Davnor SA 60 Instruction manual

i

Automated Surface Water Treatment

System

INSTALLATION, OPERATIONS &

MAINTENANCE MANUAL

ii

Table of Contents

1. Introduction ......................................................................................................1

2. Operations Summary .......................................................................................1

3. Assembly..........................................................................................................2

4. Filter Media Installation ....................................................................................6

5. System Commissioning....................................................................................7

6. Sanitizing Procedure........................................................................................8

7. System Start-Up...............................................................................................9

8. Operation .........................................................................................................9

9. Filter Maintenance..........................................................................................10

10. Degassing the Filter Media...........................................................................11

11. Winterization ................................................................................................11

12. Refilling ........................................................................................................12

13. Decommissioning / Moving ...........................................................................12

14. Trouble Shooting...........................................................................................13

1

1Introduction

Davnor Water Treatment Technologies Ltd. has developed a treatment system featuring an

intermittently operated slow sand filtration process. It is based on the continuous slow sand

filtration process that has been used for over 100 years. The BioSand Water Filter has

proven effective in removing iron (and iron bacteria), manganese, sulphur odours and other

obnoxious smells, turbidity, colour, bacteria, viruses and water borne parasites from drinking

water supplies. Do not attempt to treat wastewater, heavily polluted or contaminated water.

Please contact a Davnor representative if there is any uncertainty regarding the treatability

of the water.

2Operations Summary

The Davnor Water Treatment Technologies Ltd. surface water system is a slow sand

filtration process. The operation of the system is automated for the removal of giardia

cysts, cryptosporidia oocysts, other water borne parasites, bacteria, viruses, turbidity

and colour. The water is pumped or gravity fed to the filter. The water flows by gravity

through the filter and then the filtered water flows to a storage tank and is re-pressurized

for use or further treatment.

2

3Assembly

Important Note: Read the full set of instructions before beginning assembly.

You will be required to provide the following:

•Connection to the untreated water source

•120 V electrical outlet for the pump and the solenoid valve

•Connection to the distribution line

•Connection to a drain or sump for drainage and overflow lines (optional drainage

packages are available)

