Datron TW7201I User manual

TW7201I-MS

TW7201I

DHSL Remote Control Head

Operator/Technical Manual

Datron World Communications Inc.

Manual Part No. TW7201I-MS

Release Date: January 2008

Revision: E

3030 Enterprise Court

Vista, CA 92081, U.S.A.

Phone: (760) 597-1500 Fax: (760) 597-1510

E-Mail: [email protected]

www.dtwc.com

TW7201I-MS i

Change Description

Date of

Revision Revision

Letter Description of Changes Pages

Affected

01/08 EChange ISDN designation to DHSL. All

TW7201I-MS iii

© 2003 Datron World Communications, Inc. (Datron)

All rights reserved.

Datron World Communications, Inc.

This manual, as well as the software described in it, is

furnished under license and may only be used or copied

in accordance with the terms of such license. The information

in this manual is furnished for informational use

only, is subject to change without notice, and should not

be construed as a commitment by Datron. Datron

assumes no responsibility or liability for any errors or

inaccuracies that may appear in this book.

Except as permitted by such license, no part of this publication

may be reproduced, stored in a retrieval system,

or transmitted, in any form or by any means, electronic,

mechanical, recording, or otherwise without the prior

written permission of Datron.

Software License Agreement and Warranty

This software is licensed to the user (licensee) under the

express terms and conditions of Datron’s software

licensing policies and agreement as outlined below. By

receiving and installing this software package the user

(licensee) has indicated acceptance of the terms and conditions

of this agreement presented herewith.

As used in this document, the term “Software” shall

mean the application or control software in machine readable

format and the hardware protection key, along with any or all

supporting documentation, as well as all updated or enhanced

versions of the program supplied to the user at later date(s).

This software license does not include source code, and there-

fore, no license is granted with respect to source code of any

kind utilized directly or indirectly in any Datron or Datron

supplied third party product. Note, in some cases, covered

software may be included in Datron products in RAM or

ROM, and/or forms of machine readable code, not readily

accessible to the user or licensee.

In consideration of the terms and conditions of this

agreement, Datron grants the user a non-exclusive, nontrans-

ferable license to install and operate one copy of the program.

Licensee agrees not to attempt, aid, authorize, or direct any

effort, either directly or indirectly to reverse engineer or

reverse compile the Software. Licensee further agrees they or

their agents are not authorized to

make derivative versions or changes to the Software.

Title to and ownership of the Software shall at all times

remain with Datron and/or its licensors. Further, no

license is granted to copy or reproduce in any form whatsoever

the Software supplied without the express written permission

of Datron, prior to any such contemplated action.

Datron may terminate this agreement and discontinue

further warranty coverage at any time due to failure to

comply with the terms and conditions of this agreement.

In such an event, Datron will provide the user

with written notice of such a “failure-to-comply” and the

user will have 10 days to demonstrate that a remedy has

been implemented. If the user fails to perform, the

agreement will be terminated by further written notice

from Datron. Upon termination, the user shall immediately

return all original Software, documentation, and

any copies of each to Datron.

This Software is licensed “AS IS” and Datron provides a war-

ranty that covers the media upon which the Software is embed-

ded for a period of 30 days from receipt of the product. Under

this warranty policy Datron’s sole obligation shall be to

replace or repair, at Datron’s discretion, any such media that in

Datron’s opinion proves defective.

The user is obligated to provide Datron with a detailed

description of possible defects along with sample material

such that Datron can reproduce the identified defects.

By receipt and use, user (licensee) acknowledges that

certain software developed or distributed by Datron is

controlled by one or more governmental agencies. The

user (licensee) herewith acknowledges they will take all

necessary actions to comply with applicable regulations

concerning the use of licensed software. Further, Datron

is under no obligation to supply source code or documentation

of its software for any reason.

Datron makes no representation, express or implied, with

respect to any Software licensed under this document as to its

fitness for any particular purpose or intended use.

Furthermore, Datron shall have no liability under this

agreement for any incidental, special, or consequential

damages arising out of the use of any supplied software

programs. Datron reserves the right to make periodic

changes in it’s software for any purpose without any

obligation to notify users.

One Year Limited Warranty and Remedies

Datron warrants that its equipment is free from defects in

design, materials, and workmanship for a period of 12

months from the date of installation of the equipment,

but in no event later than 15 months from the date of

shipment. If the equipment does not provide satisfactory

service due to defects covered by this warranty, Datron

will, at its option, replace or repair the equipment free of

charge.

