Daxten THERMAL OPTIMISATION User manual

1. Thermal analysis

2. Cold-Aisle-Containment

3. Seal open rack units in cabinets

4. Optimise airflow through perforated floor tiles

5. Sealing cable openings in the raised floor

Thermal Optimisation

in the Data Centre

Best Practices for achieving optimal cooling performance and

significant energy savings in your data centre

52 Daxten | Thermal Optimisation Best Practices

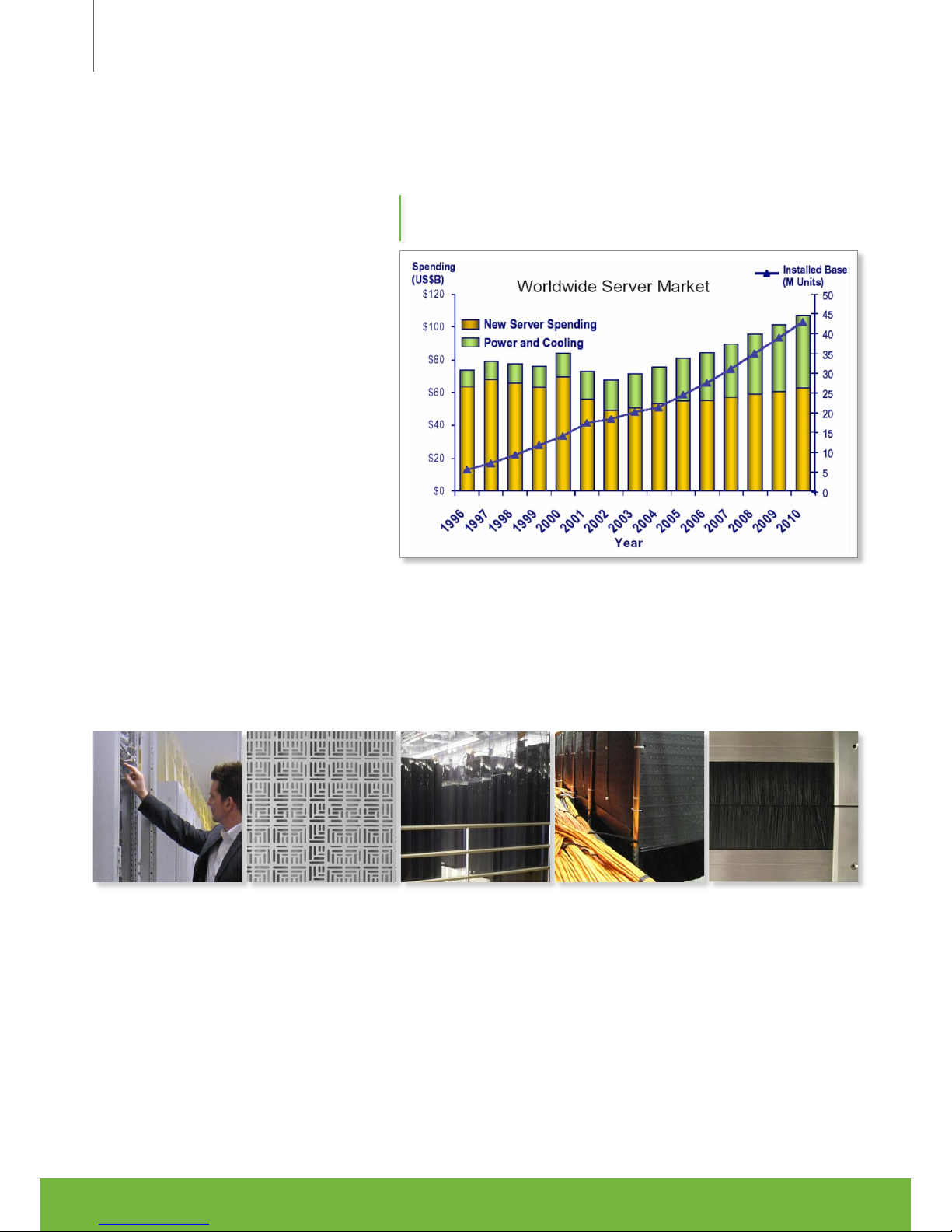

Why is the optimisation of cooling in your data centre

essential?