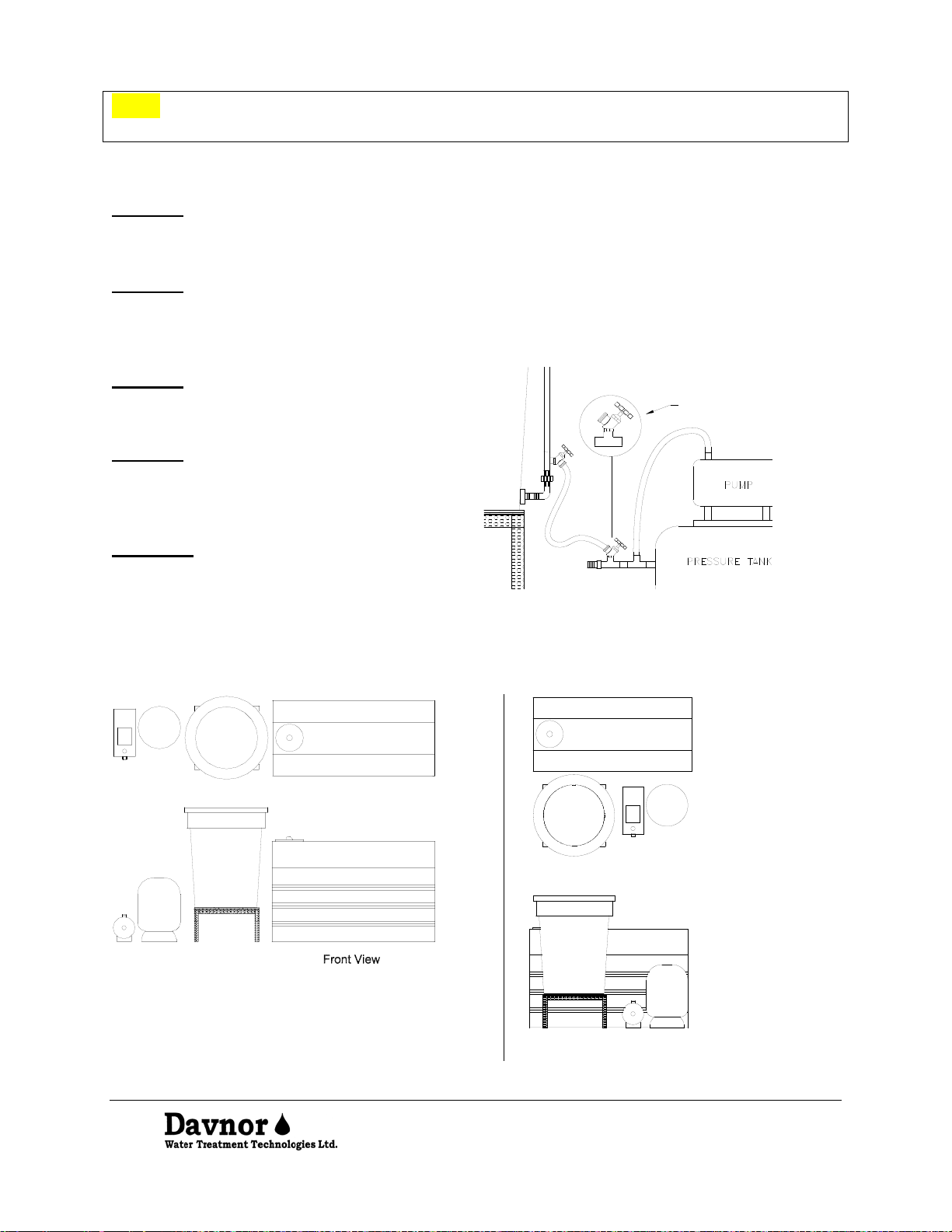

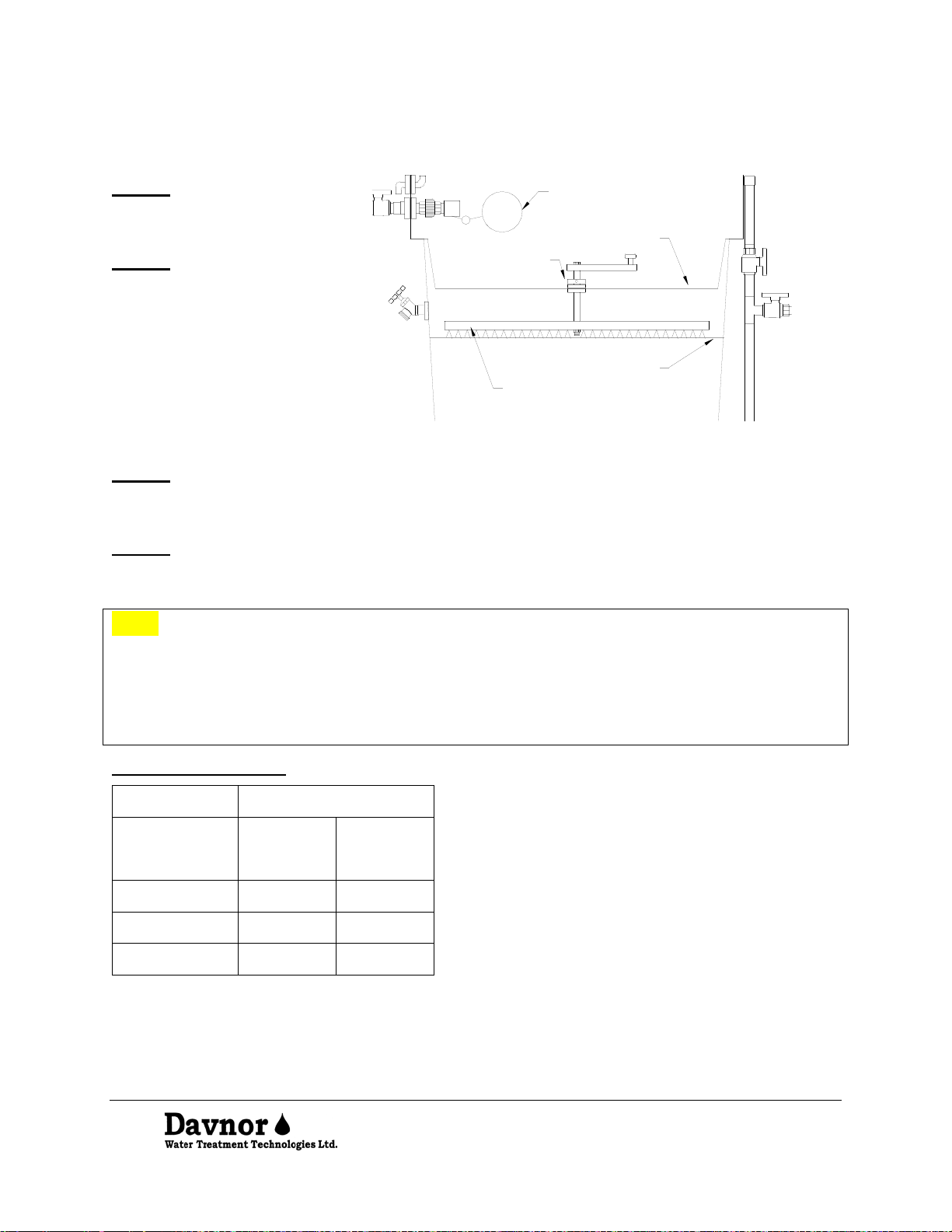

Locate System Components

•Ensure you have all the required parts and materials for assembling the system

(figure 3-1).

•Arrange the components for ease of installation and maintenance. Consider the

location of the untreated water inlet, floor drain or drainage pipe and electrical outlet.

•Place the filter on the stand, place the storage tank, pump and pressure tank.

Note: A qualified plumber should make the connection from the untreated water inlet to

the filter system and the filtered water outlet to the distribution line. Your pump and your

solenoid valve may need to have electrical plugs attached to them. This work should be

performed by a qualified electrician.

•Install a system bypass in case there is ever a need to take the system off line.

Table 1- Flow Rates and Dimensions

Model No.

Flow Rate (nominal)

Filter Dimensions

Storage Tank

L/m

gpm

Diameter (cm)

Height

(cm)

Capacity

(gallons)

Dimensions

(cm) LWH

Top

Bottom

SA 60

1

0.25

49

29

94

200

150 x 70 x 90

SA 120

2

0.5

64

42

94

200

150 x 70 x 90

SA 240

4

1.0

78

58

94

200

150 x 70 x 90

3

24

19 20

18

13

17

4

2

8

1

11

16

5

6

7

26

27

12 25

15

9

14

10

23 22

3

21

Figure 3-1 Automated System Layout

1. BioSand Filter

2. Filter Stand

3. Storage Tank

4. Raw Water Inlet

5. Filter Inlet Valve

6. Filter Float Valve with Union Connection

7. Clean In Place (CIP) and Diffuser Basin

8. Underdrain

9. Flow Rate Control Valve

10. Filter Standpipe

11. Standpipe Union Connection

12. Standpipe Lower Valve

13. Maintenance Drain Valve

14. Filter Outlet Valve

15. Anti-siphon Valve

16. Filter Overflow

17. Solenoid Valve (to high level float switch)

18. Storage Tank Inlet Valve with Union

Connection

19. Sampling Valve

20. Storage Tank Float Valve

21. High Level Float Switch (to the solenoid valve)

22. Low Level Float Switch (to the pump)

23. Storage Tank Outlet with Union Connection,

Shutoff Valve and Drain Valve

24. Check Valve

25. Pump Electrical Outlet (to the low level float

switch)

