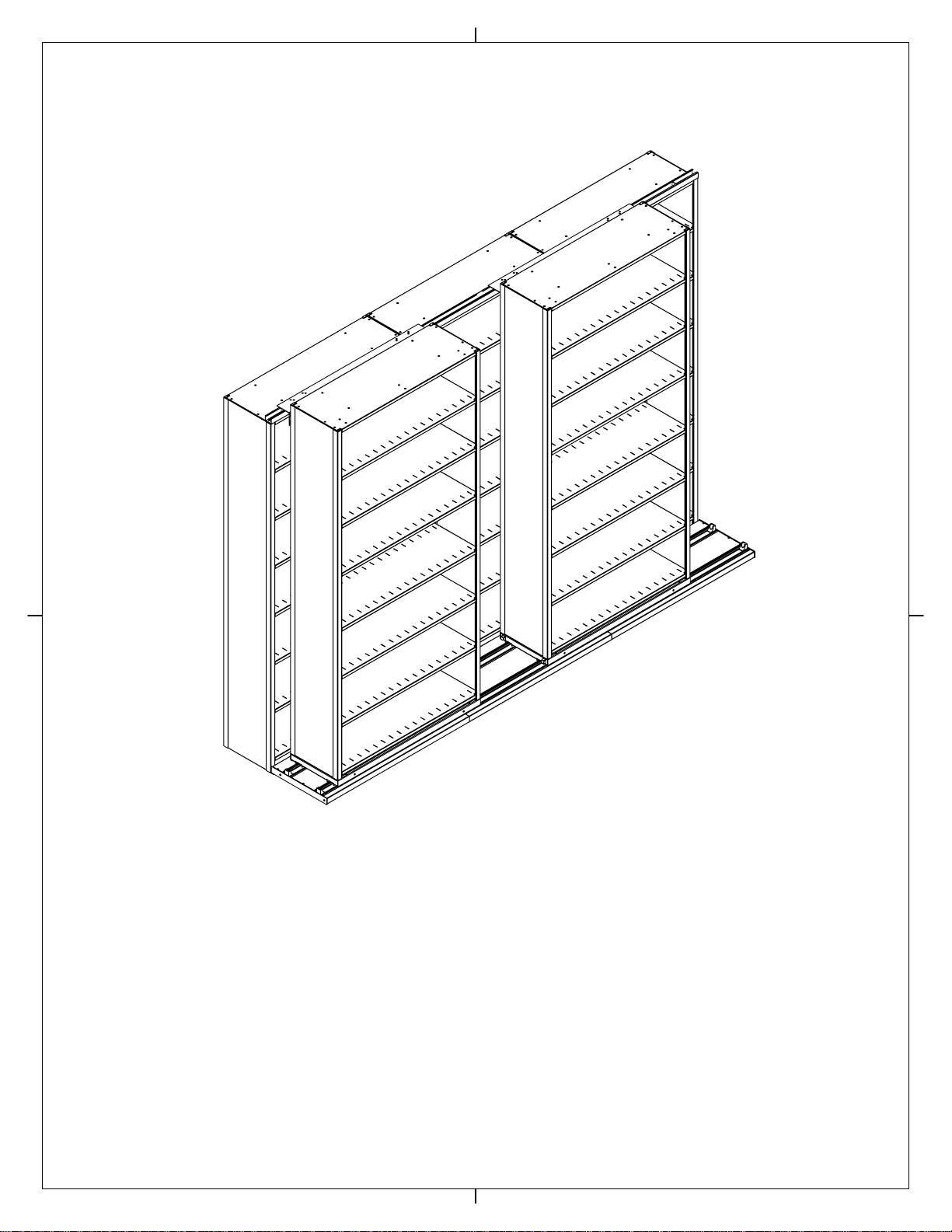

Datum Storage 4Post Trakslider User manual

FOR ASSEMBLY ASSISTANCE CONTACT CUSTOMER SERVICE AT 1-866-217-0330

(MONDAY THRU FRIDAY 8 AM - 5 PM EST)

4Post Trakslider Instructions

INST0083REV2WS4/16/08

PAGE 1 OF 31

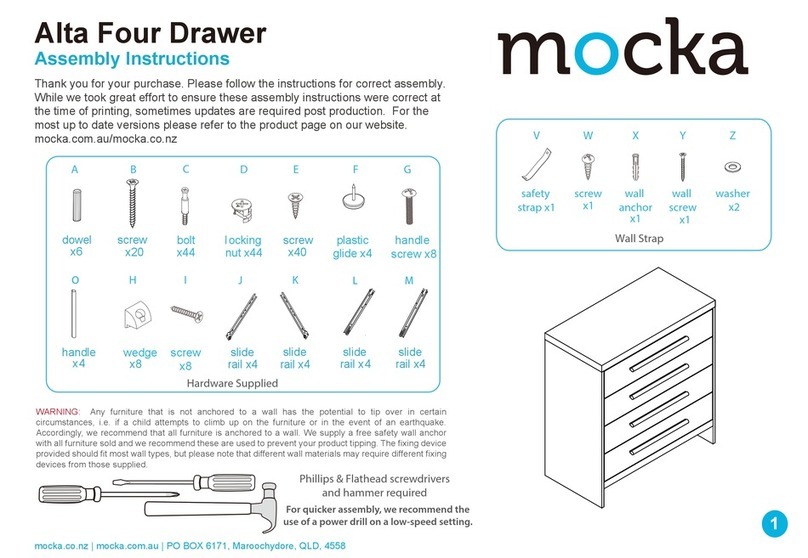

7/32" Nut

Driver

7/16" Wrench

Phillips Head

Screwdriver

5/16" Drill Bit

(Required when not

using Datum shelving)

Power Drill

Rubber Mallet

Or

Plastic Tip Hammer

4' Bubble Level

NOTE

These instructions apply to Datum 4Post Shelving with 4Post

Adapter Brackets. If other brands are used, it will be necessary

to drill holes to complete installation.

