DAV TECH DAT 096 Product manual

PRESSURE REDUCER DAT 096

0 - MAX. 7BAR

DAV TECH SRL

Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALIY

Tel. 0039 0444 574510 - Fax 0039 0444 574324

Installation and

maintenance guide

Index

1 INTRODUCTION pag. 3

2 USER INSTRUCTIONS pag. 4

3 DESCRIPTION pag. 10

4 INSTALLATION pag. 14

5 OPERATION pag. 16

6 MAINTENANCE AND ASSISTANCE pag. 17

7 DEFECTS pag. 19

8 SPARE PARTS AND ACCESSORIES pag. 20

9 TRANSPORT, PACKAGING AND STORAGE pag. 20

10 DISPOSAL pag. 21

Installation and maintenance guide

pag.3

1 INTRODUZIONE

1 INTRODUCTION

1.1 The manual

The user guide is the document that accompanies the valve from the time of its construction and throughout the period of

use, it is therefore an integral part of the valve. It requires reading the manual before taking any action involving the valve. The

manual must be readily available for use by staff and maintenance of the valve. The user and the attendant use are required

to know the contents of this manual.

Reproduction of any part of this manual, in any form, without the express written permission of DAV Tech. The text and

illustrations in this manual are not binding, the DAV tech reserves the right, at any time and without notice, the right to make

any changes to improve the product or for reasons of character manufacturing or commercial.

1.2 Warranty

The warranty is valid for a period of 12 months from the date of commissioning and no later than 15 months from the

date delivery. The interventions carried out during the warranty period does not extend in any way the validity period of the

guarantee. The seller is not liable for defects caused by normal wear of parts which by their nature are subject to wear.

1.3 Goods receiving

The original configuration of the component must never be changed.

Upon receipt of the goods, check that:

• The packaging is intact

• The exact correspondence of the material ordered.

2 TECHNICAL DESCRIPTION

Operation of the pressure reducer

DAT 096 pressure regulators are used for manual adjustment of fluid pressure.

They are available in pressure ranges of 0 - 7 bar, 0 - 25 bar and 0 - 50 bar. These regulators are made of stainless steel. In this

way they are suitable for most fluids f.i. glues, adhesives, colors, varnishes, release agents, oils.

The diaphragm is made of Viton®, resp. the material of the diaphragm on the side is made of PTFE. The diaphragm of the

0 - 50 bar regulator is also made of a special fabric. The valve balls are made of ceramic.

Technical specification

Model DAT 096

Diaphragm Viton® / PTFE

Gasket material: Viton®

Inlet pressure

0 - 7 bar = max. 40 bar

0 - 25 bar = max. 40 bar

0 - 50 bar = max. 70 bar

Manometer: Stailess steel ø 63mm

Connections: 1/2“

Material: Stailess steel

PRESSURE REDUCER DAT096

2 INSTRUCTIONS FOR THE USER

2.1 Purpose of the document

These instructions

> are intended as an important source of information and reference material for personnel to install and operate the

product.

> describe how to work, assemble and maintain the product.

> provide important advice for handling the product safely and efficiently.

2.2 Explanation of symbols

Important information, such as safety instructions, are identified by corresponding symbols.

It is essential to follow these guidelines to prevent accidents and damage to the product.

2.3 Intended use

The material pressure regulators have been manufactured according to the EC directive in line with the latest state of the

art and recognized rules of engineering.

However, its use can present risks for the life and physical integrity of the user or third parties, or it can damage the

machine or cause other damage.

Material pressure regulators are used in connection with one or more consumers for the continuous application of

fluids. Under no circumstances should aggressive materials such as acids, alkalis, detergents, etc. be used. Consult the

manufacturer if in doubt as to the suitability for use of a particular material.

WARNING! Risk of injury!

This symbol identifies all the safety instructions contained in these instructions for use. Failure to

observe them carries a risk of injury or death. Carefully observe these work safety instructions and pay

particular attention when you see this symbol.

IMPORTANT! This symbol identifies all the safety instructions contained in these instructions

for use, which must be observed as otherwise damage and/or malfunction of the device could

occur.

!

IMPORTANT!

Use the material pressure regulator only for its intended purpose and under absolutely safe

operating conditions! This is the only way to ensure operational safety!

!