Data centres contribute significantly to world-

wide energy consumption. Analysts from IDC

and Gartner state that two percent of total

energy consumed worldwide is caused by

data centres. This share is expected to double

within the next five years. The increase in CO2

emissions will have a profound impact on the

costs for companies, their data centres, and

the ecological and environmental communi-

ties at large. Energy costs for data centres

have climbed to represent 20% of the total

operation expenses in many companies. In the

short- and mid-term, this share will increase

to 30% or more. Ignoring these statistics and

failing to optimise will result in unnecessary

operating expenditure for your company. According to Gartner, a staggering 40% of the total energy costs of any given data

centre are incurred through cooling. Small investments and short amortisation periods are the most efficient method of

cooling optimisation. This increase in efficiency is achieved by adhering to the following best practices:

1. Best Practice:

Thermal analysis

When using hard facts, all attempts in optimisation will succeed. For this reason we offer you a thermal analysis.

Our certified specialists will carefully explore your IT environment, examining the airflow both within the floor plenum

and above the raised floor to identify bypass airflow, loss of cooled air and hot spots. Measurements are taken at

various locations such as 19” racks and CRAC units throughout your datacentre. Based on the findings, our specialists

will work with you to compile a catalogue of techniques and products that allow you to reduce a large portion of your

energy costs and to increase the efficiency factor of your cooling systems.

In 2010 the rate of energy costs in data centre will be more than 30% of the

whole IT budget. Thereof the portion of cooling will be 40%.

Source: IDC, 2007

2. Best Practice:

Cold-Aisle-Containment

To best realise a green computing environment and to decrease the energy consumption in a datacentre by

more than 30% the US-American Uptime Institute recommends arranging the server cabinets in aisles and separating the

hot cabinets from the cold cabinets, sealing the cold aisle. One method for this separation is a complete cold aisle contain-

ment created with aluminium profiles and solid

panels for the ceiling and racks. However, there is

a more cost efficient alternative that produces a

similar efficiency factor. By mounting a CoolCon-

trol Curtain, you can seal the cold aisle and make

a wise investment all at once. The CoolControl

Curtain fits to any dimension of current server rack,

meaning it can be retro-fitted to existing 19”

cabinets irrespective of size or manufacturer.

Recirculation of hot air causes high

hardware failures and is expensive

Active IT hardware takes the cooled air

in at the front of the racks. As the cool air travels

through the hardware, the air is heated and ex-

hausted at the back of the rack. As hot air rises up

the rear of the 19” cabinet, it flows over the top or

around the side of the cabinet and recirculates to the front of the rack in the cool aisle again. The hot air can also recir-

culate to the cold aisle through non-sealed openings between servers or vertical profiles in the cabinet. As this process

repeats itself, the temperature in the cold aisle gradually rises. Traditionally, increasing cooling output is the only way

to prevent overheating. Unfortunately, increasing cooling output increases energy consumption and your energy bill.

Cold Aisle Containment reduces the cooling consumption by up to 30 percent

It is essential to hermetically separate the hot air from the cold aisle. This separation can be done reliably with

the CoolControl Curtain. With constant cooling capacities, measurements show the temperature difference between the

hot and cold aisle are 10-15 degrees Celsius. Depending on the size and environmental specifics of individual data centres,

the cooling requirements and energy costs could be decreased by as much as 30%.

