Datexel DAT 6000 SERIES User manual

DAT 6000 SERIES

ANALOG to DIGITAL

INTERFACE UNITS

for PLC

DATA ACQUISITION

- USER MANUAL -

FEATURES

- Analog Signal Acquisition on PLC digital I/O

- Models and analog inputs :

DAT6012 - 2 channels for RTD, Resistance or Pot.

- 16-bits resolution with high F.S. accuracy

- Linearization function for Tc and RTD

- PC and DIP-SWITCH configurable

- 3-ways 2000Vac galvanic isolation

- In compliance with EMC directives - CE mark

- 12.5 mm thin profile housing

- DIN rail mounting

APPLICATIONS

- Factory Automation

- Building Automation

- Agricolture Automation

- Chemical Industry Measurement

- Security system

- Machine Control

DAT 6000

2

PRELIMINARY

DAT6000

Introduction

TheDAT6000seriesisanevolutionintheconnectiontechniquesoftheanalog

signals to the PLC.

Thedevicesofthisserieperformsmanyfunctionsas:amplification,linearization,

isolation,filteringandconversionofanalogsignals,comingfromvarioussensors,

in a high resolution digital signal. The digital signal is transfered to the PLC by

abusconnected to any oneofthe controller’sdigitalinput. It is composedbya

series of 16-bit ‘words’ containing the values of the analog signals to be

measured.ThetransferisPLC controlled by a clock signal comingfromoneof

its output ports. At every clock pulse a bit of the data is transmitted.

Using few and simple instructions the PLC is even capable to acquire more

analog signal on a single digital input.

The devices are also provided of an Enable signal which, handled by the

controller, allows to " multiplexing " many devices on the same digital input.

The DAT6000 series is composed of the following devices:

Device Channels Input Type

DAT 6011 2 mV and Tc

DAT 6012 2 RTD, Res. and Pot.

DAT 6013 2 V and mA

DAT 6021 4 mV and Tc

DAT 6023 4 V or mA

DAT 6000

3

PRELIMINARY

4.7 K4.7 K

4.7 K

DC/DC

N

P

M

O

R

Q

>560 R

18..30 Vdc

+

ENABLE

DATA

CLK

GND +V

DAT 6000 PLC

+V

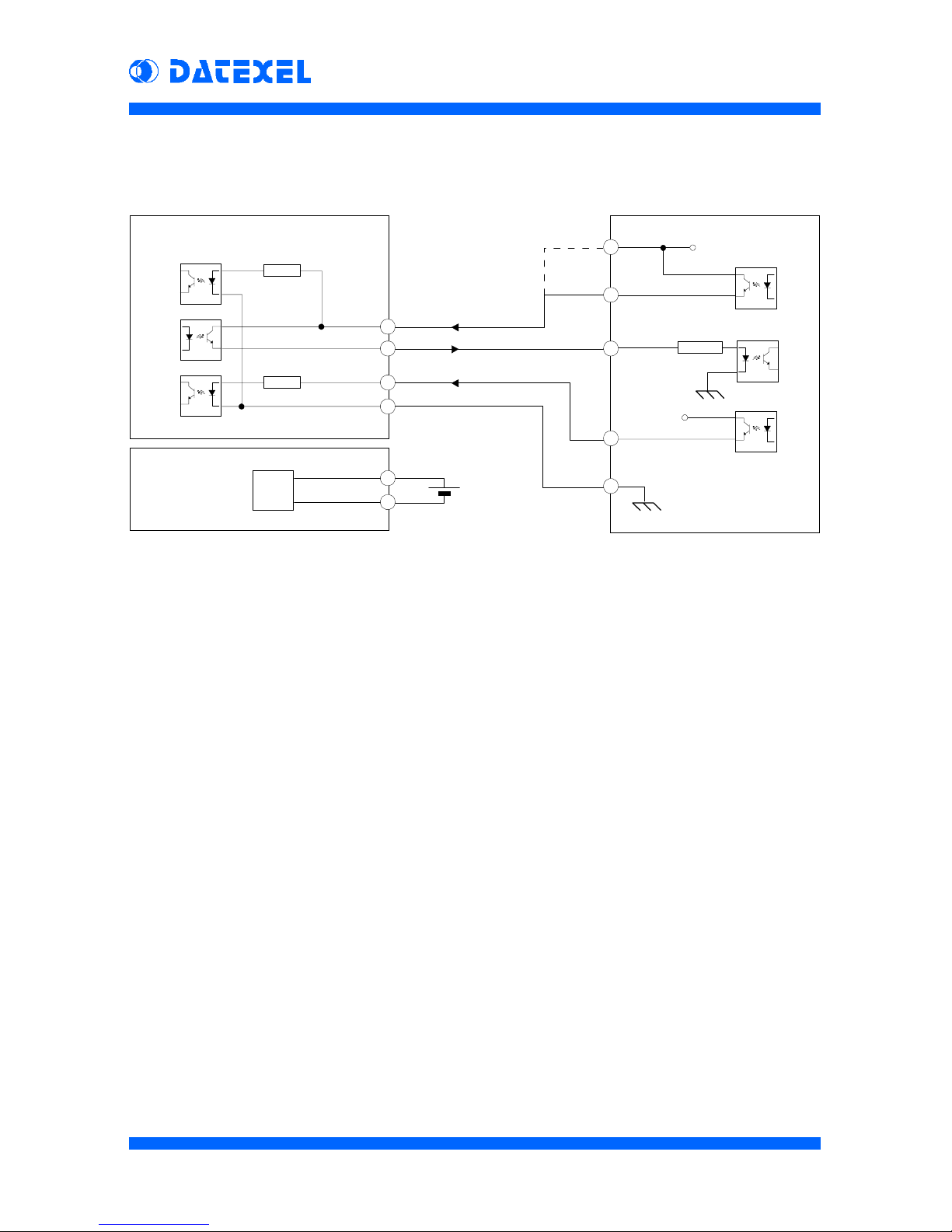

How to connect DA T6000 to PLC

TheserialinterfaceoftheDAT6000seriesdevicesisshownhereup.Inputand

output signals are optoisolated among analog input and power supply. The

DATAsignalcircuitispowereddirectlywiththeENABLEsignalvoltage.Without

the ENABLE signal, the data output is disabled. The ENABLE input

(terminalN)can beconnecteddirectlytothesupply voltage,leavingavailablea

PLC output port; in this case the data output is always enabled. Using the

ENABLEsignal,theCLKsignalcanbealwaysactive,becausewhenENABLE

signal is off, the microprocessor ignores the clock signal, stopping the data

sending; by this way, it is possible to connect many devices in multidrop

connection, using few PLC I/O ports.

The power supply of the DAT6000 is isolated from the serial interface so that

the auxiliary supply of the PLC can be used to power it.

