David White 3900HV User manual

3900HV

www.davidwhite.us.com

3900HV

Rotary Laser Owner’s Guide

FOR CUSTOMER SERVICE, PARTS AND REPAIR CALL

(765) 581-4097

IMPORTANT: IMPORTANT: IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

-2-

With David White

your sights are set on

precision and accuracy.

Congratulations! You’ve purchased a David White builder/contractor

instrument, known throughout the world for precision and accuracy.

The purpose of this user’s guide is to acquaint you with the instrument, its

components, safety, proper care and handling.

Our levels, level-transits and transits are constructed to withstand

extremely rugged field use. Like all precision instruments, however, they

should be treated with reasonable care to prolong life and accuracy.

All instruments are adjusted when they are shipped from the factory. It

is the customer’s responsibility to check and to ensure instruments are

adjusted prior to using.

David White is not responsible for errors caused by instruments that are

out of adjustment.

Contact your distributor, dealer or David White for information on the

nearest facility to check if your instrument is properly adjusted.

All specifications are subject to change without notice.

-3-

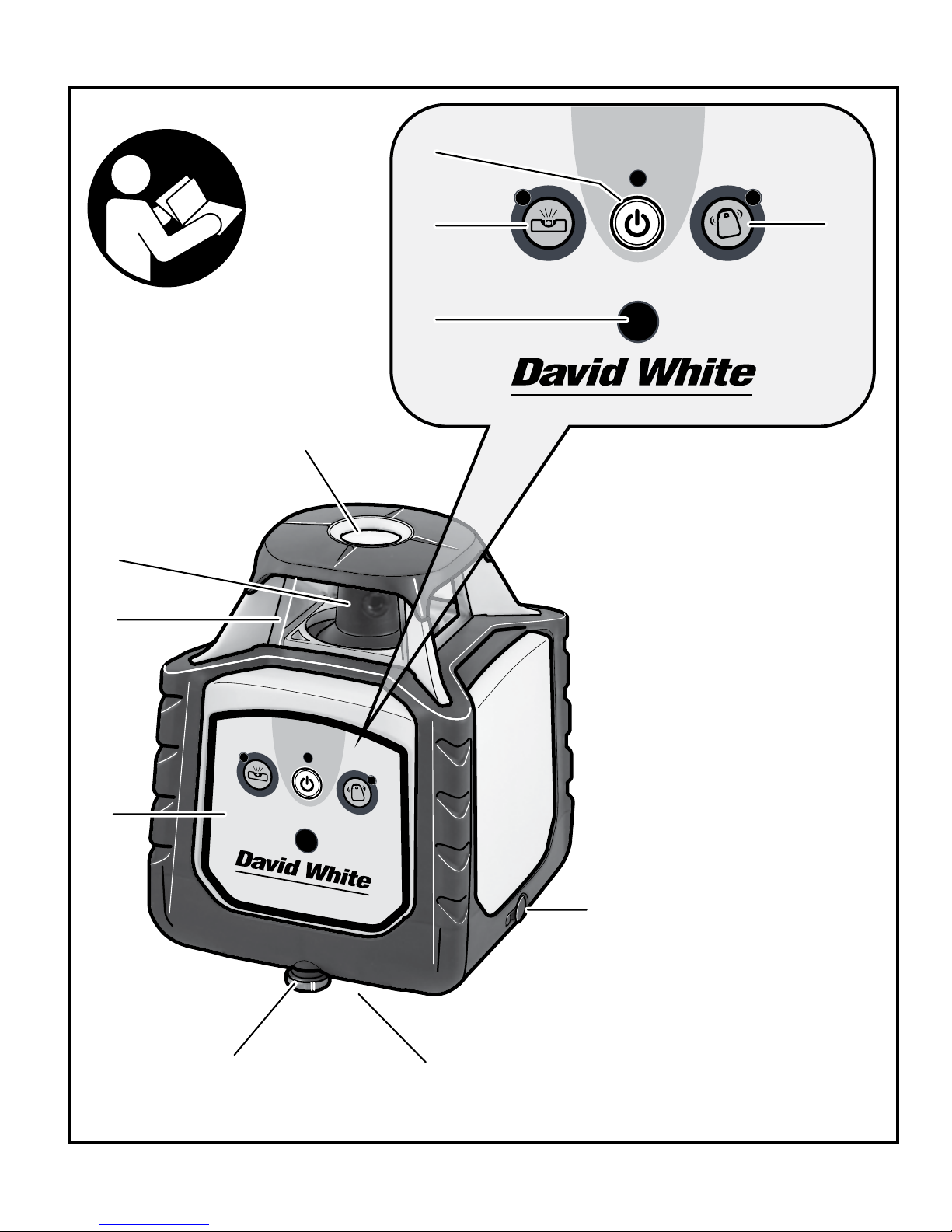

3900HV

7

3900HV

d

b

a

c

1

2

3

4

6

5

-4-

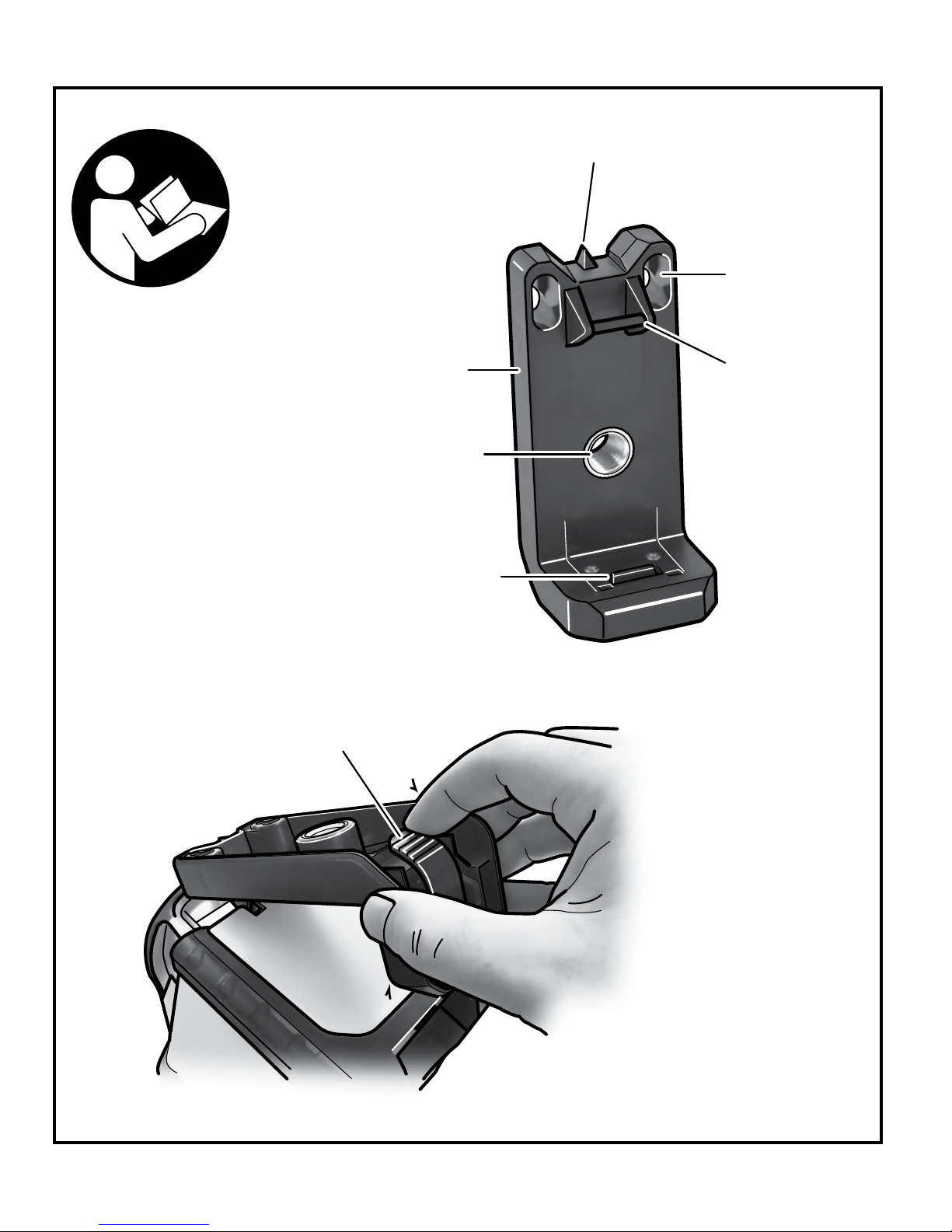

13

9

8

10

12

11

10

-5-

GENERAL SAFETY RULES

!WARNING Read all instructions. Failure to follow all instructions listed

below may result in hazardous radiation exposure, electric

shock, fire and/or serious injury.

If glass light house breaks when dropped, contact customer service

immediately. Broken glass can cause laceration hazard and unit to

lose its IP rating.

IEC 60825-1:2007-03

<

1 mW, 635 nm

DO NOT direct the laser beam at persons or animals and do not

stare into the laser beam yourself. This tool produces laser class 2

laser radiation and complies with 21 CFR 1040.10 and 1040.11

except for deviations pursuant to Laser Notice No. 50, dated June

24, 2007. This can lead to persons being blinded.