26. Clean In Place (CIP) Reverse Flow (attached to

standpipe lower valve)

27. To Distribution or Further Treatment (softener,

Reverse Osmosis, UV)

4

Important Notes:

•All of the assembled components have been loosely fitted together. Use

Teflon tape on all threaded connections and tighten. Do Not Over-Tighten the

PVC fittings. (They will crack if over-tightened)

•Refer to Figure 1 to find the locations for all system components.

•Heat the end of hose connections in hot water before installing. Use the gear

clamps to fasten the hose to the barb fitting.

Install Assembled System Components

Step 1. Locate and attach the BioSand water filter assemblies.

•

Inlet assembly.

•Maintenance drain valve

•Overflow assembly

•Standpipe

Step 2. Locate and attach the filtered water storage tank assemblies.

•Inlet assembly.

•Outlet assembly.

•Overflow assembly.

Step 3. Place the pump and pressure tank.

Step 4. Install the low level and high level float switches in the storage tank shown in

Figure 3 -1. To do this, start by removing the supporting ring on the manway of the

filtered water storage tank. Position the low level switch near the bottom of the filtered

water storage tank and the high level switch near the top. Use the notched grooves to

locate the cords for the switches. Replace the supporting manway ring to hold the level

switches in place.

Piping Connections

Step 5. Using the ¾” braided hose for connection between the barbed fittings;

•Connect the raw water supply to the solenoid valve inlet.

Look for the flow direction on the solenoid body.

•Connect the solenoid outlet to the filter inlet.

5

Note: The solenoid can either be attached directly to the filter inlet or mounted to the

filter stand or another convenient location.

•Connect the filter outlet at the filter outlet valve to the filtered water storage tank

inlet.

Step 6. Using the 1” braided hose for connection between the barbed fittings;

•Connect the filtered water storage tank outlet to the pump inlet.

•Connect the pump outlet to the pressure tank.

Step 7. Connect the overflows to the floor drain or sump. Use a separate drain line for

the filtered water storage overflow. This will prevent a cross connection between the

filter and the filtered water storage tank. Leave an air space between the overflow drain

line and the drain to prevent the drain from backing up into your filter.

