dataTaker DT800 User manual

UM-0071-A0

UM-0071-A0

UM-0071-A0

dataTaker

is a registered trademark of

dataTaker Pty Ltd.

All other brand and product names are trademarks or registered trademarks of their respective holders.

Copyright © 2000

dataTaker Pty Ltd

Getting Started

with

DT800

dataTaker

UM-0071-A0

4

Getting Started with DT800

dataTaker

UM-0071-A0

About this User’s Guide

Welcome to

Getting Started with DT800 dataTaker.

This quick-start user’s guide is a tutorial that uses step-

by-step instructions, simple explanations and simple

examples to get you up-and-running with your

dataTaker

DT800 data logging and acquisition system.

If You Never Read Manuals

If you’re new to

dataTaker

, this user’s guide is one

manual you must read.

It won’t take you long and, just like any good

investment, the time you spend working through the

information provided here will be repaid to you many

times over as you use your

dataTaker

.

Which User Are You?

This guide is primarily designed for

new

dataTaker

users. If you work through all the steps in the order in

which they’re presented, you can be confident that

you’ll learn enough about data acquisition and

logging, your DT800 data logger, and the software

you use to communicate with it to satisfy your needs for

a very long time.

If you’re an

experienced

dataTaker

user, you can skim

through this guide noting only the major instruction

steps. These are designated by the arrow icon shown

in the example immediately below. Instructions tagged

in this way form a quick guide to prompt experienced

users.

➲

This is an example of a major instruction

step. Instructions tagged like this summarize

what follows, and experienced users may need

to read only these.

If you’re an experienced

dataTaker

and computer user

in a hurry, you can go directly to the

DT800 dataTaker

User’s Manual

supplied with your DT800.

Extras

All readers will benefit from the “Extras”

included with many of the topics. Extras

are additional information intended to

supplement each topic. You don’t need to

read the Extras to be able to work through this guide,

although we do recommend you read them at some

time because they contain valuable background

information that will enhance your “big picture” of

data acquisition, data logging and the DT800

dataTaker

system.

More Information

Your DT800 is capable of extremely sophisticated data

acquisition and logging. So if you want more

information than this guide provides, refer to the

DT800 dataTaker User’s Manual

supplied with each

new DT800, or other DT800 documentation available

separately (ask your

dataTaker

distributor, or visit

www.datataker.com).

In any case, at your leisure, we recommend that you

browse through the

DT800 dataTaker User’s Manual

to

get an overview of everything your DT800 is capable

of.

This Guide Assumes…

• Microsoft

®

Windows

®

95, Windows

®

98,

Windows

®

2000 or Windows NT

®

is correctly

installed on your computer and works reliably.

• You are familiar with basic Microsoft Windows

operations and the concepts of COM ports and

Windows communications.

If you are inexperienced with Windows, refer to

Microsoft publications such as

Microsoft Windows

User’s Guide

and

Getting Started with Microsoft

Windows

, or any of the many third-party

Windows reference books available.

What Now?

Go to “Contents” on page 5 for a bird’s-eye-view of

what’s in store, then begin working through this tutorial

starting with Chapter 1 “Acquisition? Logging?…” on

page 6.

Contents

5

UM-0071-A0

Contents

About this User’s Guide......................... 4

Contents................................................ 5

CHAPTER 1

A

CQUISITION

? L

OGGING

?…

1-1 Important Concepts.........................................6

1-2 Important Terminology ..................................11

CHAPTER 2

S

ET

U

P

THE

H

ARDWARE

2-1 Checklist .....................................................13

2-2 Power the DT800 .........................................14

2-3 Make the Hardware Connection ....................14

2-4 Attach a Sensor............................................15

CHAPTER 3

S

ET

U

P

THE

D

E

L

OGGER

S

OFTWARE

3-1 Install DeLogger............................................16

3-2 Start DeLogger .............................................18

3-3 Make the Software Connection ......................19

3-4 Verify the Connection....................................20

CHAPTER 4

A Q

UICK

O

VERVIEW

OF

D

E

L

OGGER

4-1 The Big Pictures............................................22

4-2 DeLogger’s Main Toolbar ..............................26

4-3 DeLogger’s Menus........................................27

4-4 More Important Concepts and Terminology .....28

CHAPTER 5

Y

OUR

F

IRST

P

ROGRAM

5-1 DeLogger’s Program Builder Window .............31

5-2 Create a Program.........................................33

5-3 See What You’ll Send...................................36

5-4 Send the Program.........................................36

CHAPTER 6

S

EE

Y

OUR

D

ATA

— F

ORM

W

INDOW

6-1 DeLogger’s Form Window.............................38

6-2 View the Returned Data.................................41

6-3 Set the DT800’s Date and Time......................42

CHAPTER 7

S

EE

Y

OUR

D

ATA

— C

HART

WINDOW

7-1 DeLogger’s Chart Window ............................43

7-2 Chart the Returned Data................................48

CHAPTER 8

SEE YOUR DATA — MIMIC WINDOW

8-1 DeLogger’s Mimic Window........................... 49

8-2 Display Returned Data in a Meter .................. 50

8-3 Replay a File to a Meter................................ 51

8-4 Add a Graphic............................................ 52

8-5 Disconnect .................................................. 53

CHAPTER 9

EXTEND YOUR PROGRAM

9-1 Reconnect ................................................... 54

9-2 Change Schedule A’s Rate............................ 55

9-3 Add a Channel Label ................................... 55

9-4 Add More Channels to Schedule A ................ 56

9-5 Re-Send the Program .................................... 59

9-6 Reassign the Form, Chart and Mimic Windows 59

9-7 DeLogger’s Text Window.............................. 60

9-8 Return Data to the Text Window .................... 61

9-9 Add an Alarm ............................................. 63

9-10 Add Schedule B to the Program ..................... 64

CHAPTER 10

OTHER THINGS YOU CAN DOWITH

DELOGGER

10-1 Unload Logged Data .................................... 66

10-2 DeLogger’s Spreadsheet Window .................. 68

10-3 Load Data into a Spreadsheet........................ 69

10-4 Finish Off.................................................... 69

10-5 What’s Next?.............................................. 69

Index ..................................................70

6Getting Started with DT800

dataTaker

UM-0071-A0

CHAPTER 1

A

CQUISITION

? L

OGGING

?…

You really can’t avoid it — there’s just no way you can

afford to short-cut this chapter.

