Evo-water UO small 150l Instruction manual

2/38

1 Scope of this manual 3

2 Before using the unit: 3

3 General information 4

4 Correct usage 5

5 The UO SMALL SYSTEM 7

5.1 The treatment of the water 8

5.1.1 Pre-filtration 9

5.1.2 Reverse Osmosis 9

5.2 Technical characteristics 11

5.2.1 Specifications table 12

5.2.2 Equipment description 13

5.2.3 Control panel 14

5.2.4 Technical Characteristics of the osmosis unit 15

5.3 Hydraulic system 16

5.3.1 Inlet unit + bypass + filter 17

5.3.2 Pump unit 18

5.3.3 Osmosis unit 19

5.3.4 Pre-Filtration 21

5.3.5 Gauge and extraction unit 22

5.4 Electrical system 23

5.5 Installation 25

5.6 Maintenance 27

6 Unit health status (Service and commissioning form) 35

6.1 Manufacturer hygiene control information 36

3/38

1 Scope of this manual

Thank you for choosing to install this system.

This manual has been devised to provide the purchaser all the information necessary for the

installation, use and maintenance of the UO SMALL as thoroughly and clearly as possible in order

to render operation as safe and effective as possible for those who use it. It also lists all the

procedures to help you deal with any reasonably foreseeable emergency situations that might

arise from use in the manner prescribed by the manufacturer. It is therefore of utmost importance

to strictly comply with the requirements in this manual, a should be considered a necessary

condition for safe and satisfactory operation of the unit.

2 Before using the unit:

It's very important that this instruction book is retained with the appliance for future reference.

Should the appliance be sold or transferred to another party, ensure that the booklet is also

included so that new users can be aware of how to operate the machine and the relevant

warnings.

Before using the machine read the whole manual carefully.

Knowing the information and instructions contained in this manual is essential for correct

installation and proper use of the equipment.

After unpacking the unit, check that it is not damaged. Any damage must be reported to the

transporter within 24 hours. The installation and electrical connection must be carried out by a

qualified technician according to the manufacturer's instructions and local regulations. The

electrical system must be equipped with an effective earth connection as per the legislation

(Ministerial Decree 37/2008). Before doing any cleaning or maintenance, disconnect the plug from

the wall socket. Do not pull the power cord when disconnecting the plug from the socket.

After installation, ensure that the unit is not resting on the power cord.

The data and specifications listed in this manual are not binding on the manufacturer, which

reserves the right to make any changes deemed appropriate without obligation to provide prior

notice or replacement.

4/38

3 General information

This manual is intended for personnel specifically assigned to the installation and/or management

and/or repair the system.

Any handling, maintenance, repair and sanitising of equipment must be carried out by

properly trained authorized technicians.

The location housing the system, accessories and consumables must adhere to the storage, use,

and safety regulations currently in force.

The water produced by each unit should be used for the specific use to which it was intended.

EVO-WATER is not responsible for the consequences of improper use of the water produced by

his equipment. Any abnormal operation of the system must be immediately reported to the evo-

water Service Centre. The manufacturer is not responsible for the consequences of continued use

of a system with malfunctions.

Where necessary, the selection, dosage, and handling of chemicals must be performed by

qualified personnel in accordance with the instructions and safety data sheets.

Any maintenance or repairs should be carried out while the system is both electrically and

hydraulically isolated. Disposal of waste material or consumables must be in accordance with local

regulations. The packaging materials (plastic bags, polystyrene foam, etc.,) must not be left within

reach of children as they are potential sources of danger. The system must not be removed from

its original location by a non-specialist. To clean the system, do not use corrosive acids, steel wool

or steel brushes. Do not wash the appliance by directly pouring water or with high-pressure jets.

The manufacturer declines any liability for damage to persons or property caused by non-

observance of the instructions in this manual.

The manufacturer declines any liability for any damage caused to persons or property for repairs

not performed by qualified personnel, this shall void the warranty, as shall the lack of necessary

care and maintenance of the system and the replacement of parts with non-original components.

Under current legislation, the device must be connected to a socket with an effective ground.

The unit operates at 230V -50Hz; voltage variations greater than 10% of the nominal value can

damage the electrical components.

5/38

The equipment is free of electromagnetic interference as per EEC directive 87/308 of the

14/04/1989.

To perform any kind of operation on the system, please adhere to the following precautions for the

safety of persons and things.