NOTE! The warning symbol draws your attention to useful tips and other information contained in

these operating instructions. All of this information must be observed in the interest of effective

operation of the device.

Installation and maintenance guide

pag.5

2.4.1 Modifications or Changes

2.4.2 Spare parts, wearing parts and auxiliary materials

Their use other than or in excess of the intended use is considered improper use!

For damages resulting from improper use:

> the operator is solely responsible.

> the manufacturer assumes no liability.

2.4 Reasonably foreseeable misuse

WARNING! Risk of injury!

Using the material pressure regulator in a different way than intended can lead to serious

damage!

IMPORTANT!

Do not make any changes or additions without consulting the manufacturer and obtaining written

agreement!

!

IMPORTANT!

The use of spare and wearing parts from third-party manufacturers can present risks. Only use

original parts or parts approved by the manufacturer!

!

IMPORTANT!

The manufacturer assumes no liability for damage resulting from the use of spare parts, wearing

parts or auxiliary materials not approved by the manufacturer!

!

NOTE!

Never use aggressive media such as acids, alkalis, detergents, chemicals, poisons, highly

flammable substances or gases or the like. The regulator must not be used for media with solid

content. Consult the manufacturer if you are in any doubt as to the suitability of a material for

your use.

NOTE!

Unauthorized modifications or changes void any liability or warranty on the part of the

manufacturer.

PRESSURE REDUCER DAT096

During use, there is a possible risk of:

> injuries to the life and physical integrity of the operator or third parties.

> damage to the product itself.

> other damage.

2.5 Risks associated with using the product

2.6 Residual risks

The following risks in particular must be taken into consideration:

NOTE!

Knowledge of the safety and user instructions contained in this manual is the basis for safe and

trouble-free operation.

IMPORTANT!

The operating instructions must always be kept at the place of use! The instructions for use must

always be freely accessible to operators, service personnel, etc.

In addition, the following should be observed:

• General and local regulations on accident prevention and environmental protection.

!

WARNING! Risk of injury!

Danger due to the emission of high pressure liquids from the device. Always wear personal

protective equipment when working on the device!

WARNING! Danger!

Be aware that there is a possibility of residual mechanical and hydraulic energy.

WARNING! Danger due to hydraulic energy!

Hydraulic energies can cause serious injuries. If a component is damaged, high pressure

materials can escape and cause injury and damage!

Therefore:

> Before starting work on the system, always depressurize the device.

> Do not remove safety devices or deactivate them through modifications.

> Do not set pressures higher than the values specified in the instructions for use.

Installation and maintenance guide

pag.7

2.7 Obligations of the operator

The operator is obliged to allow the use of the product only to persons who:

> know the fundamental rules relating to workplace safety and accident prevention.

> have been trained on how to work with the product

> have read and understood these instructions.

The operator must also identify any other dangers that may arise from the special working conditions at the place of use

of the product by carrying out a risk assessment in accordance with Article 3 of the Ordinance on Occupational Safety

and Health (Betriebssicherheitsverordnung). In connection with the risk assessment, operating instructions according

to §9 Occupational Safety and Health Ordinance must be prepared, which bring together all further instructions and

safety instructions.

The operator will also make the necessary protective devices available to the personnel. A list of the required personal

protective equipment can be found in chapter 2.9.

NOTE!

The requirements of the EC directive on the use of work equipment 2009/104/EC must be met.

WARNING! Danger!

In addition to the precautions recommended by the manufacturer, the operator must take

adequate measures to protect himself from the risks deriving from residual energy.

Personnel must be trained on the risks and countermeasures to be adopted.

WARNING! Danger!

Danger due to pressurized media. Installation, maintenance, troubleshooting, cleaning of the

device, etc. should only be performed when the device is not pressurized.

WARNING! Danger of burns!

All components of the material pressure vessel can become hot during operation. Wear suitable

protective clothing (gloves, etc.)

Imperative!

The personal protective equipment listed here must be worn when working on

or with the product.

PRESSURE REDUCER DAT096

All the people who are called to work on the product are obliged, before starting work:

> observe the basic rules relating to safety in the workplace and accident prevention.

> to read and understand the safety chapter and the safety instructions contained in this manual.

> wear personal protective equipment according to chapter 2.9.

We have taken into consideration our existing experience and achievements in providing all information and instructions

for the operation, maintenance and cleaning of the product to the best of our knowledge.

