Datasensor SE-SRT Series User manual

ACCESSORIES FOR SAFETY DEVICES

- SE-DM: series: deviating mirrors

- SE-LP: series: laser pointer

- SE-S: series: floor stand

- SE-SR2 series: safety relay

- SE-SRT series: connection box

SE-DM SERIES

Deviating mirrors

NOTES AND WARNINGS

- To guarantee the correct functioning of the safety light curtains, we recommend the use of no more than

three deviating mirrors to deviate the beam along the optic direction.

- Each mirror used decreases the operating range of the safety light curtain by 15%, 20%, 25%. Apply a

correction factor of 85% using one mirror, 65% using two mirrors, 50% for three, of than.

- To maintain the correct functioning of the system, we advise to periodically clean the mirror surface using a

damp non-abrasive cloth. The cleaning frequency depends on the system’s surrounding environment.

- The mirror length has to be at least 100 mm superior to the length of the light curtain’s protected area.

- The mirror has to be mounted in such a manner that its axis (horizontal and vertical) coincide with the

corresponding safety device axis.

- The mirror has to be solidly fixed to avoid accidental movements or strong vibrations.

- The use of the SE-S floor stand is recommended; the mirror is fixed using the two fixing brackets and four

screws provided in the package.

- Given the limited mirror width, the entire system is particularly sensitive also to small rotations along the

vertical axis of the mirror and emitting and receiving units.

Hence particular attention has to be taken during system alignment and part fixing.

- To facilitate system installation (mirror/s and safety light curtain) the use of the Datasensor SE-LP laser

pointer is suggested.

The drawing shows an area protection system composed of a safety light curtain and two mirrors.

INSTALLATION

- Define the area to protect and the precise positions where to install the deviating mirrors and the emitting

and receiving units of the light curtain.

- Fix the floor stands, in the defined points, verifying that their axis are perpendicular to the floor.

- Install the deviating mirrors and emitting and receiving units on the floor stands respecting the warnings

given previously.

- Orient the mirrors to about 45° respect to the optic direction.

- Insert the SE-LP laser pointer in the upper part of the emitting unit; orient the unit in order that the laser

beam hits the surface of the first mirror in an central point of the vertical axis and at the same height at

which the pointer is installed.

- Repeat the same procedure inserting the pointer in the lower part of the unit; if necessary repeat these

procedures until the desired result is achieved.

- Orient the first mirror in order that the laser beam hits the second mirror as described above.

For the angular adjustment rotate the fixing brackets on the re lati ve pins and fi x the screws when the

required position is reached. For adjustments of the vertical axis use the holes present of the mirror’s body

and/or modify the inclination of the floor stand using washers.

- Orient the second mirror according to the same modes used previously guaranteeing that the laser beam

hits the receiving unit.

- Insert the SE-LP laser pointer in the upper part of the receiving unit and, orientating this unit, in order that

the laser beam, reflected from the two mirrors, hits the emitting unit.

Repeat the same procedure inserting the laser pointer in the lower part of the unit.

NOTE: The laser pointer, due to mechanical tolerance problems in the matching with the light curtain

housing, provides an approximate indication and hence small corrections may be necessary in the

unit alignment using the normal ALIGNMENT PROCEDURE described in the safety light curtain

instruction manual.

DO NOT move the mirrors as the laser beam guarantees the perfect

alignment.

856000390 Rev.A

SE-LP SERIES

Laser pointer

NOTES AND WARNINGS

NOTE: The SE-SP laser pointer uses a red laser light

beam that can be potentially dangerous to the

human eye.

Do not stare directly at the light beam.

The laser pointer is powered by three 1.5 V LR-44 type

batteries.

Battery replacement:

- Unscrew the back lid using the thin pin included in the lid slot.

- Remove the flat batteries.

- Insert the three new batteries placing the negative pole first.

- Screw back the lid.

NOTE: Avoid keeping the device powered a long time.

DIMENSIONS

26.4

48

20°

14 38.02

93.8

100.8 47

3

Ø44.8

65.55

12.8

13.7

INSTRUCTIONS FOR USE

•Install the emitting and receiving units of the SE series safety device in the defined positions

(refer to MECHANICAL MOUNTING chapter of the safety light curtain instructions manual). The

use of the SE-S floor stands are recommended, verifying that they are firmly fixed and that their

axis is perpendicular to the floor.

•Insert the SE-LP laser pointer in the upper part of the emitting unit using one of the two side

slots of the profile (refer to drawing).