In particular, observe the following points:

1. Carefully read all the instructions in the manual.

2. Prior to installing the system, take special care to verify compliance with the following

conditions: Read the relevant regulations;

3. If there are suspended solids, install a water filter directly before the system, a lack of water

filtration and removal of suspended particles may limit the system's effectiveness;

4. EVO-WATER declines any liability regarding use of the system in the event of non-

compliance with the requirements in the manual provided as an integral part of the

package.

5. The system must always be installed after the water meter or the autoclave and after all the

filtration and water treatment equipment.

6. When the system is first commissioned, the output for the first 5 minutes must be discarded

in the drain in order to purge any manufacturing residues from all the components through

which water flows.

7. The UO SMALL must only be used by adults. Ensure that children do not touch the controls

or play with the appliance.

8. The packaging materials (plastic bags, polystyrene foam, etc.,) must not be left within reach

of children as they are potential sources of danger.

9. During the warranty period, no intervention may be performed without prior authorisation

from the Service Centre. If this is not heeded, the warranty is automatically voided.

6/38

4 Correct usage

UO SMALL is suitable for the treatment of non-ferrous and bacteriologically pure water. Any other

use that is not approved in writing by our technical service is assumed non-compliant. For special

applications with water having different characteristics, you should contact our technical service,

which can indicate the optimal calibration of the system or any necessary additions on the basis of

a thorough chemical and bacteriological analysis.

The water to be treated must be consistent with that identified in Leg. Decree 31/01 and

subsequent amendments. It is critical that the installer knows and understands Ministerial Decree

37/08 and the manufacturer declines any responsibility in case of components that are not fitted

during installation. These components are not part of the supply package.

WATER PRODUCED FROM THE SYSTEM IS DESIGNED EXCLUSIVELY FOR PROCESSING

USE

The operating limits of the inlet water are:

free chlorine 0.02mg/lt

manganese max 0.05pp

turbidity 1 NTU MAX

absence of surfactants

absence of oils

Absence of coli bacteria

non-ferruginous

Maximum temperature of inlet water: 40°C

Test conditions: TDS max 1500 ppm SDI=5max

7/38

WARNING - IMPORTANT

Evo-water declines any liability regarding the installation of the system, therefore any

damages to property and\or people because of this is

NOT IN ANY WAY ATTRIBUTABLE TO EVO-WATER

IT IS THE RESPONSIBILTY OF THE INSTALLER TO SUPPLY PLUMBING FITTINGS

NECESSARY FOR THE INSTALLATION OF THE SYSTEM

The device is not intended for use by persons (including children) with reduced physical or

mental capacities, nor by persons lacking experience or knowledge, unless they have been

given, through the intermediation of a person responsible for their safety, supervision or

instruction concerning use of the appliance

8/38

5 The UO SMALL SYSTEM

The system is packaged and supplied in cardboard packaging. Please note: It is possible to the

supply the unit packed according to customer specifications.

Instructions for removing the standard packaging

There are no special precautions for unpacking the UO SMALL 150 A system, except for for

normal care and caution when handling fragile equipment. Before disposing of the cardboard

packaging, check to make sure that unit components, instruction manuals or other documentation

are not still amongst the packaging.

Transport/receiving

It is important to remember that, although carefully packed and well-protected, the system must be

considered and handled as fragile equipment. Open the packaging to check the integrity of the unit

upon receipt. In case of damage, accept the unit with reservation in order to be able to initiate a

claim.

Storage

The packaged unit must be stored in a dry environment (free from condensation), under shelter. The

permissible temperature is 0 °C to +50 °C.

Supply specifications

Supply consists of one UO SMALL unit with:

N. 1 electric motor 186 W

N. 1 rotary pump 150 lt/h

N. 1 activated carbon pre-filter

N. 1 two-way solenoid: one feeds the unit and the other acts as an automatic bypass (external switch)

N. 1 RO membrane

N. 1 Flood detector

N. 1 gauge for the pump operating pressure

N. 1 gauge for the output water pressure

N. 1 differential pressure switch

N. 1 electronic circuit board for machine management

N. 1 tap for the extraction of treated water

9/38

5.1 The treatment of the water

The UO SMALL unit is designed for the treatment of technical waters; it represents a technological

solution for the treatment of municipal water and adds value to the local resource as the filters

applied at the extraction point enhance the water and make for a more satisfying consumption of the

water resources. It is known that potable water analysed at the tap, while respecting the chemical

and physical parameters within the limits provided by law, may have unpleasant odours and traces

of unwanted substances and biological contaminants.