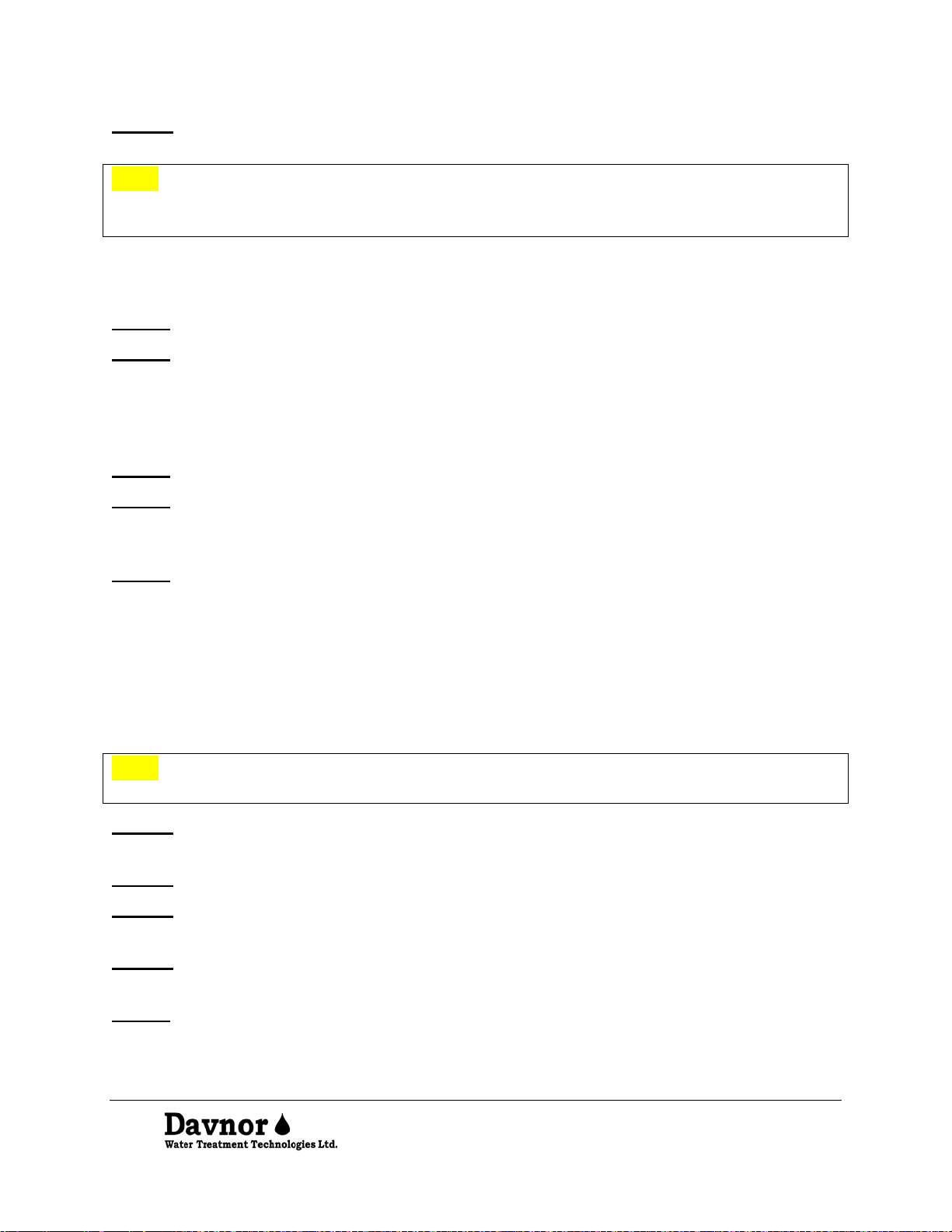

Step 8. Install the filter CIP reverse flow

assembly downstream of the pump (figure

3-3).

Step 9. Connect the hose from the CIP

reverse flow valve downstream of the

pump to the lower valve on the filter

standpipe.

Step 10. Connect the filtered water outlet

downstream of the CIP reverse flow to the

distribution system.

CIP reverse

flow assembly

Figure 3-3

Figure 3-4 Typical System Layouts

Top View

Filter

BioSand

Pump

&

Pressure

Tank

Filter

BioSand

Storage Tank

Filtered Water

Storage Tank

Filtered Water

Pump

&

Pressure

Tank

Front View

BioSand

Filter

BioSand

Filter Storage Tank

Filtered Water

Top View

Filtered Water

Storage Tank

6

4Filter Media Installation

Step 1. Leak test the filter. Close all valves

except the flow rate control valve and fill the

filter with water to the maximum water level.

Drain the filter and repair any leaks before

installing the filter media.

Step 2.

Ensure all the filter valves are

closed. Fill the filter 1/3 full with water. You

can use the water you will be filtering for this

purpose.

Note:Always add the sand to water in

order to prevent air locking in the sand

bed of the filter. The sand should be

poured quickly to prevent lensing,

which will reduce the filter’s flow rate.

You will need to add more water as the

sand is being added. When adding

additional water, pour it through the

diffuser to prevent mixi

ng of

previously installed sand layers.

Approximately 15 cm of water above

the sand is desirable.

Step 3.

Add the underdrain gravel to the

level indicated (figure 4-1).

Step 4.

Level the surface of the

underdrain gravel. Referring to Figure 4-

1, add the #3 sand to the le

vel indicated

on the filter body. Repeat this procedure

with the #2 sand and the #1 sand.

Note: There may be more sand than

required. Do not over fill the sand levels.

However, since the #2 sand tends to settle,

it is acceptable to overfill the #2 sand by a

centimetre above the indicated level.

Underdrain Gravel

Paused Water Level

Maximum Water Level

#3 Sand

#2 Sand

#1 Sand

8cm

5cm

35cm

5cm

Figure 4-1 Filter Media and Filter Water Levels

Step 5. After all of the media has been installed, use the maintenance drain on the side

of the filter to drain the dirty water off the surface.