Should it be impractical to return the equipment for

repair, Datron will provide replacements for defective

parts contained in the equipment for a period of 12

months from the date of installation of the equipment,

but in no event later than 15 months from the date of

shipment.

This warranty is limited to the original purchaser and is

not transferable. Repair service performed by Datron is

warranted for the balance of the original warranty or 90

days, whichever is longer.

Exclusive Warranty: There are no other warranties

beyond the warranty as contained herein. No agent,

employee, or representative of Datron has any authority

to bind Datron to any affirmation, representation, or warranty

concerning the equipment or its parts that is not in

conformity with the warranties contained herein.

EXCEPT AS EXPRESSLY SET FORTH ABOVE, NO

OTHER WARRANTIES, EITHER EXPRESS OR

IMPLIED, ARE MADE WITH RESPECT TO THE

EQUIPMENT OR THE PARTS CONTAINED

iv TW7201I-MS

THEREIN, INCLUDING BUT NOT LIMITED TO

THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, AND

DATRON EXPRESSLY DISCLAIMS ALL WARRANTIES

NOT STATED HEREIN.

Limitations of Warranty: This warranty does not

cover:

Physical damage to the equipment or its parts that does

not involve defects in design, material, or workmanship,

including damage by impact, liquids, temperature, or

gases.

Damage to the equipment or its parts caused by lightning,

static discharge, voltage transients, or application

of incorrect supply voltages.

Defects or failures caused by unauthorized attempts to

repair or modify the equipment.

Defects or failures caused by Buyer abuse or misuse.

Return of Equipment - Domestic: To obtain performance

of any obligation under this warranty, the equipment

must be returned freight prepaid to the Technical

Support Services. Datron World Communications Inc.,

3030 Enterprise Court, Vista, California 92081. The

equipment must be packed securely. Datron shall not be

responsible for any damage incurred in transit. A letter

containing the following information must be included

with the equipment.

a. Model, serial number, and date of installation.

b. Name of dealer or supplier of the equipment.

c. Detailed explanation of problem.

d. Return shipping instructions.

e. Telephone or fax number where Buyer may be contacted.

Datron will return the equipment prepaid by United Parcel

Service, Parcel Post, or truck. If alternate shipping is

specified by Buyer, freight charges will be made collect.

Return of Equipment - International: Contact Datron or

your local Representative for specific instructions. Do

not return equipment without authorization. It is usually

not possible to clear equipment through U.S. Customs

without the correct documentation. If equipment is

returned without authorization, Buyer is responsible for

all taxes, customs duties, clearance charges, and other

associated costs.

Parts Replacement: The following instructions for the

supply of replacement parts must be followed:

a. Return the parts prepaid to “Parts Replacement”

Datron World Communications Inc., 3030 Enterprise

Court, Vista, California 92081; and

b. Include a letter with the following information:

1. Part number

2. Serial number and model of equipment

3. Date of installation

Parts returned without this information will not be

replaced. In the event of a dispute over the age of the

replacement part, components date-coded over 24

months previously will be considered out of warranty.

Remedies: Buyer’s sole remedies and the entire liability

of Datron are set forth above. In no event will Datron be

liable to Buyer or any other person for any damages,

including any incidental or consequential damages,

expenses, lost profits, lost savings, or other damages

arising out of use of or inability to use the equipment.

1/95

Safety Considerations

This product and manual must be thoroughly understood

before attempting installation and operation. To do so

without proper knowledge can result in equipment failure

and bodily injury.

Caution: Before applying ac power, be sure that the

equipment has be properly configured for the available

line voltage. Attempted operation at the wrong voltage

can result in damage and voids the warranty. See the

manuals section on installation. DO NOT operate equipment

with cover removed.

Earth Ground: All Datron products are supplied with a

standard, 3-wire, grounded ac plug. DO NOT attempt to

disable the ground terminal by using 2-wire adapters of

any type. Any disconnection of the equipment ground

causes a potential shock hazard that could result in personal

injury. DO NOT operate any equipment until a suitable ground

has been established. Consult the manual section on ground-

ing.

Servicing: Trained personnel should only carry out servicing.

To avoid electric shock, DO NOT open the case

unless qualified to do so.

