DAYLIFF PVm015 Installation instructions

PUMPVERTER

VFD CONTROLLER

Installation &

Operating Manual

CONTROLLER SPECIFICATIONS

1.

1

2.

SYMBOLS & WARNINGS 2

INDEX

© Davis & Shirtliff Ltd 2022

Contents herein are not warranted

3. WIRING 3

3.3 Controls Terminals Connection

5

4.2 Operational Procedure 7

3.1 Main Circuit Terminals Wiring 3

4. OPERATION 6

3.4 Wiring Main Circuit Installation Accessories

5

4.1 Keypad Description 6

3.2 Main Circuit Wiring 4

5. INVERTER PARAMETER DESCRIPTION 9

6. APPLICATION GUIDANCE 18

6.2 Single Pump Constant Pressure Control 19

6.1 System First Startup/ Troubleshooting Procedure 18

6.3 Multi-pump Constant Pressure Control 20

6.4 Parameter Setting for Master and Auxiliary 21

6.5 Day Part Water Supply Application Setting 26

6.6 Terminal Start/Stop Control Wiring and Setting 28

6.7 Manual/ Auto Control Wiring and Setting 28

6.8 Water Supply Control Using Pressure Switch 29

6.9 Pumping Application 31

FAULTY AND TROUBLE SHOOTING

7.

32

TERMS OF WARRANTY

8.

37

1

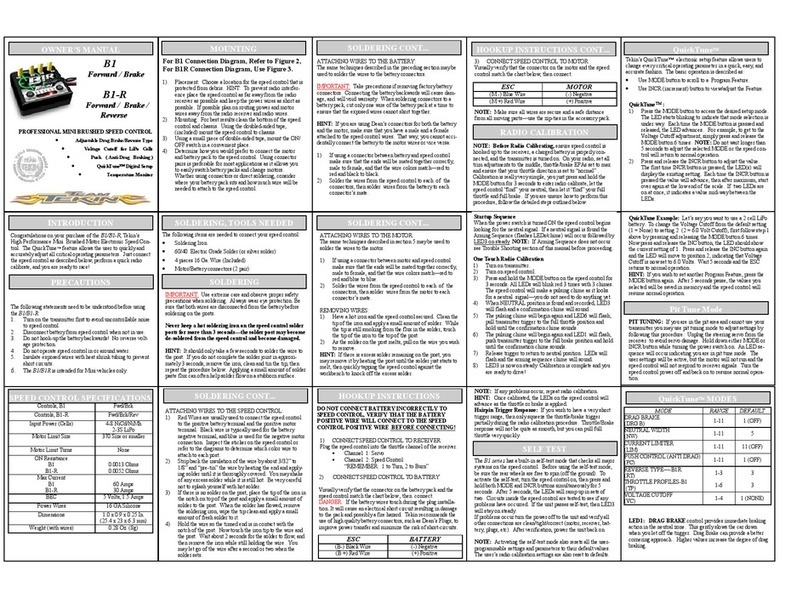

1. CONTROLLER SPECIFICATIONS

DAYLIFF Pumpverter drives are high specification VSD's suitable for use in residential and

industrial applications. They are compact and versatile and can be installed in either

motor or wall mounted configuration. The inverter varies pump motor speed with demand

thus regulating pump output to a preset outlet pressure. Particular features include:

• Maintains constant system pressure when water demand changes by use of

pressure transducers

• Can work simultaneously with other units and control up to 6 pumps in cascade

sequence.

• Sleep mode when there is no water consumption for increased energy savings

• Provides complete pump protection against pump overload, low voltage, high

voltage, phase failure, electronics overheating and dry running (when using float

switch).

• Enclosure class: IP54

Pumpverter range of inverters are proven and dependable designs using the latest

technology to give exceptional levels of performance, economy and reliability.

OPERATIONAL CONDITIONS

Frequency: 50-60Hz

Supply Voltage Tolerances: -15% ~ +10%

0

Max Ambient Temperature: 40 C

Congratulations on selecting a Dayliff Pumpverter. It is manufactured

to the highest standards and if installed and operated correctly will

give many years of efcient and trouble free service. Careful reading

of this Installation Manual is therefore important, though should

there be any queries they should be referred to the equipment

supplier.