7

5System Commissioning

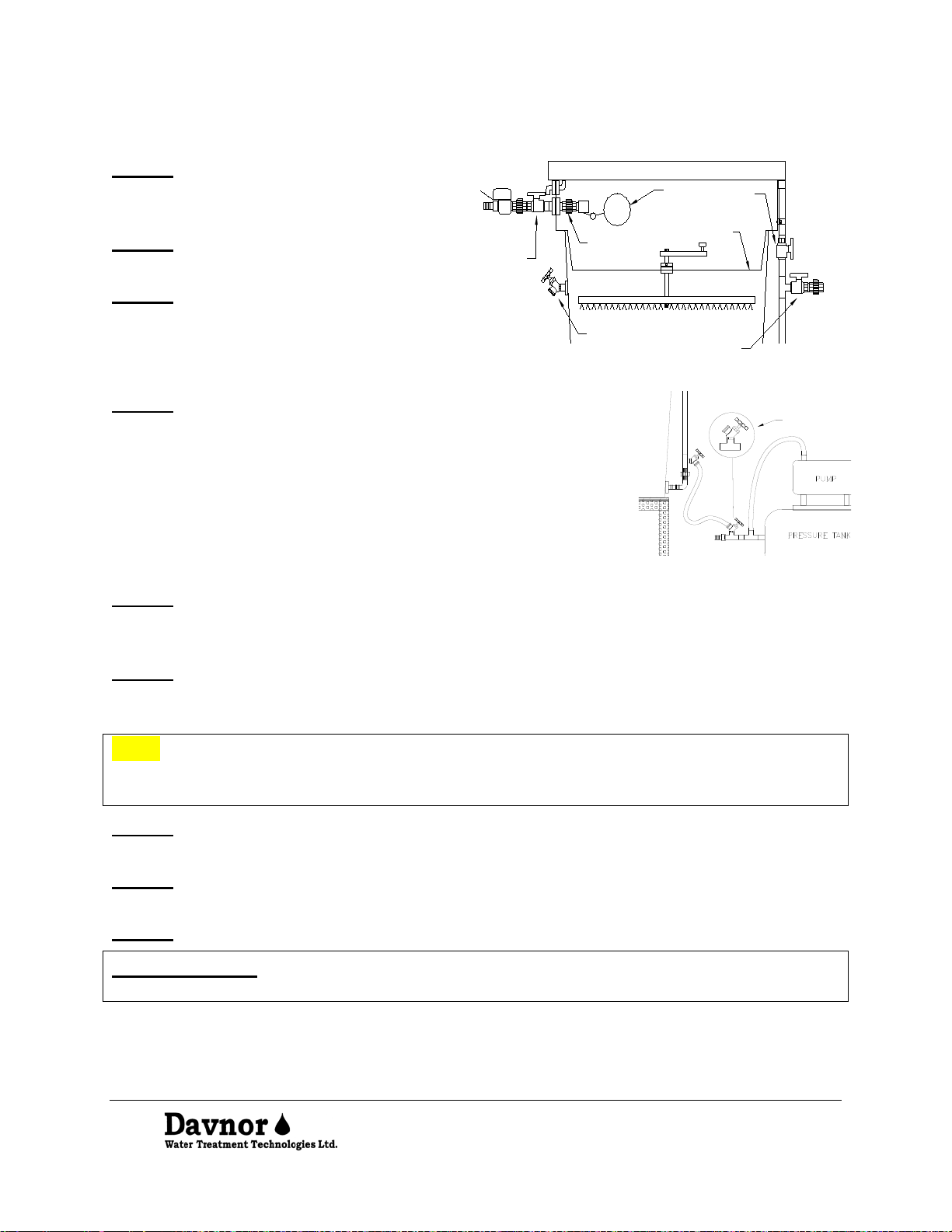

Step 1. Begin by ensuring all

valves are in the closed

position.

Step 2.

Place the diffuser

basin into the filter. Adjust the

height of the CIP cleaning

arm, using the set screw

collar, so that it rests on the

surface of the filter media.

Attach t

he filter float valve

(figure 5-1).

Surface of filter media

Set screw collar

Diffuser basin

CIP cleaning arm

Filter float valve

Figure 5-1

Step 3. Plug the solenoid valve electrical outlet into the storage tank upper float switch in a

piggyback fashion and plug into the wall outlet. Test the solenoid by moving the upper float

switch. The solenoid valve should open when the float switch is moved to the down position.

Step 4. Open the filter inlet valve to begin filling. Adjust the mechanical float valve in the

filter such that the water level does not go higher than the filter overflow. Now wait until the

water level reaches the maximum water level in the filter (Figure 4-1).

Note: See Table 2 to obtain the filter flow rate. It is critical that the filter be operated at this

flow. Faster flows will compact the upper sand layer, increase filter maintenance

requirements, and may cause poor filter performance. To ensure that this flow rate is

maintained the flow rate control valve should be set for the nominal flow rate as described in

the following steps and not moved from that position unless there is a significant change in

the inlet water temperature.

Table 2- Flow Rates

Model No.

Flow Rate (nominal)

L/m

gpm

SA 60

1

0.25

SA 120

2

0.5

SA 240

4

1.0

8

Step 5. Open the anti-siphoning

valve. Close the storage tank

inlet valve. Op

en the sampling

valve at the storage tank inlet

(Figure 5-

2). Be prepared to

collect water from this point

during the next step.

Step 6.

Set the flow rate by

adjust

ing the flow rate

adjustment valve on the

standpipe. until the flow through

the sampling valve matc

hes the

value in Table 2. The flow can

be measured by timing how long

it takes to fill a 2-litre pop bottle.

Anti-siphoning

valve

Storage tank

inlet valve

Filter outlet

valve

Sampling

valve

Flow rate

adjustment

valve

Figure 5-2

Step 7. Connect a hose to the sampling valve at storage tank inlet and begin flushing water

through the filter. Flush the filter until the water becomes clear. Close the sampling valve.

6Sanitizing Procedure

Care is taken during the manufacture of your water filter to keep it clean and sanitary.

However, during shipping, storage, installation and operation, bacteria could get into the

water filter piping. For this reason, sanitizing is recommended after installation. On

some water supplies, additional periodic sanitizing is also recommended.

Step 1. Prepare a dilute bleach solution for

sanitizing by mixing 5 ml of common household

bleach (Javex, Clorox, etc.) with 1 litre of water.

Step 2. Close the filter inlet valve and allow the

filter water level to drop to the “paused” level.

Close the storage tank inlet valve. Attach the refill

hose to the lower valve on the filter standpipe.

Insert a funnel into the end of the hose. Ensure

the flow rate adjustment valve and the anti-

siphoning valve are open. Open the lower valve

on the filter standpipe (figure 6-1).

Step 3. Hold the end of the hose at the same

height as the top of the filter. Pour the solution

into the funnel. Close the lower valve on the filter

standpipe. Let the solution “sit” for 20 minutes.

This will give sufficient contact time for the

sanitizing solution to kill any bacteria that may be

present.

Standpipe

lower valve

valve

Storage tank

inlet valve

Sampling valve

Refill hose

Flow rate

adjustment

valve

Filter

outlet

valve

Figure 6-1

9

Step 4. Open the filter inlet valve. Flush the sanitizing solution through the sampling

valve.

Note: The filter will not achieve 100% removal of bacteria. If you do not have downstream

chlorine injection bacteria may colonize in the piping downstream of the filter and the storage

tank. Periodic sanitizing of the piping and storage tank will address this problem.

7System Start-Up

Step 1. Open the inlet valve to the filtered water storage tank and continue filtering water.

Step 2. Adjust the low-level float switch in the filtered water storage tank. The low level

float switch should be set such that the water level does not go below the storage tank

outlet. The mechanical float should be set such that the water level does not go above the

storage tank overflow. Adjust the high-level float switch in the filtered water storage tank.

