DAYLIFF EXPRESS D1-1ph Installation instructions

EXPRESS

ELECTRONIC PUMP CONTROLLER

Installation &

Operating Manual

CONTROLLER SPECIFICATIONS

1.

1

2.

SYMBOLS & WARNINGS 2

CONTROLS

3.

4

ALARMS

6.

22

WARRANTY

7.

25

INDEX

© Davis & Shirtliff Ltd 2020

Contents herein are not warranted

DECLARATION OF CONFORMITY

8.

27

INDICATORS

4.1 Main Display Items

4.

4.2 Activation of Load in Manual Mode

5.

FUNCTION AND SETTINGS

5.1 Function 1: Draining with oats /

pressure Switches

5.2 Function 2: Draining with level

sensors and oats / Pressure

Switches

5.3 Function 3: Drainage with “COS FI”

Power Factor Control

5.4 Function 4: Pressurisation with

analogue signal and oats /

Pressure Switches

5.5 Function 5: Pressurisation with

analogue signal and level sensors

5.6 Function 6: Pressurisation with

analogue signal and COS PHI

Power Factor Control

5.7 Function 7: Filling with level sensors

and oat/ Pressure Switches

5.8 Function 8: Filling with level sensors

and “COS PHI” Power Factor

Control

5

5

5

6

6

8

10

12

14

17

19

20

1

1. CONTROLLER SPECIFICATIONS

Dayliff EXPRESS is a high specification multi-function electronic controller suitable for all

borehole, waste water, sewage and general water supply pump applications. Controllers

are fitted with a digital display that indicates both operating and fault parameters and can

be programmed using fascia mounted panel buttons. A range of specifications are

available for single and three phase motors, configuration to a particular motor size being

effected by adjustments of the maximum running current. Particular features include:

• Incoming mains isolator and door interlock

• Multifunction LCD display of voltage, current, power factor (cos), operating status and

system faults

• In built protection for overcurrent, over or under voltage, phase sequence and phase

failure.

• In built power factor dry run protection or connections for remote low level float

switch/probes provided.

• Connections for various analogue (eg pressure and float switch) or digital (eg PLC's and

transducers) signal inputs provided.

• Large enclosure with space for capacitors in single phase pump installations.

• Adjustable maximum operating current and voltage limit settings.

• Twin pump controllers provide for selection of duty/standby, alternate duty cycling with

auto trip changeover and parallel operation configurations.

Single and twin pump EXPRESS controllers for DOL start are available as standard while

panels for 3 and 4 pump operation and Star-Delta start can be suppled on request. Dayliff

EXPRESS is a fully integrated controller that is adaptable to almost any pump control

requirement as well as giving full motor protection and operating and fault status

Congratulations on selecting a Dayliff Express Panel. They are

manufactured to the highest standards and if installed and operated

correctly will give many years of efcient and trouble free service.

Careful reading of this Installation Manual is therefore important,

though should there be any queries they should be referred to the

equipment supplier.

2

indications. It is compact, simple to install and exceptional value for the functionality provided

and the ultimate control solution for all booster pumping requirements.

CONTROLLER FUNCTIONS

GENERAL DATA

Controller Model Start

Method

Motor

Size

Max

Current

(A)

Dimensions (mm)

Height Width Length

Wt

(kg)

EXPRESS D1-1ph DOL 0.37-2.2kW

DOL

DOL

EXPRESS D1-3ph/7.5

EXPRESS D1-3ph/15

0.55-7.5kW

0.55-15kW

18

16

32 320 240 190

2

2.5

2.5

–

–

DOL

DOL

EXPRESS D2-1ph

EXPRESS D2-3ph/7.5

0.37-2.2kW

0.55-7.5kW

18

16

2.5

3.5

Express D1/D2 - 1ph Express D1 - 3ph Express D2 - 3ph

WL

H

2. SYMBOLS AND WARNINGS

This operation and maintenance manual uses the symbols outlined below to indicate risks

that may arise in the event of failure to observe the instructions supplied.