2

SPECIFICATIONS

2. SYMBOLS AND WARNINGS

Do not dismantle the product as it may cause electric shock,

re hazard or personal injury.

WARNING

Do not open the cover during operation.

WARNING

Do not put wire, bar of metal, laments etc. into the controller

as it may cause a short circuit and/or electric shock.

WARNING

Do not splash water or other liquids on the controller.

WARNING

Never connect AC power to the output terminals.

CAUTION

Do not touch internal components of the control if they have

been exposed to static electricity.

CAUTION

Model

Power Max

Current (A)

Weight

(Kg)

Dimensions (mm)

PVm015

PVm022

PVm075

Motor

(kW)

Supply

Voltage (V)

Output

Voltage

1.5 9.6 3

216 195 154

1x240 1x240

2.2

5

14

282

370

255

350

165

221

3x415

3x240

7.5

15

17

H W D

PVm150 3x415 32

3

The motor, controller and power specications should be

properly matched, otherwise it may cause abnormal

operation and even burn the device;

CAUTION

If the controller appears to have vibration, noise, heat or

peculiar smell during initial operation, cut off power

immediately and contact authorised Dayliff retailer.

CAUTION

Do not install the controller under direct sunlight or rain.

When moving the controller lift it by its base and not by the

panel, may cause the main unit to fall off which may resulting

in personal injury.

CAUTION

CAUTION

Install the controller on reproof material (such as metal) to

avoid re.

CAUTION

When powering off, ensure indicator light is completely

extinguished, so as to ensure the device is discharged

completely.

CAUTION

Before opening the controller, ensure that all power lines are

disconnected. Wait at least 5 minutes until DC Bus capacitors

discharge.

CAUTION

3. WIRING

3.1 Main Circuit Terminals Wiring

PE POWER

R (L) S (N) U V

T

Mains circuits terminals wiring diagram for PVm15

W

MOTOR PE

POWER

1AC Input To Single

Phase Motor

LNVW

MOTOR

Ground

Mains circuits terminals wiring diagram for PVm22

4

Terminal Symbol Function Description

L,N

U, V, W

PE/

R, S, T

(+), (-)

(+), PB

P1, (+)

(-)

Terminals of single phase AC input

Motor wiring terminal. Note: V, W for PVm15

Terminals for ground

Terminals of 3 phase AC input

Reserved external terminals for braking units

Reserved external terminals for braking resistance

Reserved external terminals for braking DC reactors

Output terminals for negative DC bus voltage

In order to maintain safety and prevent electric shock and fire, PE must be well

grounded.

3.2 Main Circuit Wiring

Figure 1: Control circuits terminals wiring

Mains circuit wiring for PVm40, PVm75

POWER

PB PE

R

(+)

(+)

(-)

(-)

S T U V W PE

MOTOR

Mains circuit wiring for PVm 11-15kW

POWER MOTOR

UVWPE

PB

PE

5

Figure 2: Wiring Diagram

3.3 Control Terminals Connection

3.4 Wiring Main Circuit Installation Accessories

Figure 3: High performance main circuit wiring

PVm

6

Circuit Breaker

It is necessary to connect a suitable circuit breaker between AC power supply and the

Pumpverter. The capacity of breaker should be 1.5~2 times the rated current of

controller.

AC Reactor (Optional)

In order to prevent the rectifier damage resulted from the large current, AC reactor

should be installed at the input side. It can also prevent rectifier from sudden variation of

power voltage or harmonic generated by phase-control load.

Input EMC Filter (Optional)

EMC filter can minimize the interference of the surrounding device which may be

disturbed by the cables when the controller is working.

Output EMC Filter (Optional)

EMC filter should be installed to minimize the current leakage caused by the cable and

minimize the radio noise caused by the cables between the controller and motor.

Output Reactor (for long motor cables)

When the distance between the Pumpverter and motor is more than 50m, the controller

may be tripped by over-current protection frequently because of the large current

leakage resulting from the parasitic capacitance with ground. In order to avoid the

damage of motor insulation, the output reactor should therefore be installed.