The high-level float switch should be set at a level just below the mechanical float valve.

Step 3. Prime the distribution pump, following the pump manufacturer’s instructions.

Step 4. Plug the pump electrical outlet into the storage tank low level switch in a

piggyback fashion, and plug into the wall outlet. Test the pump by moving the lower float

switch. The pump should operate when the switch is moved to the ‘up’ position.

Step 5. Water should continue to run through the system until the water level in the

filtered water storage tank is just below the overflow. The high-level float switch should

close the solenoid valve and allow the filter to drain to the "paused" water level. The

mechanical float valve will stop the flow of water if the high-level float switch is out of

adjustment. Adjust the mechanical float valve and high-level float switch as required.

Check the system for plumbing leaks and repair as required.

8Operation

Note: In cases where extremely turbid water is being treated, it may be necessary to

perform filter maintenance immediately following installation.

Step 1. The system is operational once the filter flow rate has been set, water has

been flushed through the filter and the standpipe has been sanitized.

Step 2. Ensure the anti-siphoning valve is fully open during normal operation.

Step 3. To test the system, turn on a water source, such as a bath tap. The pump

should start up and draw water from the storage tank.

Step 4. Continue the water demand until you are sure the system is functioning well

and all mechanical floats and storage tank level switches are adjusted as specified.

Step 5. Your BioSand Filter system is now up & running. During normal operation, the flow

rate will decrease as the filter accumulates sediment on the top layer of sand. Once an

acceptable flow rate cannot be maintained, it will be necessary to perform maintenance on

the filter.

10

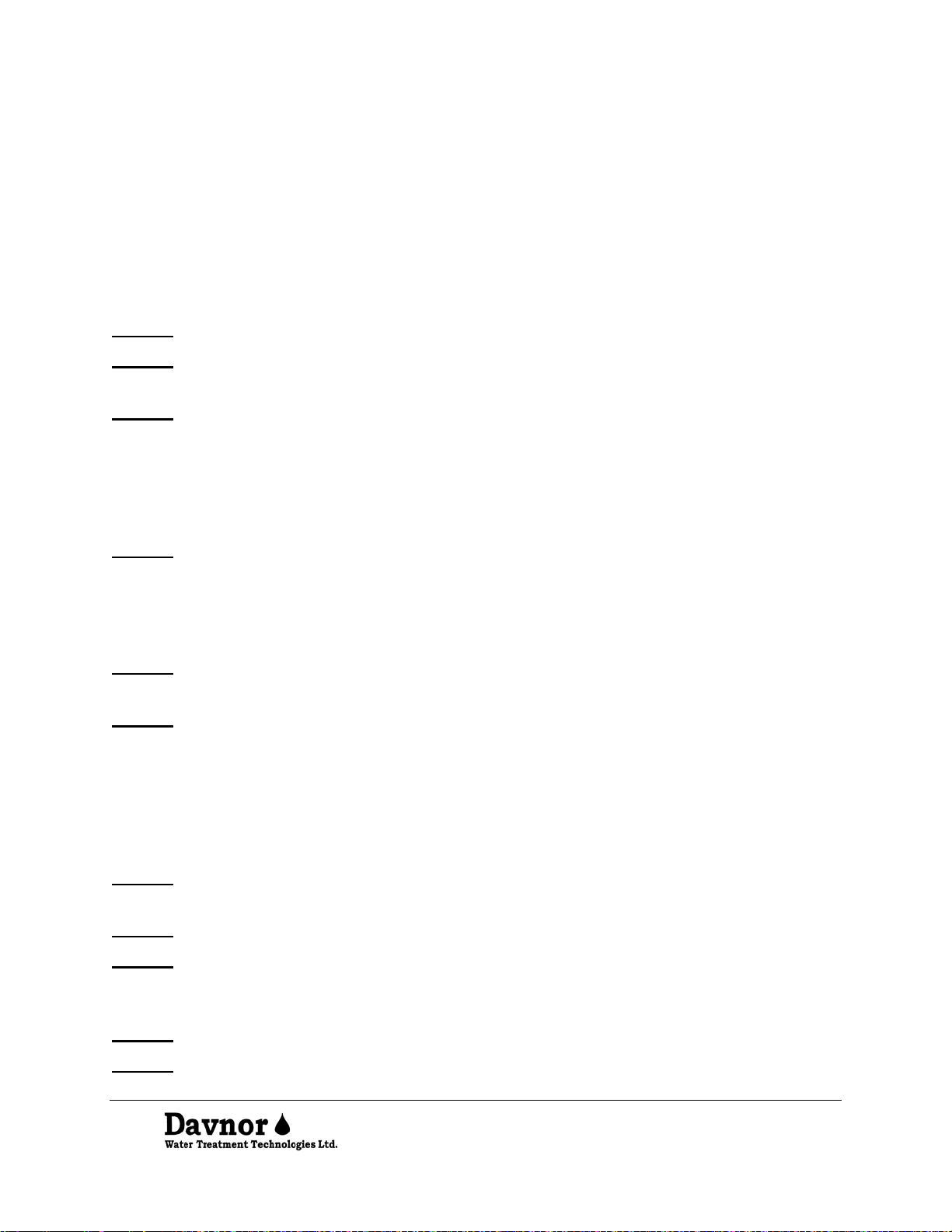

9Filter Maintenance

Step 1. Close the inlet valve to the filter.

Allow the filter to drain to its "paused"

level before beginning this procedure.

Step 2.

Close the filter outlet valve

(figure 9-1).

Step 3.

Remove the filter float valve

assembly at the union connection.