The issues relating to the health aspects of municipal water are essentially two:

1. The condition of the conduits: at least 30% of water is lost between the source and the tap;

older pipes may release materials that are carried by the water or inorganic and organic trace

substances may be accidentally introduced during maintenance work;

2. Chlorine: most purification systems employ chlorination processes. Substances such as

sodium hypochlorite or chlorine dioxide, which by their unstable nature dismutate into chlorine

(used to kill bacteria) and chloride, are added in such quantities as to ensure the bactericidal action

up to the point of extraction. The chlorine ensures the safety of the water because it runs with water

right up to the tap. It is therefore essential for the protection of public health in order to ensure

bacteriological control. Unfortunately it releases an unpleasant odour that combines with other

organic gases to alter the organoleptic properties of water.

The purpose in designing the UO SMALL is to present the consumer with a solution that allows a

finishing system, (refinement) of municipal water at the end of its journey through the pipes in

order to enhance the organoleptic properties without altering the saline content. It is therefore

suitable for all aqueduct waters for technical use, and at the same time represents a solution to any

real or suspected problem, foreseeable or unforeseeable.

The treatment carried out on the water can be summarised as follows:

1. Elimination of all suspended impurities;

2. Elimination of chlorine taste and odour

The UO SMALL system is therefore able to be used in order to deprive water of chlorine smells and

any substances in suspension. A refinement process, therefore, at the end of the passage through the

tubes in order to enhance the organoleptic properties of potable water, without altering the saline

content.

The UO SMALL system can only accept input water as defined in Directive 98/83/EC of 03/11/98,

or Leg. Decree 31/2001.

The filter traps suspended matter down to 0.005 microns, and according to tests conducted at

Serchem Laboratory, showed total effectiveness against chemicals such as chlorine, derivatives of

microorganisms and large organic molecules that may be present in very low concentrations in

potable water distributed through urban networks.

10/38

Abb. 5.1

Filtrazione = Filtering Microfiltrazione = Microfiltering Ultrafiltrazione = Ultrafiltering Osmosi inversa = reverse Osmosis

Radium = Radium Amianto = Asbestos Arsenico = Arsenic Dimensioni ioniche = ionic dimensions

Colloidi = colloids Virus = Virus Dimensioni molecolari = Molecular dimensions

Microbatteri: Micro bacteria Virus: Virus

Microparticelle = Microparticles Batteri = Bacteria

Particelle fini = fine particles

DIMENSIONI PORI IN MICRON = Pore dimensios in micron

5.1.1 Pre-filtration

This is the first stage. The incoming water is passed through a carbon filter (polypropylene on

request). Microfiltration is crucial before introducing the water into the RO unit as particles larger

than 5 microns may damage the membranes. The filtration elements combine the proven depth filter

technology with a design concept that eliminates the entire core for a solution which is affordable,

convenient, efficient and environmentally friendly in applications with high flow rates. Adsorption

with activated carbon is a process where a solid is used for the removal of a soluble substance from

the water.

In this process, activated carbon is the solid. It is specifically produced to have a very large internal

surface area (500–1500 m2/g). This high internal area surface makes activated carbon ideal for

adsorption. The activated carbon used is Granular Activated Carbon (GAC). This version GAC is

the most widely used in water treatment and according to documentary evidence and scientific data,

it adsorbs the following:

mineral oils

Poly aromatic hydrocarbons (PACs)

Phenyl chlorides

This filter allows the correct and complete removal of chlorine.

For polypropylene filters, the filtration element is a septum in polypropylene with low pressure loss

so that a smaller number of filtration elements is required for the same flow rate. The filtration

elements are produced according to highest standards of quality and cleanliness.

11/38

B

A

Clean water

Salin solution

direct osmosis

B

A

Clean

water

Saline solution

pressure

Balance osmotic

B

A

Clean

water

Salin solution

pressure

reverse osmosis

5.1.2 Reverse Osmosis

This is the second stage. The water emanating from the pre-filtration stage is sent to the two reverse

osmosis membranes made of vegetable fibres (polyamide) and conserved in a natural manner. The

membranes have also passed the usage admissibility tests by the Food and Drug Administration

(FDA). Reverse osmosis is a process of separation of foreign bodies from the water through the use

of semipermeable membranes. These structures allow water to pass through them while removing

dissolved mineral elements, pollutants, viruses and bacteria. Consider a container divided into two

compartments by a semipermeable membrane, we see that the pure water A from osmosis tends to

pass into the saline solution B, increasing its level until reaching a hydrostatic pressure (referred to

as the osmotic pressure of the solution) that balances the system and stops the passage of pure

water.