It’s quick to read, and it will make you comfortable

with some fundamental

dataTaker

data acquisition and

logging concepts, terminology and conventions.

So read on…

1-1

IMPORTANT

CONCEPTS

Your first job as you work through this tutorial-in-the-

form-of-a-user’s-guide is to familiarize yourself with the

following concepts.

Data Acquisition versus Data Logging

Data acquisition and data logging are NOT the same.

Traditionally, data

acquisition

has been defined as the

regular collection of data — scanning sensors, making

instantaneous measurements, then feeding these to a

recorder or computer.

Data

logging

has two possible definitions:

• It’s considered by some to be simply making a

permanent record of data that has been collected:

printing or plotting it, writing it on a sheet of paper,

or storing it on a computer’s hard disk or in

electronic memory.

• Others perceive data logging as the total operation

of collecting data and making a permanent record

of it. Therefore, they see data acquisition as part of

data logging.

Now, with

dataTaker

, any distinction between these

two terms has become even more blurred because the

dataTaker

DT800 combines acquisition and logging

(and much more) in a single instrument about the size

of a house brick.

So, when using your DT800, it’s important that you

treat acquisition and logging as two separate

functions.

dataTaker

’s Acquisition Function

One of the DT800’s two basic functions is to read

sensors (that is, to measure, sample or scan sensors)

and present the values to you on a computer screen or

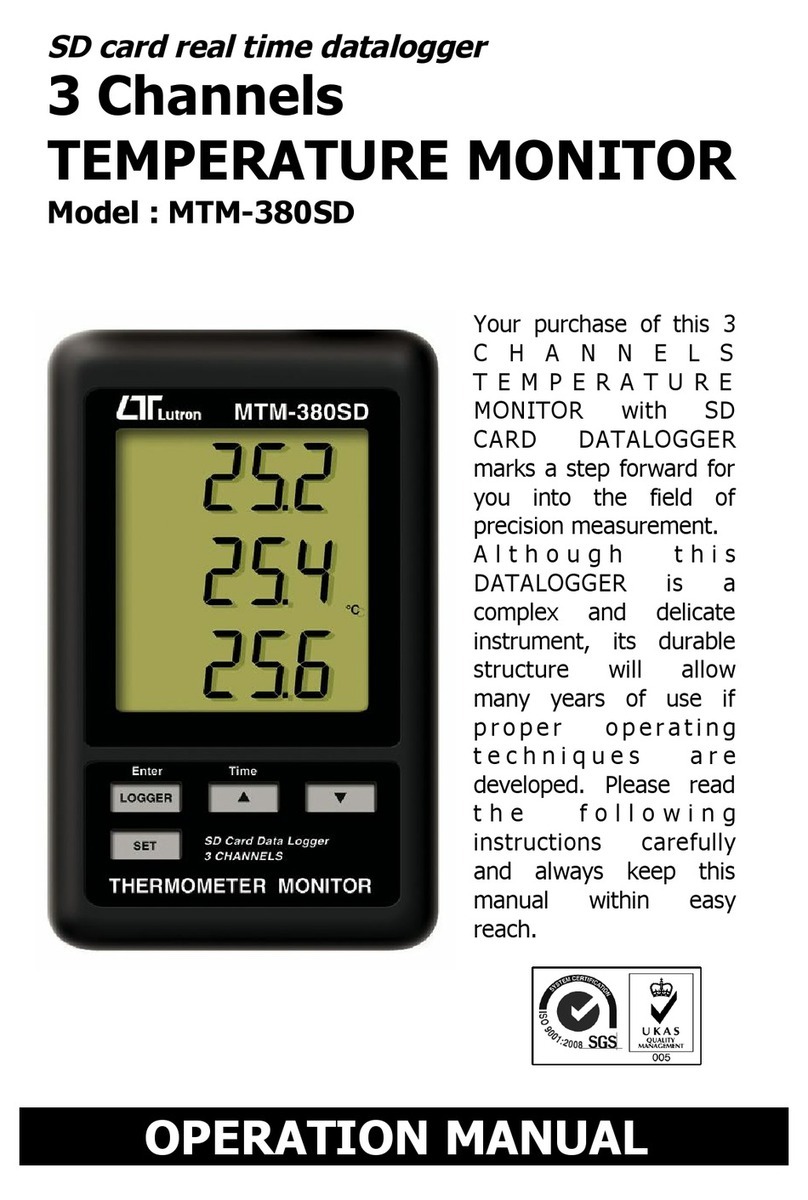

other display (Figure 1).

Although these readings can be used, say, to trigger

an alarm, they are temporary: the DT800 has not

recorded, stored or remembered them anywhere —

CHAPTER 1ACQUISITION? LOGGING?…: Important Concepts 7

UM-0071-A0

that is, the data has not yet been logged by the

DT800.

dataTaker

’s Logging Function

The second of the DT800’s two basic functions is to log

data

— that is, to record or store data (Figure 2).

Once you’ve instructed the DT800 to acquire data,

you must then issue the LOGON command (explained

later) if you want it to store the data.

The DT800

The

dataTaker

DT800 is an instrument for intelligently

acquiring data from sensors connected to it, recording

(logging) the data for later reference and analysis, and

taking action (like raising alarms or altering its

operation) based on the values it measures or

calculates.

What It Can Do

More specifically, your DT800 can perform any or all

of the following tasks:

•

acquire

data (scan sensors, make instantaneous

measurements and forward them to a computer)

•

log

data (that is, store measurements in its own

internal memory and/or its removable memory

card)

•

convert

measurements according to your

requirements (voltages to ºC or ºF, for example)

• carry out calculations on the measurements

(average, standard deviation, maximum,

minimum,…)

• log the converted measurements and the results of

calculations to its internal memory and/or a

removable memory card, or transfer them to a

computer

• display all of this on a computer screen

• return data directly to a computer in

real time

(that

is, as each measurement is made) as well as, or

instead of, logging it

• raise

alarms

when data is outside specified ranges.