Tools Required for Assembly

PAGE 2 OF 31

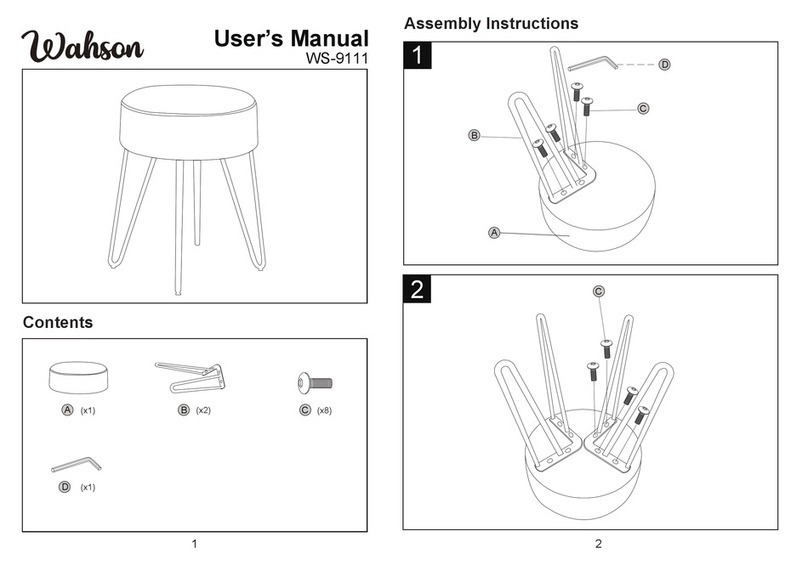

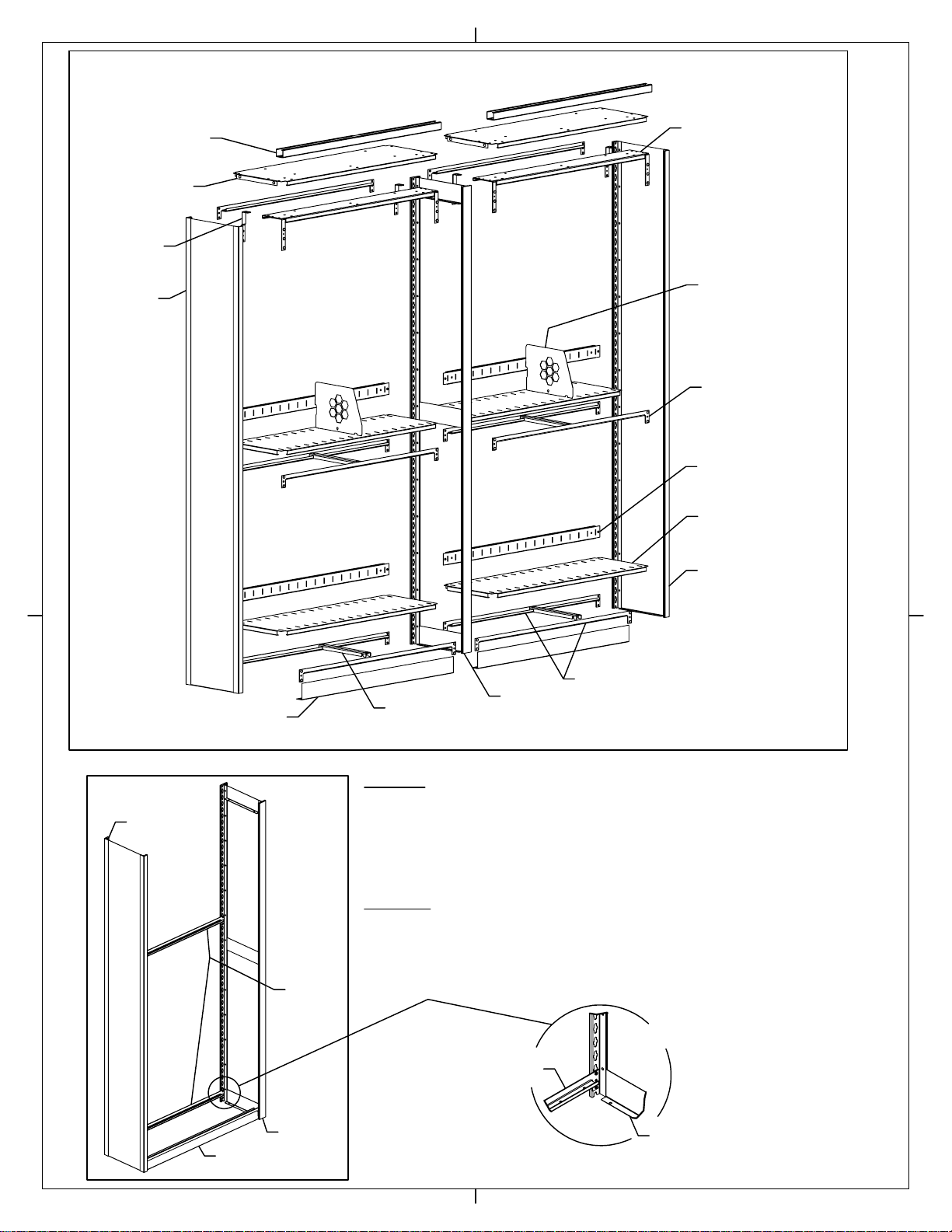

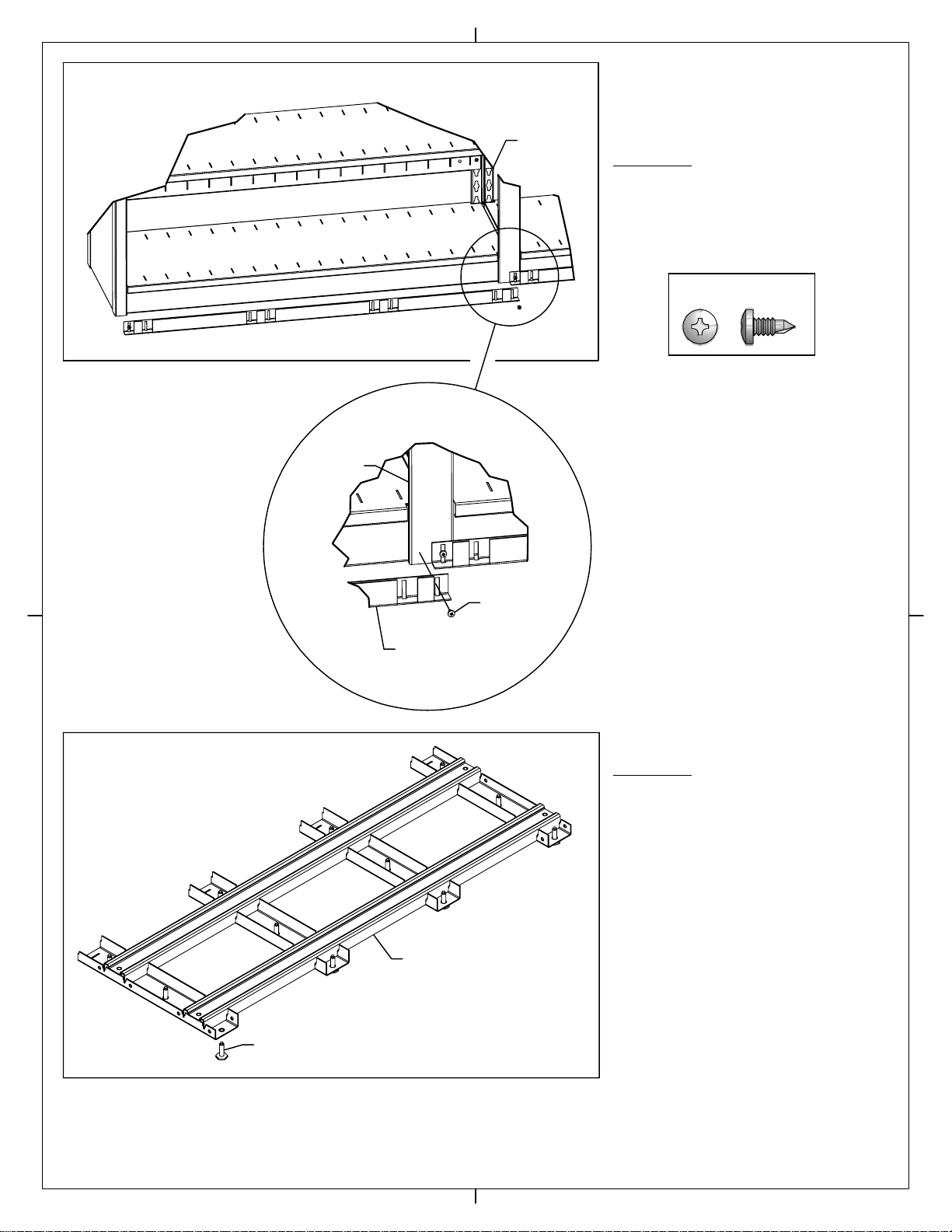

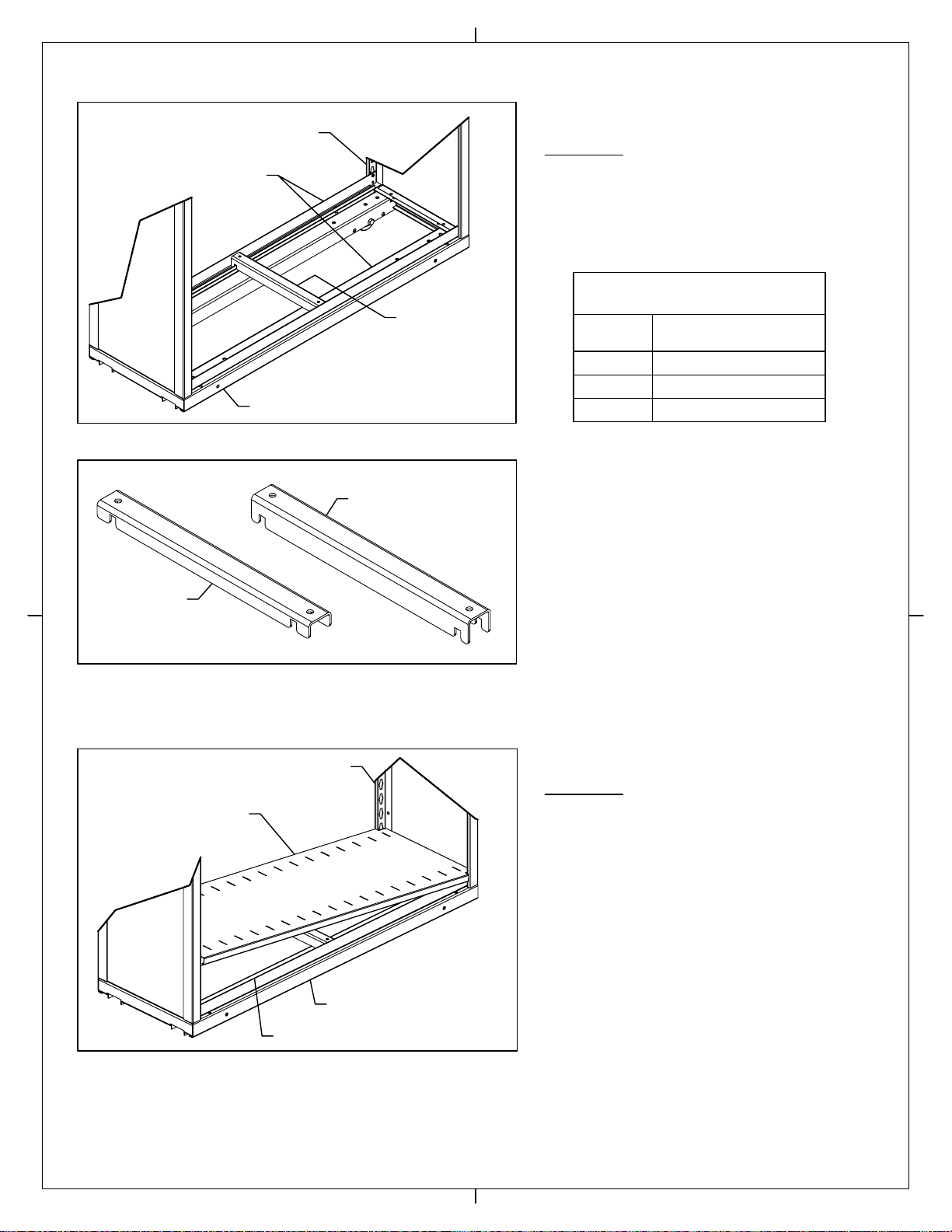

Figure A

Detail B

Step1:

Temporarily mount a standard shelf support at chest height between a closed "L"

upright on left and an open "T" upright on right to hold uprights in position (see

Figure A). Make sure that the uprights are positioned so that bent flanges are at

the bottom of the unit as shown in Detail B. Rivets of shelf support fit into keyholes

on uprights as shown in Figure A & Detail B. Use a rubber mallet or plastic tip

hammer to tap shelf support into bottom of keyholes.

Step 2:

A kick plate will only be used on the forward facing side of a single entry unit or

both sides of a double entry unit. Place kick plate against uprights then place

standard shelf support into uprights and tap in place with a rubber mallet or plastic

tip hammer to seat rivets into bottom of keyholes.

Parts Required for Typical Rear