DAT 6000

4

PRELIMINARY

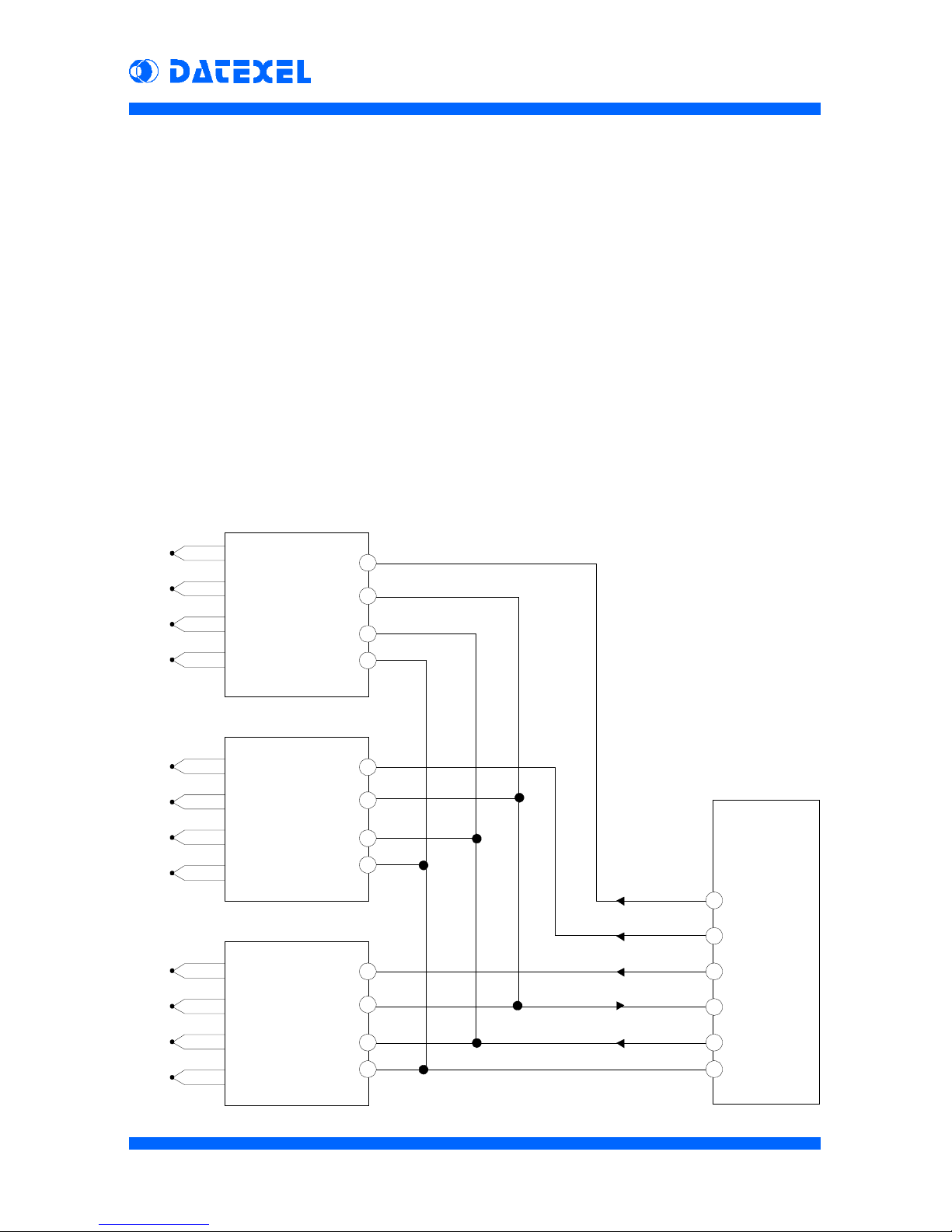

Multidrop connection

The CLK input and the DATA output of the DAT6000 devices are actives only

when the ENABLE signal is on. Consequently It is possible to connect all the

DATA signals to the same PLC digital input and all the CLK signals to the same

PLCdigitaloutput. Devices can beactivatedone by one sendingtheENABLE

signal to the selected device only.

Asshownin the figure below,using n°3 DAT6000 devices it ispossibleto read

thevalueofupto12analog sensorsusingonly4PLC digitaloutputsand1PLC

digital input. Each new device connected will use only one more PLC digital

output(ENABLE).

Changingthedevicetype,itispossibletocreatemany combinations of analog

inputs (i.e.: 4 Tc inputs on the first device, 4 mA inputs on the second device

and2Potentiometerinputsonthethirddevice),withoutto change the wiring to

thePLCandthesoftwaredatareadingprocedure.