As shown, the laser pointer is positioned inside the detection

field of the safety device and thus inhibits the functioning

during the alignment phase. In case of safety devices for

access control, this inconvenience can be avoided by

positioning the laser pointer in a zone not affected by optic

groups. The device functioning is thus not inhibited and the

alignment results can be observed directly on the receiving

unit’s signalling LEDs.

•Power the laser pointer rotating the front ring nut.

Orientate the emitting unit in order that the laser beam hits the

receiving unit at the same height of the pointer.

NOTE: The holes of the fixing bracket or the orientable supports available as accessories

can be used to orientate the unit, allowing angle adjustment along the vertical unit

axis. If necessary the inclination of the floor stand can be changed by simply

mounting washers under the base.

•Repeat this procedure inserting the pointer in the lower part of the emitting unit; if necessary

repeat this procedure unit the desired result is obtained.

•Insert the laser pointer in the upper part of the receiving unit and orient this unit in order that the

laser beam hits the emitting unit as indicated.

•Repeat this procedure inserting the laser pointer in the lower part of the receiving unit.

After this operation switch on the safety device and verify the correct alignment.

NOTE: The laser pointer, due to mechanical tolerance problems in the matching with the

light curtain housing, provides an approximate indication and hence small

corrections may be necessary in the unit alignment, following the ALIGNMENT

PROCEDURE described in the safety light curtain instructions manual.

•Proceed with the definitive mounting of the emitting and receiving units.

856000400 Rev.00

SE-S SERIES

Floor stand

The floor stand of the SE-S series can be used for the installation of both the emitter

and receiver units of the SAFEasyTM safety light curtains series, as well as for the SE-

DM deviating mirrors series.

Five versions with different lengths are available in order to satisfy all application needs.

In particular the support post lengths available are given below:

800, 1.000, 1.200, 1.500, 1.800 mm.

Moreover protective stands of the SE-P series are available. These have to be mounted

on the support post using two M6 x 10 screws, and relative washers and square nuts.

The different lengths of the protective stands have been calculated to suit each safety

light curtain model.

ISTRUCTIONS FOR USE

Mount the three angle brackets (A) on the post using the nine M6 x 10 screws (B),

relative washers and square nuts inserting the latter in the side slot of the floor support

post (refer to the figure). Do not tighten the screws in order to allow the angle brackets

to move along the post.

Position the assembled part on the plate (C) and fix the angle brackets using the six M6

x 16 screws (D) and relative washers.

Tighten the fixing screws of the angle brackets to the post.

Before inserting the protection cap (E) on the top part of the post, the square nuts

necessary for the fixing of the emitting and receiving units or deviating mirrors have to

be inserted inside the front slot.

NOTE: For the correct safety device functioning, the floor stand has to be firmly

fixed to the ground using the four inserts given, ensuring that the post is

perpendicular to the ground.

The washers with an one-side opening (given in the package) can be used

to correct the post inclination respect to the ground, inserting them

between the support plate and the ground itself.

DIMENSIONS

856000380 Rev.00

AA

A

C

B

C D

E

Model L (mm) X (mm)

SE-S 800 800 30x30

SE-S 1000 1000 30x30

SE-S 1200 1200 30x30

SE-S 1500 1500 45x45

SE-S 1800 1800 45x45

SE-SRT SERIES

INSTRUCTION MANUAL

GENERAL INFORMATION

The SE-SRT connection box facilitates the connection and use of the

SE4T-L MUTING and SE4-R safety light curtains.