Stationary Shelving Section

Closed 'L'

Upright

Standard

Shelf

Support

Open 'T'

Upright

Shelf

Support

Bent Flange of Upright

at bottom of unit

Top Stabilizer

Channel

Top Cover

w/Knockouts

Top Cover

Lock Bracket

Closed 'L'

Upright

Shelf

Reinforcement

Open 'T'

Upright

Standard

Shelf Support

Closed 'L'

Upright

Slotted

Shelf

Back

Stop

Standard

Shelf Support

Divider

Top Cover Front

Support Channel

PAGE 3 OF 31

Kick Plate

Kick Plate

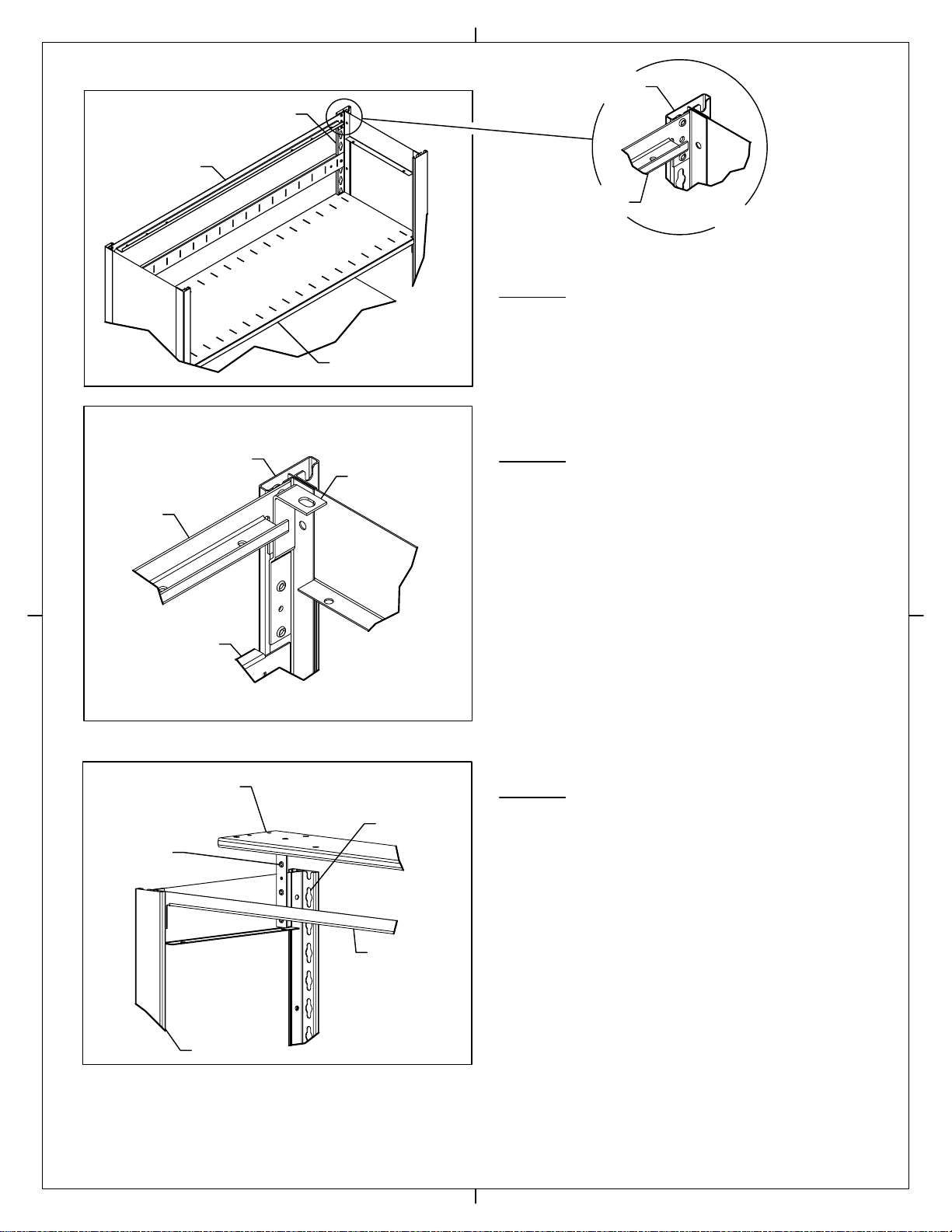

Figure C

None

Number of

Reinforcements/Shelf

None

Two

Table 1 - Shelf Reinforcements

for Stationary Shelving

15"

12"

Depth of

Shelving

18"

Step 3:

If required (See Table 1), install shelf reinforcements

as shown in Figure C.

Step 4:

Install bottom shelf by tilting the shelf as shown if

Figure D. Shelf should then lie flat on shelf supports.

Figure D

Figure E

Step 5:

Install back stop for bottom shelf. Count up three

complete keyholes from top of shelf and place rivets

located on each end of back stop in these keyholes

(see Figure E).