P

M

O

ENABLE 3

DATA

CLK

GND

DAT6021

N° 1

P

M

O

P

M

O

N

N

N

ENABLE 2

ENABLE 1 Digital out

Digital out

Digital out

Digitalin

Digital out

Ground

Tc 1

Tc 2

Tc 3

Tc 4

Tc 5

Tc 6

Tc 7

Tc 8

Tc 9

Tc 10

Tc 11

Tc 12

DAT6021

N° 2

DAT6021

N° 3

PLC

Digital I/O

DAT 6000

5

PRELIMINARY

Analog Inputs connection

Tc

wiring

mV

wiring

DAT 6011

Tc

wiring

mV

wiring

DAT 6021

DAT 6000

6

PRELIMINARY

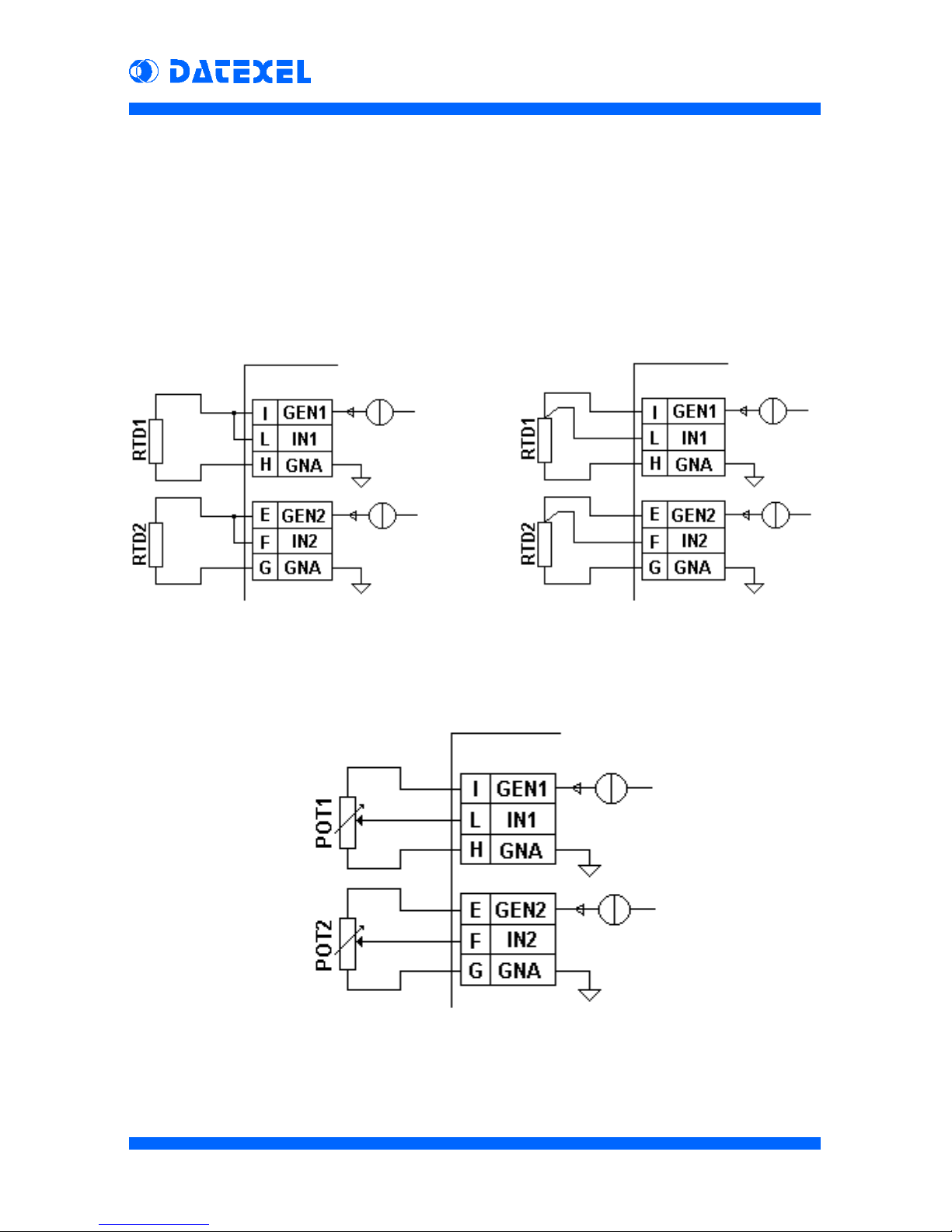

3wiresRTD/Res

wiring

2wiresRTD/Res

wiring

DAT 6012

Potentiometer

wiring

DAT 6000

7

PRELIMINARY

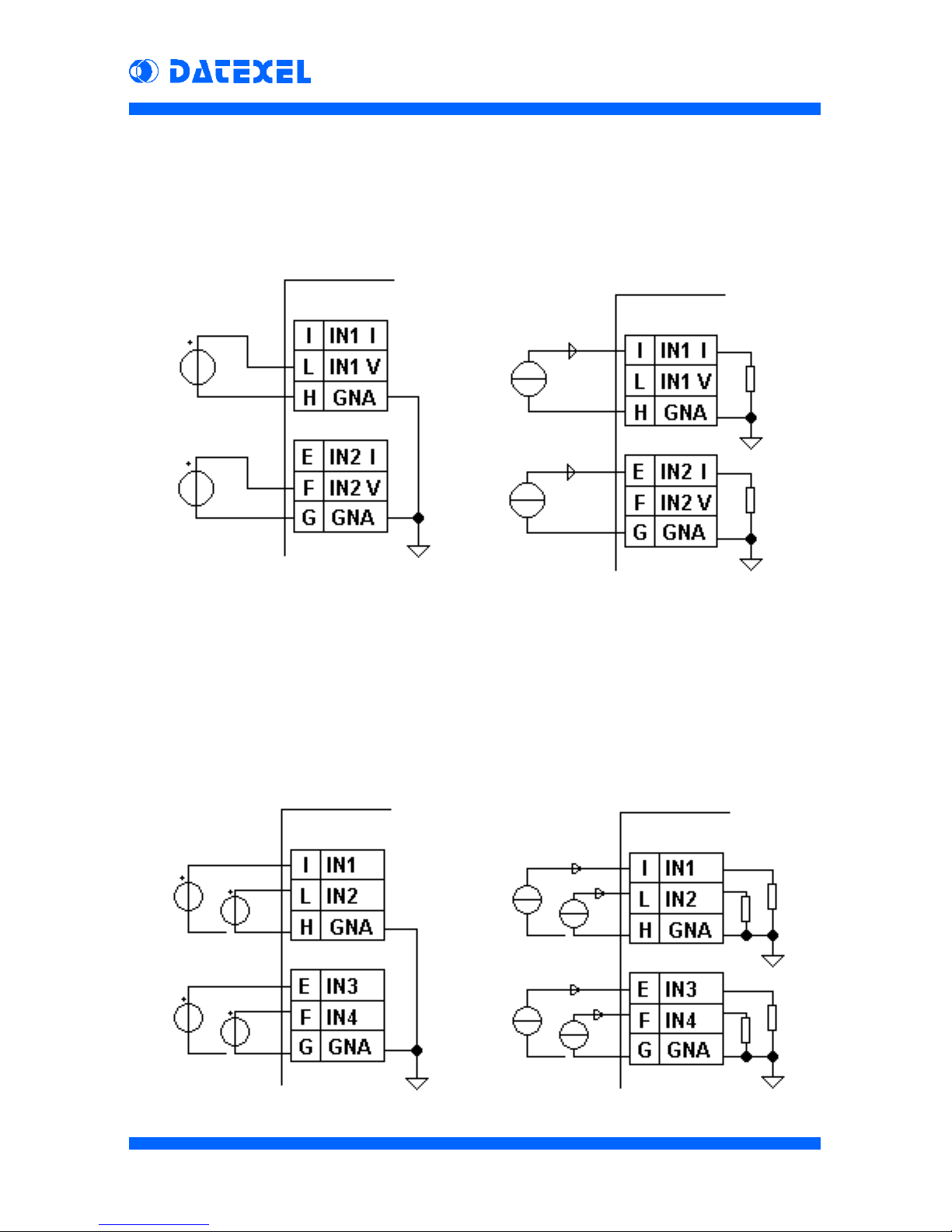

mA

wiring

V

wiring

DAT 6023

V

wiring

DAT 6013

mA

wiring

DAT 6000

8

PRELIMINARY

Technical Characteristics

Analog Inputs

mV

Input Min Max

50 mV -50 mV +50 mV

100 mV -100 mV +100 mV

500 mV -500 mV +500 mV

1000 mV -1000 mV +1000 mV

DAT 6011, DAT 6021

Channels: 2 ( DAT 6011 )

4 ( DAT 6021 )

InputType: ± 50 mV to ± 1V

Tc: J, K, T, E, R, S, B, N

Calibration Accuracy: ± 0.1 F.S.