DO NOT remove or deface any warning or caution labels.

Removing labels increases the risk of exposure to laser radiation.

Use of controls or adjustments or performance of procedures other than those

specified in this manual, may result in hazardous radiation exposure.

ALWAYS make sure that any bystanders in the vicinity of use are made aware

of the dangers of looking directly into the laser tool.

DO NOT place the laser tool in a position that may cause anyone to stare into

the laser beam intentionally or unintentionally. Serious eye injury could result.

ALWAYS position the laser tool securely. Damage to the laser tool and/or

serious injury to the user could result if the laser tool falls.

ALWAYS use only the accessories that are recommended by the manufacturer

of your laser tool. Use of accessories that have been designed for use with

other laser tools could result in serious injury or unsatisfactory performance.

DO NOT use this laser tool for any purpose other than those outlined in this

manual. This could result in serious injury or unsatisfactory performance.

DO NOT leave the laser tool “ON” unattended in any operating mode.

DO NOT disassemble the laser tool. There are no user serviceable parts inside.

Do not modify the product in any way. Modifying the laser tool may result in

hazardous laser radiation exposure.

-6-

Work area safety

Keep work area clean and well

lit. Cluttered or dark areas invite

accidents.

DO NOT operate the laser tool around

children or allow children to operate

the laser tool. Serious eye injury

could result.

DO NOT use instruments, attachments

and accessories outdoors when

lightening conditions are present.

Electrical safety

Batteries can explode or leak, cause

injury or fire. To reduce this risk,

always follow all instructions and

warnings on the battery label and

package.

Remove the batteries from the tool

when not using it for extended

periods. When storing for extended

periods, the batteries can corrode

and discharge themselves.

DO NOT short any battery terminals.

DO NOT charge alkaline batteries.

DO NOT mix old and new batteries.