Various measurements and adjustments described in this man-

ual are performed in ac power applied and the protective

covers removed. Capacitors (particularly the

large power supply electrolytics) can remain charged for

a considerable time after the unit has been shut off. Use

particular care when working around them, as a short circuit

can release sufficient energy to cause damage to the equipment

and possible injury.

To protect against fire hazard, always replace line fuses

with ones of the same current rating and type (normal

delay, slow-blow, etc.). DO NOT use higher value

replacements in an attempt to prevent fuse failure. If

fuses are failing repeatedly this indicates a probable

defect in the equipment that needs attention.

Use only genuine Datron factory parts for full performance

and safety of this product.

Made in the USA

TW7201I-MS v

CONTENTS

Chapter 1: Introduction

1.1 The TW7201I DHSL Remote Control Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 TW7000 Series Family . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 Referenced Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2: Installation

2.1 Installation Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 The TW7000 Transceiver and 7000RI Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Audio Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Table 2-1 Audio Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-1 TW7201I Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-2 Microphone Jack J9 and J10 Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Table 2-2 Microphone Connector (J9) and (J10) Pin Assignments . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 Rear Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-3 TW7201I Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-4 AC Voltage Selector Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-5 DB9 Remote Connector Pinout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-6 DB Accessory Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2-3 ACC 1 Accessory Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2-4 ACC 2 Accessory Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Chapter 3: Operation

3.1 Powering the TW7201I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Figure 3-1 TW7000 Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 Using Knobs, Buttons and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 VSWR Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4 Using Menus to Change Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Table 3-1 Alpha Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Table 3-2 ALE Submenu - ALPHA 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.5 Programming Channels and Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.6 Scanning (for TA/TC only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.7 Placing an ALE Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.8 Placing a TransAdapt, Transcall or Selcall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.9 Activating the Noise Blanker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

3.10 Activating Encryption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

3.11 Activating Voice Enhancement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

vi TW7201I-MS

Chapter 4: Theory of Operation

4.1 TW7201I Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Figure 4-1 TW7201I Remote System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Front panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2 Front Panel Assembly Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table 4-1 Jumper Block J11 Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3 Rear Panel Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4-3 Power Supply/Interface Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-4 DHSL Modem Board Block Diagram (Remote Head). . . . . . . . . . . . . . . . . . . . . . . 4-9

4.4 7000RI Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Figure 4-5 DHSL Modem Board Block Diagram (Transceiver) . . . . . . . . . . . . . . . . . . . . . . . 4-12

Chapter 5: Testing and Troubleshooting

Table 5-1 TW7201I Subassemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3 Component Locations, Pin Assignments, Schematics and Part Lists . . . . . . . . . . . 5-6

Table 5-2 Front Panel Processor J1 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Table 5-3 Front Panel Processor J3 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Table 5-4 Front Panel Processor J4 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Table 5-5 Front Panel Processor J5 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Table 5-6 Front Panel Processor J6 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Table 5-7 Front Panel Processor J7 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Table 5-8 Front Panel Processor J8 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Table 5-9 Front Panel Processor J9 and J10 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Figure 5-1 Front Panel Processor Board Component Locations (738207 Rev. J) . . . . . . . . . . 5-10

Figure 5-2 Front Panel Processor Board Schematic Diagram (994359 Rev. E). . . . . . . . . . . . 5-11

Table 5-10 Front Panel Processor Board Parts List (001-03001 Rev. E) . . . . . . . . . . . . . . . . . 5-13

Table 5-11 DHSL Modem J1 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Table 5-12 DHSL Modem J2 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Table 5-13 DHSL Modem J3 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Table 5-14 DHSL Modem J4 Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Table 5-15 DHSL Modem J11 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Table 5-16 DHSL Modem J12 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Table 5-17 DHSL Modem Board Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Figure 5-3 DHSL Modem Board Component Locations (738248 Rev. E) . . . . . . . . . . . . . . . 5-24

Figure 5-4 DHSL Modem Board Schematic Diagram (994184 Rev. E) . . . . . . . . . . . . . . . . . 5-25

Table 5-18 DHSL Modem Board Parts List (002-03100 Rev. L). . . . . . . . . . . . . . . . . . . . . . . 5-27

Table 5-19 Power Supply/Interface Board J1 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Table 5-20 Power Supply/Interface Board J2 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Table 5-21 Power Supply/Interface Board J3 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Table 5-22 Power Supply/Interface Board J5 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . 5-34

Table 5-23 Power Supply /Interface Board J6 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . 5-35

Table 5-24 Power Supply /Interface Board J7 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . 5-36