4. OPERATION

4.1 Keypad Description

Figure 4: Keypad Schematic Diagram

7

H: Operating Frequency

P: The Actual Pressure of Pump Outlet

L: The Set Pressure of Pump Outlet

A: Output current

D: DC Bus Voltage

U: Output Voltage

4.2 Operation Procedure

Power-on Initialization

When power is switched on the system initializes and LED displays controller model.

After the initialization is completed, the controller switches to stand-by mode.

Parameter Setting

Three levels of menu are available as below:

1. Primary Interface first-level function code

2. Second-level function code

3. Function code setting value third-level function code setting value

ŸPress <</SHIFT or >>/SHIFT to switch to display running/stop status

monitoring parameters.

ŸAt the primary interface, press PRG/ESC to enter the first-level menu then press

PRG/ESC to return to the primary interface.

ŸAt the first-level menu, press DATA/ENT to enter the second-level menu. Second-

level menu press PRG/ESC and DATA/ENT to return to first-level menu or enter

third-level menu.

ŸAt third-level menu, press both PRG/ESC and DATA/ENT to return to the second-

level menu the difference being by:

ŸPressing DATA/ENT the controller save the parameters in the controller

and returns to the second-level menu with shifting to the next function code

automatically.

ŸPressing PRG/ESC will return immediately to the second-level menu without

saving the parameters; and stay at the current function code.

Example 1: Change factory pressure setting 3.0 bar to 2.5 bar

Method 1: Enter parameter setting

8

Figure 5: Operation Flow Chart

Operation flow chart:

Method 2: Direct setting at the primary interface

1. Press or at primary interface, the system will switch-over to display set pressure

2. Press or again, to increase or decrease set pressure.

3. After completing the pressure setting, press DATA/ENT to save the value.

4. During operation press <</SHIFT or >>/SHIFT to scroll through the parameters

in left or right order until there are only two upper lights on.

5. Read out the pressure value.

49

5. INVERTER PARAMETERS DESCRIPTION

Function

Code

Set at b06.09, default is 65535

Debugging

Password

Name

b00.00

Setting Range Factory

Setting Description

0~65535 65535

S et a c c o rdin g t o t h e a c t u a l

requirements

Pressure Setting

Valve

b00.01 0.0~100bar 3.0bar

0: Forward 1: Reverse

Ensure pump motor is running

correctly

Motor Rotating

Direction

b00.02 0~1 0

Prevention measures

0: Invalid 1: Valid

Anti-clogging

b00.04 0~1 0

Anti-clogging

Rotating Cycle

b00.05 1~300s 20.0s Set the forward/reverse rotating

direction cycle and corresponding

output frequency of anti-clogging

(should not be higher than the rated

frequency of the pump).

Anti-clogging

Output

Frequency

b00.06 0~600

Hz 15.0Hz

When pressure is higher than the

preset value, the controller will stop

show alarms and display HP

High Water

Pressure/Level

Alarm Value

b01.00 0.0~100.0

bar 8.0bar

When the pressure is lower than the

preset value for the low pressure

running time, the controller will stop,

show alarms and displays LP

Low Water

Pressure/Level

Alarm Value

b01.01 0.0~100.0

bar 0.5bar

Low Pressure/

Level Alarm

Running Time

b01.02 0~300s 20s

Be valid when b00.03 was set to 1,

whenever sleeps, running with the

setting frequency in case of freezing

Minimum

Freeze Proofing

Frequency

b01.03 1.00-30.00

Hz 5.00Hz

When anti clogging is valid, b01.04

sets the FWD/REV transition time

Anti-clogging

FWD/REV

Dead Time

b01.04 0.0~3600s 1.0s

E.g. If the rated max. range of

transducer is 10bar, b01.05 should

be set to 10.0

Maximum

Transducer

Setting Range

b01.05 0.0~100.0

bar 10.0bar

10

Function

Code Name Setting Range Factory

Setting Description

All Lower

Limit

b01.06 0.00~

10.00V 1.00V • Lower limit use to transducer zero

setting

• Higher limit use to accordant

display and transducer pressure

• When display smaller than

gauge increase higher limit.