We reserve the right to make technical changes in the interest of improving the product described in these operating

instructions.

2.8 Obligations of the operator

2.10 Liability and Warranty

2.9 Personal protective equipment

IMPORTANT! Only authorized, trained and instructed specialist personnel are authorized to handle

the product.

!

NOTE!

Please contact the product manufacturer if you have any unanswered questions!

NOTE!

The use of personal protective equipment depends on the environment in which the device is

used and the medium used. For this reason, also observe the risk assessment of the workplace

prepared by the operator.

Safety glasses!

(to protect the eyes from airborne objects and fluids)

Safety shoes!

(to protect the feet from injury caused by a falling material pressure regulator)

Protective gloves!

(to protect the skin from rubbing, abrasions, aggressive materials, punctures and deep wounds

on the hands)

Installation and maintenance guide

pag.9

Translations are also provided to the best of our knowledge. We cannot accept responsibility for translation errors. The

German version of the operating instructions is authoritative.

Descriptions and illustrations may differ from the product supplied. Drawings and diagrams are not to scale.

It is forbidden to pass on these operating instructions to third parties and this will lead to liability for damages.

A warranty with the following scope is provided for this product:

All parts which are unusable or whose suitability for use is severely impaired within 24 months for one shift, 12 months

for two shifts and 6 months for three shifts from delivery to the buyer due to this delivery - especially faulty design

and defects in materials and workmanship - will be repaired or a replacement provided at our option free of charge.

The guarantee takes the form of the replacement or repair of the product or individual parts of the same, at our

discretion. We shall bear any expenses incurred herein (transport, toll, labor or material costs), unless the expenses

increase because the device was subsequently moved to a location other than the customer’s premises. These extra

charges are the responsibility of the customer/buyer.

We make no warranty for damages caused solely or in part by the following:

improper or improper use, incorrect installation and/or commissioning, natural wear, incorrect handling and/or

maintenance, unsuitable coating substances, substitute materials and/or chemical, electrical and/or physical effects,

unless we are responsible.

This declaration does not affect your statutory rights or contractual rights arising from our general terms and conditions.

Wear parts are all parts that come into direct contact with the material being processed and/or are subject to wear due

to their function. Such parts are excluded from the warranty and from claims for defects insofar as they are based on

wear. Replacement of a part does not extend the warranty period of the product.

2.10.1 Warranty

2.10.2 Wear parts, lifetime warranty

PRESSURE REDUCER DAT096

3 DESCRIPTION

The manual pressure regulator 0 - max. 7 bar is used to regulate the pressures in the material lines. A star grip

adjustment spindle is located on top of the device. Screwing it in manually pre-tensions a pressure spring, which

activates a tappet in the lower part of the device which, in turn, pushes a ceramic ball out of its sealing seat. This frees

up the flow of material. The controlled pressure of the material is now set on the outlet side. Unscrewing the regulating

rod releases the pressure spring tension and closes the sealing seat.

We reserve the right to make technical changes!

3.1 Risks associated with using the product

3.3 Dimensions

3.2 Parameters (technical data)

Type DAT 096

Dimensions in mm (approx) dia. 88 x 220

Total weight in kg (approx) 3

Diameter 88 x 220 1/2“

max. material inlet pressure 40 bar

max. material outlet pressure 7 bar

Installation and maintenance guide

pag.11

Diaphragm material pressure regulator

MMDR

Copyright ALFRED SCHÜTZE Apparatebau GmbH

2022. All rights reserved.

26

Doc-ID 1983

4.3 Exploded view

4.3.1 MMDR/MMDR back pressure regulator, manual, 0-7 bar

Fig. 4.3-1 –Exploded view: MMDR/MMDR back pressure regulator, manual, 0-7 bar

3.4 Breakdown

PRESSURE REDUCER DAT096

3.5 Spare parts list

N. Code Unit Description

1.0 10148 1 Main Body

2.0

2.a

2.b

10102

40057

20155

1

1

1

Locking screw, stainless steel

alternatively:

Copper sealing ring

Locking screw, stailess steel

3.0 40154 2 Sealing ring - alternatively without connection - 1/2” internal thread (item 3.0 + 4.0 N/A)

4.0 * 2 Connection - - alternatively without connection - 1/2” internal thread (item 3.0 + 4.0 N/A)

