5

GENERAL INFORMATION

•Clean a new pool as well as possible before filling

pool and operating filter. Excess dirt and large particles

of foreign matter in the system can cause serious dam-

age to the filter and pump.

NEVER test this filter with compressed air.

Do not operate filter at water temperatures above

95°F (35°C).

NEVER operate this filter system at more than 50

pounds per square inch (50 PSI/345 kPa) pressure!

Plug system into electrically isolated, Ground Fault

Circuit Interrupter protected circuit ONLY!

• Clean a new pool as well as possible before filling

pool and operating filter. Excess dirt and large particles

of foreign matter in the system can cause serious dam-

age to the filter and pump.

• Keep pool water pH at recommended level (7.2 to 7.6)

to avoid irritation to eyes and skin.

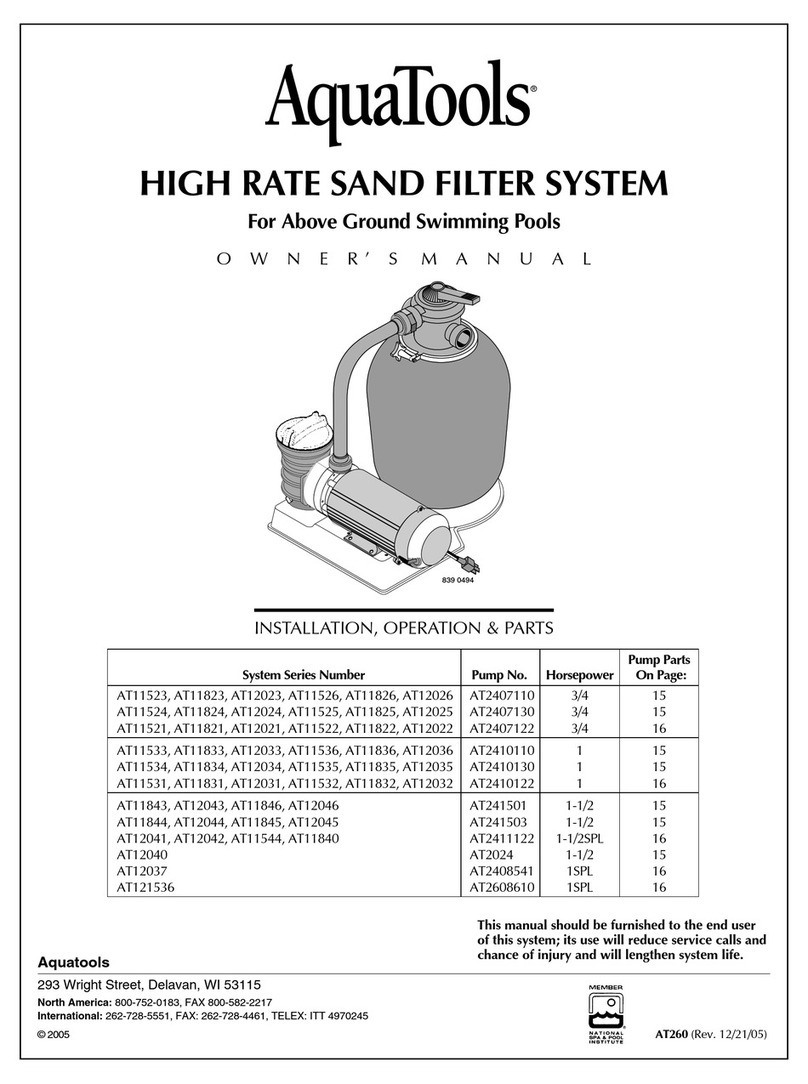

• The Hi-Rate Sand Filter System is designed for use

with above ground swimming pools only.

• Use only #20 Silica sand with a screen mesh of .45 to

.55mm. Use of other sands will reduce filter perfor-

mance. To reduce risk of electric shock, install

pump at least 10 feet from the inside wall of the pool.

Do not use an extension cord.

INSTALLATION

Trap to Pump Assembly:

Using four 5/16” cap screws, flat washers and lockwashers,

mount trap to pump body; be sure to install gasket be-

tween trap and pump body. Tighten cap screws to 80 inch-

lbs (92 cm-kg) torque; do not overtighten.

Filter Mount Must:

• Provide weather and freezing protection.

• Provide space and lighting for easy access for routine

maintenance. (See Table I and Figure 1, Page 4, for

space requirements.)

• Be on a reasonably level surface and provide adequate

drainage.

• Be as close to pool as possible to reduce line loss from

pipe friction.

• Be solid – level– rigid – vibration free.

• Be installed so that trap suction inlet is below pool

water level at all times. This allows pump to prime.

• Have adequate ventilation to prevent motor overheat-

ing.

Piping:

• Use teflon tape or Plasto-Joint Stik1on all male con-

nections of plastic pipe and fittings except unions. DO

NOT use pipe compounds on plastic pipe; it will

cause the pipe to crack. Do not use sealant or tape on

unions – assemble them dry and hand tight.

• Do not damage union sealing surfaces and “O” Rings.

• Support pipe independently to prevent strains on filter

and valve.

• Use 1-1/2 or 2” pipe to reduce pressure losses as

much as possible. If flex hose is used, use the type

with smooth internal walls.

• Fittings restrict flow; for best efficiency use fewest pos-

sible fittings.

• Keep piping tight and free of leaks: pump suction line

leaks may cause trapped air in filter tank or loss of

prime at pump; pump discharge line leaks may show

up as dampness or jets of water.

• When unions are provided, use as follows for leak free

connections:

1. O-Ring and sealing surfaces must be clean.

2. Assemble hand tight only (no wrenches).

3. No pipe compound or teflon tape on unions.

Valves:

• For servicing filter system and for cleaning pump trap,

install ball or gate valves

A. Between pump trap and pool skimmer, and

B. Between selector valve and return pipe to pool.

• A check valve installed between filter and heater will

prevent hot water from backing up into filter and de-

forming internal components.

• Use care before assembly not to damage union sealing

surfaces or O Ring.

Wastewater:

• Be sure all provisions for waste water disposal meet

applicable local, state or national codes. 100 gallons

(379 liters) or more of pool water will be discharged

during filter backwashing. Do not discharge where

water will cause flooding or damage.

1Lake Chemical Co., Chicago, IL