Shelf

Reinforcements

Shelf

Support

Shelf

PAGE 4 OF 31

Kick Plate

Kick Plate

Bottom

Shelf

Back

Stop

Third

Keyhole

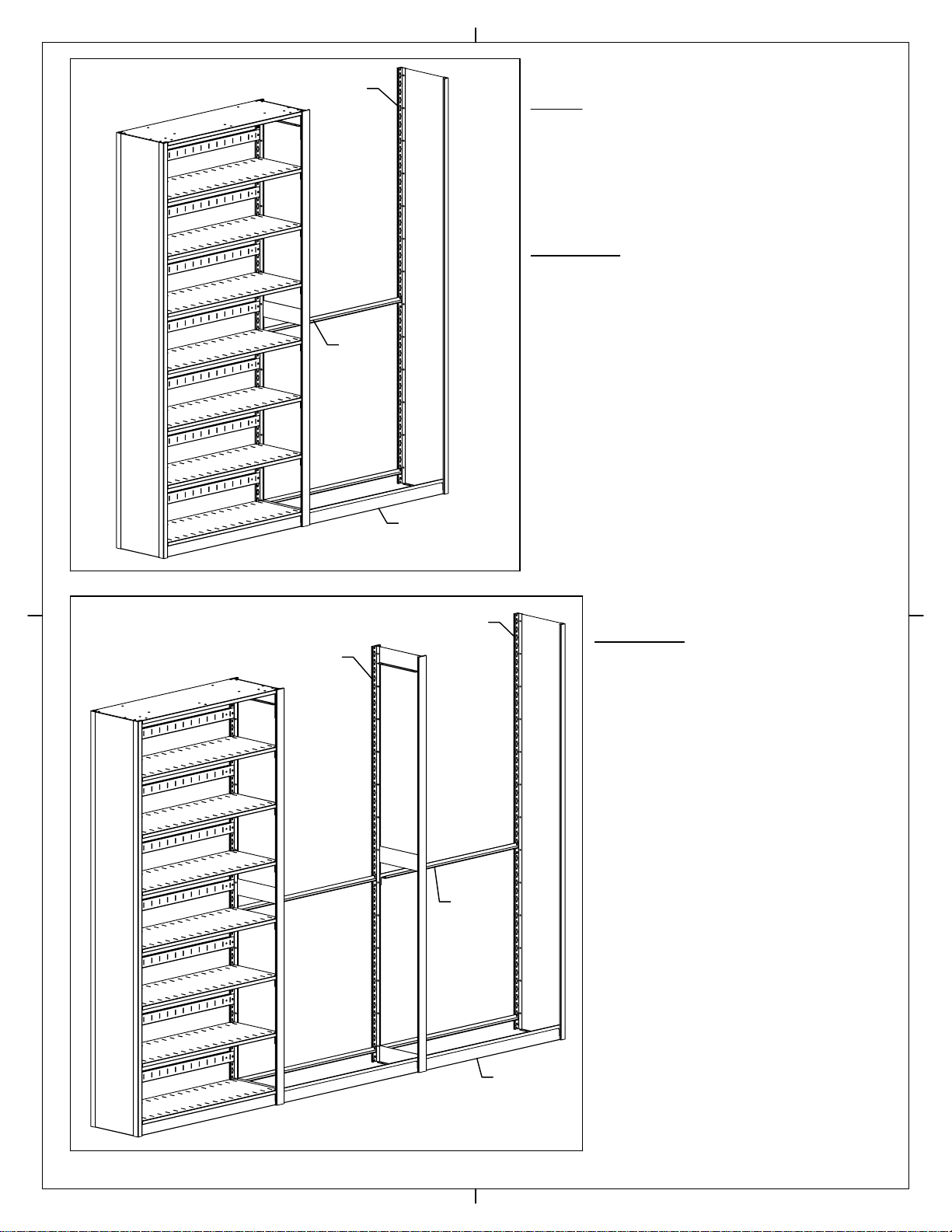

Figure F

Figure G

Step 6:

Install remainder of shelf supports, shelves, back stops, & shelf reinforcements

(if required) as previously shown, working from bottom to top. Keep in mind

your installation may be different, as shelf spacing varies from job to job (See

Figure F for typical configurations). Do not install components at the top of unit

at this time; when complete the assembled unit should look similar to Figure G.

Fourth Opening Typically

Has Posting Shelf (Letter/Legal)

11 5/16

9 13/16

Third Opening Typically

Has Posting Shelf (X-Ray) 18 9/16

15 9/16

Typical Clear Openings for

Letter/Legal Shelving Typical Clear Openings for

X-Ray Shelving

If using or planning to use a posting shelf, leave space for it to be mounted when installing shelf supports and

shelves. Not all shelving unit combinations will allow equal spacing of shelves when installing posting shelves.

One opening will need to be larger than the rest. Check with your dealer or supplier for the correct choices of

uprights and shelf openings required when a posting shelf is desired.

PAGE 5 OF 31

Figure H

Detail I

Figure J

Step 8:

Install top cover lock brackets into both uprights as shown

in Figure J by placing rivets of the brackets into first two

keyholes under the shelf support.

Install rear standard shelf support for top panel by placing

rivets of support into the top two keyholes of the uprights as

shown in Figure H and Detail I.

Step 7:

Step 9:

Install top cover front support channel by placing top rivet

on each side of channel into the first complete keyhole in

the top of both uprights as shown in Figure K.

Figure K

Upright

Standard

Shelf Support

Top Shelf

Top of

Upright

Shelf

Support

Top Cover

Lock Bracket

Upright

Cover Shelf

Support

Back Stop

for Top Shelf

First Complete

Keyhole

Shelf

Support

Top Cover Front

Support Channel

Top Rivet

Upright

PAGE 6 OF 31

Figure L

Step 10:

Secure top cover front support channel and both top

cover lock brackets to uprights using #10-24 x 3/8"

screws as shown in Figure L.

Place top cover on unit as shown in Figure M. Unit

should now look similar to Figure N.

Step 11:

Figure M

Figure N

#10-24 x 3/8" Phillips Pan

Head Sheet Metal Screw

#10-24 x 3/8"

Screw Shelf Support

Upright

Top Cover

Top Cover Front

Support Channel

Upright

PAGE 7 OF 31

Top Cover Front

Support Channel

Figure O

Note:

If the stationary shelving section consists of three or more

units (Figure P), skip to Step 12b. If your section consists

of two units only (Figure O), continue here with Step 12a.

Step 12a:

Position a closed 'L' upright to the right of assembled unit

and install shelf supports and kick plate by repeating

Steps 1 & 2 (Figure O). Go to Step 13.

Repeat steps one and two as needed to set up

all units in the section except for the end unit.

For the end unit substitute a closed 'L' upright

for an open 'T' upright (Figure P).

Step 12b:

Figure P

Closed 'L'

Upright

Standard

Shelf

Support

Standard

Shelf

Support

Closed 'L'

Upright

Open 'T'

Upright

PAGE 8 OF 31

Kick

Plate

Kick

Plate

Figure Q

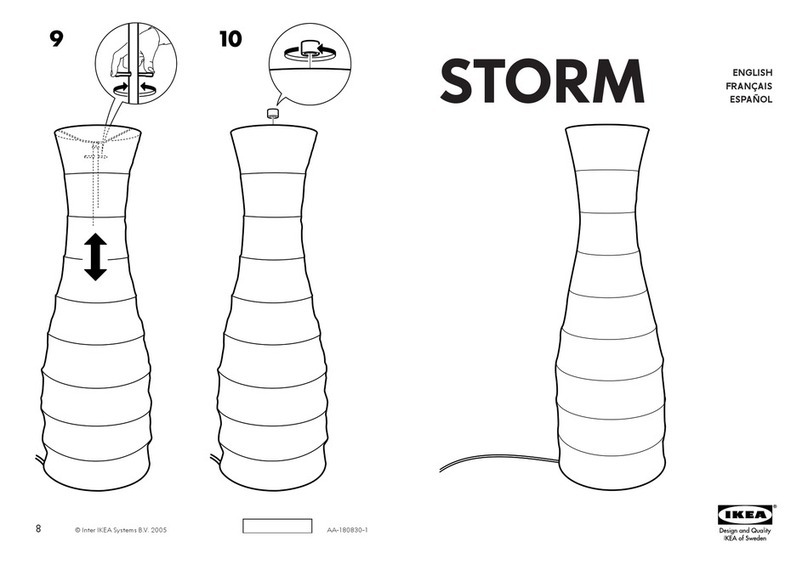

Remove bi-slider (all systems), tri-slider (tri-slide and quad-slide

systems only) and lock bracket knockouts on top cover of first unit

(see Figure Q). Remove knockouts with phillips screwdriver and

rubber mallet or plastic tip hammer.

Step 13:

1/4-20 x 3/4" Hex Bolt

1/4-20 Flanged Hex

Nut

Figure S

Use (3) 1/4-20 x 3/4 hex bolts and (3) 1/4-20 flanged hex nuts to

attach top stablizer channel to top cover of first unit using the first

set of holes in the top cover. Use (1) 1/4-20 x 3/4 hex bolt & (1)

1/4-20 flanged hex nut to secure each top cover lock bracket (see

Figure R).

Step 14:

Step 14a:

Repeat steps 13 & 14 for all units except the end unit which will

not have a stabilzer channel attached during this part of assembly

(See Figure S).

Step 14b:

For Tri/QuadSlider Systems Only, add a second top stabilizer

channel behind channels that were attached in Steps 14 and 14a

(See Figure T).

Step 14c:

For QuadSlider Systems Only, add a third top stabilizer channel

behind channels that were attached in Steps 14, 14a and 14b. You

will need to drill holes to mount this set of channels, maintain

similar front to back spacing as for Bi/TriSlider stabilizer channels.