Anti-siphon

valve

Filter

outlet

valve

Float

valve

Union connection diffuser basin

Maintenance

drain valve

Filter

inlet

valve

Figure 9-1

Step 4. Connect the CIP hose to the CIP reverse flow valve

downstream of the pump. Open the valve to ens

ure that the

flow rate restriction device is limiting the flow rate to

approximately 4 litres per minute to prevent damage to the

filter media. Connect the

other end of the hose to the lower

valve on the filter standpipe (figure 9-

2). Open both valves

and dispel any air in the line through the anti-

siphoning valve.

Close the anti-siphoning valve.

CIP reverse

flow assembly

Figure 9-2

Step 5. Turn the handle on the clean in place (CIP) mechanism to agitate the top of the

sand while the water level is slowly filling from the bottom. Allow the water level to rise

until the diffuser basin is filled with water.

Step 6. Once the diffuser basin is full of water, stop stirring the CIP and wait for 30

seconds. Now flush the dirty water from the sand surface through the maintenance

drain.

Note: It is important to wait for 30 seconds after stirring the sand before flushing the

dirty water off the top of the filter media. This will prevent sand from being lost from the

top layer of the filter media.

Step 7. To restart the filter, close the filter maintenance drain valve, the CIP reverse

flow valve downstream of the pump and the lower valve on the filter standpipe.

Step 8. Re-attach the filter float valve assembly inside the filter. Open the inlet valve to

the filter and the anti-siphoning valve on the filter.

Step 9. Open the filter outlet valve.

SUGGESTION:Keep a maintenance log posted nearby to keep track of when the

filter is maintained.

11

10Degassing the Filter Media

Degassing is part of the normal filter maintenance procedure. In some situations, the

surface of the filter media may appear clean, but there is low flow. This is an indication

the filter media is air locked. This may be due to accidental de-watering of the filter or

the presence of dissolved gases (hydrogen sulphide, carbon dioxide, air, methane) in

the raw water source. Air locking in the filter bed will cause a reduction in the flow rate

through the filter. Remove the trapped gases from the filter media using the following

procedure.

Step 1. Close the filter inlet valve and outlet valve.

Step 2. Remove the filter float assembly at the union connection and remove the

diffuser basin to view the top surface of the sand.

Step 3. Connect the CIP hose to the CIP reverse flow valve downstream of the pump.

Open the valve to ensure that the flow rate restriction device is limiting the flow rate to

approximately 4 litres per minute to prevent damage to the filter media. Connect the

other end of the hose to the lower valve on the filter standpipe (figure 9-2). Open both

valves on the CIP hose and dispel any air in the line through the anti-siphoning valve.

Close the anti-siphoning valve.

Step 4. The water will slowly enter the filter from the bottom, expelling any trapped

gasses through the filter surface. Continue to bottom fill the filter until you don’t see any

more air bubbles surfacing. Be sure to run this for a minimum of 15 minutes to ensure

all gas pockets are filled with water. Periodically tap the sides of the filter during this

process. Drain excess water through the maintenance drain.

Step 5. To restart the filter, close the filter maintenance drain valve, the CIP reverse

flow valve downstream of the pump and the lower valve on the filter standpipe.

Step 6. Replace the diffuser basin. Re-attach the filter float assembly. Open the anti-

siphoning valve and the outlet valve.

11 Winterization

Do not allow the filter system to freeze when it is filled with water. Winterization

consists of the following steps.

Step 1. Perform a complete maintenance cycle on the BioSand Water Filter as

described in Section 9.

Step 2. Unplug the pump.

Step 3. Turn off the water supply and drain the filtered water storage tank and the

plumbing system. Make sure all water is drained from the pump head. (See the pump

manufacturer’s instructions.)

Step 4. Close the outlet valve and anti-siphoning valve.

Step 5. Undo the hose from the lower valve on the filter standpipe. Slowly drain all of

the water out of the sand bed using the standpipe lower valve.

12

12 Refilling the BioSand Water Filter

Step 1. Attach the refill hose to the lower

valve on the filter standpipe. Insert a funnel

into the end of the hose and hold it above the

filter. Pour water into the funnel, allowing

water to fill the filter from the bottom (figure

12-1).

Step 2. The water will slowly enter the filter

from the bottom, expelling any trapped gasses

through the filter surface. Continue to bottom

fill the filter until you don’t see any more air

bubbles surfacing. Periodically tap the sides

of the filter during this process. Drain excess

water off th

e media surface through the

maintenance drain.

Step 3.

To restart the filter, close the

maintenance drain

valve and follow the

procedure outlined in Section 5 of this manual

to start up the entire treatment system.

Standpipe

lower valve

Funnel

Anti-siphon

valve

Storage tank

inlet valve

Sampling valve

Refill hose

Flow rate

adjustment

valve

Filter

outlet

valve

Figure 12-1

13 Decommissioning / Moving

The system can be decommissioned and moved to a new location. Care must be taken to

label all parts and components for ease of re-installation.

Note: Do not move the filter with media in it.

Step 1. Perform a complete maintenance cycle on the filter.

Step 2. Close and disconnect the raw water inlet and the filtered water outlet.

Step 3. Drain the entire system.

Step 4. Disconnect the filter from the storage tank.

Step 5. Remove, clean and label all parts and components from the filter and storage

tank.

Step 6. Remove the filter media. Take care to remove the layers of the media without

mixing. Store the media in clean woven poly bags or plastic pails. Label the media as

it is removed, especially the #1 sand and #2 sand, for ease of re-installation.

Note: The filter media is wet and will be heavy. If desired, new media can be ordered

from Davnor.