Table 5-25 Power Supply /Interface Board J8 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . 5-37

Table 5-26 Power Supply /Interface Board J9 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . 5-37

Table 5-27 Power Supply /Interface Board J10 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . 5-37

Figure 5-5 Power Supply/Interface Board Component Locations (738277 Rev. B) . . . . . . . . 5-38

Figure 5-6 Power Supply/Interface Board Schematic Diagram (994222 Rev. D) . . . . . . . . . . 5-39

Table 5-28 Power Supply/Interface Board Parts List (003-03005 Rev. G) . . . . . . . . . . . . . . . 5-41

TW7201I-MS vii

Figure 5-7 Switching Board Component Locations (738195 Rev. B) . . . . . . . . . . . . . . . . . . . 5-44

Figure 5-8 Switching Board Schematic Diagram (994149 Rev. A). . . . . . . . . . . . . . . . . . . . . 5-45

Table 5-29 Switch Board Parts List (001-00110 Rev. A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

TW7201I-MS 1-1

CHAPTER 1

INTRODUCTION

1.1 The TW7201I DHSL Remote Control Head

The TW7201I is the Datron High Speed Link (DHSL) remote control unit that

uses a high speed modem to provide remote operation of the TW7000 series

transceivers configured with the 7000RI option over a two-wire line. The

TW7201I includes a DHSL modem that communicates with its DHSL

counterpart (7000RI modem option) in the TW7000(F) transceiver.

The TW7201I is microprocessor controlled and features one full-duplex

digitized voice channel and two full-duplex data channels.

The TW7201I remote control head includes the following features:

• Full remote control and operation of TW7000 series transceivers

• Dual front panel microphone jacks

• Front panel LCD

• Alphanumeric keypad and function buttons

• Dual rear panel accessory connectors

• AC and DC power source support

1: Introduction

1-2 TW7201I-MS

1.2 Specifications

Note: All specifications subject to change without notice or obligation.

Characteristic Description

General

Transmission type High speed modem and audio.

Modem channels 2 data channels, 1 voice channel.

Range 2 km (maximum).

Control Controls TW7000 series HF transceivers with

7000RI option.

Display Front panel LCD.

Audio Internal loudspeaker (2W output).

Input power

AC

DC 120 VAC or 240 VAC.

13.8 Vdc.

Protection Fused for AC and DC, overvoltage and reverse

polarity.

Modem

Format High speed slave modem (MC145426) in remote

head, master modem (MC145422) in transceiver.

Data 256 kHz modified differential phase shift burst.

Channels

voice

data

One full-duplex 64 kb/second digitized voice

channel.

Two full-duplex 9600 baud data channels.

Remote interface 2-wire (maximum distance 2 km).

Physical

Size (HWD) 10.16 cm x 33.02 cm x 15.24 cm.

(4 in. x 13 in. x 6 in.).

Weight 3.175 kg (7 lbs.).

Environmental

Temperature

operating

storage –30° C to +60° C.

–40° C to +70° C.

1: Introduction

TW7201I-MS 1-3

1.3 TW7000 Series Family

The TW7000 series is a complete family of RF communications equipment

that includes the following components:

• Transceivers (TW7000, TW7000F)

• Internal options

• External options

• Accessories

• Remote control devices

The TW7201I modem operates in conjunction with an DHSL modem (7000RI

option) installed in a TW7000 series transceiver. The two modems connect

through a 2-wire remote line.

1.3.1

Front Panel

Control

When using transceivers such as the TW7000 that include front panel

controls, the transceiver controls are the master. In this case, the transceiver

controls are live from the transceiver and TW7201I. For security and limited

operation applications, the key functions can be inhibited at either the

transceiver or TW7201I control panels. Two variations of the TW7000 series

transceivers, the TW7000E and TW7000C, do not include control panels.

1.3.2

7000RI Option The TW7000 series transceiver must have a 7000RI option installed to

communicate with the TW7201I remote head. The 7000RI option includes the

DHSL Modem board, and a dual UART chip and two jumpers that must be

installed on the transceiver Processor board.

1.3.3

TW7201I

DHSL Remote

Control

The TW7201I includes a DHSL Modem board that communicates with the

DHSL Modem board (7000RI option) installed in the transceiver through a

remote line using a high speed data packet format. The information is

compressed and sent between the master (transceiver) and slave (remote

head). Line loss and balance variations do not effect the system performance.