If a pressure greater than the osmotic pressure is applied to the saline solution B, the pure water

tends to return to A, resulting in the phenomenon of reverse osmosis (i.e., opposite to the natural

phenomenon). (fig. 5.1.2).

The reverse osmosis treatment therefore involves forcing water through a semipermeable membrane

to separate dissolved foreign bodies, both organic and inorganic in nature.

Despite having a minimal pore size, reverse osmosis does not operate like conventional filtration,

but rather as "cross-flow filtration".

In conventional filtration, the entire aqueous solution to be filtered is forced through the filtration

medium and any impurities too large to pass through the pores of the filter medium is retained or

trapped inside the medium itself .

In cross-flow filtration, there are two output streams from the system: the "concentrate" or the

stream that contains the impurities that are rejected or do not pass through the membrane, and the

"permeate" or the stream that is pushed through the membrane.

fig. 5.1.2

12/38

5.2. Technical characteristics

1) Solenoid valve, unit supply

2) Solenoid valve, bypass

3) Filter, sediments/carbons

4) Motor

5) Booster capacitor

6) Pump

7) Membrane

A inlet ¾”

B permeate outlet ¾”

C concentrate outlet ¾”

13/38

5.2.1 Specifications table

UO small 150

incl.expansion vessel

TECHNICAL CHARACTERISTICS

Width x depth x height

(mm)

200 x 560 x 590

Weight

(kg)

17

Sound level

(db (A))

< 70

membrane

(n°)

1

Activated carbon filter

SUPPLY WATER CHARACTERISTICS

Type of water

Drinkable

Minimum water temperature

(°C)

5

Maximum water temperature

(°C)

45

Minimum supply flow rate

lit/hr

700

Maximum supply pressure

(bar)

3

Minimum supply pressure

(bar)

1

OPERATING ENVIRONMENT

Maximum relative humidity

(%)

90

Minimum air temperature

(°C)

3

Maximum air temperature

(°C)

40

ELECTRICAL CHARACTERISTICS

Supply type

Single-phase + earth

Voltage rating

(V)

230

Frequency

Current consumption

(Hz)

50

Power

(W)

186

Circuit board protection fuse type

PERMEATE CHARACTERISTICS

Maximum flow at 15°C

lit/hr

approx. 150

Permate/concentrate production ratio

approx. 1:1.5

REPLACEMENT CONDITIONS

Activated carbon filter

(l)

12,000

Reverse osmosis membrane

When blocked

14/38

5.2.2 Equipment description

The unit is divided into three distinct technical compartments (as shown in the figure

below) to reduce and facilitate routine maintenance involving: replacement of

membranes, filter replacement and inspection of electrical/electronics components.

The hydraulic inlet and outlet connections of the permeate and concentrate including the electrical

connections are present at the rear.

Electrical cabling

Concentrate outlet

Permeat outlet

Main water attachement

Operational hydraulic

compartment

Control panel and

electrical

Frontal inspection and

maintenance

compartment

15/38

5.2.3 Control panel

The control panel has two command buttons and three warning lights:

1pressure gauge for the pressure of the membranes

2Red warning light indicating flooding of compartment

3white light indicating bypass activated

4white light on indicating the machine is electrically live

5a button for activating and deactivating the bypass

6button for powering the machine on and off

1

2

3

4

5

6

16/38

5.2.4 Technical Characteristics of the osmosis unit

Vessel

Particular attention has been devoted to the vessel made of stainless steel 304. It has an internal

system that prevents the telescopic effect of the membrane due to the higher pressures generated as

the membrane becomes more and more clogged. The frontal compartment allows easy inspection

and replacement of the membrane without removing the unit from its housing.

Membrane

Produces a quantity of permeate equal to 150 litres/hour using only one selective wound spiral

membrane in polyamide (PA), type 3512 650GDP.

•Membrane type: Thin-film composite

•Membrane material: Polyamide

•Configuration of the elements; wound spiral

•Maximum pressure 10 bar

•Maximum operating temperature: 45°C

•pH: 3-10

•Maximum turbidity; 1.0 NTU

•Maximum SDI: 5.0

•Maximum chlorine concentration: 0.1 mg/lt

Flood detector

To render the working area safer and prevent damage to the system, the machine is equipped with a

flood detector.