When display is greater than

gauge, decrease higher limit.

• When analog input is interfered,

prolong filtering time so as to

increase the ability of anti-

interference but decreases the

sensitivity.

• Corresponding relationship of

transducer parameter setting:

Corresponding

Setting of AI1

Lower Limit

b01.07 -100~100% 0.0%

Al1 Higher

b01.08 0.0~10.0V 5.00V

b01.09

Corresponding

Setting of Al1

Higher Limit

-100~100% 100%

b01.10 Al1 Filtering

Time 0.00-10.00s 0.10s

b01.11 AI2 Lower

Limit 0.00-10.00V Corresponding

Pressure Setting

Lower

Limit

Upper

Limit

Max Range of

Transducer

0

1.00V

Figure 5.1.1 Transducer

Parameters

b01.12

Corresponding

Setting of AI2

Lower Limit

-100~100% 0.0%

b01.13 AI2 Lower

Limit 0.00-10.00V 5.00V

b01.14

Corresponding

Setting of AI2

Higher Limit

-100~100% 100%

b01.15 AI2 Filtering

Time 0.00~10.00s 0.10s

0:Invalid 1:Valid

b01.16 0~1 0

Restart After

Power-on

0:Synchronous 1:Master-Slave

b01.17 0~1 1

Control Mode

0:Keypad 1:Reserved

b02.00 0~1 0

PID Source

Selection

0:A11 1:Reserved

b02.01 0~1 0

PID Feedback

Source

Selection

411

Function

Code Name Setting Range Factory

Setting Description

0:Water Supply 1:Pumping

b02.02 0~1 0

PID Output

Characteristics

Determining the strength of PID

regulation, KP is bigger, regulation is

stronger but fluctuates easily

b02.03 0.00~100.00 2.50

Proportional

Gain (KP)

Bias between the feedback and the

given, determining the speed of

regulation. If K1 is bigger, regulation

is stronger

b02.04 0.00~10.00 1.00

Integral

Coefficient (KI)

Variable ratio between the feedback

and the given, KD is bigger,

regulation is stronger. Be cautious

use, for differential regulation

amplifies interference of system

b02.05 0.00~10.00 0.00

Derivative

Coefficient

(KD)

Calculating time of regulator, when

increased response sluggishly

b02.06 0.01~100s 0.10s

Sampling cycle

(T)

Max. bias of PID output value

corresponding to closed loop given

value

b02.07 0.0~100% 0.0%

PID Control

Bias Limit

Figure 5.2 PID control curve Corresponding

S y s t e m D i a g r a m

of Max. Limit and Output Frequency.

Properly set the value so as toregulate the

accuracy and stability of PID system.

Bias Limit

(PID stops

regulating)

Feedback

Set

point

t

t

Output

Frequency

4

12

Function

Code Name Setting Range Factory

Setting Description

Transducer fault detecting setting

value, corresponding to full range

(100%), when the detecting time

exceeds feedback lost time, it is

d e e m e d a s m a l f u n c t i o n b y

transducer, the system will report

E022 as transducer fault code.

b02.08 0.0~100.0% 1.0%

Al1 Feedback

Lost Detecting

Value

b02.09 0.0~100% 0.0%

AI2 Feedback

Lost Detecting

Value

b02.10 0.0~3600s 1.0s

Feedback Lost

Detecting Time

00: Master Controller

01~05: Auxiliary Controller

06~31: Reserved

Communication

Address

b03.00 0~31 02

Data of master and slave comes

into the rate

0: 1200BPS 1: 2400BPS

2: 4800BPS 3: 9600BPS

4: 19200BPS 5: 38400BPS

Band Rate

Selection

b03.01 0~5 3

Data Format (parity check)

Data Format

b03.02 0~5 0

Interval of data responding

Communication

Delay Time

b03.03 0~200ms 15ms

If the interval time exceeds the setting

value, the system will report E018 as

fault

Communication

Timeout Delay

0.0: invalid

b03.04 0~100s 0.0s

0: Halt and display alarm

1: Do not display alarm, continue

Communication

Error Action

b03.05 0~1 0

0: Responding to write operation

1: Un-responding to writer operation

Communication

Response

Action

b03.06 0~1 0

E n s u r e t h e e f f e c t s o f d a t a

transmission, long-time setting will

slow down data transmission and

short-time setting will easily make

mistakes

Data

Transmission

Time Interval

b03.07 0.05~2.00s 0.10s

413

Function

Code Name Setting Range Factory

Setting Description

0: None

Slave Quantity

b03.08

0~5

0

Fault Master Shift

• Invalid: Factory Setting: 2

• Valid: Master set as 0;

Slave1 set as 1

Re mark s: Fault shift requ ires

connection of backup transducer to

Slave 1. Slave 1 acts as standby

master.