Alarms can trigger outside events (turn on a

warning light or siren, for example), or make the

DT800 carry out additional tasks (scan more

frequently, stop logging, or scan and log additional

sensors, for example).

You’re the Boss

Being microprocessor-based, you send instructions

(“commands” — see the Extras panel “Sending

Commands” on page 8) to the DT800 from a

computer running DT800-compatible software such as

DeLogger

(used later in this guide). These instructions

tell the DT800

• which sensors to read

• how often to read them

• what to do with the data.

Then you sit back and let the DT800 do the work.

DT800

scans

sensors DT800

displays data

Alarms, actions

FIGURE 1Data acquisition

DT800 saves data to

• its internal memory

• a removable memory card

• the host computer.

DT800

displays data

Alarms, actions

FIGURE 2Data logging

8Getting Started with DT800

dataTaker

UM-0071-A0

Look, No Hands

Once you’ve set the DT800 running you can

disconnect the computer if you wish — the DT800

continues to operate as programmed because the

software which controls the logger is inside the logger

itself. This is called

stand-alone

operation.

Input Types

The DT800 lets you monitor, record and raise alarms

for readings from many types of sensors and

transducers — temperature (thermocouples,

thermistors, RTDs and solid-state sensors), pressure,

flow, strain, digital state (high or low, off or on), count,

frequency, period, voltage, current, resistance and so

on.

You can connect many sensors — each one different

— to a single DT800 and have them scanned

whenever you choose.

Meaningful Quantities

Whatever the sensor, its raw output will be either

voltage, current, resistance, frequency, time, counts or

digital state. For example, the output from a

thermocouple is a voltage that varies according to the

temperature being measured: the thermocouple’s raw

output is volts (under 100 millivolts, actually), not

degrees Centigrade or Fahrenheit.

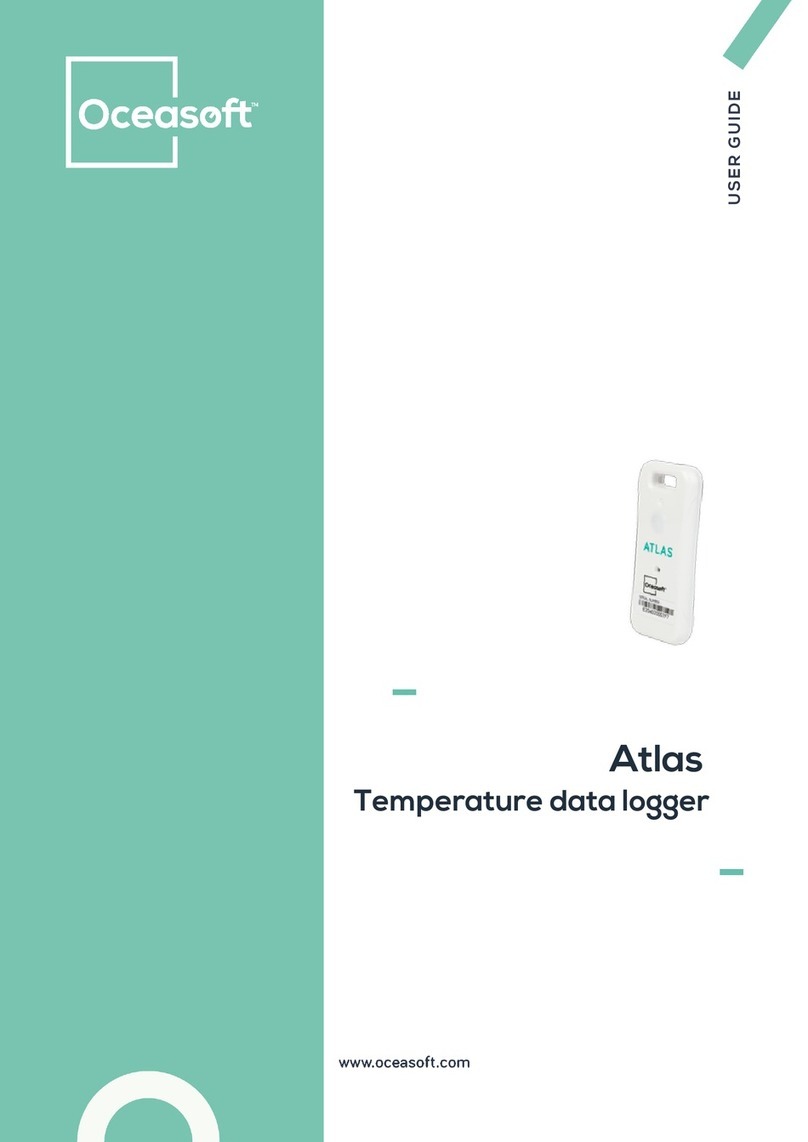

Then the raw output must be converted to a meaningful

quantity (to a temperature value in this example).

Depending on the type of sensor, this conversion

involves

linearization

and possibly

compensation

,

terms which are beyond the scope of this guide. Just

be aware that raw measurements usually have to be

converted before they become the meaningful

quantities that are useful to you (Figure 3).

One of the features of the DT800 is that it

automatically performs these conversions for you. All

you have to do is tell the logger what

type

the sensor is

(a type T thermocouple, for example) and the

microprocessor inside the logger performs the

appropriate linearization and compensation, turning

the raw sensor output into a quantity with meaningful

units.

The DT800 measures these fundamental

parameters, from which all others are derived:

voltage

resistance

frequency

time

counts (pulses)

thermocouple reference temperature

Sending Commands

There are three ways you can send commands to

the DT800:

• from a computer connected to the DT800

• from a removable memory card — commands

loaded into a memory card can be transferred to

the DT800 and acted upon the moment the card is

inserted into the DT800’s memory card socket (this

is a handy way of configuring and programming

a remote DT800)

• using alarms (see the

DT800 dataTaker User’s

Manual

).

This means that the DT800 supports many types of

inputs. For example:

voltage

resistance

current (including 4–20mA loops)

thermocouples

thermistors

RTDs (Resistance Temperature Detectors)

solid-state temperature sensors

bridges (strain gauges)

frequency

time

counts

pressure sensors

flow sensors

load cells

digital state (on/off, high/low)

CHAPTER 1ACQUISITION? LOGGING?…: Important Concepts 9

UM-0071-A0

In addition, the DT800 allows you to

• define your own linearization characteristics for any

unusual sensor that is not directly supported by the

DT800

• carry out statistical operations on the measurements,

only returning the statistical results you want

(average, standard deviation, maximum,

minimum,…)

• apply other calculations or expressions you define

to process the collected data.