5.0

5.a

21509

10102

1

1

90° screw-in angle, V4A

alternatively:

Locking screw, stainless steel

6.0

6.a

6.b

55702

56300

1Manometer pipe

Manometer pipe (manual)

Manometer pipe(pneumatic 1:1)

(N/A if item 5.a is installed)

7.0 40019 1 O-Ring / Viton® -(N/A if item 5.a is installed)

8.0 * 1 Manometer (Tip: Manometer with maximum pressure > inlet pressure) - (N/A if item 5.a is installed)

9.0 20058 1 Conical spring - (N/A if item 5.a is installed)

10.0

10.a

10.a

10.b

50016

50024

50020

1Ball

Ball, ceramic (version: Stainless steel / Ceramic - KG)

Ball, stainless steel (version: Stainless steel / Stainless steel - KG)

Ball, ceramic (version: Carbide / Ceramic - KG)

(N/A for back pressure regulator version)

11.0 40038 1 O-Ring / Viton®

12.0

12.a

12.b

12.c

10029

10218

10212

1Sealing seat

Sealing seat (version: Stainless steel sealing seat)

Sealing seat (version: Carbide sealing seat)

Sealing seat (version: Back pressure regulator, stainless steel sealing seat)

13.0

13.a

13.b

13.c

20166

21012

20893

1 Valve tappet

Valve tappet (version: Stainless steel sealing seat)

Valve tappet (version: Carbide sealing seat)

Valve tappet (version: Back pressure regulator, stainless steel sealing seat)

14.0 40181

41087 1Diaphragm

Diaphragm, FDA

15.0 30041 1 Diaphragm counter bearing

16.0 10007 1 Hexagonal nut

17.0

17.a

17.b

20056

20055

1Pressure spring

Pressure spring (manual, 0-7 bar)

Pressure spring (manual, 0-50 bar)

(N/A for version DAT 096, pneumatic 1:1)

18.0 30040 1 Spring counter bearing - (N/A for pneumatic 1:1 version)

Installation and maintenance guide

pag.13

N. Code Unit Description

19.0

19.a

19.b

19.c

10107

10108

12602

1 Lock housing

Lock housing (for DAT 096, manual, 0-7 bar)

Lock housing (for DAT 096, manual, 0-50 bar)

Lock housing (for DAT 096, pneumatic1:1)

20.0 20024 6 / 18 Spring washer

21.0 10944 6 / 18 Cylinder head screw

22.0 10063 1 Nut (in connection with item 23.1) - (N/A for version DAT 096, pneumatic 1:1)

23.0

23.a

23.b

23.c

10138

10271

10853

1Regulating spindle

Star grip

Regulating spindle

Regulating spindle with handwheel

(N/A for version DAT 096, pneumatic 1:1)

24.0 * 1 Connection (only for DAT 096, pneumatic 1:1)

25.0 40089 1 Sealing ring (only for DAT 096, pneumatic 1:1)

26.0

26.a

*

20154

1

1

Manometer (only for DAT 096, pneumatic 1:1)

Alternatively: Locking Screw

IMPORTANT! If the seat/seat ball system is dirty or worn, it is possible that the pressure on the outlet side will exceed the

preset pressure. If a pressure gauge whose maximum pressure is lower than the inlet pressure is installed, the pressure

gauge may be damaged if the sealing seat is not replaced/cleaned in a timely manner.

!

Nr. Description

1 Material inlet

2 Material outlet

3

Material return flow regulator (clockwise increases the pressure - counterclockwise decreases the pressure)

4Manometer (output side pressure)

Abb. 3.6/1

3.6 Structure and links

PRESSURE REDUCER DAT096

4 INSTALLATION

4.1 Hose installation / Pipe installation

WARNING! Risk of injury!

Hydraulic energies can cause serious injuries. If a component is damaged, high pressure

materials can escape and cause injury and damage!

WARNING! Risk of injury due to material pressure!

Only qualified personnel may work on the material pressure regulator in compliance with the

safety regulations.

When working on the material pressure regulator, be sure to:

> Depressurise the regulator before starting work

> Do not remove or disable safety devices.

> Do not set pressures higher than the maximum allowed values.

> Install all hoses securely so that the pressure lines cannot be damaged by moving parts of

the machine or system.