Linearity: ± 0.2 % for Tc

Lead wire resistance influence: < 0.8 uV/Ohm

Input impedance: > 10 MOhm

Cold Junction Compensation: ± 0.5 °C

Thermal Drift: ± 0.005 % F.S. /°C

Sampling Rate: 10 samples/sec

Bandwidth: 4Hz

Thermocouple

Input Min Max

Tc J -210 °C +1200 °C

Tc K -210 °C +1372 °C

TcT -210 °C +400 °C

Tc E -210 °C +1000 °C

Tc R -50 °C +1767 °C

Tc S -50 °C +1767 °C

TcB +400°C +1825 °C

Tc N -210 °C +1300 °C

DAT 6000

9

PRELIMINARY

DAT 6012

RTD

Input Min Max

Pt100 -200°C +850°C

Pt1000 -200°C +200°C

Ni100 -80°C +180°C

Ni1000 -60°C +150°C

Resistance

Input Min Max

Low 0 Ohm 500 Ohm

High 0 Ohm 2000 Ohm

Potentiometer

Input Min Max

<500 Ohm 0 % 100 %

<2000 Ohm 0 % 100 %

Channels: 2

InputType: RTD (Pt100, Pt1000, Ni100, Ni1000)

Resistance and Potentiometer (up to 2KOhm)

Calibration Accuracy: ± 0.1°C for RTD; ± 0.1 Ohm for Resistance;

± 0.1 % for Potentiometer;

RTD Linearity: ± 0.2 °C

RTD Excitation Current: 0.350 mA typ.

Lead wire resistance influence: < 0.05 %/Ohm (50 Ohm max.) for 3 wires RTD

Thermal Drift: ± 0.005 % F.S. /°C for RTD

Sampling Rate: 10 samples/sec

Bandwidth: 4Hz

DAT 6000

10

PRELIMINARY

DAT 6013 - DAT 6023

Voltage

Input Min Max

10 V -10 V +10 V

Current

Input Min Max

20 mA -20 mA +20 mA

Channels: 2 ( DAT 6013 )

4 ( DAT 6023 )

InputType: ± 10V or ± 20 mA *

Calibration Accuracy: ± 0.05 %

Linearity: ± 0.1 %

Input Impedance: > 1MOhm for V ; 47 Ohm for mA

Thermal Drift: ± 0.005 % F.S. /°C

Sampling Rate: 10 samples./sec

Bandwidth: 4Hz

* For DAT 6023 the input type is not configurable.

It must be to defined at order (V or mA).

SupplyVoltage: 24 Vdc typical (30 Vdc max)

ON state voltage: > 9 Vdc

InputImpedance

(ENABLE,CLK): 4.7KOhm

MinimumOutputLoad

(DATA): 560 Ohm

Maximum Clock signal frequency:

< 500 Hz (with 1ms filter)

< 50 Hz (with 10ms filter)

DebounceFilter: settable to 1ms or 10 ms

RiseTime: <0.2 ms

DIGITAL INTERFACE

DAT 6000

11

PRELIMINARY

SUPPLY

SupplyVoltage: 18 to 30 Vdc

SupplyCurrent: 35 mA @ 24 Vdc

Polarityreversalprotection: 60Vdc

Temperature and Humidity

OperatingTemperature: -10 ÷ +60 °C

StorageTemperature: -40 ÷ +85 °C

RelativeHumidity(notcondensing): 0 ÷ 90 %

EMC

Emission EN50081-2

Immunity EN50082-2

RF Immunity tested @ 10 V/m up to 1000 Mhz

Housing

Material Selfestinguishing Plastic

Mounting DINRail

Weight 50 g. approx.

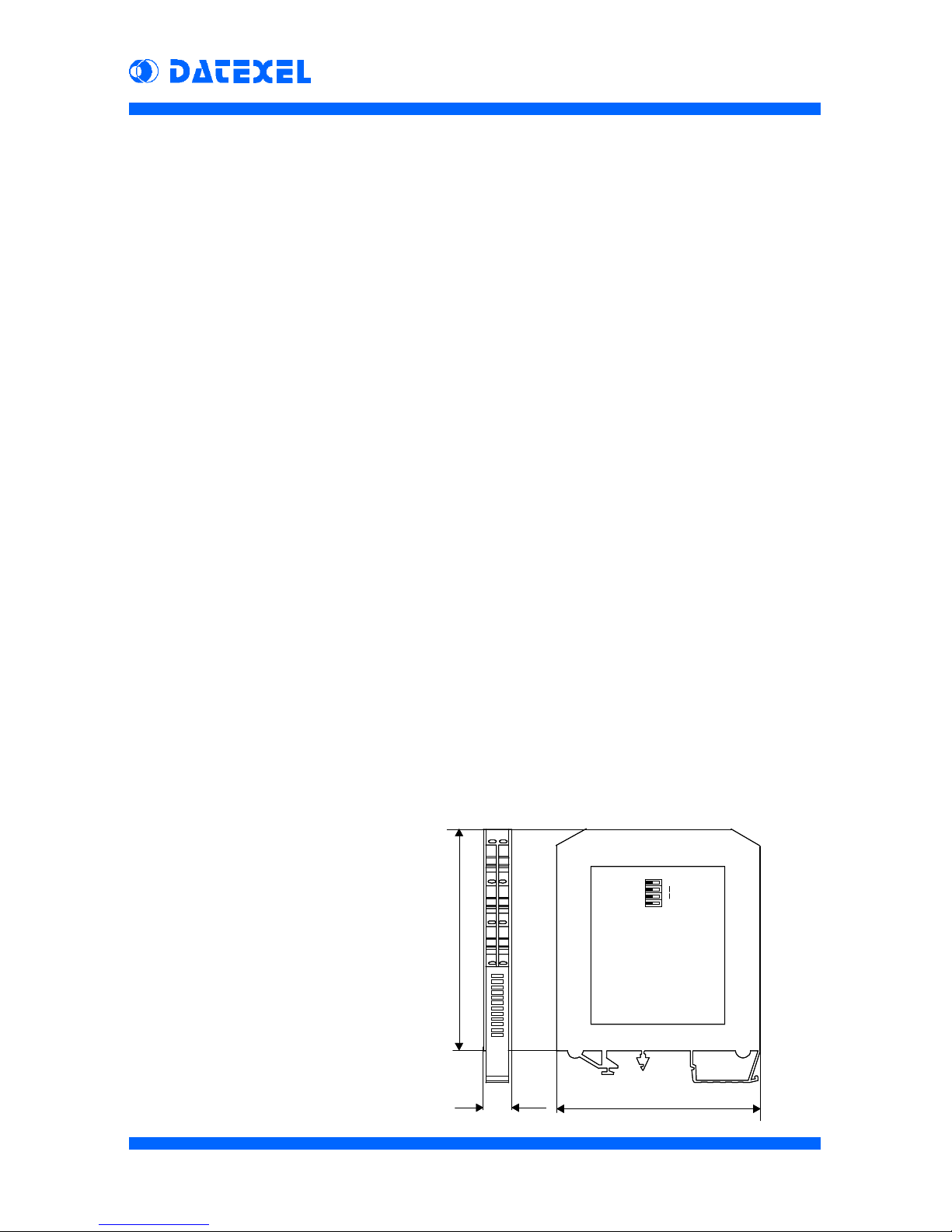

Dimensions

(W x H x T) in mm: 90 X 98 X 12.5

Mechanical

Dimensions (mm)