The DHSL modem requires wide bandwidth so it does not work over standard

analog telephone channel. This system is ideal for distances of 1.6 km (1 mile)

or less (2 km max.) over a 2-wire pair.

Voice Channel The TW7201I provides one voice channel. The voice audio is digitized before

being sent over the modem link. This provides excellent voice quality even

with poor line conditions and requires no adjustment even when line

conditions change.

Data Channels The TW7201I provides two data channels, using one channel for

communications between the transceiver and the remote head. The other data

channel is a spare, normally used by accessory equipment or other special

functions. The second channel is typically used for an external computer

1: Introduction

1-4 TW7201I-MS

control device. This configuration allows for full computer control of the

transceiver at the remote control head. Both channels are high speed data

channels with a 9600 N81 standard interface.

Operating Modes The TW7201I is designed to be a high speed modem link to the transceiver for

both voice and data. The high speed characteristic allows for a wide variety of

voice and data capabilities. The TW7201I supports all standard operating

modes including USB, LSB, CW, PCS, and AME.

1.3.4

Options and

Accessories

The TW7201I supports the following accessories:

• PM palm microphone for voice operation

• DM desk microphone for voice operation

• KEY CW key

• EPL lightweight headset

• TW7201MM mobile mounting kit

• TW7201RM rack mounting kit

The TW7201I is supported with the following optional maintenance and

service items:

• TW7201I-TK tool kit

• TW7201I-MRK module repair kit

• TW7201I-MK module kit

• TW7201I-PSK spare parts kit

1.3.5

Accessory

Equipment

The TW7201I supports the following optional external devices through the

rear panel accessory connectors:

• Telephone couplers

• Data terminals

• Voice encryptors

• External speaker

1.4 Manual Conventions

Bold type denotes all items that appear in the display and for any button, knob

or switch on the front panel. For example:

• Press ALPHA 17, then press E.

• Press 1to set the status to OFF.

1: Introduction

TW7201I-MS 1-5

1.5 Referenced Manuals

• RC2-MSOP Radio Control 2 Operator Manual

• 7000ENCR-MSOP 7000-Series High-level Encryption Operator Manual

• 7000ALE-MSOP 7000ALE Radio Control Program Operator Manual

TW7201I-MS 2-1

CHAPTER 2

INSTALLATION

2.1 Installation Types

The TW7201I can be installed in the following configurations:

• Desktop

• Mobile

• Rack

The desktop model is the standard configuration for the TW7201I and requires

no additional mounting hardware.

For vehicle and marine applications, the TW7201I can be ordered with mobile

mounting brackets (TW7201MM) that are designed for either top or bottom

mounting.

For rack mount applications, the TW7201I can be ordered with the rack mount

kit (TW7201RM).

For local operation, the TW7201I requires a 2-wire line between the remote

head and the transceiver. The line connections are transformer-coupled at each

end. The line length is limited by the time delay of the high speed packets as

they travel from each end. Datron offers the C992307 10m (33 ft.) DHSL

interface cable.

Datron offers an unterminated remote cable (C992309) for connecting to

pre-existing wiring system. Two C992309 cables would be required: one for the

transceiver; the other for the TW7201I.

2.2 The TW7000 Transceiver and 7000RI Option

To use the TW7201I with a TW7000 series transceiver, the transceiver must

have the 7000RI option installed. This option includes the DHSL Modem

board, a serial dual UART IC and jumpers that are installed on the transceiver

Processor board. The remote system uses a 2-wire cable between the

transceiver and the remote head.

2: Installation

2-2 TW7201I-MS

2.3 Audio Connections

The TW7201I front panel hosts two 6-pin microphone connectors. These two

connectors are wired in parallel and are compatible with various audio

accessories. The input impedance is 150 ohms (nominal). The TW7201I

supports most dynamic, ceramic and magnetic microphones.

All Datron audio accessories have the correct mating connector. Datron offers

mating adapters for other low-level audio accessories.