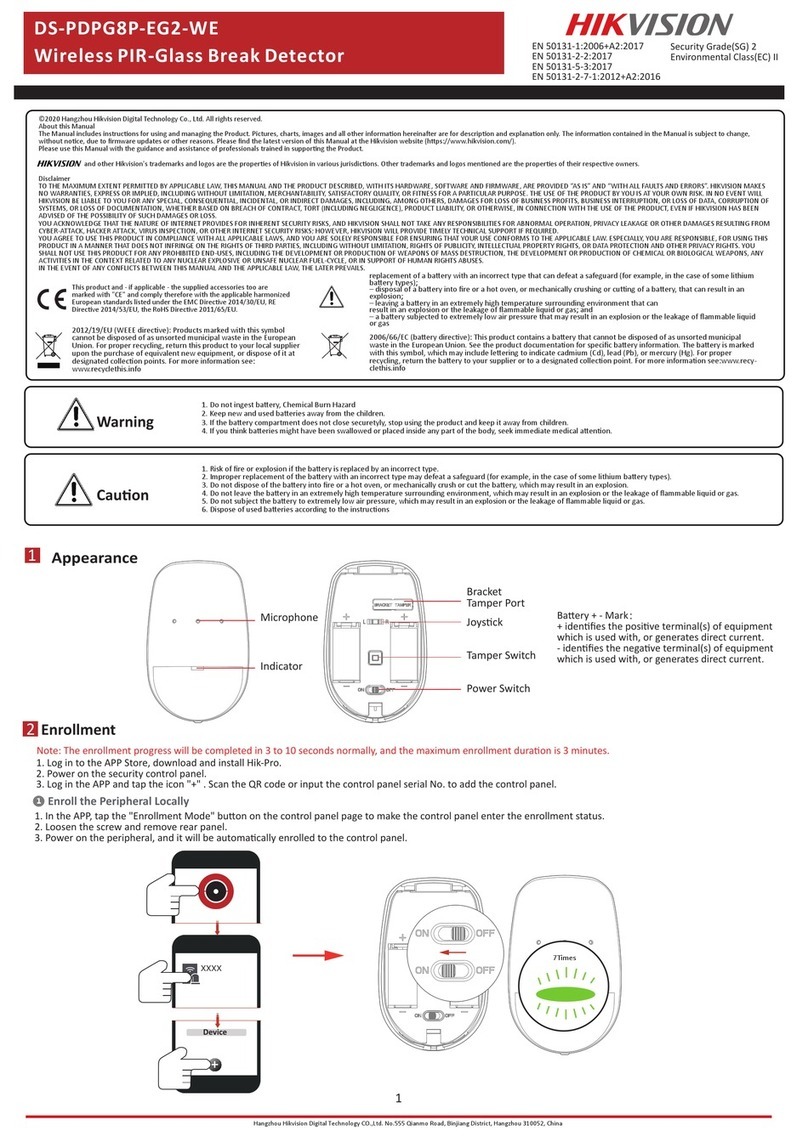

The device externally presents:

-A key-switch for override function.

-A TEST/START push-button for the activation of the Test, Restart,

Reset .

The connection box contains:

•Extractable clamps for

-Receiving unit connection (J1)

-Emitting unit connection (J2)

-Power supply connection to 24V (J3)

-Relay output connection (J4)

-External control unit connection (precabled).

•Two RLY1 and RLY2 relay outputs each with two N.O. open contacts.

Use both relays to guarantee the safety function.

The use of one single relay can reduce the system’s safety

degree.

K11 K12 + K21 K22 K11 K12 + K13 K14

FUNCTIONS

The SE-SRT connection box allows to manage directly the following

functions, without the need to carry-out other operations:

FUNCTION USING PROCEDURE

TEST TEST/START

push-button Press push-button for at least 0.5 sec.

RESTART TEST/START

push-button

Press push-button for at least 0.5 sec. if

manual reset function has been selected

using the dip-switches of the RX unit.

RESET TEST/START

push-button

Press push-button for at least 5 sec. if

device presents functioning irregularity.

EDM Precabled

The control is active if the function has

been selected using the dip-switches of

the RX unit.

OVERRIDE

Key-switch +

TEST/START

push-button

Switch the key selector kept the position

. It can be possible to enable the function

under certain condition only (refer to the

instruction manual of the SE4T-L

MUTING and SE4-R series.

Note 1: When Override function is

active, the external Muting signalling

device blinks to indicate the exclusion of

the safety device.

Note 2: The maximum duration of the

Override function is 120 sec., after which

the light curtain returns to normal

functioning even if key selector is kept

pressed.

If the key selector is released before the

maximum period, the Override function is

immediately deactivated.

For more information please refer to the instruction manual of the SE4T-

L MUTING and SE4-R series.

RELAY SPECIFICATIONS

The connection box uses 2 force-guided contact relays.

The use of these relays within the given specifications is recommended,

even if the manufacturer specifies the use of these relays for voltage

and currents superior to these values.

To guarantee the correct isolation and avoid damage as well as

premature ageing, each line has to be protected using a delayed 6A

fuse and the load characteristics have to conform with the following

indications:

Max. switching voltage: 250 Vac

Max. switching current: 2 A

INSTALLATION

Wall mounting is possible using the internal slots that can be accessed

opening the box and eliminating the screws necessary for the fixing of

the PCB.