Fault Shift/

Standby Master

b03.09

0~2

2

No consuming auto stop

0:Invalid 1: Valid

Sleeping

Function

b04.00 0~1 1

Delay time

Sleeping

Waiting Time

b04.01 0.0~300.0s 5.0s

Water consuming test frequency rate

Sleeping

Test

b04.02 0.0~10.0% 4.0%

During sleep the wake-up pressure

bias e.g. the setting value (L)=3.0bar,

bias (b04.03)=0.5bar, practical

pressure (P)<L-0.5=2.5bar, the

pump will restart again.

Wake up

Pressure Bias

b04.03 0.0~20.0bar 0.5bar

The pressure fluctuation which allows

sleeping

Sleeping

Bias

b04.04 0.0~1.0bar 0.0bar

Water level switch style

0: Invalid 1: NC 2: NO

Water Level

Control

b05.00 0~2 2

Delay time of restart after water level

recover

Low Level

Restart Delay

Time

b05.01 0~300min 1min

0: Invalid

1: Electric Contact Control

S1-COM on: Frequency rise

S2-COM on: Frequency drop

2. Manual/Auto Control

S2-COM off: Auto Control

S2-COM on: Manual Control

3. Terminal run/stop

S1-COM on: Run

S1-COM off: Stop

S2-COM off: Auto Control

S2-COM on: Manual Control

Terminal S1S2

Control

b05.02 0~3 2

414

Function

Code Name Setting Range Factory

Setting Description

Setting time from zero to max

Acceleration

b05.03 0.1~3600s Model

The setting time from max. frequency

to zero

Deceleration

Time

b05.04 0.1~3600s Model

Set

Time Set Frequency

Determine the Acc./Dec. rate

Maximum

Output

Frequency

b05.05 10-600Hz 50Hz

Maximum running frequency

Up limit of

Output

Frequency

b05.06

b05.07~

b05.05

(Maximum

Frequency)

50Hz

The minimum running frequency of

pump

Lower limit of

Output

Frequency

b05.07 0Hz~b05.07 20Hz

Use to check the noise of motor and

controller ’s interference to the

surroundings. A high carrier makes a

low motor noise, but leads to a big

temperature rise and interference.

Should not be altered if unnecessary.

Carrier

Frequency

b05.08 1~15kHz Model

Set

Low Pressure

(LP) Restart

Delay Time

b05.09 0~60min 10min

In case of low pressure, b05.09=0,

the controller restarts according to

the setting time automatically, without

artificial restart. b05.09=0, restart

invalid

Alternating

Time

b05.10 0~300h 8h

In order to balance and prolong the

pump service life to set the parameter,

unit: hour. When the parameter is set

to 0.0, it means no alteration.

Operational time of master and

auxiliary pump switches over

according to the setting alternating

time

415

Function

Code Name Setting Range Factory

Setting Description

bit0: Operational frequency

bit1: The actual pressure of pump

outlet

bit2: The setting pressure of pump

outlet

bit3: Output current

bit4: DC bus voltage

bit5: Output voltage

bit6: Present time

bit7: The actual pressure of pump

inlet

bit8: Input terminal status

Running Status

Display

Selection

b06.00 0~0x1FF 0x01F

bit0: The setting pressure of pump

outlet

bit1: The actual pressure of pump

outlet

bit2: Giver frequency

bit3: DC bus voltage

bit4: Input terminal status

bit5: Output terminal status

bit6: Al1 input voltage

bit7: The actual pressure of pump

inlet

Bit8: Present time

Stop Status

Display

Selection

b06.01 0~0x1FF 0x001F

0: External keypad prior enable

1: Both display enable, only external

keypad control

2: Both display enable, only on board

keypad control

3: Both display enable and keypad

control.