Replace all old batteries at the same

time with new batteries of the same

brand and type.

DO NOT mix battery chemistries.

Dispose of or recycle batteries per

local code.

DO NOT dispose of batteries in fire.

Keep batteries out of reach of

children.

Personal safety

Stay alert, watch what you are

doing and use common sense

when operating a tool. Do not use

a tool while you are tired or under

the influence of drugs, alcohol or

medication. A moment of inattention

while operating a tool may result in

serious personal injury or incorrect

measurement results.

Use safety equipment. Always wear

eye protection. Safety equipment

such as dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate

conditions will reduce personal

injuries.

DO NOT use the laser viewing glasses

as safety goggles. The laser viewing

glasses are used for improved

visualization of the laser beam, but

they do not protect against laser

radiation.

DO NOT use the laser viewing glasses

as sun glasses or in traffic. The

laser viewing glasses do not afford

complete UV protection and reduce

color perception.

DO NOT use any optical tools such

as, but not limited to, telescopes

-7-

or transits to view the laser beam.

Serious eye injury could result.

DO NOT stare directly at the laser

beam or project the laser beam

directly into the eyes of others.

Serious eye injury could result.

Use caution when using instruments

in the vicinity of electrical hazards.

Magnets

IEC 60825-1:2007-03

<

1 mW, 635 nm

Keep the tool and laser

detector away from

cardiac pacemakers. The

magnets of the tool and

laser detector generate a field that

can impair the function of cardiac

pacemakers.

Keep the tool and laser detector away

from magnetic data medium and

magnetically-sensitive equipment.

The effect of the magnets of the

tool and laser detector can lead to

irreversible data loss.

Use and care

Use the correct tool for your

application. The correct tool will do

the job better and safer.

Do not use the tool if the switch does

not turn it on and off. Any tool that

cannot be controlled with the switch

is dangerous and must be repaired.

Store idle tool out of the reach of

children and do not allow persons

unfamiliar with the tool or these

instructions to operate the tool.

Tools are dangerous in the hands of

untrained users.

Maintain tools. Check for

misalignment or binding of moving

parts, breakage of parts and any

other condition that may affect the

operation. If damaged, repair tool

before use. Many accidents are

caused by poorly maintained tools.

Use the tool, accessories, etc., in

accordance with these instructions

and in the manner intended for the

particular type of tool, taking into

account the working conditions and

the work to be performed. Use of

the tool for operations different from

those intended could result in a

hazardous situation.

SAVE THESE INSTRUCTIONS.

INTENDED USE

The instrument is intended for determining and checking precise horizontal

and vertical lines. The instrument is suitable for indoor and outdoor use.

-8-

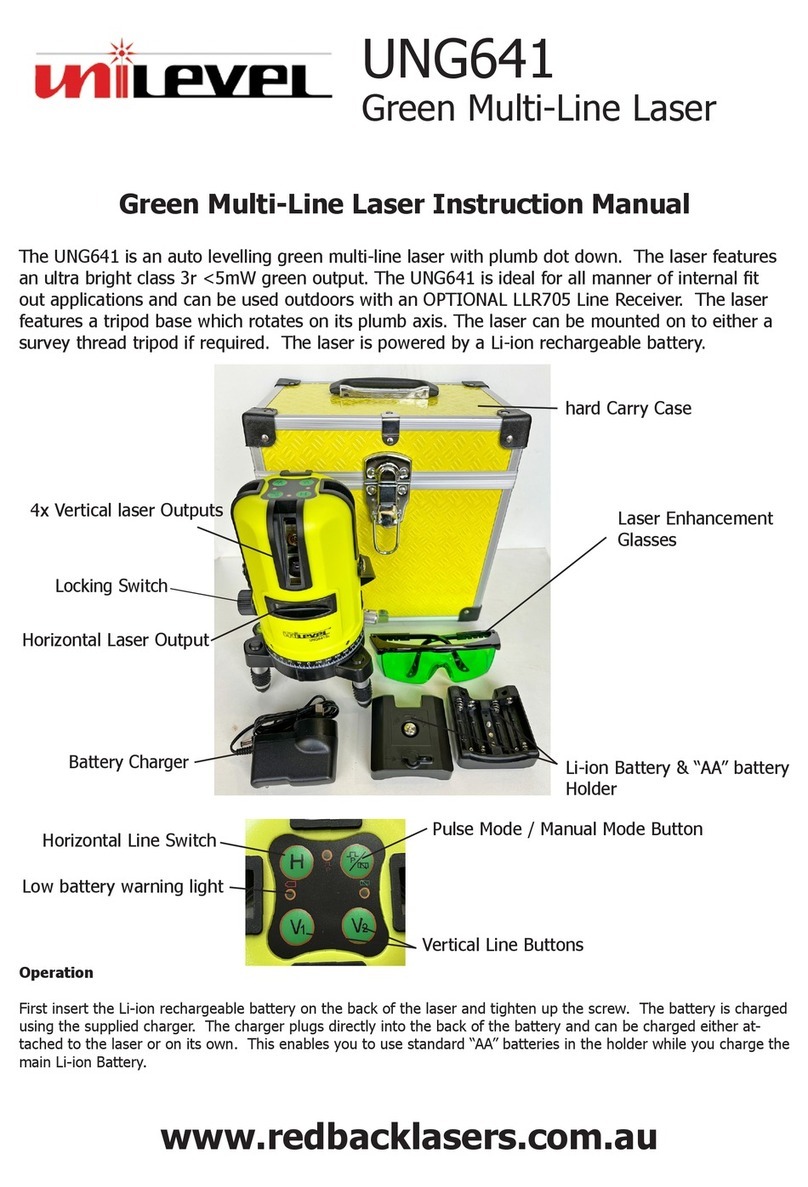

FEATURES

The numbering of the product

features shown refers to the

illustration of the instrument on the

graphic page.