Figure R

Figure T

Lock

Bracket

Knockout

Top Cover

Lock Bracket

Knockout

Bi-Slider

Knockouts

Tri-Slider

Knockouts

Do Not Attach Channel

To End Unit at This Time

Top Stabilizer

Channel

1/4-20 x 3/4"

Hex Bolts

Top Cover

Top Stabilizer Channel

w/Notch Towards Back

of Unit

Front Set

of Holes

1/4-20 Flanged

Hex Nut

Add Second Set

of Stabilizer Channels only

on Tri/QuadSlider Systems

PAGE 9 OF 31

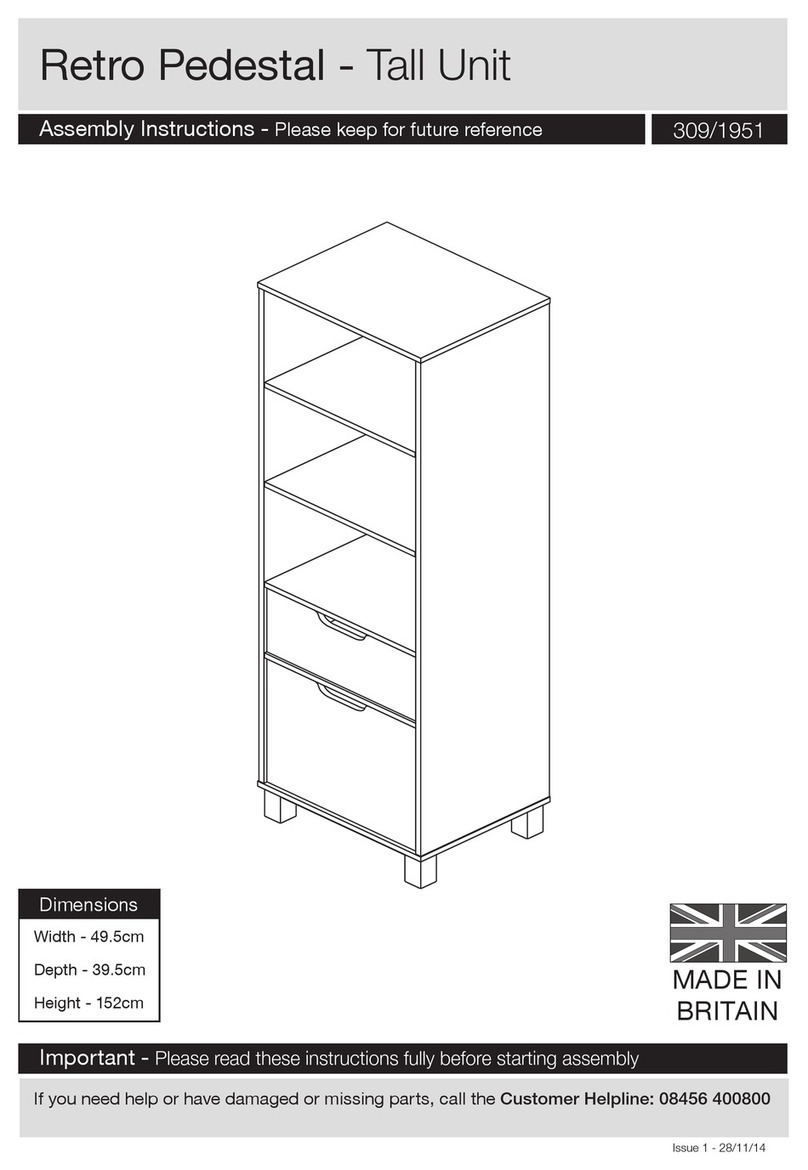

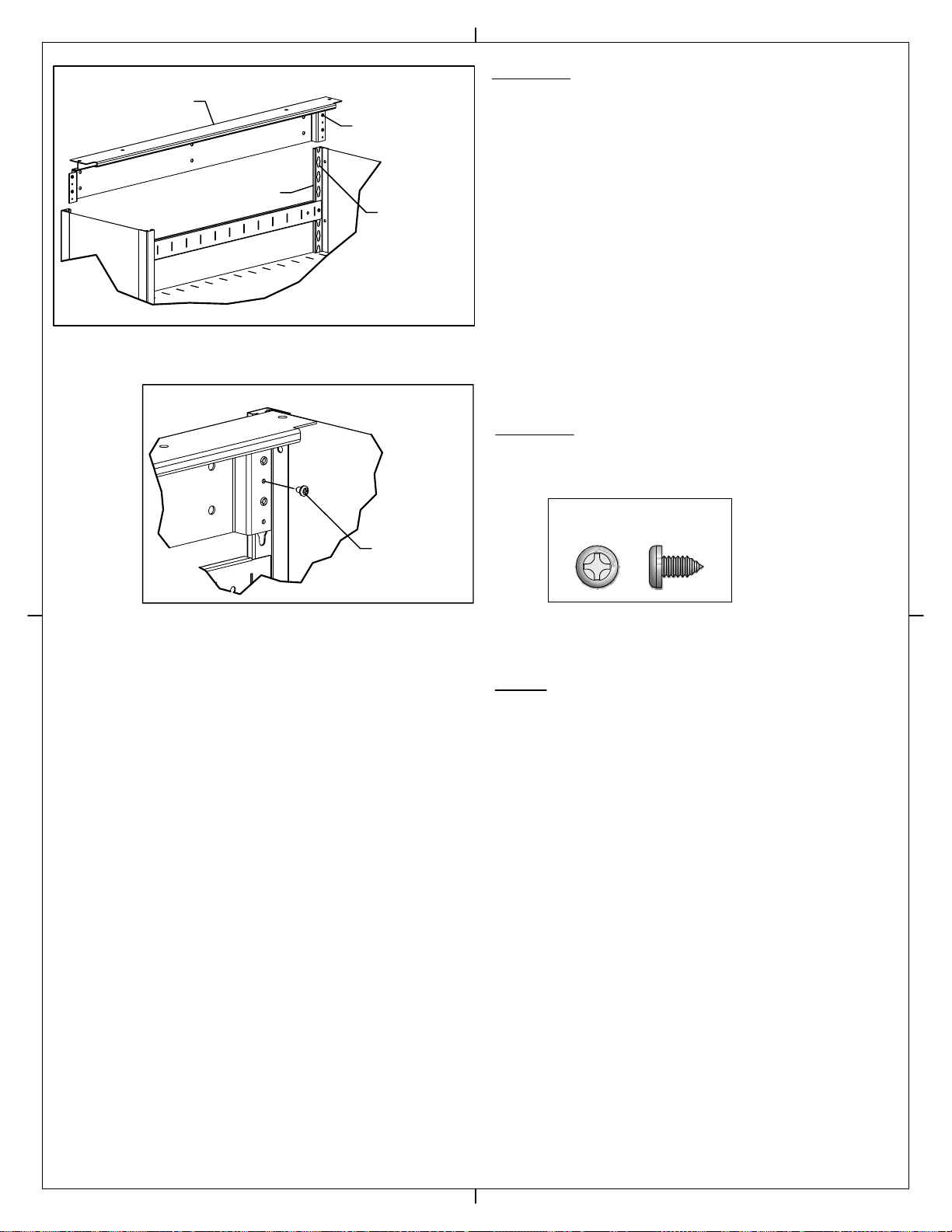

Parts Required for Typical

Moveable Shelving Section

Stainless Steel

Front Cap

Shelf

Reinforcement

Decking

Welded Rail End Stop

End Cap

Stationary

Connector

Channel

Carriage

Single Rivet

Shelf Support

Back

Stop

Divider

Shelf

Standard

Shelf

Support

Closed 'T'