12.5 90

98

EF

GH

IL

SW1

SW4

DAT 6000

12

PRELIMINARY

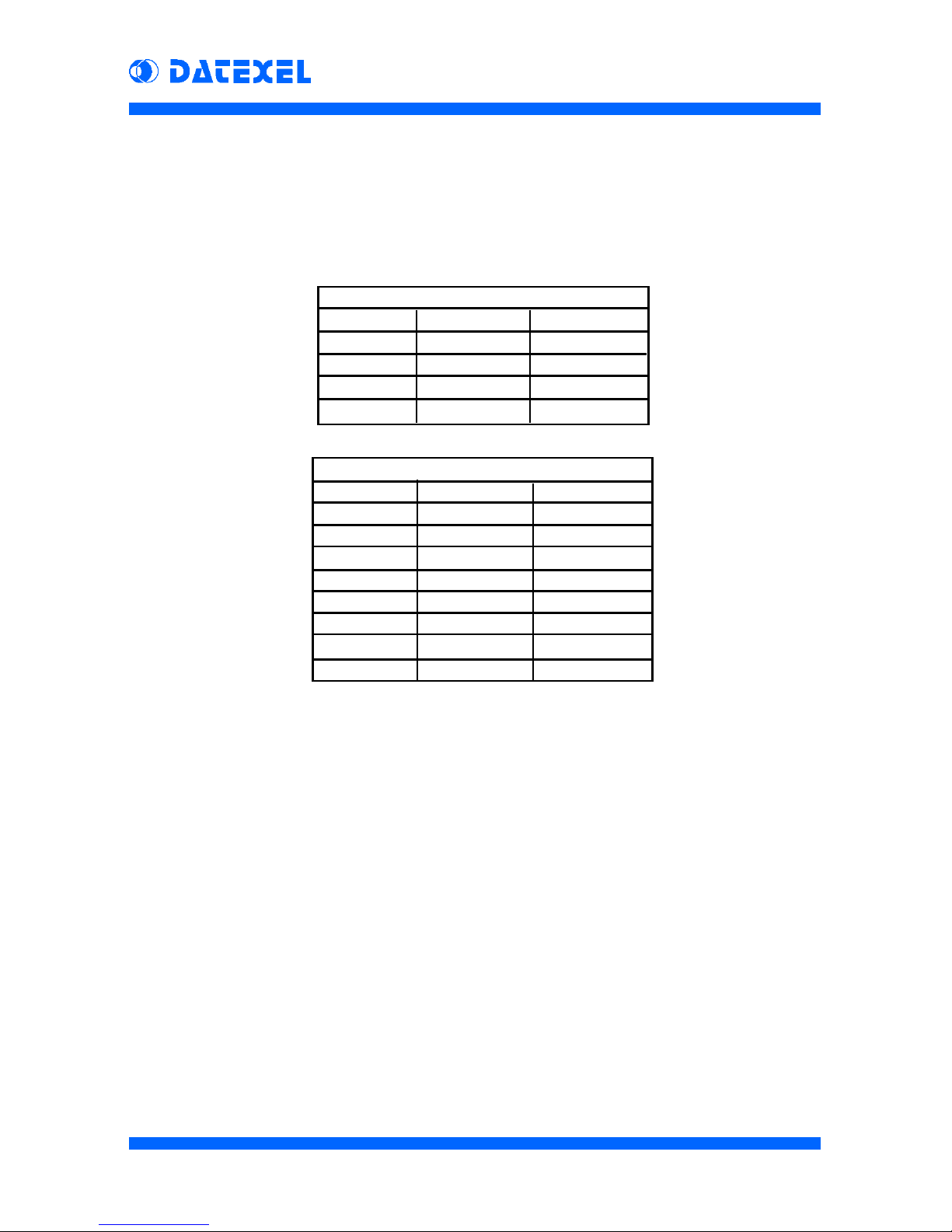

How to Program the module

The input type is in-field configurable by means of the dip-switches. The input

type configuration is made by SW1..SW3 dip-switches which can be used to

setup to8differentinput types.Thestandardcorrespondance betweenthedip-

switchsettingandtherelative input type is shown in thetablesbelow. It can be

modifiedusingthe ‘PRO6000’softwareandthePRODAT-03interface.

By this way, it is possible to reconfigure the module for a wide range of input

signal types at any time.

Also the CLK signal’s digital filter can be set to 1 ms or 10 ms (half-period

duration) by a dip-switch (SW4). The digital filter eliminates all the signal

variations shorter than the specified time, avoiding undesired command

simulations.

Hereafterthestandardtablesofthevariousmodulesareshown:

DAT6012 and DAT6013 modules, having a limited number of possible input

types, are availables with a fixed table. Whereas DAT6011 and DAT6021 are

available as in Tab.A or in Tab.B, indicating the choice at the order, or in any

desired configuration using the software, as previously mentioned. DAT6023

module is not configurable; consequently the input type (V or mA) must be

definedattheorderphase.