ELECTRICAL CONNECTION:

Connector Pin Description

J1 1 24 Vdc (RX unit)

2 GND (RX unit)

3 OSSD1 (RX unit)

4 OSSD2 (RX unit)

5 EDM (RX unit)

6 OVERRIDE 1 (RX unit)

7 TEST/START (RX unit)

8 OVERRIDE 2 (RX unit)

J2 1 24 Vdc (TX unit)

2 GND (TX unit)

J3 1 24 Vdc (External power supply)

2 GND (External power supply)

J4 1 K11

2 K12 N.O. external contact #1, Relay 1

3 K13

4 K14 N.O. external contact #2, Relay 1

5 K21

6 K22 N.O. external contact #1, Relay 2

7 K23

8 K24 N.O. external contact #2, Relay 2

J5 1 TEST/START push-button (precabled)

2

TEST/START push-button (precabled)

3 Key-switch (precabled)

4 Key-switch (precabled)

5 Key-switch (precabled)

6 Key-switch (precabled)

DECLARATION OF CONFORMITY

We DATASENSOR S.p.A. declare under our sole responsibility that these products are conform

to the 2004/108 CEE, 73/23 CEE Directives and successive amendments.

WARRANTY

DATASENSOR S.p.A. warrants its products to be free from defects.

DATASENSOR S.p.A. will repair or replace, free of charge, any product found to be defective

during the warranty period of 36 months from the manufacturing date.

This warranty does not cover damage or liability deriving from the improper application of

DATASENSOR products.

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro - Bologna - Italy

Tel: +39 051 6765611 Fax: +39 051 6759324

http://www.datasensor.com e-mail: info@datasensor.com

DATASENSOR S.p.A. cares for the environment: 100% recycled paper.

DATASENSOR S.p.A. reserves the right to make modifications and improvement

s

without prior notification.

826002821 Rev.B

This manual suits for next models

15

Table of contents

Popular Security Sensor manuals by other brands

HIK VISION

HIK VISION Pyronix KX15DT quick start guide

HIK VISION

HIK VISION DS-PDC10DM-EG2-WE user manual

SignalFire

SignalFire Sentinel-yTherm Series Interface manual

Elk Products

Elk Products ELK-319HRR Installation guidelines

Thermo Scientific

Thermo Scientific Surveyor RI Plus Hardware manual

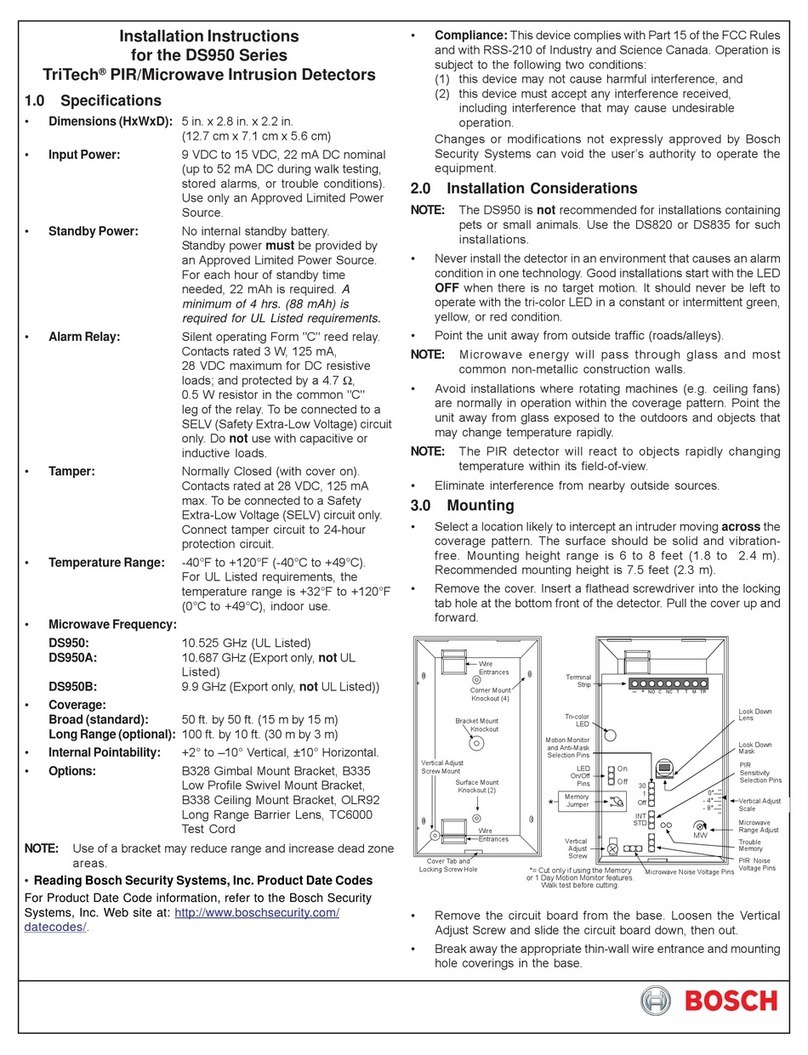

Bosch

Bosch TriTech DS950 Series installation instructions