Differential pressure switch

The differential pressure switch is used to activate and deactivate the pump motor that pressurises

the membranes when a command signal is received.

The differential is divided into two signals:

stop signal, when the pressure of the circuit which includes the expansion vessel reaches the

preset value (e.g., 3 bar), the machine stops. The value can be changed with a standard Phillips

screwdriver.

17/38

on signal, occurs when the pressure falls within a range set by the manufacturer

or changed by the installer if necessary.

5.3 Hydraulic system

18/38

5.3.1 Inlet unit + bypass + filter

1

Two-way solenoid for supply and bypass at ¾”

2

John Guest check valve, 12mm tube

3

John Guest 90° curve with spigot, 12mm tube

4

John Guest ½” threaded attachment, 12 mm tube

5

T joint ½”

1

2

4

5

3

19/38

5.3.2 Pump unit

1

Motor, 560 Watt

2

Pump, 800 lt/h

3

John Guest 90° curve with spigot, 12mm tube

4

John Guest 90° curve with spigot, 12mm tube

5

Tube ø12

4

3

5

4

3

2

1

20/38

5.3.3 Osmosis unit

1

Nipples ½”M – ¾”M

2

M8 Nut

3

Membrane connection tube

4

Vessel cap

5

Vessel cap o-ring

6

Bolt, M8x100

7

Membranes

8

Vessel support

9

Stainless steel vessel

1

2

3

1

4

6

7

8

9

5

Table of contents

Popular Water Filtration System manuals by other brands

Geyser

Geyser ECO Installation and operation manual

BANDELIN

BANDELIN Sonorex Technik operating manual

flamco

flamco Flamcovent Installation and operating instructions

NaturalSof

NaturalSof 6L installation manual

Brita

Brita mypure P1 Instructions for use

ESK

ESK BOS2-R Series Installation and operating instructions

BWT

BWT TFPKIT Installation and operating instructions

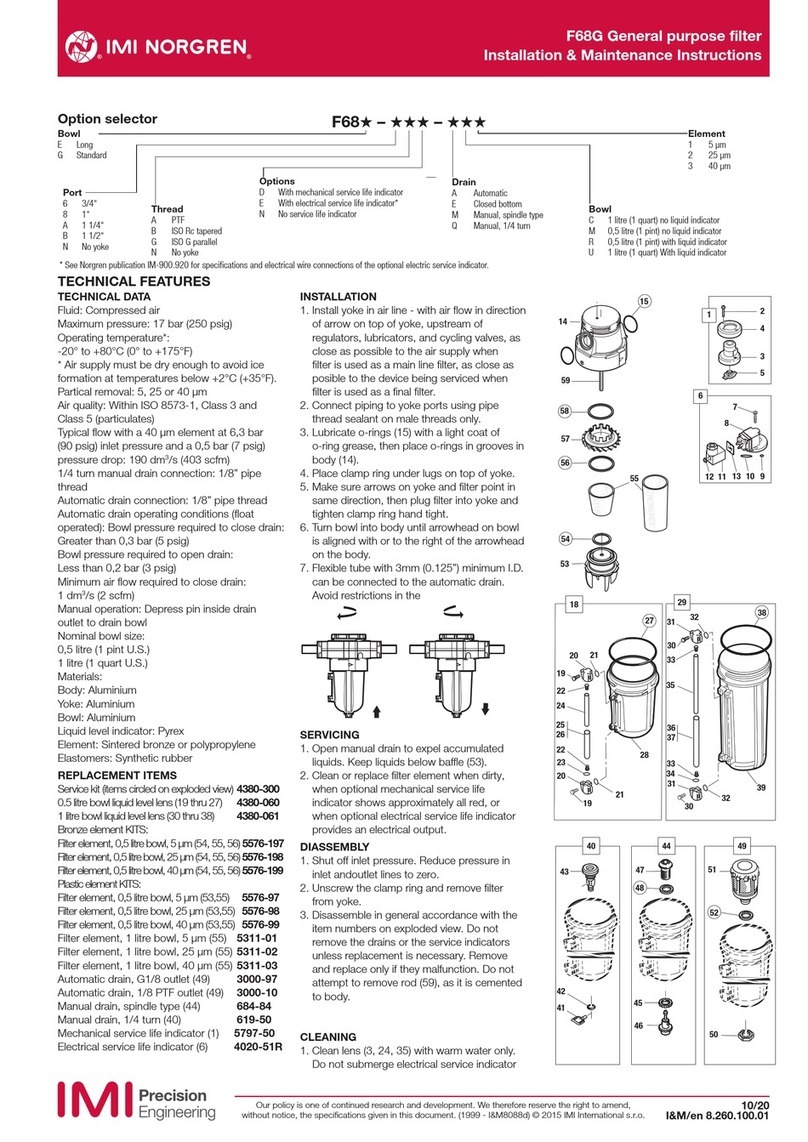

IMI NORGREN

IMI NORGREN F68G Installation & maintenance instructions

Camfil

Camfil FB Series Installation, operation and maintenance manual

ELGA

ELGA PURELAB UHQ II Service manual

Eaton

Eaton Cutler-Hammer 66A8060 Instructions for Replacing

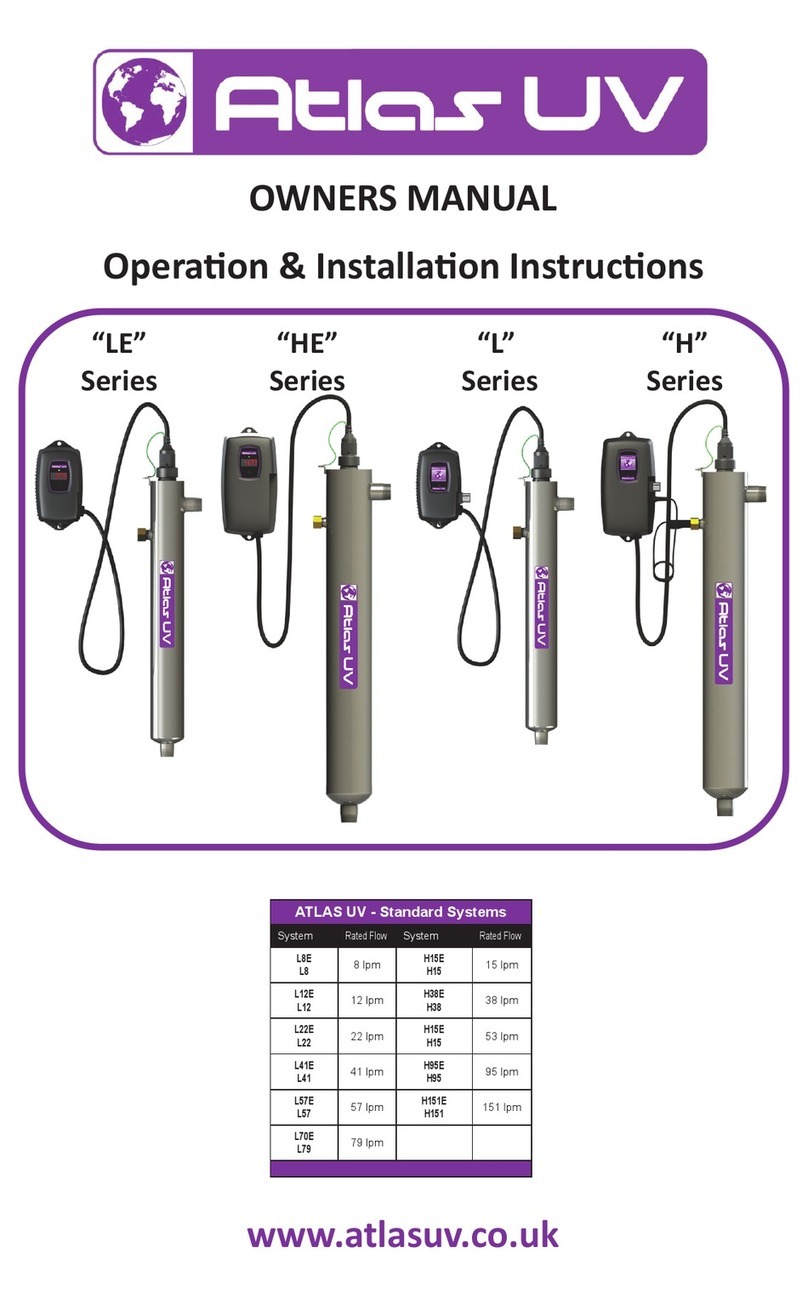

Atlas UV

Atlas UV LE Series owner's manual