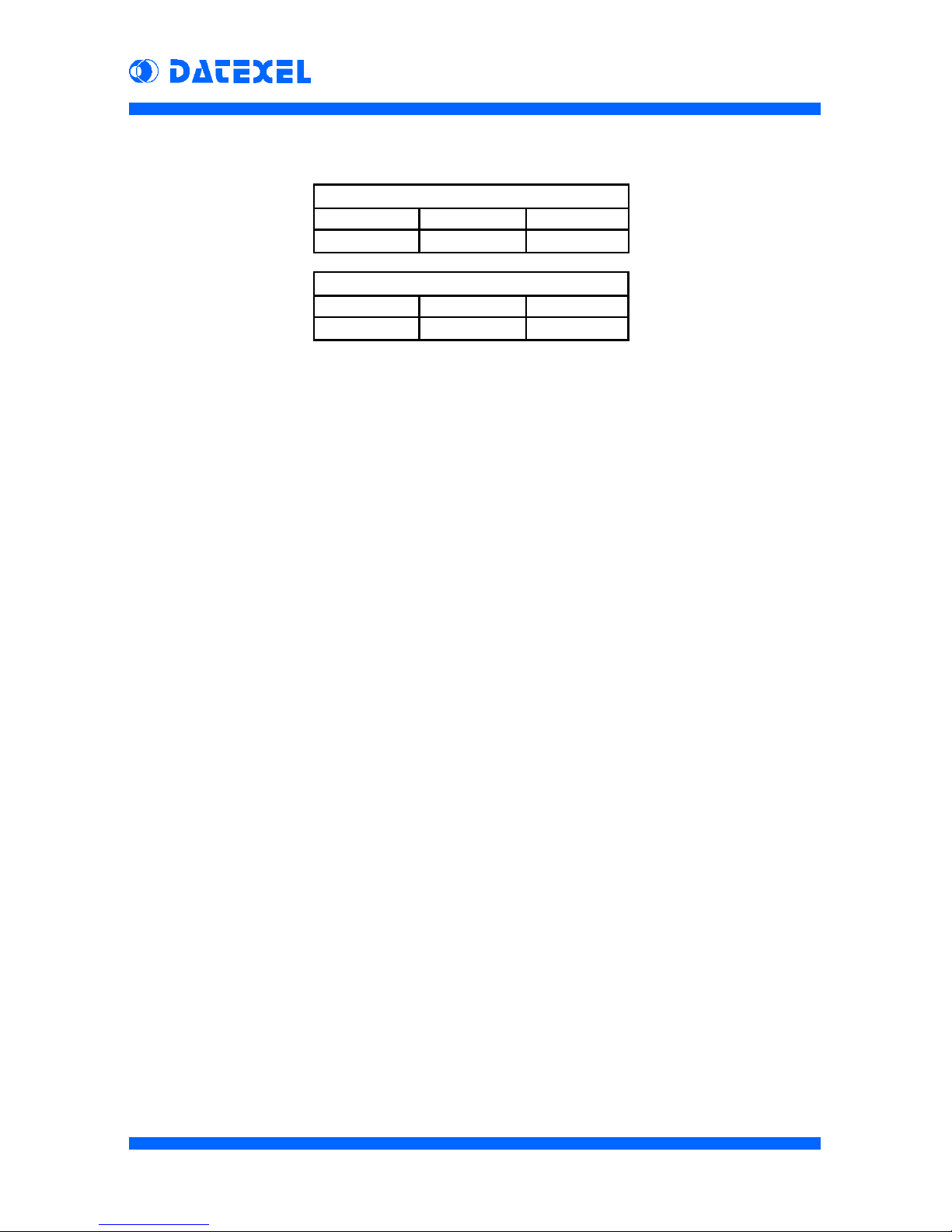

SW1 SW2 SW3 Input Input

Tab.A Tab.B

0 0 0 Tc J 50 mV

0 0 1 Tc K 100 mV

0 1 0 TcT 500 mV

0 1 1 Tc E 1000 mV

1 0 0TcR---

1 0 1TcS---

1 1 0TcB---

1 1 1TcN---

SW1 SW2 SW3 Input

0 0 0 Res. L

0 0 1 Res. H

0 1 0 Pt100

0 1 1 Ni100

1 0 0 Pt1000

1 0 1 Ni1000

1 1 0 Pot. L

1 1 1 Pot. H

DAT6011-DAT6021 DAT6012

DAT6013

SW1 SW2 SW3 Input

x x 0 10 V

x x 1 20 mA

DAT 6000

13

PRELIMINARY

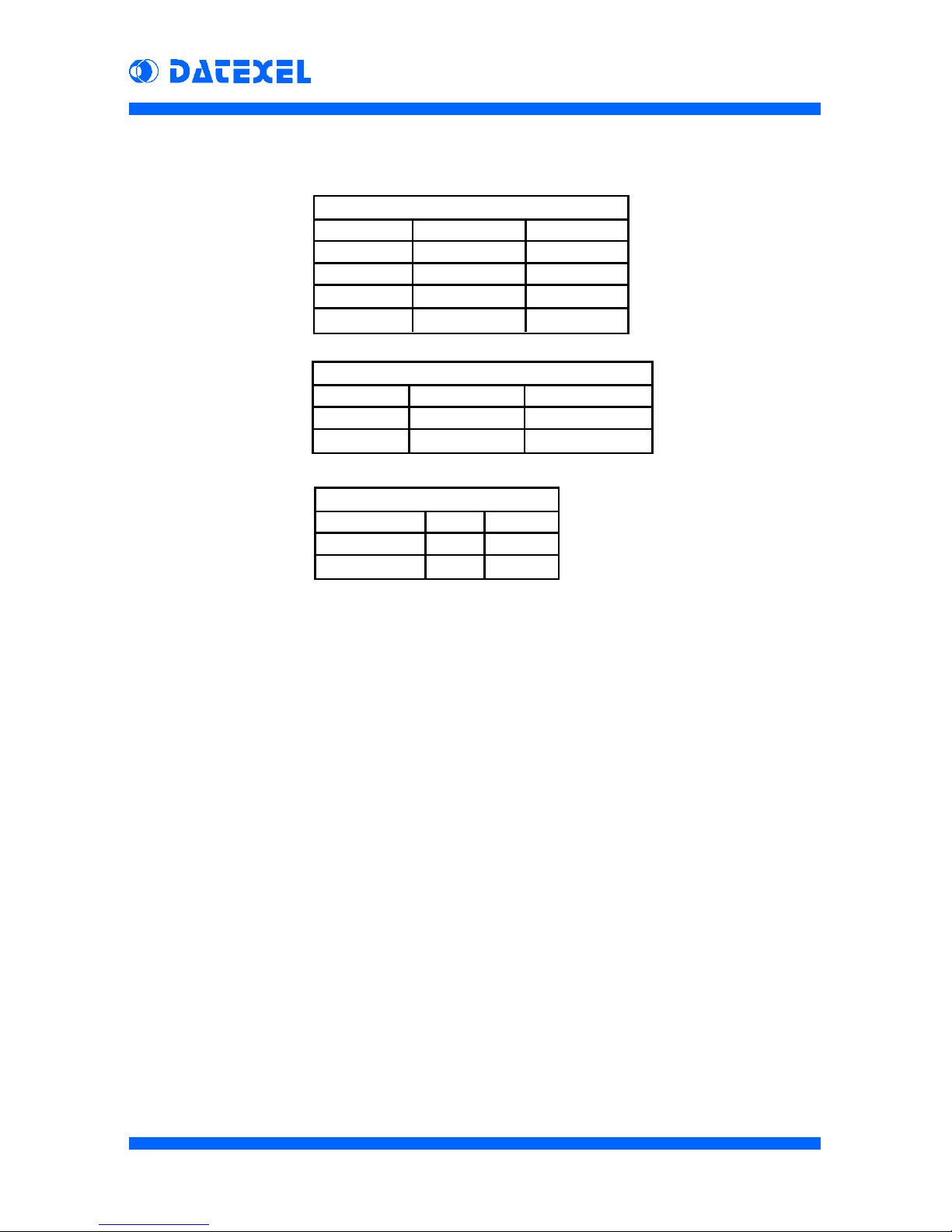

How to create an Input Table

Allthepossible input types ofthemodule are listed inamain table (Tab.1).Itis

possibleto associate up to 8 of this input types to eachone of the 8 dip-switch

combinations,followingtheorderofTab.1 andcomplingtoeverychoosedtype

the first free dip-switch combination. By this way the ‘dip-switch to input type’

correspondencetableiscreated (Tab.2).