This symbol corresponds to an immediate risk of death or serious physical

injury or material damage. When present, take great care to observe

warnings and instructions.

DANGER

Display of Analogue Signals expressed as

a percentage, in meters or Bar

Display of Motor Operating Parameters

Display of Motor Operating Status

DAYLIFF

www.dayliff.com

230V 7.0At 1.0b

PL (L) P2(L) P3 (0)

230V 7.0At Ot

PL (L) P2(L) P3 (0)

230V 0.0A 1.0

MAN () AUR(*) PL (L)

Enclosure Class: IP55 Power Supply: 110V-240V/+10% 1ph, 310V - 450V/+10%, 3ph

Failure to observe the instructions in the presence of this symbol may lead to

malfunctions and damage to equipment, with possible consequent injuries

to the operator.

Before performing any work on the electrical panel or system, shut off the

electrical power supply.

WARNING

WARNING

The electrical panel must be connected by a qualified electrician in

observance of the relevant electrical standards.

WARNING

Before any other operation, ensure the installation is connected to an

efficient earthing system.

WARNING

After making the electrical connection, check that all electrical panel

settings are correct to ensure automatic start-up of the electric pump.

WARNING

Before performing any work on the electrical panel or system, shut off the

electrical power supply.

On receipt of the goods, perform an inspection immediately to ensure that the equipment

has not been damaged during transport. If defects or missing material are found, the

client should promptly notify, and in any event within 5 days of receiving the goods, the

nearest Davis & Shirtliff retailer.

The Dayliff EXPRESS electrical panel must be used exclusively for the purpose and function

as specified in design. Any other application or use is to be considered improper and

therefore hazardous.

WARNING

3

This symbol corresponds to a possible risk of death or serious physical injury

or material damage. Take care.

CAUTION

DANGER

In the event of a fire in the place of installation or the surrounding area,

avoid the use of water jets and use the appropriate extinguishing equipment

and means (powder, foam, carbon dioxide).

Install the equipment far from heat sources and in a dry and sheltered

location in observance of the stated protection rating (IP).

DANGER

The installation of a safety device is recommended to protect the panel

power line in compliance with current electrical standards.

Davis & Shirtliff declines all liability in the event of the following:

• Incorrect installation;

• Use by personnel not adequately trained in the correct use of the panel;

• Serious failure to perform scheduled maintenance;

• Use of non-original spare parts or parts not specific to the model;

• Unauthorised modifications or interventions;

• Partial or total failure to observe instructions.

The Dayliff EXPRESS electrical panel has been designed for settable protection of 1 to 4

motors with the option of selecting the operating mode according to the specific system

used.

Among the various modes, the panel enable motor control by means of:

• Pressure switches.

• Floats

• Remote Contacts

• Start/Stop Floats

• Level Sensors

• 0-10V signals

• 4-20mA pressure transducers

• "COS-PHI" power factor (where "Phi" is the timing angle between current and voltage).

4

3. CONTROLS

All Dayliff EXPRESS panel installation and maintenance operations must be

performed by a specialised technician who is fully aware of the relevant

current safety standards.

No parts of the panel must be disassembled without prior formal

authorisation from supplier: any tampering with or modifications to the unit

will render all terms of the warranty null and void.

Always disconnect the unit from the power supply before maintenance or

cleaning.

If Dayliff EXPRESS is not used for prolonged periods, store the product in a

clean and safe location protected against atmospheric agents and the

potential risk of dropping/falling.