Time and Date Stamps

Because you’ll often want to know the time and date

each measurement was made, the DT800

automatically keeps this information along with the

measurements. This facility ensures that every reading

from every sensor can be

time-stamped

and

date-

stamped

.

Data Format, Display and Storage

Your DT800 is extremely powerful and flexible in the

ways it allows you to format, view and store data.

Data Format

You can format (layout, arrange) the data provided by

your DT800 to best suit the way you want to use it,

and the DT800 has two modes for doing this: free-

format mode and fixed-format mode.

In

free-format mode

, you’re free to format the data

any way you want. For example, you can make it easy

and meaningful to read, like

or comma-separated ready for direct importing into a

software spreadsheet, like

or with the time of each reading included, like

In

fixed-format mode

, the DT800 returns data in a

predictable, repeatable, comprehensive format ready

to be imported into spreadsheets and other data

analysis software.

Real-time data can be returned in either free- or fixed-

format mode, but logged data is always returned in

fixed-format mode. These two modes are discussed in

“Format of Returned Data" in Part A of the

DT800

dataTaker User’s Manual

.

Data Display

You can connect the DT800 to any computer and,

using appropriate software, data can be viewed on

the computer screen as it is acquired.

Data Storage

Data can be stored in the DT800’s own internal

memory, in a removable memory card, or you can

transfer it to a computer.

Once in the computer, you can save the data file for

later reference, or bring it into one of many

spreadsheet or plotting programs for analysis. For

example, you can use Microsoft®Excel to create a

printed report (including graphs), or

dataTaker

’s

CONVERSION

BY DT800

DT800

automatically performs

linearization

and

compensation

Raw

thermocouple

output

(volts)

Meaningful

quantity

(degrees

Centigrade)

FIGURE 3One of the DT800’s many automatic

conversion routines

Example

Me

Dat

Measurement 3

Date 3 Time 3

Measurement 2

Date 2 Time 2

Measurement 1

Date 1 Time 1

5/6

162.1°C

5/6/00 9:16:00

163.7°C

5/6/00 9:15:00

163.4°C

5/6/00 9:14:00

FIGURE 4Your DT800 produces a series of

information “chunks”.

Boiler temperature 123.4 Deg C

123.4,123.7,123.1,123.6

123.3,123.7,124.2,124.5

124.2,124.6,124.8,125.1

00:00:00,24.8

00:00:02,24.9

00:00:04,24.5

00:00:06,24.2

00:00:08,24.0

10 Getting Started with DT800

dataTaker

UM-0071-A0

DeLogger or DeLogger Pro to plot graphs of your data

versus time directly on the computer screen.

Communication

The most common method of supervising your DT800

is to send commands to it directly from a computer.

(There are other methods — see the Extras panel

“Sending Commands” on page 8.)

To do this, and for the DT800 to return data to the

computer,

• your computer must be running one of

dataTaker

’s

DT800-friendly software packages such as

DeLogger, DeLogger Pro, or DeTransfer

• the computer’s communications port must be

connected to one of the DT800’s communications

ports by any of the methods described in the Extras

panel “Communications Links”.

Power

You can power the DT800 from three sources:

A mains adaptor and 12 volt internal battery are

supplied with your DT800. This 12V battery is known

as the

internal main battery

to distinguish it from the

DT800’s other internal battery, the

internal memory-

backup battery

(next topic).

NOTE

The DT800 is shipped with its internal main

battery disconnected. Although you don’t need it to

work through this user’s guide (because we instruct you

to power the logger from its mains adaptor), it’s a

good idea to connect the internal main battery in the

near future so that it can be fully charged — see “Main

Battery is Disconnected for Shipping” in Part C of the

DT800 dataTaker User’s Manual

supplied with your

DT800.

Good Power Practice

The recommended method of working with the DT800

is — while you are programming it “back at base” —

to power it from the mains using a mains adaptor. The

mains adaptor supplies the logger and charges the

main internal battery.

When you’ve finished programming and are ready to

use the logger “in the field”, you disconnect it from

both the computer and the mains adaptor and it

continues to operate from the freshly-charged main

battery. The amount of power consumed by the DT800

depends on the program running.

Communications Links

With appropriate software, the DT800 and the host

computer can communicate with each other by

means of

• a communications cable (called a “direct”

connection) — for distances of up to 50 meters / 55

yards (a

dataTaker

communications cable, product

code IBM-6, is supplied with your DT800)

• a communications cable fitted with line drivers —

for distances of up to 5000 meters / 5500 yards

• telephone or radio modems, or satellite links — for

much longer distances (you’ll need to upgrade to

DeLogger Pro if you want to use modems)

• an Ethernet network — the DT800 supports

10BaseT Ethernet.

Internal The DT800’s internal main battery

External A mains adaptor (11 to 28 volts DC)

External External batteries, solar panels, vehicle

power supplies and other DC sources

(11 to 28 volts DC)

DT800 Mains Adaptor

Sometimes called a plug pack.

Converts mains power (that is,

power from a wall outlet) to a

voltage suitable for the DT800

(11–28Vdc).

CHAPTER 1ACQUISITION? LOGGING?…: Important Terminology 11

UM-0071-A0

Internal Memory-Backup Battery

In addition to the main internal battery, the DT800

contains a small 3.6V lithium

internal memory-backup

battery

that ensures your data, real-time clock and

primary settings are not lost if power to the logger is

interrupted. The backup battery can maintain this

information for up to 12 months if necessary.

Sleep Mode

To conserve battery power, the DT800 “goes to sleep”

if it has no measurements to do and there has been no

communication for a period of 30 seconds.

This applies only if the logger is powered by its internal

battery. If it’s powered from an external source, the

DT800 never goes to sleep (unless you override this

default behaviour).

In sleep mode, most of the internal electronics shuts

down. The current drain drops from 400mA when

awake to a tiny 250µA when asleep; just 0.07% of the

awake value.