The example is referred to DAT6011 module and shows how to associate the

heightdip-switchcombinationstothree‘mV’inputs(50mV/100mV / 1000mV)

andfive ‘Tc’ inputs (Tc J/K/R/S/N):

In any case, it is sufficient to set the desired data in the “PRO6000” program,

andthetablewillbeautomaticallycreated.Moreoverthesoftwarewillprovideto

program the module in the correct way.

Tab.2

SW1 SW2 SW3 Input

0 0 0 50 mV

0 0 1 Tc J

0 1 0 Tc K

0 1 1 Tc R

1 0 0 Tc S

1 0 1 Tc N

1 1 0 100 mV

1 1 1 1000 mV

Tab.1

Pos. Input

0 50 mV

1 Tc J

2 Tc K

3 TcT

4 Tc E

5 Tc R

6 Tc S

7 Tc B

8 Tc N

9 --

10 --

11 --

12 --

13 100 mV

14 500 mV

15 1000 mV

50 mV

Tc J

Tc K

Tc R

Tc S

Tc N

100 mV

1000 mV

DAT 6000

14

PRELIMINARY

Data Reading

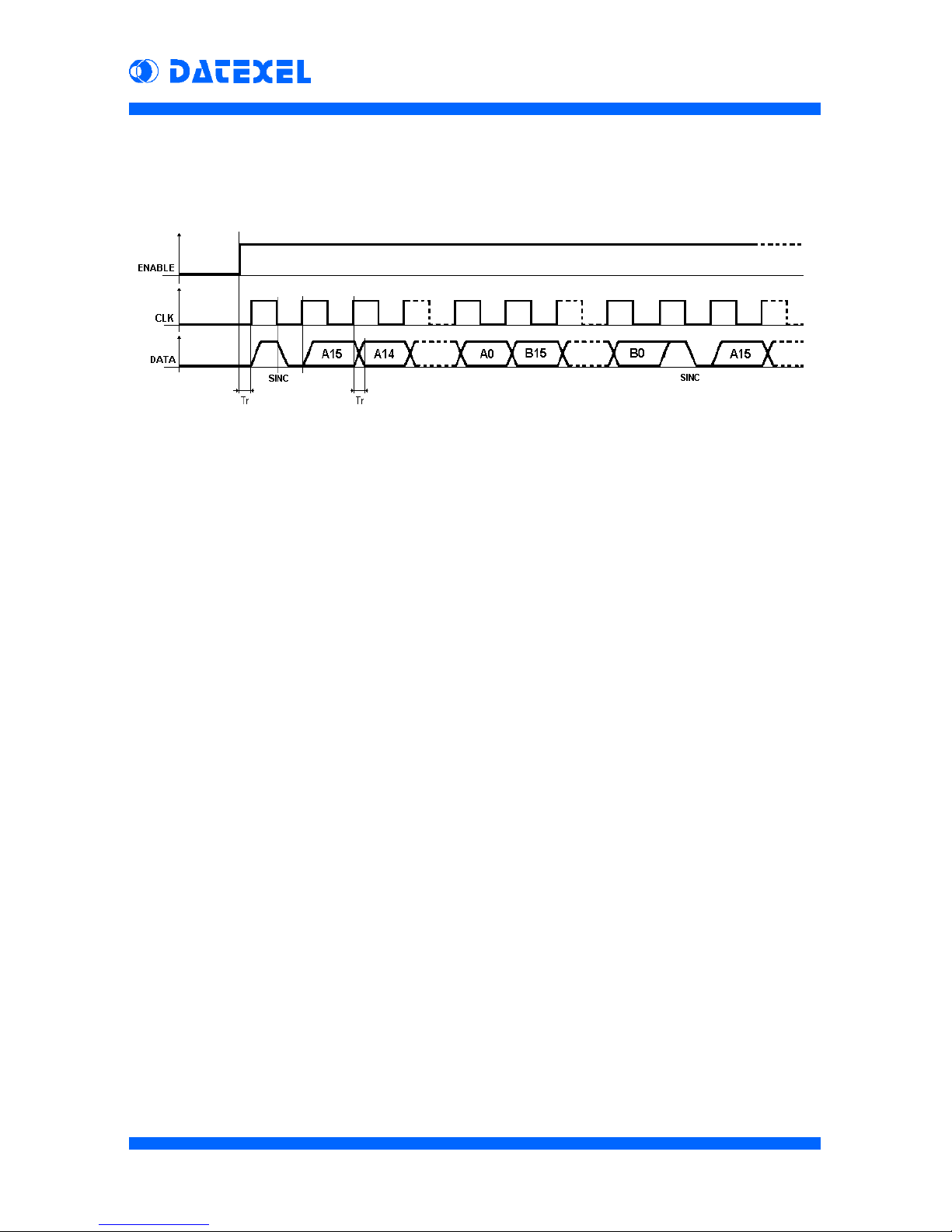

The data transfer is made sending an enabling signal (ENABLE) and a clock

signal (CLK). If the ENABLE signal is high, a bit composing the reading is

providedon the output (DATA) at every clock pulse.

Everyreadingcycleiscomposedof1synchronismbitfollowed of a 16 bit word

for each analog input signal (channel). So that any reading is composed of 33

bitsfor 2-channels and 65 bits for 4-channels.

The synchronism bit indicates that the next bit is the most significant bit of the

first channel value (A15); the following remaining bits of this value will be

transmitteddowntotheleast significant bit (A0). This bit willbefollowedbythe

mostsignificantbitofthesecondchannelvalue(B15),downtotheleastsignificant

bit (B0). After the last bit, a new synchronism bit will be transmitted.

The value to be transmitted will be updated during the transmission of the

synchronism bit. During the reading cycle, the ENABLE signal must stay at

logiclevelHI.

The first bit after the ENABLE signal rise front will be a synchronism bit.

The synchronism bit level is high when the CLK signal is high and is low when

theCLKsignalislow. Differently, each data bit isupdatedontheCLKrise front

and mantains its level until the next CLK rise front.

At any moment it is possible to send a rise front on the ENABLE signal to

restart the reading cycle (by the synchronism bit).

The‘DebounceFilter’eliminatesallthesignalvariationsshorterthanthespecified

time,avoidingundesiredcommandsimulations.