53 Daxten | Thermal Optimisation Best Practices

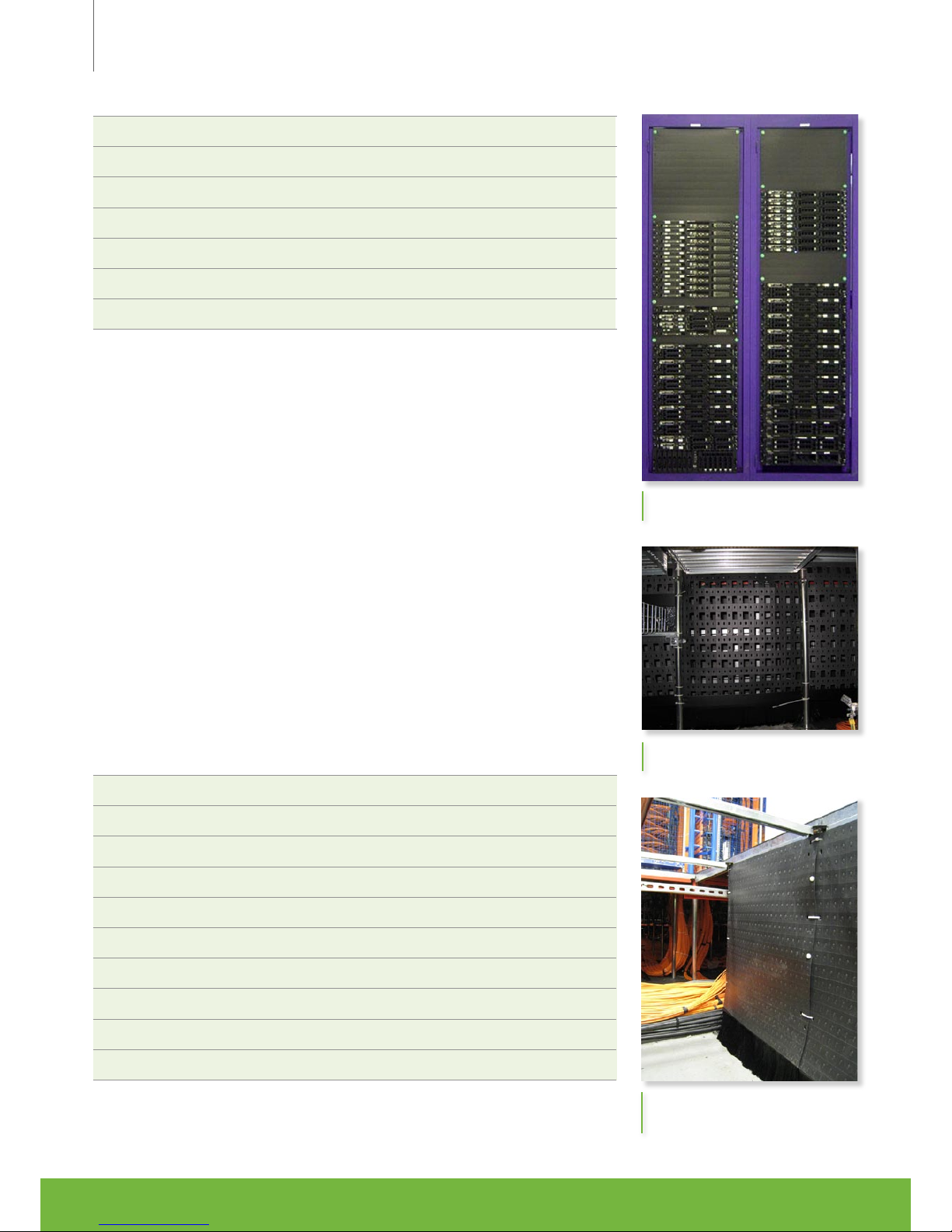

An example of cold aisle containment

with a PVC curtain.

Hot air recirculates into the cold aisle.

A separation of the hot from the cold aisle is a standard

in modern datacentres.

Play it safe: Test before installing a complete cold aisle containment solution

For companies who want to first test the efficiency of cold aisle containment the CoolControl Curtain is ideal.