1. Rotating Laser Beacon

2. Glass Lighthouse

3. Control Keypad

3a. On/Off button with Indicator

3b. Manual Mode Button with

Indicator

3c. ADS Button with Indicator

3d. Remote Sensor Window

4. Battery Compartment Screw

5. 5/8-11 Tripod Mount

6. Charger Port

7. Window for Plumb Beam

8. Trivet Attachment for Vertical

Laydown Positioning

9. 5/8-11 Tripod Mount

10. Mounting Clip with Lever

11. Trivet Hinge

12. Slots for Mounting

13. Alignment Marker for Laydown

Position

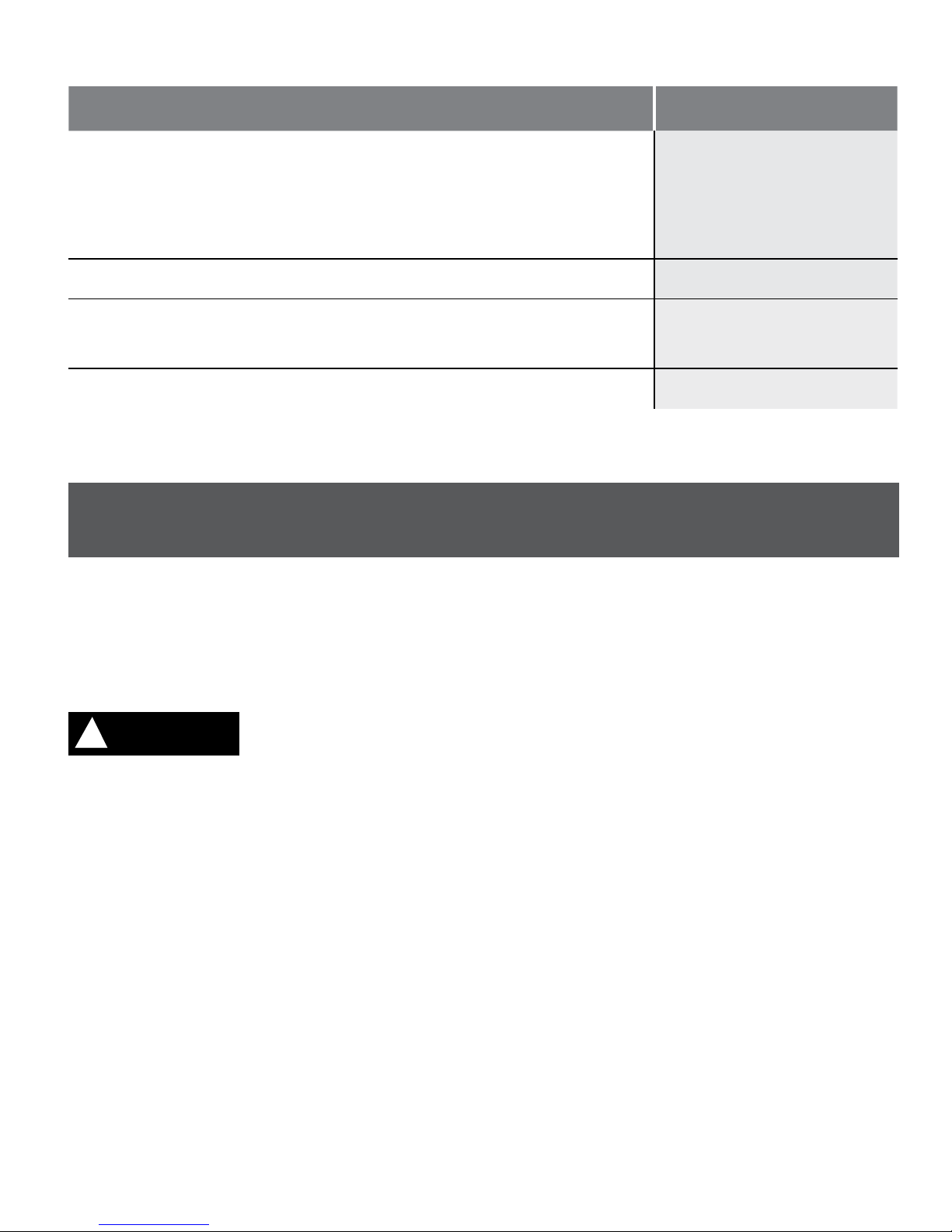

TECHNICAL DATA

Description 3900HV

Accuracy, Horizontal leveling 3/16-in at 100-ft

(4.5mm at 30m)

Accuracy, Vertical/Laydown 1/4-in at 100-ft

(6mm at 30m)

Working Range (diameter)

- without Laser Detector, approx.

- with Laser Detector, apprx.

100-ft (30m)

1000-ft (300m)

Rotational Speed (with Remote Control Only) 0, 120, 300, 600 RPM

Leveling Type (Degrees) Electronic (±5º)

Beam Rating Class 2M 635nm

-9-

PREPARATIONS

Description 3900HV

Power Supply 4-AA Cell, NiMh

Rechargeable Approx.

25hr.(Ni-MH);

Approx. 20hr (Alkaline)

Water/Dust Protection IP54

Dimension (with Trivet Attachment) 5.0 x 5.9 x 6.4-in

(127 x 150 x 163 mm)

Weight: 2.9 lb (1.3kg)

Inserting/Replacing Batteries

Rechargeable or alkaline batteries

are suitable for use to power your

instrument.