Table 2-1 Audio Devices

Part Number Description

DM Dynamic desk microphone

PM Heavy-duty hand microphone

HP Headphones, twin

EP Headphones

EPL Lightweight headphones

KEY CW key (Morse key)

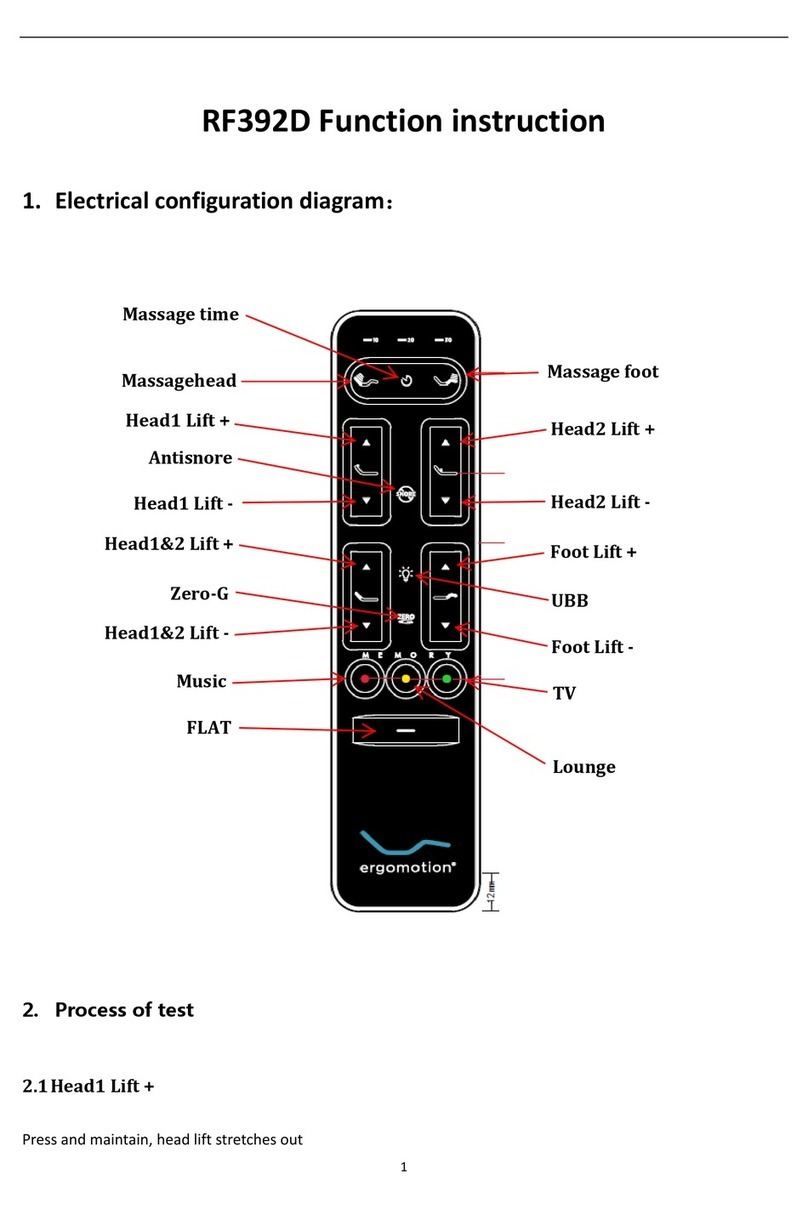

Figure 2-1 TW7201I Front Panel

Figure 2-2 Microphone Jack J9 and J10 Pinouts

OPTIONS

STATUS

123

4

7

.

5

8

0

6

9

F

E

C

A

B

C

J

K

L

S

T

U

/

\

+

D

E

F

M

N

O

V

W

X

S

P

G

H

I

P

Q

R

Y

Z

-

PRICALLSCAN TUNE

POWER

OFF

CLAR (PUSH)

AUDIO CONNECTORS

1

2

6

5

4

3

1

2

65

4

3

2: Installation

TW7201I-MS 2-3

2.4 Rear Panel Description

The rear panel provides the AC and DC power connections and fuse blocks,

accessory connectors and the remote line connector to the transceiver.

2.4.1

Input Power The TW7201I can accept input power from either an AC or DC power source.

AC Power The rear panel includes a standard IEC AC power connector that can be

configured for 120 or 240 VAC. A standard AC power cable is included with

the TW7201I (769004 IEC320 to NEMA 5-15). The AC connector includes a

fuse holder and the AC voltage selector card. The AC fuse should be a 1A

slow blow 3AG fuse (550014).

The AC power voltage selector card must be configured for the intended

power source. The AC power is preconfigured for the AC power level in the

area where it is shipped.