Upright

Standard

Shelf

Support

Top Cover

Front

Support

Channel

Top Cover

Rear Support

Channel

Tri-Slider

Hat Channel

Tri-Slider

Stabilizer

Bracket

Top

Cover

Lock

Bracket

Safety

Stop

BiSlider

Roller Bracket

Top Cover

PAGE 10 OF 31

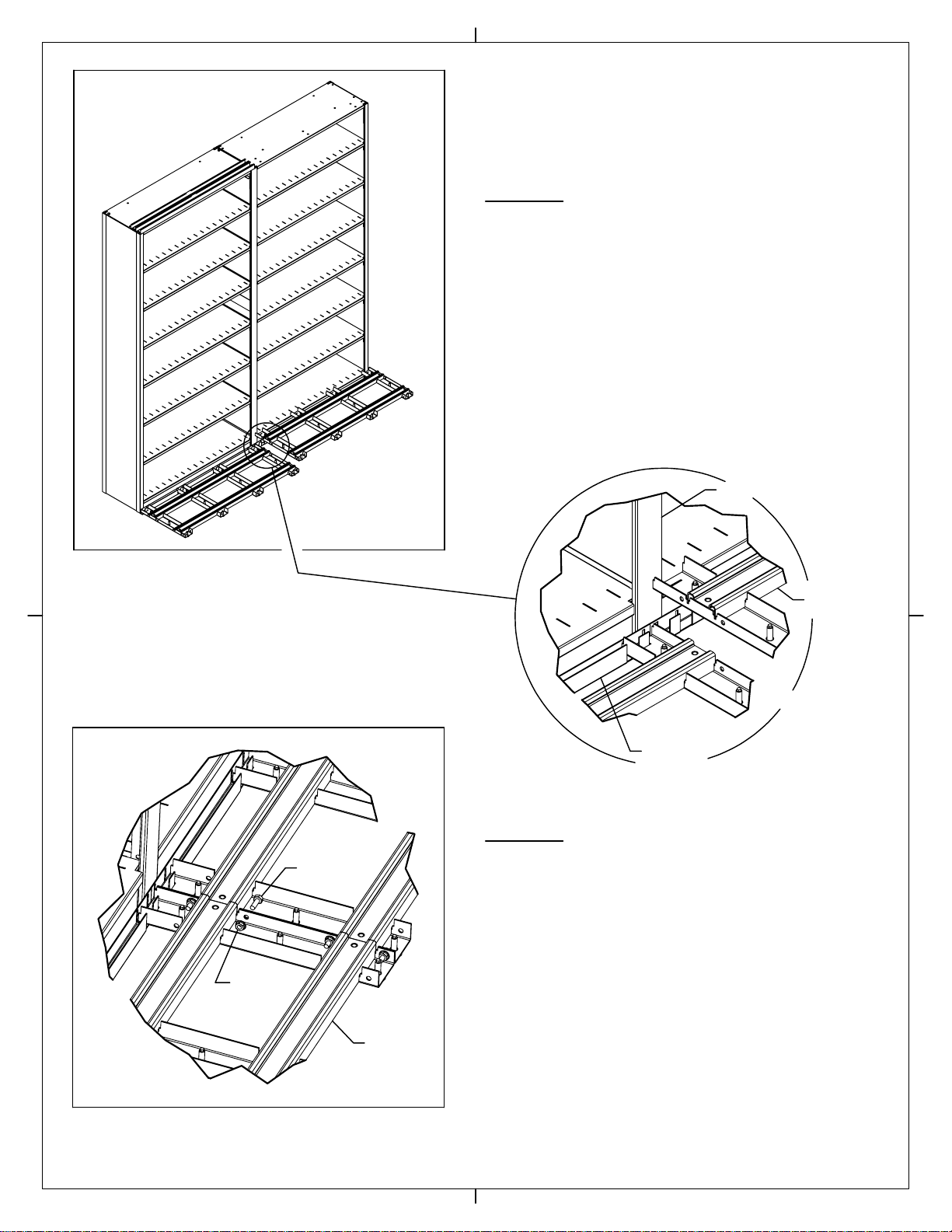

Figure U

Detail V

Figure W

#8 x 3/8" Tek Screw

Step 15:

Position a stationary connector channel in

front of each stationary base unit. Attach each

channel to the uprights of the stationary units

using #8 tek screws as shown in Figure U and

Detail V.

Step 16:

Install (12) leveling glides in each rail

assembly making sure that each glide is

screwed in completely and is flush with the

bottom of the rail assembly (See Figure W).

Stationary

Units

Stationary

Connector

Channel

#8 x 3/8"

Tek Screw

Upright

Leveling Glide

Welded Rail Assembly

Page 11 of 31

Figure X

Figure Z

Detail Y

Step 17:

Attach a rail assembly to each stationary connector channel.

Rail assemblies have corresponding slots which slide over

connector channel to secure rail assembly into place (See

Figure X and Detail Y).

Step 18:

Join rail assemblies together using (4) 1/4-20 x 3/4" hex bolts

and (4) flanged hex nuts. Make sure rails are flush from one

assembly to the next before tightening bolts (See Figure Z).

-For BiSlider Systems, continue with Step 19

-For TriSlider Systems, skip to Step 20

-For QuadSlider Systems, skip to Step 22

1/4-20

Nut

1/4-20 x 3/4"

Bolt

Rail

Assembly

Upright

Rail

Assembly

Stationary

Connector

Channel

Page 12 of 31

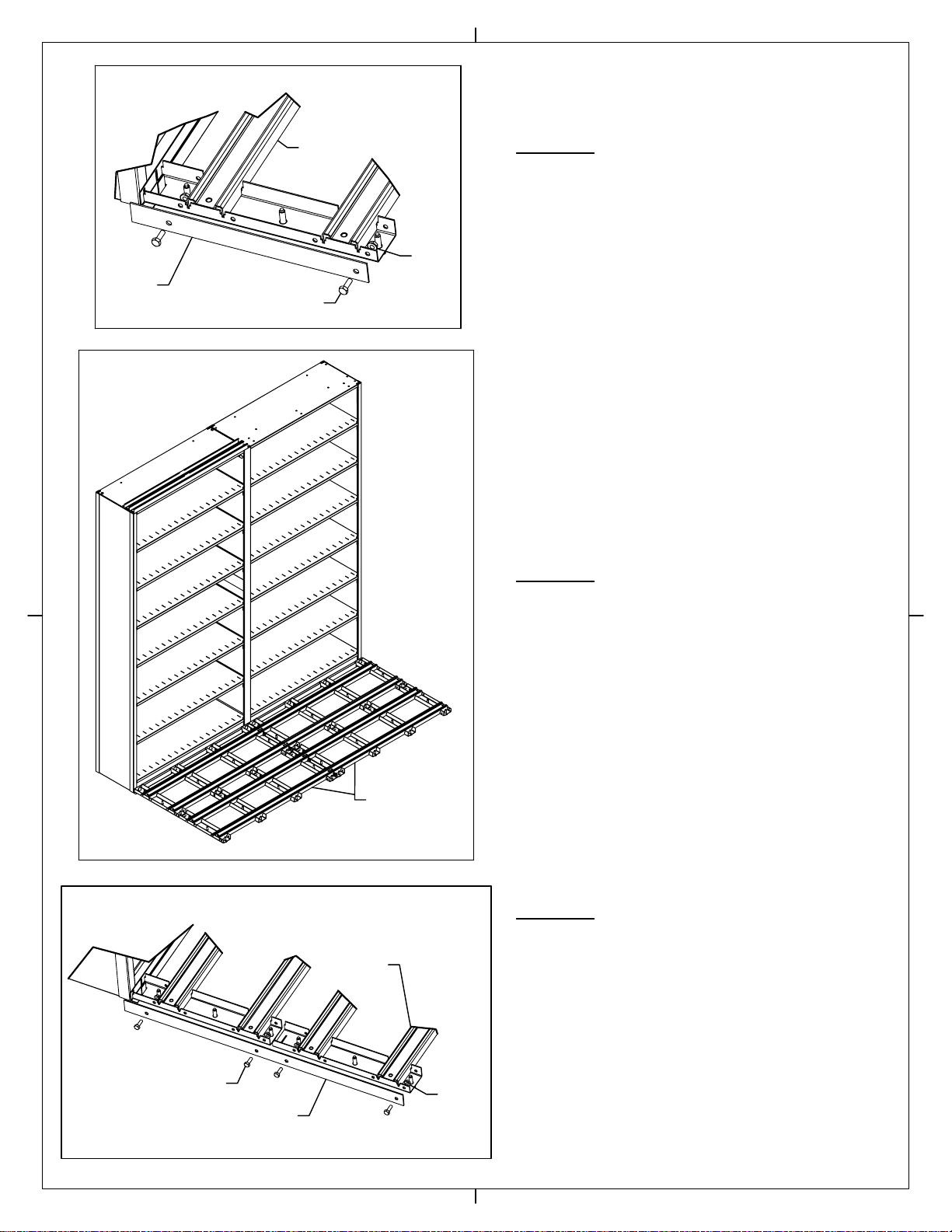

Figure AA

Figure AB

Figure AC

Step 21:

For TriSlider Systems Only

Attach deck end cap to rail assemblies starting from left end

of rail assembly. Use (4) 1/4-20 x 3/4" hex bolts and (4)

1/4-20 flanged hex nuts to secure end cap to rail assembly

as shown in Figure AC. Repeat for right side of system.

Skip to Step 24.

Position additional row of rail assemblies in front of Bi-Slider

rail assemblies that were already in place as shown in

Figure AB. Join second row of rail assemblies to each other

with 1/4-20 hardware as instructed in Step 18 for first set

of rails.