!WARNING Always replace all

alkaline batteries at

the same time. Only use batteries

from one brand and with the identical

capacity.

Remove the batteries/pack from the

tool when not using it for extended

periods. When storing for extended

periods, the batteries can corrode and

discharge themselves.

Un-screw the battery compartment

screw 4 at the bottom front of

instrument base. Remove the

batteries.

Use either alkaline batteries or

Ni-Mh batteries. When inserting

alkaline batteries, pay attention to

the correct polarity according to the

representation on the inside of the

battery compartment. Always replace

all batteries at the same time. Only

use batteries from one brand and

with the identical capacity.

Secure by tighten the screw 4into

the bottom of instrument base.

Remove the batteries from the

tool when not using it for extended

periods. When storing for extended

periods, the batteries can corrode

and discharge themselves.

-10-

OPERATION

!WARNING Do not subject the

instrument to

extreme temperatures or variations in

temperature. As an example, do not

leave it in vehicles for long time. In

case of large variations in

temperature, allow the instrument to

adjust to the ambient temperature

before putting it into operation. In

case of extreme temperatures or

variations in temperature, the

accuracy of the instrument can be

impaired.

Avoid heavy impact to or falling

down of the instrument. After severe

exterior effects to the instrument,

it is recommended to carry out an

accuracy check each time before

continuing to work.

Setting Up the Instrument

Position the instrument on a firm

surface in the horizontal or vertical

position, mount it to a tripod or to the

trivet mount 8with alignment unit.

The instrument reacts sensitively

to ground vibrations and position

changes. Therefore, pay attention

that the position of the instrument is

stable in order to avoid operational

interruptions due to re-leveling.

Switching On and Off

Press the Power ON/OFF 3a keypad

and allow the laser instrument to

self-level. If the power indicator LED

blinks, the voltage of the batteries

is low and batteries need to be

replaced or recharged.

The laser instrument can stand

alone on a level, sturdy surface

or preferably secured to a 5/8-11

tripod.

When the instrument is powered ON

it will automatically self-level. After

self-leveling, the laser instrument will

begin operating in Rotation Mode at

the speed of 600 RPM.

If the instrument is placed improperly,

or the slope of instrument exceeds

the range of +/-5°, the Power

indicator LED and the laser beam will

blink at the same time.

The instrument will shut down

automatically if the unit exceeds the

self-leveling system range for more

then 5 minutes.

-11-

OPERATION MODES

Variable Rotation Speed

(Remote Only)

The Variable Rotation Speed Mode

keypad

180°

10°

45°

90°

RPM

on the remote control will

give you the option of increasing or

decreasing the speed of the rotating

laser. Repeatedly pressing the

180°

10°

45°

90°

RPM

keypad will adjust the speed from

600, 300, 120, and 0 RPM.

Scanning or Sweeping

(Remote Only)

The Scanning Mode on the remote

control creates a shorter, brighter

laser “chalk line” that can be used for

leveling or plumbing. This feature can

also be used to keep the instrument

from interfering with other lasers

and detectors on site. Pressing the

Scanning Mode keypad

180°

10°

45°

90°

RPM

, will

lengthen or shorten the scan area

of the laser beam. There are five (5)

preset angles of 0°, 10°, 45°, 90°,

and 180°.

While in Scanning Mode, the

position of the scanning area can be

adjusted. Press the Clock-Wise

180°

10°

45°

90°

RPM

and Counter-Clock-Wise

180°

10°

45°

90°

RPM

Beam

Positioning keypads on the remote

control.

Slope/Automatic Mode

When the instrument is set upright for

horizontal rotation, the slope can be

adjusted by using Manual Mode 3b.

Press the Manual/Automatic keypad

180°

10°

45°

90°

RPM

, the instrument will enter into the

mode of manual adjustment.

The slope/automatic mode can also

be switch ON and OFF with the

remote control.

Anti-Drift System (ADS)

Enable to the ADS system 3c to alert

user when laser has been disturbed.

Press the ADS button

180°

10°

45°

90°

RPM

to activate.

When the LED is blinking slowly, the

laser is in H.I Alert mode. When the

light is blinking quickly, the laser level

will not level as it has been disturbed

and needs reset.

Vertical Laydown Positioning

Using the trivet 8, place the laser

instrument in the laydown position on

a flat, level surface.

Press the Power ON/OFF 3a keypad.

Allow the instrument to self-level.

-12-

ACCURACY CHECK

The ambient temperature has

the greatest influence. Especially

temperature differences occurring

from the ground upward can divert

the laser beam. The deviations play a

role in excess of approx. 65-ft (20m)

measuring distance and can easily

reach two to four times the deviation

at 330-ft (100m). Because the largest

difference in temperature layers is

close to the ground, the instrument

should always be mounted on a

tripod when measuring distances

exceeding 65-ft (20m). If possible,

also set up the instrument in the

center of the work area.

Checking the Leveling Accuracy

Apart from exterior influences,

device-specific influences (such as

heavy impact or falling down) can

lead to deviations. Therefore, check

the accuracy of the instrument each

time before starting your work. A

free measuring distance of 165-ft

(50m) on a firm surface is required for

the check. A reversal measurement

must be carried out over both axes X

and Y (each positive and negative; 4

complete measurements).