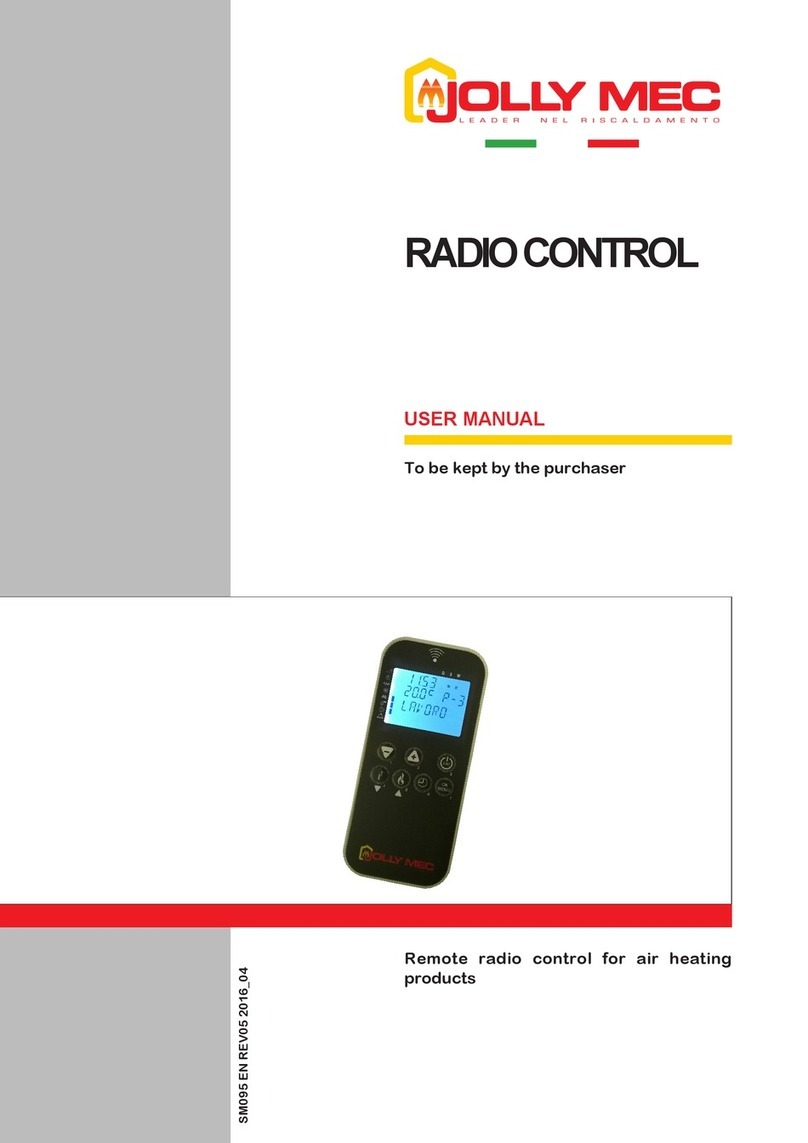

CAUTION: Always verify the correct AC power setting on the AC

voltage selector card before applying AC power.

To reconfigure the AC power setting:

1. Move the clear plastic fuse cover to the left so that it covers the AC power

connector. The AC voltage selector card is located just below the fuse.

The current AC power setting is visible on the voltage selector card.