Auto-Sleep in the Event of Power

Supply Failure

If the power supply to the DT800 drops below 9.5

volts, the logger automatically attempts to minimize its

power requirements and maintain any logged data

and settings by going to sleep. When the supply is

restored, the logger senses this and automatically

returns to its previous mode of operation.

1-2

IMPORTANT

TERMINOLOGY

This section introduces you to some data acquisition

and logging terms you’ll need right away. Others are

explained as they arise.

Sensors and Transducers

Origins of data in a data acquisition and logging

system.

Sensors

are the raw, basic devices that detect variable

quantities (temperature, pressure, flow,…) and convert

them into electrical signals. Sensors see, hear, taste,

sniff or feel the environment and tell the DT800 (in

electrical terms) what’s going on.

If electronic components are added to a sensor, the

result is sometimes called a

transducer

. The electronics

may be added to excite, amplify, compensate,

linearize, filter or interface to other equipment.

If the electronics include a software-controlled

microprocessor, the result is a

smart sensor

.

Power-up

Applying power to a previously un-powered device.

Format

With

dataTaker

, you can “format” data in a variety of

ways. That is, you can arrange the physical

appearance and layout of data as it comes from the

DT800 so that it best suits the way you want to use it.

Host Computer

The computer you use for supervising the DT800.

Host Software

The software you run on the host computer to supervise

the DT800 (

DeLogger

,

DeLogger Pro

and

DeTransfer

,

for example). See the Extras panel “DT800 Host

Software” on page 16.

PC Card

A plug-in card meeting the PCMCIA standard

(Personal Computer Memory Card International

Association). It can be a storage card such as an ATA

Flash card, or a communications device such as a

PSTN modem card or GSM modem card.

12 Getting Started with DT800

dataTaker

UM-0071-A0

Male and Female Connectors

Male connectors (plugs) have protruding pins,

whereas female connectors (sockets) have holes to

receive the pins. See the “Connectors, Adaptors”

Extras panel.

Communications Ports

The DT800 has three communications ports:

•a

Host RS-232

port

• a 10BaseT

Ethernet

port

•a

USB

port

They are located on the DT800’s left side panel.

The communications connector(s) on the back of your

computer are also known as “COM ports” (or “serial

ports”). Most computers have one or more COM ports,

named COM1, COM2 and so on, and may also have

other connectors for Ethernet and USB.

Comms Cable

An abbreviation of “communications cable”.

Many types of comms cables exist. But, because the

DT800’s Host RS-232 port is a standard DTE device,

you only need a standard null-modem serial cable —

also known as a “crossover cable” — to connect this

port to the host computer.

In fact, the Host RS-232 port on the DT800 is exactly

the same in form and function as the serial port on

your PC. This means that you can connect a modem or

other serial device to the DT800 using standard serial

cables intended for connecting the modem to a

computer.

NOTE

The comms cable supplied with your DT800

is not the same as that supplied with

dataTaker

DT50

and DT500/600 Series data loggers.

Serial Channel

The DT800 has a serial port for smart sensors, located

on the DT800’s front panel and labelled

Serial

Channel

. This port can be configured as RS-232,

RS-422, RS-485 or SDI-12.

The DT800’s Serial Channel is not a standard, serial

COM port.

Characters

Things you type. The generic name for numbers (0, 1,

2, 3,…), letters (A, b, c, D,…) and symbols ($, %, &,

+,…).

Connectors, Adaptors

The connectors on the communications cable

supplied with your DT800 are of the “DE” female

type. This is a 9-pin D-shaped connector, as shown

below.

Another common comms connector is the “DB”

type, which is also D-shaped but has 25 pins. If

your computer’s COM port has one of these, you’ll

need to add a 9-pin to 25-pin adaptor to the end of

your DT800 comms cable.

Pin 1

DE-9 MaleDE-9 Female

DB-25 MaleDB-25 Female

Pin 1

FIGURE 5Typical comms connectors

CHAPTER 2SET UPTHE HARDWARE: Checklist 13

UM-0071-A0

CHAPTER 2

S

ET

U

P

THE

H

ARDWARE

In this chapter, you get the DT800 hardware up-and-

running.

You firstly check that you have everything, then you

power the DT800 from the mains adaptor and connect

the computer to the DT800.

2-1

CHECKLIST

Make sure you have everything you’ll need to

successfully work through this user’s guide.

➲ Check that you have the following items:

a) From your DT800 shipping box:

• a DT800 data logger

• a mains adaptor

• a communications cable (“comms cable”; DE-9

female to DE-9 female) to connect between the

DT800 and the host computer

• a pair of cage-clamp tools to open the terminal

cage clamps for sensor wiring

• a potentiometer (variable resistance) mounted in

a child’s building block

• a thermocouple

• a DT800 CD (contains software and manuals)

•a

DT800 dataTaker User’s Manual

• the document you’re reading now (

Getting

Started with DT800 dataTaker

)

If anything is missing, contact your supplier

immediately.

b) You also need a PC running Windows 95, 98,

2000 or NT with

• a CD-ROM drive

• a 200MHz Pentium®II processor or better

• at least

•64MB of RAM (“memory”) for Windows 95

or 98

•128MB of RAM for Windows 2000 or NT

(NT also requires Service Pack 4 or later)

• 40MB of free space on the hard disk for

installing

dataTaker

’s DeLogger software

(installed DeLogger occupies 25MB).

Mains adaptor

Comms cable

Cage-clamp tools

Potentiometer

Thermocouple

CD containing

software

and manuals

User’s manual

FIGURE 7Accessories supplied with your DT800 (plus

the user’s guide you’re reading now)

14 Getting Started with DT800

dataTaker

UM-0071-A0

2-2

POWER THE

DT800

There are several ways of providing power to your

DT800, which are covered in “Powering the DT800”

in Part C of the

DT800 dataTaker User’s Manual

. In

particular, be sure to read “Main Battery is

Disconnected for Shipping”.

For this tutorial, you’ll simply use the mains adaptor.

➲ Provide external power to the DT800 using

the mains adaptor supplied.

To do this…

a) Plug the coaxial connector of the mains adaptor into

the coaxial

11–28Vdc

socket on the left side of the

DT800.

b) Plug the mains adaptor into a wall outlet and, while

watching the DT800’s front panel, switch on at the

wall.