Keypad

Display

Selection

b06.02 0~3 3

0: Error or external fault

1: Forward running

2: Frequency reaching

3: Stop status

4: Lower limit of output frequency

reaching

5: The frequency is not equal to zero

Relay Output

Selection

b06.03 0~5 0

416

Function

Code Name Setting Range Factory

Setting Description

Password set prevent user from

modifying the parameters randomly,

avoiding abnormal running and

damages.

Set the

password of

b00.00

b06.09 0~65535 65535

Third Latest

Fault Type

b06.04

Second Latest

Fault Type

b06.05

Latest Fault

Type

b06.06

Read

Only

E000~E022

Refer to chapter 9

Parameters

Storage

Condition

b06.07 0~2 0

0: Power off storage

1: Power off default storage

2: Invalid

Accumulated

Running

Time

b06.08 0~65535h Read

Only Display accumulated running time

0: Invalid

1: Day part A

2: Day part A and B

3: Day part A, B, C

Day part

Function

Selection

b07.00 0~3 0

Day part A

Starting Time

b07.01 00:00~24:00 00~00 • Setting starting time and finishing

time to 0 is invalid.

• Pressure setting determines the

steady state value of outlet

pressure

• Once actual pressure from inlet

pipe network lower than inlet

pressure lower limit, the pump

stops.

Day part A

Pressure

Setting

b07.02 0.0~20bar 3.0bar

Day part A

Finishing Time

b07.03 00:00~24:00 00~00

AI2 Lower

b07.04 0.0~20bar 2.0bar

417

Function

Code

• When regardless of the inlet

water pressure, just set the lower

limit as 0.

Limit of

Day part A

Name

b07.05

Setting Range Factory

Setting Description

00:00~24:00 00-00

Day part B

Starting Time

b07.06 0~20.0bar 3.0Bar

Day part B

Pressure Setting

b07.07 Day part B

Finishing Time 00:00~24:00 00-00

b07.08

AI2 Lower

Limit Day

part B

0~20.0bar 3.0Bar

b07.09 Day part C

Starting Time 00:00~24:00 00-00

b07.10 Day part C

Pressure Setting 0~20.0bar 3.0Bar

b07.11 Day part C

Finishing Time 00:00~24:00 00-00

b07.12

AI2 Lower

Limit of

Day part C

0~20.0bar 2.0Bar

b07.13 Lower Limit of

Inlet Pressure 0~100.0bar 0.0Bar

Valid all day, especially when taking

into account the inlet water pressure.

When not needed, set as 0.

b07.14 Restore

Defaults 0~2 0

0: No action

1: Set to default

2: Clear error records

0: G model 1:P model

b07.15 Password of

Group Br08 0~65535 65535

b08.00 G/P Option 0~1 1

Depending on model, setting

parameters according to nameplate

of motor

b08.01 Motor Rated

Power 0.4~350kW Model

Set

b08.02 Motor Rated

Frequency 0~600Hz 50Hz

418

Function

Code Name

b08.03

Setting Range Factory

Setting Description

0~36000

RPM

Model

Set

Motor Rated

Speed

b08.04 0~460V

Motor Rated

Voltage

b08.05 0.0~2000A

Motor Rated

Current

b08.06 0~65535

Reserved 00000

b08.07 0~65535

Set the

Password of

b07.15

65535 Modify password of b07.15

b08.08 0~65535

Password of

Factory

Parameters

xxxxx Don't try to enter or will cause

abnormal operations and damages

In order to ensure the pumps running safety, carefully enter rated value from motor

nameplate.

6. APPLICATION GUIDANCE

Pumpverter has functions to handle various use cases. This section introduces typical

use cases with relevant parameter settings.

6.1 System First Startup/ Troubleshooting Procedure

System Wiring

Figure 6: Startup/Troubleshooting Flow Diagram

Confirm Direction

of Rotation

This manual suits for next models

3

Table of contents

Other DAYLIFF Controllers manuals