Table 2-2 Microphone Connector (J9) and (J10) Pin Assignments

Pin Description Pin Description

1GND 4TX AUDIO

2RX AUDIO 5CW

3PTT 6+12 Vdc

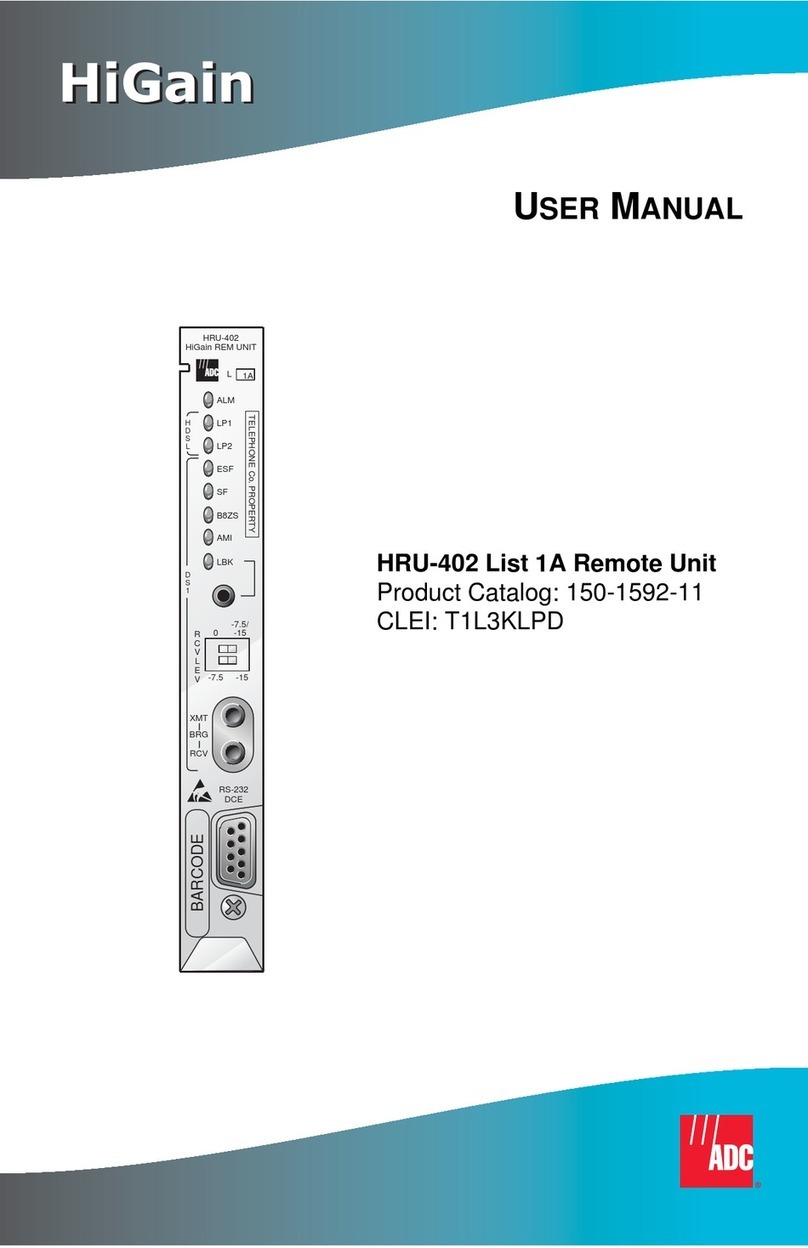

Figure 2-3 TW7201I Rear Panel

13.8VDC

DC INPUT

FUSE

REMOTE GND

ACCESSORY 1

ACCESSORY 2

Fuse

Pull

Fuse

Pull

AC INPUT

2: Installation

2-4 TW7201I-MS

2. Pull the fuse ejector tab toward you and to the left. This forces the fuse

partially out of the fuse holder.

3. Remove the fuse.

4. Using a long nose pliers, remove the AC voltage selector card.

5. Orient the card to the correct AC level to be used. The voltage selector

card has two numbers on each side corresponding to AC power levels,

100 and 220 on one side, and 120 and 240 on the other side. To get the

correct setting, hold the voltage selector card toward the AC

connector/fuse holder, with the correct setting facing you as shown in

Figure 2-4 below. In this example the TW7201I is configured for

220 VAC.

6. Insert the card below the fuse holder, install the fuse and push the fuse

extractor handle back into the fuse holder.

7. Slide the fuse cover to the right to cover the fuse holder. Install the AC

power cable into the AC power connector.

DC Power The TW7201I rear panel also includes a DC power connector and fuse holder.

The DC input circuitry is designed for 13.8 Vdc with a typical current

requirement of approximately 300 mA. The recommended DC voltage range

is 12 Vdc to 16 Vdc. An optional 2m (6.5 ft.) 3-conductor DC power cable is

available (C991829). One end of the DC power cable is left without a plug for

convenient connection to a variety of DC power sources.

The DC fuseholder should include a 3A 250VAC fast 3AG fuse (550003) and

a spare fuse of the same rating. To access the fuse, push to the left on the

fuseholder cover and pull out.

2.4.2

Remote

Connector

The TW7201I communicates with the TW7000 series transceiver through a

10m (33 ft.) remote cable (C992307). The remote cable connects to the

TW7201I through the rear panel 9-pin D Submini socket. The FSK remote

head uses the same remote cable.

Figure 2-4 AC Voltage Selector Card

Fuse

Pull

Fuse

Pull

This manual suits for next models

1

Table of contents