Step 20:

For TriSlider Systems Only

Attach deck end cap to rail assembly starting from left end

of rail assembly. Use (2) 1/4-20 x 3/4" hex bolts and (2)

1/4-20 flanged hex nuts to secure end cap to rail assembly

as shown in Figure AA. Repeat for right side of system.

Skip to Step 24.

Step 19:

For Bi-Slider Systems Only

1/4-20

Nut

Deck End

Cap

Rail

Assembly

1/4-20 x 3/4"

Bolt

Additional Rail

Assemblies

1/4-20

Nut

1/4-20 x 3/4"

Bolt Deck

End Cap

Rail

Assembly

Page 13 of 31

Figure AD

Figure AE

Attach deck end cap to rail assemblies starting from left end

of rail assembly. Use (6) 1/4-20 x 3/4" hex bolts and (6)

1/4-20 flanged hex nuts to secure end cap to rail assembly

as shown in Figure AE. Repeat for right side of system.

Step 23:

For QuadSlider Systems Only

Position (2) additional rows of rail assemblies in front of

Bi-Slider rail assemblies that were already in place as shown

in Figure AD. Join second & third rows of rail assemblies to

each other with 1/4-20 hardware as instructed in Step 18

for first set of rails.

Step 22:

For QuadSlider Systems Only

Additional Rail

Assemblies

1/4-20

Nut

1/4-20 x 3/4" Bolt

Deck End Cap

Rail Assembly

Page 14 of 31

Figure AF

Detail AG

Detail AH

Install unit decking. Deck sections interlock with rail

assemblies and should be flush with the top of the rails

when installed (See Figure AF). After decking is in place,

install end stops at the end of each rail using (1) 1/4-20 x

1/2" cap screw (See Figure AF).

Step 25:

Step 24:

LEVELING OF UNIT

Determine highest point on rail assembly. Working out from

this point, level rails by adjusting leveling glides. For

system to function properly all rails must be level

from left-to-right, front-to-back, and rail-to-rail. All

leveling glides must be in contact with the floor.

Step 26:

Remove protective film from stainless steel front cap before

attaching to rail assembly. Position cap with notches towards

floor, then attach to each rail section by snapping into place

over front rail crossmembers (See Details AG & AH).

1/4-20 x 1/2" Allen

Head Cap Screw

See Details AG & AH

Leveling Glides

Decking

Rail Cross-

Member

Stainless Steel

Front Cap

Notched Side

Rail Assembly

Stainless Steel

Front Cap

Rail Assembly

1/4-20 x 1/2"

Cap Screw

End

Stop

Rail

Assembly

Page 15 of 31

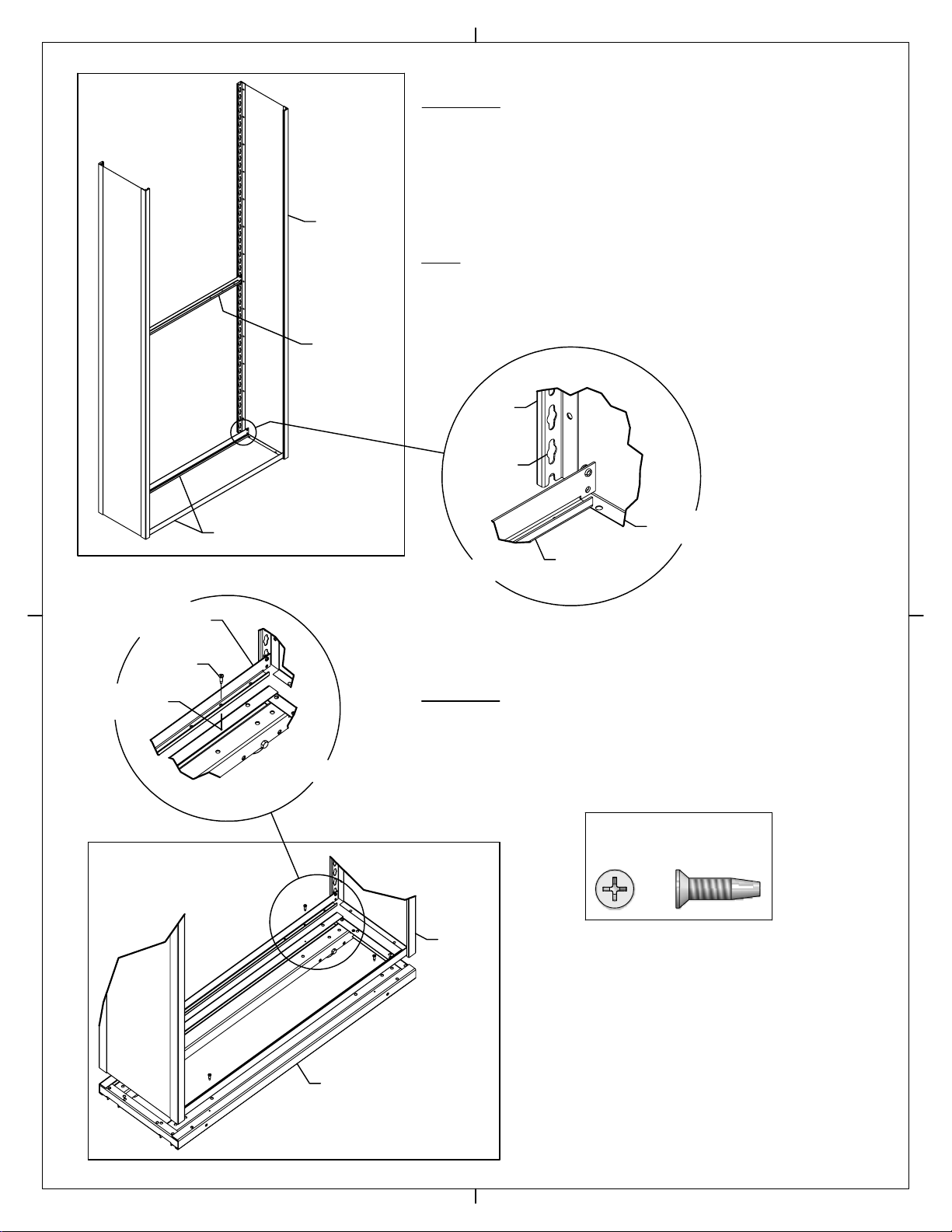

Figure AI

Detail AJ

Detail AL

Figure AK

#10 x 3/4" Flat Head

Tek Screw

Fasten the shelving unit assembled in the previous step to a

carriage using (4) #10 x 3/4" flat head tek screws (See Figure AK

& Detail AL).

Step 28:

Note: Single rivet shelf supports are used only for the bottom

shelf on units that will be attached to a carriage. Standard shelf

supports are used for the rest of the unit.

Temporarily mount a shelf support at chest height between (2)

closed 'L' uprights to hold them in position. Check to make certain

that the flanges on the uprights are at the bottom of the unit.

Mount (2) single rivet shelf supports into the first complete set of

keyholes at the bottom of the uprights (See Figure AI & Detail AJ).

Step 27:

Closed

Upright

Standard

Shelf Support

Single Rivet

Shelf Supports Flange at Bottom

of Upright

Single Rivet

Shelf Support

First

Complete

Keyhole

Upright

#10 x 3/4"

Screw

Single Rivet

Shelf Support

Pre-Punched Hole

in Carriage

Shelving

Unit

Carriage

Page 16 of 31

Figure AM

Figure AN

Figure AO

Step 29:

Install heavy duty shelf reinforcements for the bottom

shelf as shown in Figure AM. See Table 2 for proper

number of reinforcements. Figure AN shows the visual

difference of a standard shelf reinforcement compared

to a heavy duty reinforcement.

Step 30:

Install bottom shelf by tilting as shown in Figure

AO. It should then lie flat on shelf supports and

reinforcement(s).

18"

Depth of

Shelving

12"

15"

Table 2 - Shelf Reinforcements

for Mobile Section - Bottom Shelf

Number of Heavy Duty

Reinforcements

One

Two

One

Heavy Duty Shelf

Reinforcement

Carriage

Single Rivet

Shelf Supports

Upright

Standard Shelf

Reinforcement

Heavy Duty Shelf

Reinforcement

Shelf

Upright

Shelf Support

Carriage

Page 17 of 31

Figure AP

Figure AQ

Figure AR

Step 31:

Install back stop for bottom shelf. Count up three

complete keyholes from top of shelf and place rivets of

back stop into these keyholes (See Figure AP).

Step 32:

Install (2) standard shelf supports at the correct locations

based on unit configuration. See Figure F on Sheet 5 for

guidance on shelf spacing.

Step 33:

If required (See Table 3) install standard shelf

reinforcement(s) as shown in Figure AR.