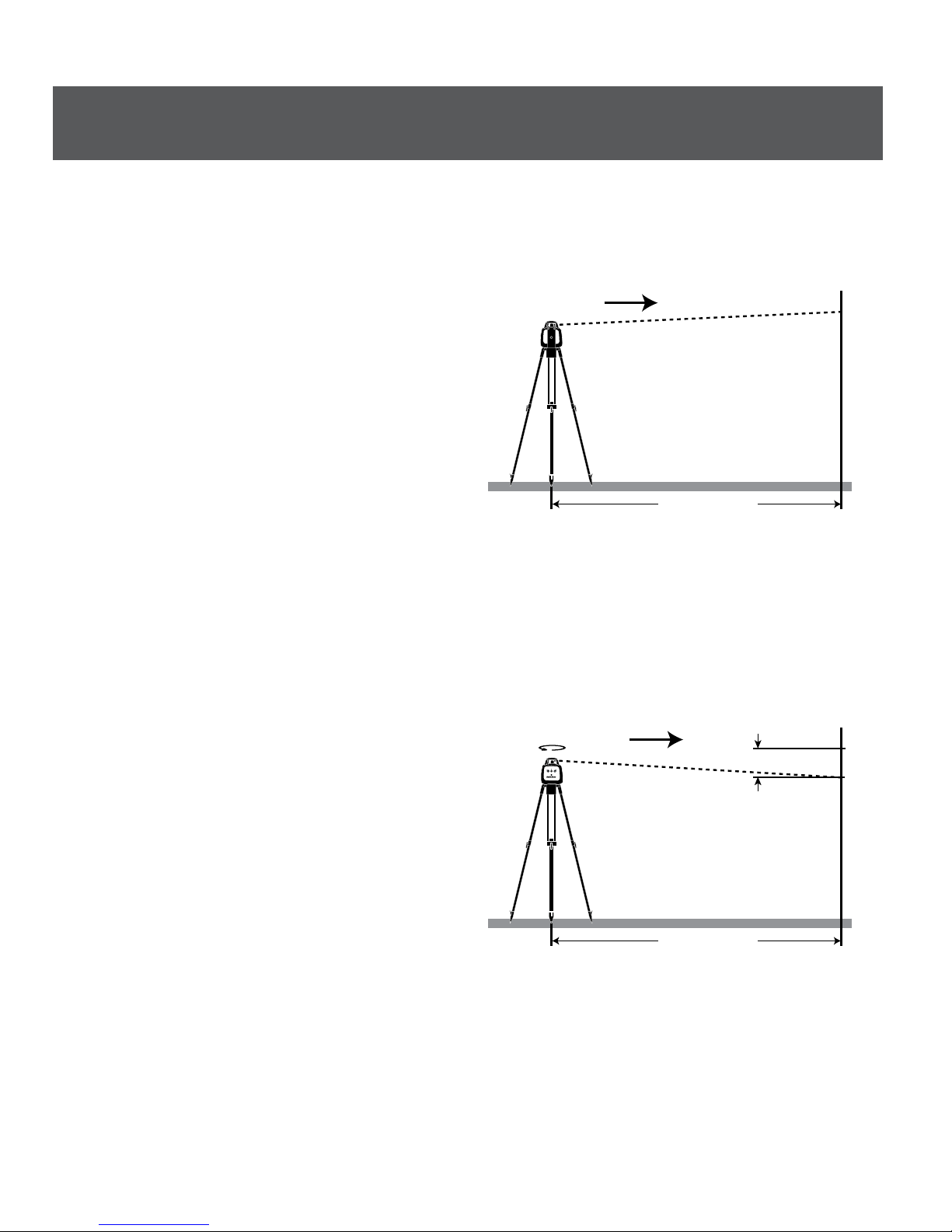

– Mount the instrument in the

horizontal position onto a tripod

or place it on a firm and level

surface 100-ft (30m) from a wall.

Switch the instrument on. Position

the X-axis to aim to wall or target

plate.

100 ft (30 m)

H1

Y1

100 ft (30 m)

H1

H2

Y2

100 ft (30 m)

1.5-ft

(0.5 m)

A

H1

B

100 ft (30 m)

1.5-ft

(0.5 m)

A

H1 H2

B

100 ft (30 m) 1.5-ft

(0.5 m)

A

H1

D

H3 H2

B

100 ft (30 m) 1.5-ft

(0.5 m)

A

H1 H2

B

D

180°

100 ft (30 m)

H1

X1

100 ft (30 m)

H1

H2

X2

D

180°

180°

180°

3900HV

–

After the leveling, mark the center of

the laser beam on wall (point H1).

– Rotate the instrument by 180°,

allow it to level in and mark the

center point of the laser beam on

the wall (point H2).

100 ft (30 m)

H1

Y1

100 ft (30 m)

H1

H2

Y2

100 ft (30 m)

1.5-ft

(0.5 m)

A

H1

B

100 ft (30 m)

1.5-ft

(0.5 m)

A

H1 H2

B

100 ft (30 m) 1.5-ft

(0.5 m)

A

H1

D

H3 H2

B

100 ft (30 m) 1.5-ft

(0.5 m)

A

H1 H2

B

D

180°

100 ft (30 m)

H1

X1

100 ft (30 m)

H1

H2

X2

D

180°

180°

180°

3900HV

– The difference Dof both marked

points H1 and H2 on wall is the

actual deviation of the instrument

for the measured axis.

-13-

The value of D(deviation) should be

less than or equal to 3/16-in (4.5mm).