If the DT800’s internal main battery is not connected

(we’re assuming yours is not), the five red LED (light-

emitting diode) indicators on the front panel flash

rapidly four times. Then the Acquiring LED begins its

“heartbeat” flash — every three seconds. (The

functions of these LEDs are described in “Indicator

LEDs” in Part B of the

DT800 dataTaker User’s

Manual

supplied with your DT800.)

2-3

MAKE THE

HARDWARE

CONNECTION

For the computer to talk to the DT800, and the DT800

to return data to the computer, you must establish a

communications link between the two.

You can use any of the links described in the Extras

panel “Communications Links”, but in this guide we’ll

use the simplest of all, the comms cable supplied with

the DT800. You’ll connect it between the DT800’s Host

RS-232 port and a COM port on your computer.

➲ Locate and identify your computer’s COM1

serial port then connect the comms cable to it.

To do this…

a) On the rear of your computer, locate the COM1

port and remove anything plugged into it (a

modem, for example).

If you find several likely connectors and don’t know

which is COM1, just choose any one. Later, if

communication with the DT800 is unsuccessful,

simply change to a different connector (we’ll remind

you about this in the next chapter).

b) Plug either end of the comms cable supplied with

the DT800 into the computer’s COM1 port.

➲ Connect the comms cable to the DT800.

To do this…

a) On the left side panel of the DT800, plug the other

end of the comms cable into the connector labelled

Host RS-232

.

11–28Vdc

FIGURE 8Powering the DT800 from a mains

adaptor

CHAPTER 2SET UPTHE HARDWARE: Attach a Sensor 15

UM-0071-A0

2-4

ATTACH A

SENSOR

Now use the potentiometer supplied with your DT800

(see Figure 7 on page 13) to simulate a resistive

sensor.

Firstly, you attach this “sensor” to your DT800.

➲ Attach the potentiometer supplied to analog

channel 1 of your DT800 as shown in Figure 9.

To do this…

a) Locate the potentiometer (variable resistance)

supplied with your DT800.

It’s the child’s building block with a knob on top and

four wires.

b) Connect the potentiometer’s yellow and white wires

to the

+

and

–

terminals of analog channel 1 on the

front panel of the DT800, as shown in Figure 9.

To open the terminals, we recommend that you use

one of the cage-clamp tools supplied — refer to

“Connecting Sensors to Channel Terminals” in Part

B of the

DT800 dataTaker User’s Manual

.

Analog Channel 1

Yellow and white potentiometer

wires: one wire to the +terminal,

the other to the –terminal

(polarity is not important for this

type of “sensor”).

FIGURE 9Connecting the potentiometer

16 Getting Started with DT800

dataTaker

UM-0071-A0

CHAPTER 3

S

ET

U

P

THE

D

E

L

OGGER

S

OFTWARE

Host Software

You communicate with, supervise, and transfer data

from a DT800 by sending commands to it from the

host computer using host software.

DeLogger

host software is a powerful Windows

application designed to make this communication,

supervision and data return as simple yet fully-featured

as possible.

As you work through this chapter, you’ll become

familiar with DeLogger and some basic DT800

operations.

3-1

INSTALL

DELOGGER

Follow the steps in this section to install DeLogger from

the CD supplied with your DT800 to your computer’s

hard disk. The process requires about 40MB of free

space on the hard disk (installed DeLogger occupies

25MB) and takes less than five minutes.

If you already have DeLogger or DeLogger Pro

installed on your computer, see the Extras panel

“Re-Installing and Project Compatibility”.

DeLogger Serial Number

DeLogger is free to use and requires no serial number.

(But you do need one for DeLogger Pro — see the

“Enabling DeLogger Pro” Extras panel on page 18.)

DT800 Host Software

Although you can use any terminal software to

communicate with your logger, you’ll find that

DT800-friendly software packages incorporate

productivity features specific to data acquisition,

data logging and the DT800 that make it pointless

to use anything else.

•

DeLogger

(used predominately throughout this

guide) has a totally graphical interface, which

means that knowledge of the

dataTaker

programming language is not required. Instead,

you supervise the DT800 just by clicking on icons

and making selections from menus and dialog

boxes. And, in addition to standard text output,

you can display and print real-time and logged

data in dynamic table, chart and mimic (needle

meter) views, load data into a fully-featured

spreadsheet, and replay saved data to any of the

dynamic views.

•

DeLogger Pro

is the big brother of DeLogger. It has

the added features of modem support, a database

data storage option, the ability to connect to more

than one data site at a time, enhanced mimic

screens, and additional spreadsheet/graphical

analysis tools.

•

DeTransfer

(included on the CD provided with

your DT800) is the easiest non-graphical host

software to use with the DT800 programming

language. It provides complete access to all of the

DT800’s capabilities, and has separate send and

receive windows, which are the basis of its

exceptional and unique functionality. If you prefer

command-line interfaces, DeTransfer is for you.

CHAPTER 3SET UPTHE DELOGGER SOFTWARE: Install DeLogger 17

UM-0071-A0

➲ Run the DeLogger installer Setup.exe,

which is located in the DeLogger folder on the

CD supplied (

Software

> DeLogger > Setup.exe

).

You do not need a serial number for this

installation of DeLogger.

To do this…

a) Place the CD supplied with your DT800 into your

computer’s CD drive.

b) Follow the numbered steps in Figure 10.

You are returned to the Run dialog box, which now

contains the path to DeLogger’s Setup.exe.

c) In the Run dialog box, click

OK

.

The DeLogger installer starts.

d) Follow the on-screen instructions.

e) After clicking

Finish

in the Setup Complete dialog

box, restart the computer (

Start

menu >

Shut Down…

> select

Restart

>

OK

).

f) When the computer has restarted, notice that the

Start

>

Programs

menu now contains a

DeLogger

folder

(Figure 11), from which you can launch

•

DeLogger

— the main application

• On-Line Help

•

Schedule

— for DeLogger Pro users; a utility that

automatically runs DeLogger Pro events at pre-

determined times (for example, dial a data site

at 6:00pm every day, unload data on the

second Tuesday of every month, or run Job3

every 15 minutes between 11am and 3pm

every Friday)

•

SiteAdmin

— a utility that allows you to clear

DeLogger’s error and alarm logs

•

Uninstall DeLogger

— use to remove DeLogger

from the hard disk.