With the curtain, facility managers and IT managers can measure the actual savings and efficiency factors without

placing strain on their budgets.

Highlights

• Cost-saving separation of the hot and the cold aisle (H/CAC)

• Prevents recirculation of hot air in the cold aisle

• Temperature difference between hot and cold aisle: more than 10° and 15°C

• Up to 30% energy savings

• Significant increase in cooling system efficiency

• Easily installed: in hours not in weeks

• No downtime required for installation

• Ideal as test installation to measure cold aisle containment results

• Compatible with all rack dimensions and vendors

3. Best Practice:

Seal openings in the front of 19” cabinets

PlenaFill blanking panels and PlenaForm air baffles are indispensable tools that increase the efficiency of hot

aisle / cold aisle containment (H/CAC) and for general optimisation of data centre airflow.

PlenaFill® blanking panel

PlenaFill is an inexpensive solution for sealing the openings between

servers preventing recirculation of hot air through the cabinet. The physical

barrier keeps cold air at the front of the cabinet separated from the hot air at

the back. This prevents hot spots and helps prevent hardware failures or

downtime caused by overheating.

PlenaFill is critical in separating hot and cold air areas in the server

racks, which leads to an optimal cooling efficiencies. When PlenaFill

blanking panels are deployed throughout the data centre, cooling units can

operate more efficiently resulting in energy savings.

PlenaFill blanking panels are made from lightweight non-flammable

(fire rated to UL94-V0) material and can be installed into any 19” rack

without tools. Each blanking panel is 27U with air tight perforations every

1U which can be torn to create smaller panels from 1U upwards. This patent

protected and flexible design along with tool-free rivets makes for quick and

easy installation.

4 Daxten | Thermal Optimisation Best Practices

PlenaFill panels prevent the recirculation of hot

air into the cold aisle.

5

5 Daxten | Thermal Optimisation Best Practices

A server cabinet sealed with PlenaFill.

PlenaFill Highlights

• Prevents hot and cold air mixing caused by bypass airflow

• Fire rated to UL94-V0

• Tool free installation

• Each panel covers 27U - separable in 1U sections

• Easy to install in all 19” EIA racks

• Extremely inexpensive, with high efficiency factor and quick ROI

• Cost effective compared to metal or plastic blanking panels.

PlenaForm® - Airflow Diffuser and Raised Floor Baffle

PlenaForm is an airflow baffle that helps to guide airflow under the raised

floor to the server racks. By directing the airflow, cooled air will not escape into

unused areas in the raised floor increasing air pressure. Cooled air is directed

effectively and efficiently to the openings in the raised floor where it is needed

most.

PlenaForm is a flexible airflow baffle system which helps to solve dynamic

thermal imbalances in data centres. The baffles are die cut both vertically and

horizontally in sections that can be removed to correct sizes for installation under

the plenum. These individual sheets can be joined together creating impenetrable

air barriers. PlenaForm baffles are constructed of a flame retardant polypropylene

compound that is inert, non-conductive, and non-hygroscopic with a UL94-V0

rating.

PlenaForm Highlights

• Control and balance data centre airflow

• Separate hot aisles from cold aisles

• No installation tools required

• On-site configurable (width and height)

• Fits any raised floor pedestal

• Reduces energy consumption and operating costs

• An inert, non-conductive and non-hygroscopic material

• Flammability rating of UL94-V0

• RoHS and WEEE compliant

• An energy saving and thermal tuning tool

PlenaForm controls and balances airflow

in the raised floor.

PlenaForm fits any raised floor pedestal.

4. Best Practice:

Optimise airflow through perforated floor tiles

To ensure cooled air makes its way through the front of the

cabinets and servers with ample pressure, it is necessary to have high

density perforated floor tiles. To create an optimal pathway, it is

advised to use high density airflow vented floor tiles which allow high-

plume stratification. While conventional vented floor tiles achieve

airflow rates of 20-30%, our solutions provide up to 65% airflow. The

higher the flow rate, the higher the volume of cold air that reaches

your rack equipment. It is critical that the vented floor tiles provide

enough cold air via high-plume stratification. Only then can the cold

air reach the top of the cabinets to cool the upper most hardware.