Two

None

Number of

Reinforcements/Shelf

Table 3 - Shelf Reinforcements

for Mobile Section

None

12"

15"

18"

Depth of

Shelving

Back

Stop

Standard

Shelf Supports

Standard Shelf

Reinforcement

Page 18 of 31

Figure AS

Figure AT

Figure AU

Step 34:

Install second shelf by tilting as shown in Figure AS. It

should then lie flat on shelf supports and reinforcement(s).

Step 35:

Install back stop for second shelf. Count up three complete

keyholes from top of shelf and place rivets of back stop into

these keyholes (See Figure AT).

Step 36:

Install remainder of shelf supports, shelves, back stops, &

shelf reinforcements (if required), working from bottom to

top. Keep in mind your installation may be different, as shelf

spacing varies from job to job (See Figure F on Sheet 5 for

typical configurations). Do not install components at the top

of unit at this time; when complete the assembled unit

should look similar to Figure AU.

Shelf

Shelf

Support Back

Stop

Fourth Opening Typically

Has Posting Shelf on

Letter/Legal Systems

Page 19 of 31

Figure AV

#10-24 x 3/8" Phillips Pan

Head Sheet Metal Screw

Figure AW

Step 37:

Place the rivets of the top cover rear support channel into the

keyholes at the top of the upright at the rear of the unit. The

top rivet on each side should be inserted into the first complete

keyhole at the top of the uprights (See Figure AV). Tap channel

into place with rubber mallet or hammer to seat rivets firmly

into bottom of keyholes.

Step 38:

Use (2) #10-24 x 3/8" phillips pan head screws to secure

channel to uprights as shown in Figure AW.

Note:

For BiSlider carriage assembly, continue with Step 39.

However, if you have finished assembling all BiSlider

carriages and are now assembling Tri-QuadSlider

carriages, skip forward to Step 50.

Upright

Top Cover Rear

Support Channel

Top Complete

Keyhole

Top

Rivet

#10-24 x 3/8"

Screw

Page 20 of 31

Table of contents

Other Datum Storage Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Politorno

Politorno Fenix 1181 Assembly instructions

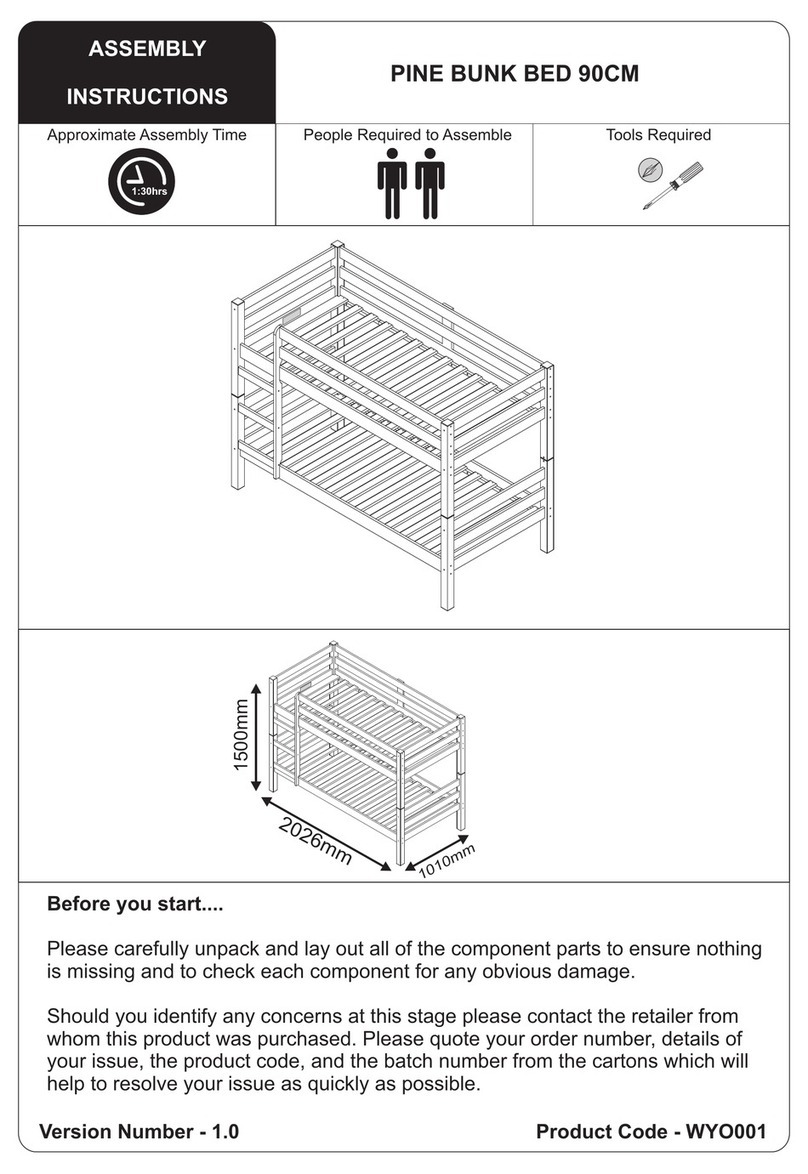

Julian Bowen Limited

Julian Bowen Limited WYO001 Assembly instructions

Dorel Home Products

Dorel Home Products DA2071369 Instruction booklet

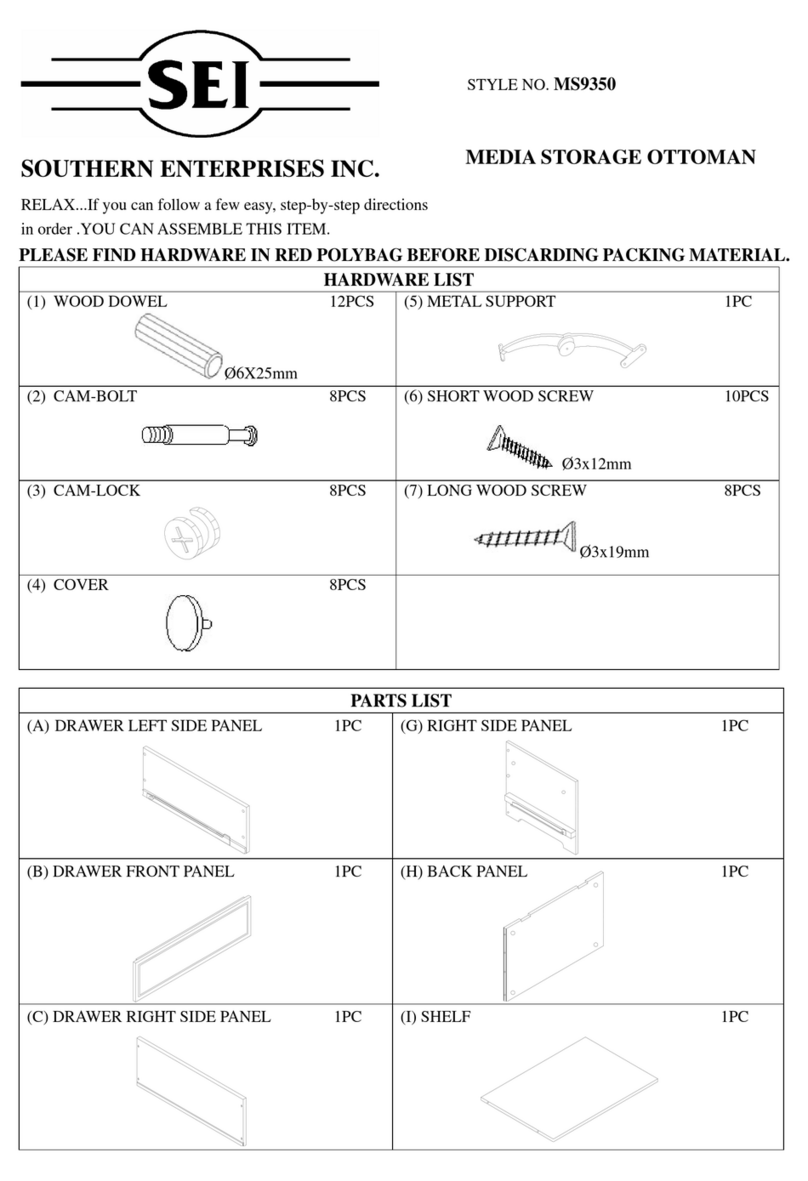

Southern Enterprises

Southern Enterprises MS9350 manual

Furniture of America

Furniture of America FGI-19801C24 Assembly instructions

Birlea

Birlea DAKOTA Assembly guide