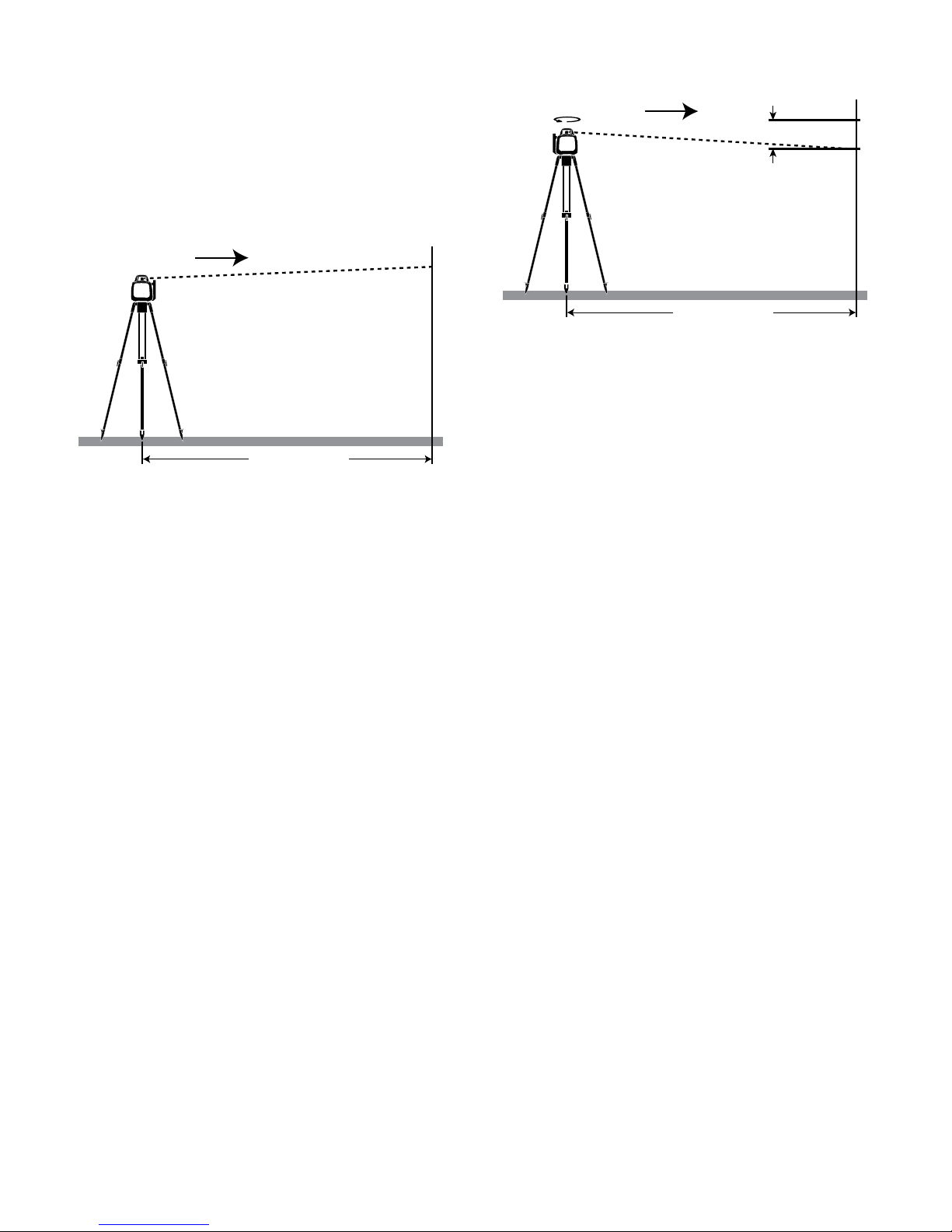

Repeat the measuring procedure for

the Y-axis. Position the Y-axis to aim

to a wall or target plate.

100 ft (30 m)

H1

Y1

100 ft (30 m)

H1

H2

Y2

100 ft (30 m)

1.5-ft

(0.5 m)

A

H1

B

100 ft (30 m)

1.5-ft

(0.5 m)

A

H1 H2

B

100 ft (30 m) 1.5-ft

(0.5 m)

A

H1

D

H3 H2

B

100 ft (30 m) 1.5-ft

(0.5 m)

A

H1 H2

B

D

180°

100 ft (30 m)

H1

X1

100 ft (30 m)

H1

H2

X2

D

180°

180°

180°

3900HV

– After the leveling, mark the center

of the laser beam on wall (point

H1).

– Rotate the instrument by 180°,

allow it to level in and mark the

center point of the laser beam on

the wall (point H2).

100 ft (30 m)

H1

Y1

100 ft (30 m)

H1

H2

Y2

100 ft (30 m)

1.5-ft

(0.5 m)

A

H1

B

100 ft (30 m)

1.5-ft

(0.5 m)

A

H1 H2

B

100 ft (30 m) 1.5-ft

(0.5 m)

A

H1

D

H3 H2

B

100 ft (30 m) 1.5-ft

(0.5 m)

A

H1 H2

B

D

180°

100 ft (30 m)

H1

X1

100 ft (30 m)

H1

H2

X2

D

180°

180°

180°

3900HV

– The difference Dof both marked

points H1 and H2 on wall is the

actual deviation of the instrument

for the measured axis.

The value of D(deviation) in either

axis should be less than or equal to

3/16-in (4.5mm).

If the instrument should exceed

the maximum deviation in anyone

of the measuring procedures, have

it checked at a SitePro after-sales

service agent.

-14-

The 3900HV includes a remote

control.

!WARNING Have the remote

control repaired

only through a qualified repair person

and only using identical replacement

parts. This will ensure that the

functionality of the remote control is

maintained.