DAT 6000

15

PRELIMINARY

Start condition:

ENABLE low and CLK low, then DATA is automatically low.

Initialization:

1 - ENABLE High

2 - Wait for Tr

Synchronism:

3 - CLK High

4 - Wait for Tr

5 - Read DATA

6 - DATA logic level must be 1 otherwise go to point 3 *

7 - CLK Low

8 - Wait for Tr

9 - Read DATA

10 - DATA logic level must be 0 otherwise go to point 3 *

Bit reading:

11 - CLK High

12 - Wait for Tr

13 - Read DATA

14 - CLK Low

15 - Wait for Tr

16 - Read DATA

17 - DATA logic level read on point 13 and on point 16 must be the same,

otherwise go to point 3 *

18 - Save the DATA logic level as bit in the reading register

Channel reading:

19 - Repeat points 11 to 18 for all the 16 bits of the measure, writing the bits

in the reading register from the most significant one down to the least

significant one

20 - Repeat points 11 to 19 for all the channels to read

21 - After the 16° bit of the last channel (2nd or 4th) return to point 3

To abort the reading without to read all the channels:

22 - Be sure the CLK is Low

23 - ENABLE Low

24 - Wait for Tr

25 - Go to point 1

* Synchronization is failed, then disregard the last reading. The data acquisition will

be delayed until the next synchronism bit will be recognized. It is advisable to abort

the reading procedure going to point 22.

NOTE: ‘Tr’ is the Debounce Filter time setting (1ms or 10 ms)

Thecorrect proceduretoacquirethemeasuresbythemodulecanbedescribed

asfollowing:

How to write the PLC’s instructions

DAT 6000

16

PRELIMINARY

EXAMPLE n°1 : 2 or 4 channels reading

The procedure is fast and with few instructions because there are not

synchronismcontrols.However,if thesynchronismis lost (i.e. foranoise), the

readingwillbewrong.Toavoidthat,itisadvisabletousetheENABLEsignalto

synchronize the procedure at the reading start.

The following two examples, each one toghether with its flow-graph, illustrate

theprocedure to be followedfor writing the PLC’sinstructions.

START

ENABLE HIGH

DELAY

n = n - 1 n = 0 ?

READ BIT

REGISTER [n] = y

CHANNAEL (a) =

REGISTER

n = 15

a = a + 1

a = 2 ?

(NOTE 1)

DELAY

CLK LOW

DELAY

CLK HIGH

y = DATA

READ BIT

a = 0

end of channels reading

YES

NO

YESNO

read next channel

end of channel reading

read next bit

read input bit

READ BIT

The first bit is the

most significant

ENABLE LOW

DELAY

NOTE 1 : to be modified following the number of channels to be read ( write " a = 4 ? " for the 4 channels reading )

NOTE 2 : follow the (A) option to reset the device or for not reading the unused channels

A

NOTE 2

Definitions:

ENABLE, CLK and DATA = interface signals

SYNC = synchronism bit

REGISTER = data reading buffer

n = a bit of REGISTER buffer (0..15)

CHANNEL = digital channel measurement value

a = channel number (1,2,3 or 4)

x, y = bits

DELAY = delay function (ms). The delay time must be

higher than the setting of the digital filter

DAT 6000

17

PRELIMINARY

EXAMPLE n°2 : 2 or 4 channels with synchronism control

The continuous control of the received bit allow a sure synchronization of the

procedure.Whenthe synchronismislost,thenextreading willbesurelycorrect

because it will starts only when a synchronism bit will be recognized. It is not

necessary to use the ENABLE signal.

START

ENABLE HIGH

DELAY

n = n - 1 n = 0 ?

READ BIT

SYNC

?

REGISTER [n] = y

CHANNEL (a) =

REGISTER

n = 15

a = a + 1

Definitions:

ENABLE, CLK and DATA = interface si

g

nals

SYNC = synchronism bit

REGISTER = data readin

g

buffer

n = a bit of REGISTER buffer (0..15)

CHANNEL = di

g

ital channel measurement value

a = channel number (1,2,3 or 4)

x, y = bits

DELAY = delay function (ms). The delay time must be

hi

g

her than the settin

g

of the di

g

ital filter

DELAY

CLK LOW

DELAY

x = DATA

y = DATA

CLK HIGH

x & y

compare

SYNC ERROR

READ BIT

a = 0

end of channels reading

YES

NO

YESNO

NO

YES

read next channel

end of channel reading

read next bit

read input bit

READ BIT

DATA

?

YES

NO

data-bit received

wrong bit received

DATA

x=1

y=0 x=0

y=1

x=y

the first bit is the

most significant

synchronism found

first channel reading

ENABLE LOW

DELAY

a = 2 ?

(NOTE 1)

NOTE 2

A

NOTE 1 : to be modified following the number of channels to be read ( write " a = 4 ? " for the 4 channels reading )

NOTE 2 : follow the (A) option to reset the device or for not reading the unused channels

DAT 6000

18

PRELIMINARY

Data Format

Themoduleacquiresthe analog signal value ofeachchannelandconvertsitin

a digital string (bit). Each analog signal is converted in a 16 bit word which is

seriallytransmittedas before described.

Then,itis possible to convertthereceived string in thecorrespondingdecimal

value, considering that each value is expressed in signed integer (the most

significantbitindicates the sign: 0=positive1=negative).

Theuserwill must insert thedecimalpoint as illustrated inthefollowing tables.

Input Binary Hex Decimal Measure

Ohm 0000 0000 0000 0001 0001 1 0.1 Ohm

100 mV 0010 0001 0011 0100 2134 8500 85.00 mV

1000 mV 1111 1111 1111 1111 FFFF -1 -0.1 mV

Tc J 1111 1000 0011 0000 F830 -2000 -200.0 °C

Examples:

Input Decimals Format

RTD (°C) 1 +850.0

Res (Ohm) 1 +2000.0

Pot (%) 1 +100.0

Input Decimals Format

+/- 50 mV 3 +50.000

+/- 100 mV 2 +100.00

+/- 250 mV 2 +250.00

+/- 1000 mV 1 +1000.0

+/- 20 mA 3 +20.000

Tc J .. Tc N 1 +1200.0

DAT 6000

19

PRELIMINARY

NOTE :

DAT6012 2 Channel RTD PLC Input

This manual suits for next models

5

Table of contents

Other Datexel Recording Equipment manuals

Popular Recording Equipment manuals by other brands

Mastervolt

Mastervolt MasterBus LIN Interface User and installation manual

Axxess

Axxess AX-FD1-SWC installation instructions

Attero Tech

Attero Tech unAIO2X2+ user manual

aci

aci TIF-401 Installation and reference guide

Basler

Basler BE3-25A instruction manual

PRACQ

PRACQ MELODIC STEP SEQUENCER Reference manual