Step 7. Follow the system installation instructions to re-install.

13

14 Trouble Shooting

Problem

Possible Cause and Solution

Low flow rate

1. Filter flow rate has slowed due to sediment build up on the top

layer of sand. Perform maintenance on the filter (Section 7).

2. Filter has become air-locke

d due to dissolved gases in the

water coming out of solution. Follow the degassing procedure

(Section 9).

3. Draining the filter below the top of the sand. Fol

low the

degassing procedure (Section 9).

4. Outlet valve has been closed. Ensure that it is open.

5. Surface of sand has become compacted due to excessive

flow rate. Follow the degassing procedure (Section 9).

6. Inlet water temperature has dropped since the flow rate

control valve was last set. Reset the control valve (Section 5).

Note that the valve will

have to be reset again when the water

temperature increases.

Water not entering

the filter

1. Filter inlet valve not fully open. Check the valve to the filter.

2. Mechanical float valve out of adjustment. Re-

adjust as

required.

3. Solenoid valve closed. See sol

enoid valve not functioning

below.

Storage tank

overfilling

1. Mechanical float valve out of adjustment. Re-adjust as

required.

Pump not operating

1. Storage tank low level float switch out of adjustment. Re-

adjust as required.

2. Pump doesn’t have electricity.

Check electrical connection

and breakers.

3.

Valves not open. Check valves on the storage tank and pump

/ pressure tank.

4. Consult the pump manufacturer’s instructions.

Solenoid valve not

functioning

1. Check float switch adjustment. Re-adjust as required.

2. Check electrical outlet. (Solenoid is normally closed)

3. Consult the solenoid manufacturer’s instructions.

This manual suits for next models

2

Table of contents

Popular Water Filtration System manuals by other brands

Fiap

Fiap TrommelSieve Active Series operating instructions

Clean Water Systems

Clean Water Systems Birm 7800 Installation & start?up guide

Dupla

Dupla Perfect Clean PC 1 Instructions for use

Schenker

Schenker SMART 30 Installation, use and maintenance manual

Panasonic

Panasonic ET-SFD320 operating instructions

Delta Electronics

Delta Electronics 20GENG3E Specifications

Katadyn

Katadyn 8018280 Hiker Pro manual

VGE

VGE Xclear UV-C Professional manual

Premier

Premier WP-2 LCV Installation, operation and maintenance manual

AquaTools

AquaTools AT11523 owner's manual

BWT

BWT SOLIFLOW Instructions for installation and recommendation

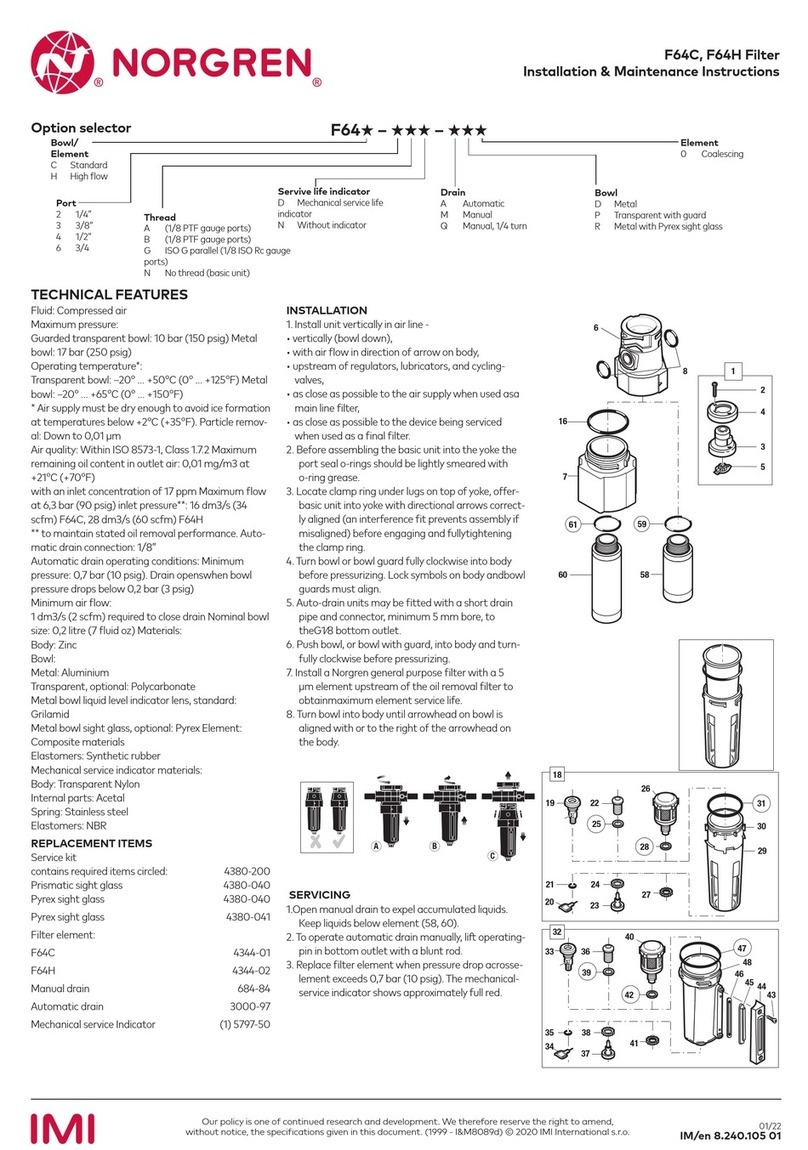

IMI

IMI norgren F64C Installation & maintenance instructions