> Do not start the material pressure regulator until the work is finished.

Fig. 4/1

The material pressure regulator can be installed in

any position.

Screw the material pressure regulator tight and

tight!

For screw connection of the material pressure

regulator, there are four M6 threads located under

the device.

To avoid damage to connected devices on the

outlet side, a safety valve can be integrated into

the hose, which allows any pressure exceeding the

permissible level to safely escape.

How the pipe or various hoses are installed depends on the size of the pipe and the type of connections.

IMPORTANT!

Only supply cables, lines, hoses and screw connections may be used which are designed and constructed

in accordance with the applicable regulations. They must be designed to withstand the thermal, chemical

and mechanical stresses expected during operation.

!

Installation and maintenance guide

pag.15

4.2 Installation instructions

4.3 Commissioning

WARNING! Risk of injury!

To avoid personal injury and/or property damage, it is essential to observe the following when

installing the device.

WARNING! Risk of injury!

Only trained and qualified personnel may put the machine or system into operation in accordance

with the safety and accident prevention regulations.

The device must be installed in a machine or plant in such a way that dangers such as:

> the leakage of high pressure fluids

> electricity

> malfunctions of the device, machine or system

> failure or malfunction of the system control

> loud noises or interference with the acoustic signals

nearby. To protect people working on the device, machine or system, effective safety devices and warning signs must

be provided. Furthermore, the relevant safety instructions must be integrated into the operating/installation instructions

of the machine or system.

Observe the following before putting the machine or system into operation:

> Make sure that there are no tools or other foreign bodies inside the machine or system.

> Check that the device and all other parts are secure.

> Check that all electrical, hydraulic and pneumatic connections are on the correct ports and are secure.

> Check that the set pressures correspond to the nominal and connection values of the device.

> Check the functioning of the safety devices.

1. Turn on the power.

2. Activate the material flow.

3. Start the device manually.

4. Verify that the device works and works properly.

5. Verify that the device is within all specified set value ranges.

Once it is ascertained that the device works perfectly, the device can be used

in compliance with all accident prevention regulations.

PRESSURE REDUCER DAT096

5 OPERATION

5.1 General and safety instructions for operation

5.2 Shutdown

The product presents the following dangers during operation:

WARNING! Risk of injury!

If used incorrectly, there is a risk that fluids will be sprayed under high pressure.

WARNING! Risk of injury!

The material pressure regulator should never be opened until the pressure has been fully

released.

WARNING! Danger of burns!

All components of the material pressure regulator can become hot during operation. Wear

suitable protective clothing (gloves, etc.)

In normal operation the material pressure regulator requires no operating personnel. To avoid failures, the function of the

material pressure regulator must be checked regularly by qualified inspectors.

Regular monitoring of the outlet pressure will prevent damage to devices connected to the outlet side caused by

overpressure.

Before switching off the appliance for a long time, the following operations must be carried out in compliance with the

safety regulations:

> Depressurise the connected lines.

> Unmount Lines

> Remove material residues from the device.

> Clean the device inside and out. (Observe chapter 6 “Maintenance and service”).

In the event that the faults cannot be eliminated (see chap. 6.2 “Faults”), inform the customer service of the manufacturer.

Use only trained personnel for regular cleaning.

IMPORTANT!

In the event of malfunctions or irregularities, switch off the material pressure regulator immediately.

!

Installation and maintenance guide

pag.17

6 MAINTENANCE AND SERVICE

Safety instructions

Cleaning

6.1 General and safety instructions for maintenance and service

WARNING! Risk of injury!

Improper use of the material pressure regulator carries the risk of serious personal injury and serious

damage. Therefore, maintenance and cleaning work must only be carried out by qualified personnel or

personnel specially trained for these tasks (training to be documented)!

Carry out maintenance and cleaning work on the material pressure regulator only when the regulator

and the system are pressureless!

WARNING! Danger of burns!

Allow the device to cool down before carrying out any work on the material pressure regulator!

The material pressure regulator needs to be cleaned if

> is dirty from use

> a different material must be used

> parts subject to wear must be replaced.

Before starting any maintenance work:

> Wear personal protective equipment.

> Depressurise the material pressure regulator.

> Disconnect the lines.