Re-Installing and Project Compatibility

Earlier Versions

If an earlier version (that is,

pre-version 4) of DeLogger already exists on the

computer, you can do one of the following:

•

Clean Install

Remove the existing version (use

Windows’ Add/Remove Programs control panel)

then install the new version.

•

Have Both

Install the new version to a different

directory from the old one (both version 3 and

version 4 can co-exist on your computer, but not

in the same location).

Project Compatibility

Project files from earlier

versions (that is, pre-version 4) of DeLogger or

DeLogger Pro can not be used with this version

(version 4) of DeLogger (or DeLogger Pro). You’ll

need to re-create your version 3 projects using the

new version of DeLogger.

DeLogger and DeLogger Pro Together

Do

not install DeLogger 4 and DeLogger Pro 4 together

on a computer.

➊On the Windows taskbar, click the

Start button and select Run….

➋Click the

Browse…

button.

➌Double-click in order:

My Computer,

dataTaker (the current CD),

the Software folder,

the DeLogger folder,

and finally

Setup or Setup.exe (may

appear in uppercase).

FIGURE 10 Starting the DeLogger installer

FIGURE 11 Typical Programs menu after installation

18 Getting Started with DT800

dataTaker

UM-0071-A0

3-2

START DELOGGER

➲ Start your new installation of DeLogger for

the first time.

To do this…

a) On the

Start

menu>

Programs

>

DeLogger

menu,

click

DeLogger

— see Figure 11.

DeLogger starts and presents you with its Serial

Number Entry dialog box (Figure 12).

b) In the Serial Number Entry dialog box, leave the

field empty and click

OK

.

The Welcome dialog box opens.

For more information about serial numbers and

upgrading see the “Enabling DeLogger Pro” Extras

panel.

c) In the Welcome dialog box, click

Start New Project

(Figure 13).

d) In the New Project dialog box that opens, type

Project99

(or whatever you like) and click

OK

(Figure 13).

Project99’s windows open within DeLogger’s main

window. Your screen should look like Figure 18

(page 25).

e) Notice that two windows are open in DeLogger’s

workspace (labelled

Prog1.dlp

and

Prog1.dl8

in

their title bars) and five windows are minimized at

the bottom of the workspace (

Mimic1.dlm

,

Form1.dlf

,

Text1.dlt

,

Chart1.dlc

and

Spread1.dls

).

Prog1.dlp

is the program builder for DT500/600

series

dataTaker

s, and

Prog1.dl8

is for your DT800.

f) Click

Prog1.dlp

’s minimize button ( in its title

bar).

You’re not using the DT500/600 program builder

in this tutorial.

Enabling DeLogger Pro

If you purchase DeLogger Pro, or purchase an

upgrade from DeLogger to DeLogger Pro, you’ll

receive a serial number that you use as follows:

•

If you’ve purchased DeLogger Pro

Install and

start DeLogger exactly as described in topics 3-1

and 3-2 beginning on page 16 but, when the

Serial Number Entry dialog box opens

(Figure 12), enter your DeLogger Pro serial

number.

•

If you’ve purchased an upgrade from DeLogger to

DeLogger Pro

With DeLogger running, choose

Register Product…

from DeLogger’s File menu. In

the dialog box that opens (Figure 12), replace

0000-0000 in the field with your Pro serial

number and click

OK

. (0000-0000 is the default

serial number that enables basic DeLogger.) The

next dialog box offers you the choice of quitting

then restarting the program with the new

functionality either now or later.

Leave the field empty (unless you’re upgrading

to DeLogger Pro and have purchased a Pro

serial number) and click OK.

FIGURE 12 No serial number for DeLogger

Click.

Then click OK.

Type a

name

for your

new

project.

FIGURE 13 Creating a new DeLogger project

CHAPTER 3SET UPTHE DELOGGER SOFTWARE: Make the Software Connection 19

UM-0071-A0

g) In DeLogger’s File menu, choose

Save Project

.

This saves the change you just made to the window

view (minimizing Prog1.dlp).

We’ll introduce you to the things you can see in the

DeLogger window in the next chapter. For now,

continue with “Make the Software Connection”.

3-3

MAKE THE

SOFTWARE

CONNECTION

Your computer is physically connected to the DT800

(you did this in the previous chapter). Now you

complete the communications link by making the

software connection between DeLogger and the DT800.

From now on in this guide we use the term

“Connection” — note the uppercase C — to mean

“software connection” (see also page 28).

The “dt800 Com1” Connection

Although you can create your own Connections, in this

tutorial you’ll use one already provided with DeLogger.

It’s called

dt800 Com1

and contains instructions that tell

DeLogger

• that the

dataTaker

at the other end of the

communications link is a

DT800

• to detect the DT800’s communications baud rate

and match the computer’s baud rate to it

• to use software flow control when communicating

with the DT800 (see the “Flow Control” Extras

panel).

In addition, this Connection specifies that the DT800 is

directly connected to the computer’s COM1 serial port.

So, if you chose to plug the comms cable into a serial

port other than COM1 on the back of your computer,

modify the dt800 Com1

Connection in DeLogger now

(

Connections

menu >

Properties…

).

Connection Troubleshooting

If DeLogger responds with an “Error connecting

to…” message, try the following:

• Check that the comms cable’s connectors are

firmly plugged into their sockets, then repeat

“Make the Software Connection” above.

• If the computer has more than one COM port,

swap the comms cable to the other port, then

repeat “Make the Software Connection” above.

• Perform a hardware reset on the DT800

(described in “Resetting the DT800” in Part H of

the

DT800 dataTaker User’s Manual

), then repeat

“Make the Software Connection” above.

• Make sure there is no software configured to

access the computer’s COM port you’re using for

the DT800 (COM1 if you’re following this tutorial

“to the letter”). If there is such software, you can

• re-configure it to use a different COM port, or

• quit it while you use DeLogger (you’ll have to

do this every time), or

• remove it (use Windows’ Add/Remove

Programs control panel).

Then repeat “Make the Software Connection” above.