Sufficient cold air is the primary factor in preventing system failures

and downtime created by overheating. The formula for the best choice

of vented floor tiles is simple: Higher airflow rate and air pressure

equal lower required cooling capacity resulting in increased energy and cost savings.

Not only does the airflow

rate matter, but also the strength

of the perforated floor tiles. These

panels often carry fully loaded cabinets.

Conventional vented floor tiles manage to carry a maximum weight of 200 - 300kg - without tightened

edges. Our CoolControl Vented Floor Tile can reliably carry between 680 and 1360kg. Of course easy

access is also required. The patent protected integrated Lift-n-Lock® handles allow you to lift the floor

panel without any tools.

Airflow panel Highlights

• Optimised hi-plume stratification fins

• Airflow rate up to 65 percent

• Integrated dual Lift-n-Lock® handles

• Protects cabinet hardware against overheating and downtime

• Optional dampers to reduce airflow

• Significant reduction of energy consumption and costs

• Ultimate load of up to 1360kg

56 Daxten | Thermal Optimisation Best Practices

High-end airflow panels grant for airflow

rates up to 65 percent.

Airflow panel with an airflow rate up to 65%.

Airflow panel with an airflow rate up to 56%.

Solid Panel supporting loads up to 1360kg.

1 2 3

1

2

3

5. Best Practice:

Sealing cable openings in the raised floor

The majority of companies today are investing in expen-

sive cooling technologies to ensure the active hardware in the

racks can operate in a cool environment without failure. In spite

of these expensive investments, companies suffer from over-

heating and system failure caused by hotspots in the data centre.

The culprits are almost always unsealed or insufficiently-sealed cable

openings in the raised floor. The Uptime Institute states that up to 63%

of expensive cooled air is lost through unsealed cable openings; this condi-

tioned air is therefore no longer available for cooling vital locations and cabinets

where servers are located.

Sealing openings puts an end to bypass airflow

Conventionally, these problems have been solved

by increasing the capacity of the cooling systems. Often

companies invest in additional cooling units to maintain

air pressure and air flow. However, this can be done much

more efficiently and at a lower price. Our solutions easily

close and seal cable openings. Your data centre will be

protected against the loss of cooled air, the formation of

hot spots and the risk of downtime. All of this can be done

using existing cooling units while significantly increasing

capacity and increasing efficiency.

Installed in seconds with immediate effects

Our sealing solutions consist of a special filament that seamlessly encloses cables and other equipment

protruding through the raised floor. The system is installed quickly using

a simple installation procedure. This can be either retro-fitted to existing

cabinets without the need for downtime or put into new openings.

57 Daxten | Thermal Optimisation Best Practices

The split seal solutions are ideal for

the usage in existing cabling infrastrcutures.

Sealing cable openings Highlights

• Up to 60% higher energy efficiency in the data centre

• Reliable sealing of openings in the raised floor and elimination of bypass airflow

• Prevents system failures and downtime caused by overheating and hot spots

• Significant increase in under floor air pressure.

Bulky cable bundles are reliable sealed air-tight with

Daxten solutions.

58 Daxten | Thermal Optimisation Best Practices

Your benefits and advantages:

4Significant optimisation of your cooling infrastructure

4High energy costs saving potentials

4No bypass airflow

4Prevents hot spots and associated downtime

4No need for additional cooling systems

4Minimum investment with maximum cost effectiveness

4Quick ROI

4Increased energy efficiency so you are well prepared for the future

Contact us for further information and your cost free individual consultancy appointment

at +44 (0)20 8991 6200, [email protected] or www.daxten.co.uk

Table of contents

Other Daxten Power Supply manuals