Maintenance

The material pressure regulator must be serviced/checked regularly, as the seals begin to wear out after a certain time

and are subject to natural wear. Defective seals can be identified by the fact that air or fluid escapes from the connection

points where the seals are mounted.

Make sure that the gasket material used is compatible with the fluid used.

IMPORTANT!

Do not use sharp-edged metal tools for external cleaning; use only soft brushes.

Solvents or halogenated cleaners can cause chemical reactions when used on aluminum and galvanized

components. This can lead to explosive and chemical reactions! Therefore, only cleaners may be used that

do not contain the ingredients mentioned above.

!

NOTE!

The material pressure regulator should be checked regularly for wear. It is not possible to

concretely predict when wear will occur, since this depends on the material being processed and

the conditions of use.

PRESSURE REDUCER DAT096

6.2 Replacing the seat and the ball

1. Depressurise all connections and shut off the material supply by disconnecting the lines!

2. Unscrew the adjusting rod (1) until you no longer feel any tension on the compression spring.

3. Undo the Allen screws (2) and unscrew them.

4. Remove the lock housing (3).

5. Remove the compression spring (5) and spring counter bearing (4).

6. Loosen the nut (6) and remove the diaphragm counter bearing (7) and diaphragm (8).

7. Pull the valve tappet (9) out of its sealing seat.

8. Unscrew the O-ring (10) and remove the ball (11). The ball spring located below must remain in its position in

the main body (12).

9. Place the new ball on the conical spring and screw in the new seat.

10. Reassemble the device by repeating the same steps in reverse order.

11. Carry out a function test of the device after replacing the seat and the ball!

Fig. 6.2/1

IMPORTANT!

Always replace the seat (10) and the ball (11) together.

!

NOTE! When installing seal seats and balls that have already been used, these must first be

cleaned of all deposits and material residues. Material residues in the sealing seat can cause

leaks in the system, while balls with hardened material residues can damage the sealing seat.

Installation and maintenance guide

pag.19

7.1 General and safety rules relating to breakdowns

7.2 In case of failure

7.3 Malfunctions

7 DEFECTS

Mechanical, pneumatic or hydraulic faults must be eliminated by personnel trained and qualified in the relevant field. The

manufacturer must be informed of defects which cannot be remedied by the measures described.

In the event of a malfunction, the material pressure regulator must be switched off immediately.

WARNING! Risk of injury!

Improper and incorrect interventions on the material pressure regulator, machine or system lead

to serious risks of personal injury and/or damage! Therefore, only trained qualified personnel

can correct faults.

Before, during and after all work to eliminate faults, the warnings and safety regulations in

chapter 5.2 “Maintenance and repairs” must be observed!

WARNING! Risk of injury!

Improper and incorrect interventions on the device, machine or system lead to serious risks of

personal injury and/or damage. Therefore, only trained qualified personnel can correct faults.

Before, during and after all troubleshooting work, the warnings and safety regulations in chapter

6 “Maintenance and repairs” must be observed!

Defect Possible Cause Solution

The pressure on the

outlet side increases

without actuation of

the regulating rod

Seal seat dirty or

worn (12.0)

Clean/replace the seat (12.0) and the ball (14.0)

In no case should you try to suppress the problem by

re-fixing something.

Fluid escapes between

the diaphragm and

housing or from the

bleed port in the lock

housing.

Diaphragm (10.0)

defective Replace diaphragm (10.0)

PRESSURE REDUCER DAT096

8 SPARE PARTS AND ACCESSORIES

9 TRANSPORT, PACKAGING AND STORAGE

9.1 Transportation

8.1 Material Links

IMPORTANT!

Only use spare and wear parts approved by the manufacturer!

!

The material inlet and outlet are connected via the G1/2” internal thread in the main body of the material pressure

regulator.

The following add-on parts are used for other thread sizes:

Further connection options available upon request.

Cod. Description Version

220240 Double nipple, stainless steel, 3/8” external thread – 1/2” external thread. 400168

Always transport and store the material pressure regulator with the utmost care:

> Do not throw or drop the device.

> Do not place other objects on the material pressure regulator or on the packaging.

> Protect the material pressure regulator from dirt, moisture, heat and cold.

> Do not use force when unpacking the device. Do not damage the plastic parts.

> When storing the material pressure regulator, leave it in its packaging until assembly.

9.2 Transport Inspection

Immediately upon receipt of the device, check that it is complete and has not been damaged in transit.