• Change the serial port specification in the

DeLogger software Connection (

Connections

menu

>

Properties

) to, say, COM2. Then repeat “Make

the Software Connection” above.

20 Getting Started with DT800

dataTaker

UM-0071-A0

➲ Connect to the DT800 using dt800 Com1.

To do this…

a) In DeLogger’s Connections menu (fourth from the

left), choose

Connect…

.

b) In the Connect dialog box that opens, highlight (one

click)

dt800 Com1

and click

OK

.

Two progress bar dialog boxes open, then close

automatically to indicate that you’ve successfully

connected to the DT800.

If a dialog box opens asking if you want to upgrade

to a later version of the

dataTaker

firmware, click

No

. (You can do this at another time.)

If DeLogger is unable to connect (you’ll see an

“Error connecting to…” message), go to the Extras

panel “Connection Troubleshooting”.

3-4

VERIFY THE

CONNECTION

Now carry out some simple communication with the

DT800.

➲ Get the

dataTaker

’s status.

To do this…

a) From DeLogger’s

dataTaker

menu (sixth from the

left), choose

Status…

.

DeLogger communicates with the DT800, retrieves

information about what’s currently happening in the

DT800, and presents the information to you in the

large dialog box that opens (Figure 15).

You can do this anytime you’re connected to a

DT800. In fact, as well as using this command to

find out which schedules (see page 33) and alarms

(see page 63) are currently running in the DT800,

how much data storage (memory) is used and free

in the DT800 and so on, you can send this

command simply to confirm that you’re connected

to the DT800.

b) Look through the Status dialog box tabs to

familiarize yourself with the information you can get

from it, then click

OK

.

Flow Control

Flow control is a communications feature that allows

communicating devices to control each other’s

transmission of information.

DeLogger and the DT800 support two types of flow

control:

•

Hardware Flow Control (HWFC)

Flow control

signals are sent between the communicating

devices by means of RTS and CTS control wires in

the cable.

•

Software Flow Control (SWFC)

Flow control

commands XOFF and XON are sent between the

communicating devices by means of the

data wires in the cable.

Setting Flow Control

You must set the same

type of flow control at each end of a

communications link. For example, for this tutorial,

both the DT800 and your DeLogger Connection

must be set for software flow control.

This Tutorial

We recommend that you use

software

flow control for this tutorial. This is the

default/factory setting for a new DT800 and for

DeLogger’s

dt800 Com1

Connection. (If you’re using

a DT800 that has previously been set to hardware

flow control, you must either change the DeLogger

Connection to hardware flow control also, or change

the DT800 to software flow control.)

FIGURE 14 Connect dialog box

Other manuals for DT800

1

Table of contents

Other dataTaker Data Logger manuals

Popular Data Logger manuals by other brands

Convergence Instruments

Convergence Instruments ACAM 64 user manual

METER

METER ZL6 quick start

GHM

GHM GREISINGER EB-Logg 80K Series Installation and operating manual

Omega

Omega OM-EL-WiFi-TP user guide

Kilowatt Labs

Kilowatt Labs SIRIUS 1364-24-B-1C-TM-SD-A-G user manual

PCE Instruments

PCE Instruments PCE-SDL1 user manual

Measurement Computing

Measurement Computing USB-5201 user guide

Extech Instruments

Extech Instruments 42275 user guide

Brandywine

Brandywine Portable Timing Unit user guide

LogTag Recorders

LogTag Recorders USRIC-8 quick start guide

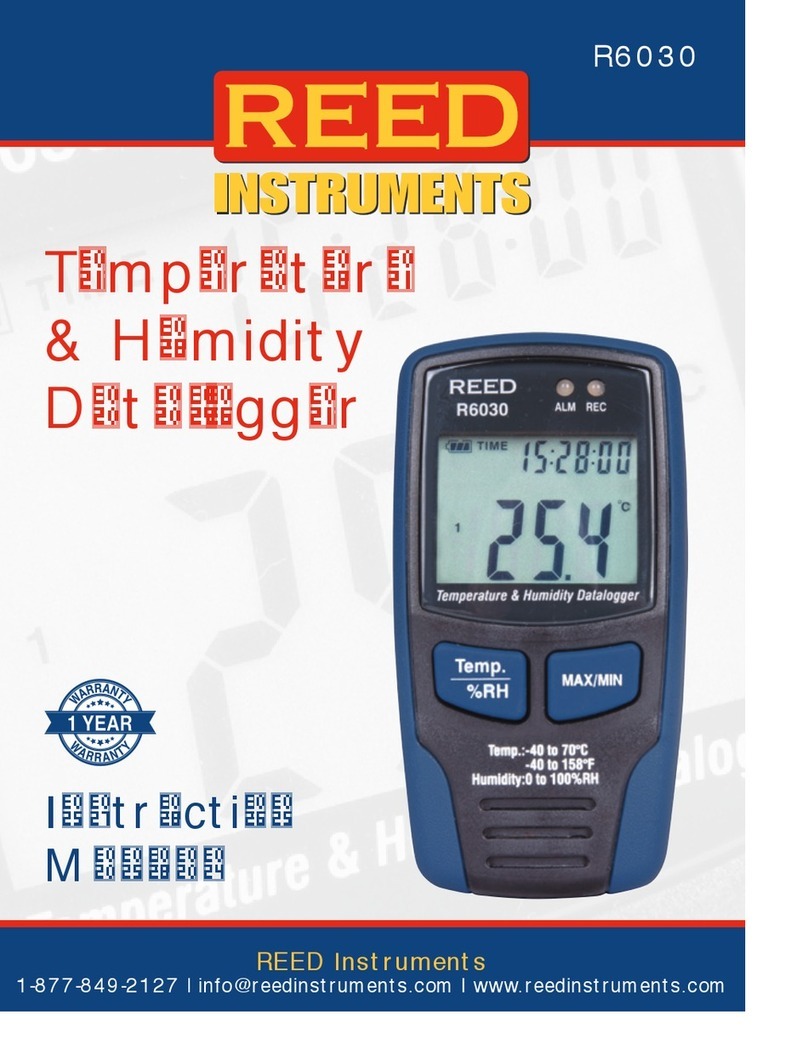

Reed Instruments

Reed Instruments R6030 manual

Datalogic

Datalogic Dragon Reference manual