels. See the Operator’s Manual for details.

[3] For details see PRINTER OPTIONS / GPIO PORT in the Operator’s Manual.

8

Setup and Operation

The GPIO card has the following menu configurable features and can be tailored to your

application.

GPIO PORT

Controls the optional Applicator Interface Card’s GPIO function, where:

GPIO DEVICE Sets the option to work with a specific device type, where:

DISABLED Disables the option.

APPLICATOR

Enables parameters for related label applicator functions:

• Completion upon last SOP, de-asserts Data Ready (DRDY);

• FEED allowed at any time; and,

• DRDY upon PAUSE.

APPLICATOR2

Enables parameters for alternate label applicator functions:

• Completion upon 1 msec. overlap of Data Ready (DRDY) and End of Print

(EOP);

• DRDY signal end inhibits FEED; and,

• De-asserts DRDY upon PAUSE or FAULT.

BARCODE

VERIFIER

Enables the GPIO Port to work with a bar code verifier.

START OF PRINT Selects the type of input signal required to initiate Start of Print (SOP), where:

LOW PULSE Triggers printing with a low pulse.

HIGH PULSE Triggers printing with a high pulse.

ACTIVE LOW Triggers printing with a low signal.

ACTIVE HIGH Triggers printing with a high signal.

EDGE Triggers printing with a signal edge transition.

END OF PRINT Sets the type of output signal generated to indicate End of Print (EOP), where:

LOW PULSE Outputs a low pulse upon completion.

HIGH PULSE Outputs a high pulse upon completion.

ACTIVE LOW Outputs a logic low upon completion.

ACTIVE HIGH Outputs a logic high upon completion.

RIBBON LOW Sets the type of output signal generated to indicate Ribbon Low condition where:

ACTIVE LOW Outputs a logic low upon condition.

ACTIVE HIGH Outputs a logic high upon condition..

SLEW ENABLE Selects the type of input signal required to initiate label slew, where:

STANDARD Triggers slew with a low signal.

LOW PULSE Triggers slew with a low pulse.

HIGH PULSE Triggers slew with a high pulse.

ACTIVE LOW Triggers slew with a low signal.

ACTIVE HIGH Triggers slew with a high signal.

Err On Pause

(App2)

Sets the output when a service required fault occurs (Applicator Interface Card

Type 2 equipped only), where:

ENABLED Enables the output signal.

DISABLED Disables the output signal.

9

Test an Diagnostics

Input Monitor – Display incoming GPIO binary signal states using the

DIAGNOSTICS OPTIONS TESTING TEST GPIO MONITOR GPIO INPUT

selection.

SOP FEED PAUSE REPRT

1 1 1 1

Note: Unused, non-connected inputs will have an indeterminate state, and may

assume a value of 1 or 0.

Output Monitor – Display outgoing GPIO binary signal states using the

DIAGNOSTICS OPTIONS TESTING TEST GPIO TEST GPIO OUTPUT

selection.

Note: Unused, non-connected outputs will have an indeterminate state, and may

assume a value of 1 or 0.

GPIO Report – Print the configuration and current signal state information using the

DIAGNOSTICS OPTIONS TESTING TEST GPIO PRINT SIGNAL INFO

selection:

GPIO SIGNAL INFO

W ED 11:0 4A M 4J UL2 011

CARD ID#3

OUTPUT SIGNALS

END OF PRINT

PIN# 11 GPIO A

LOW P UL SE

CURRENT LEVEL 1

RIBBO N LOW

PIN# 9 G PIO A

ACTIVE LO W

CURRENT LEVEL 0

SERVI CE REQUIRED

PIN# 10 GPI O A

ACTIVE LO W

CURRENT LEVEL 1

ME DIA OU T

PIN# 12 GPI O A

ACTIVE LO W

CURRENT LEVEL 1

RIBBO N OUT

PIN# 13 GPI O A

ACTIVE LO W

CURRENT LEVEL 1

DATA READY

PIN# 14 GPI O A

ACTIVE LO W

CURRENT LEVEL 1

OPTIO N FAULT

PIN# 15 GPI O A

ACTIVE LO W

CURRENT LEVEL 1

INP UT SIGNALS

START OF PRINT

PIN# 3 GP IO A

A CTI VE H IG H

CURRENT LEVEL 1

FEED

PIN# 4 GP IO A

A CTI VE L OW

CURRENT LEVEL 1

TOGG LE PAU SE

PIN# 5 GP IO A

A CTI VE L OW

CURRENT LEVEL 1

REPRINT

PIN# 6 GP IO A

A CTI VE L OW

CURRENT LEVEL 1

EP RL SR MO RO DR OF

1 1 1 1 0 1 0

Other manuals for I-Class Mark II

4

Table of contents

Other Datamax Printer Accessories manuals