If you see external damage during transport, do not accept the delivery or only accept it with reservations. Note the extent

of the damage on the carrier’s transport documentation/delivery note. Make a complaint.

Report hidden defects as soon as they are discovered, as claims for damages can only be made within the applicable

time limits.

9.3 Packing

Only environmentally friendly materials are used for the packaging. Therefore, please follow these rules:

> Separate the different types of packaging material for environmentally friendly disposal.

> Recycle recyclable materials.

> Reuse reusable packaging materials.

Safety shoes! (to protect your feet from injury caused by material pressure regulator falling).

Installation and maintenance guide

Table of contents

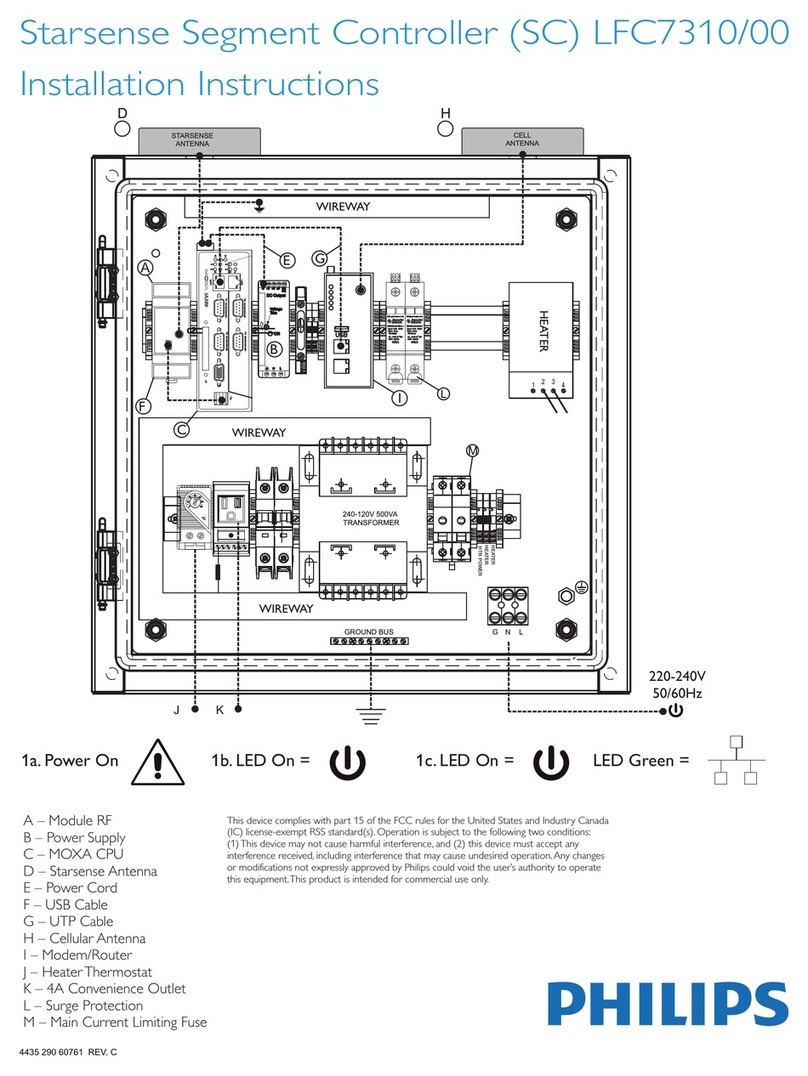

Popular Controllers manuals by other brands

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-F Series Training manual

Hanna Instruments

Hanna Instruments pH 500 Series instruction manual

M-system

M-system MSP4 instruction manual

Contemporary Research

Contemporary Research ICC1-232 Specifications

Whelen Engineering Company

Whelen Engineering Company Wireless Traffic Advisor Installation guides

Vector

Vector TRA-F12x-A manual

Compu-aire

Compu-aire SYSTEM 2200 Plus 3L user manual

Motorola solutions

Motorola solutions Openpath OP-2ESH-POE installation guide

JUMO

JUMO AQUIS 500 RS operating manual

Desoutter

Desoutter CVI3 Function user manual

STEP

STEP AS380 Series instruction manual

Continental Instruments

Continental Instruments CICP1200 datasheet