Do not operate the remote control in

explosive atmospheres, such as in

the presence of flammable liquids,

gases or dusts. Sparks can be

created in the remote control which

may ignite the dust or fumes.

The remote control can be used up

to a maximum of 65 feet (20m) away

from the instrument.

The remote must be pointed

towards the instrument for proper

operation. All the features of the

4200HV can be controlled using the

remote.

Requires 2 ‘AA’ Alkaline batteries.

RC420 REMOTE CONTROL

LD20

RC390

RPM

180°

10°

45°

90°

4

9

10

5

6

3

2

1

8

7

c

b

e

fg

a

d

-15-

LD20 DETECTOR

The detector aids in locating and targeting a visible or invisible beam emitted by

a rotary laser instrument; perfect for use in outdoor conditions, where sunlight

and distance may make locating the beam more difficult.

The laser detector includes a rod clamp which allows to mount the detector

onto square, round or oval sighting rods.

LD20 FEATURES

LD20

RC390

RPM

180°

10°

45°

90°

4

9

10

5

6

3

2

1

8

7

c

b

e

fg

a

d

-16-

Inserting/Replacing the Battery

9V alkaline battery is recommended

for the tool. Pull the latch of battery lid

outward and open the battery lid.

When the batteries are low, the

battery low indicator gwill display.

Remove the battery when not using it

for extended periods. When storing

for extended periods, the battery can

corrode and discharge.

LD20 PREPARATIONS

The numbering of the product

features shown refers to the

illustration of the tool above.

1. On/Off switch

2. Center mark

3. LCD Display

3a. “Fine” adjustment indicator

3b. “Coarse” adjustment indicator

3c. Direction indicator “move

downward”

3d. Center indicator

3e. Direction indicator “move upward”

3f. Audio signal indicator

3g. Battery low indicator

4. Reception area for the laser beam

5. Button for adjustment of measuring

accuracy

6. Spirit level

7. Speaker

8. Audio signal button

9. Locking screw for leveling rod

10. Magnetic mounts

-17-

Store and transport the tool only in

the supplied protective case.

Keep the tool clean at all times.

Do not immerse the tool into water or

other fluids.

Wipe off debris using a moist and soft

cloth. Do not use any cleaning agents

or solvents.

Regularly clean the surfaces at the

exit opening of the laser in particular,

and pay attention to any fluff of fibers.

If the tool should fail despite the care

taken in manufacturing and testing

procedures, repair should be carried

out by an authorized after-sales

service center for Dave White’s SitePro

instruments.

In all correspondence and spare parts

orders, please always include the

model number and serial number of

the instruments.

All precision instruments should

be cleaned, lubricated, checked

and adjusted ONLY at a qualified

instrument repair station or by the

manufacturer, at least once a year.

In case of repairs, send in the

instrument packed in its protective

case.

ENVIRONMENT PROTECTION

Recycle raw materials

& batteries instead of

disposing of waste.

The unit, accessories,

packaging & used

batteries should be

sorted for environmentally friendly

recycling in accordance with the

latest regulations.

MAINTENANCE AND SERVICE

-18-

LIMITED WARRANTY

Dave White’s SitePro (“Seller”) warrants to the original purchaser only, that

all David White laser tools and optical instruments will be free from defects in

material or workmanship for a period of two (2) years from date of purchase.

SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under

this Limited Warranty and, to the extent permitted by law, any warranty or

condition implied by law, shall be the repair or replacement of parts, without

charge, which are defective in material or workmanship and which have not

been misused, carelessly handled, or misrepaired by persons other than

Seller or Authorized Service Center. To make a claim under this Limited

Warranty, you must return the complete laser, optical instrument or David

White product, transportation prepaid, to SITEPRO Service Department or

Authorized Service Center. Please include a dated proof of purchase with your

tool. For locations of nearby service centers, please call 1-855-354-9881.

THIS LIMITED WARRANTY DOES NOT APPLY TO ACCESSORY ITEMS

SUCH AS TRIPODS, RODS, HAND LEVELS, FIELD SUPPLIES, TAPES,

MOUNTING DEVICES AND OTHER RELATED ITEMS. THESE ITEMS

RECEIVE A 90 DAY LIMITED WARRANTY.

To make a claim under this Limited Warranty, you must return the complete

product, transportation prepaid. For details to make a claim under this

Limited Warranty please visit www.davidwhite.com or call 1-855-354-9881.

ANY IMPLIED WARRANTIES SHALL BE LIMITED IN DURATION TO ONE

YEAR FROM DATE OF PURCHASE. SOME STATES IN THE U.S., AND

SOME CANADIAN PROVINCES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY

NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT LIMITED TO

LIABILITY FOR LOSS OF PROFITS) ARISING FROM THE SALE OR USE

OF THIS PRODUCT. SOME STATES IN THE U.S., AND SOME CANADIAN

-19-

PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND

YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE

TO STATE IN THE U.S., OR PROVINCE TO PROVINCE IN CANADA AND

FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO PRODUCTS SOLD WITHIN

THE UNITED STATES OF AMERICA, CANADA AND THE COMMONWEALTH

OF PUERTO RICO. FOR WARRANTY COVERAGE WITHIN OTHER

COUNTRIES, CONTACT YOUR LOCAL SITEPRO DEALER OR IMPORTER.

David White is a registered trademark and offered exclusively by SitePro.

42348D3900 09/15 Printed in China

© Dave White’s SitePro 7619 S 1150 E Otterbein, IN 47970

Tel. +1 (765) 581 4097

Table of contents

Other David White Laser Level manuals