DANGER

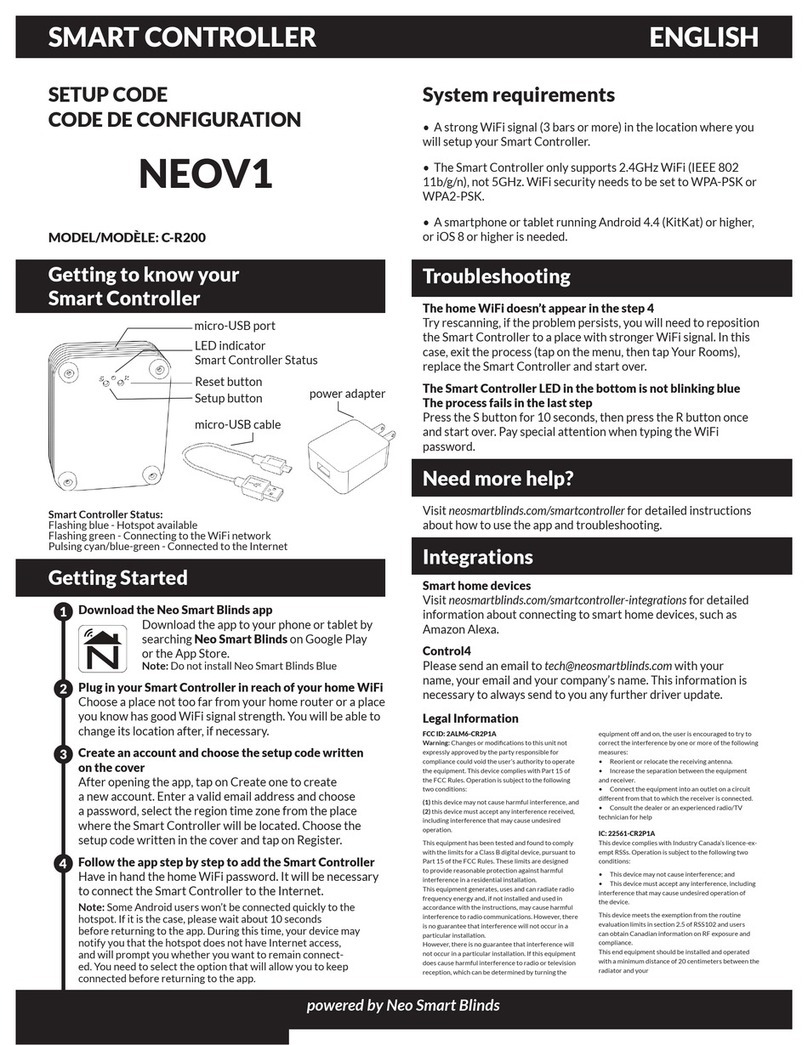

4.1 Main display items

On activation of the panel, the display shows the following:

At the end of the start-up sequence, the main menu is displayed, as described below;

This screen enables the display of active motors, voltage on input and

total absorption of the panel:

• 230 V = Power supply voltage reading.

• 7.0 Atot = Total current absorbed by the panel.

• P1 ( 0 ) = Motor 1 deactivated • P1 ( 1 ) = Motor 1 active.

• P2 ( 0 ) = Motor 2 deactivated • P2 ( 1 ) = Motor 2 active

• P3 ( 0 ) = Motor 3 deactivated • P3 ( 1 ) = Motor 3 active

If operating modes are used with analogue signals, the main screen

also displays the input signal expressed as a percentage, in metres or

bar.

EXPRESS E L E N MODEL

By pressing OK the user can view the screen of each motor (P1, P2 and

P3), where the following is displayed:

•230 V = Power supply voltage reading.

•0.0 A = Current absorbed by connected load.

•1.0 ( ) = Power factor of connected load.

•MAN (*) = Panel set to manual mode.

•AUT (*) = Panel set to automatic mode.

•MAN ( ) AUT ( ) = Panel on standby.

•P1 = Motor 1 deactivated.

•P1 = Motor 1 active.

j

45

4. INDICATORS

Display of values and programming.

Red led: general alarm

SETUP (or multifunction) button

UP arrow button

DOWN arrow button

OK button

OK

EXPRESS

230v 7.0A to t

P1 (1) P2 (1) P 3 ( 0)

230v 7.0At 1 . 0 b

P1 (1) P2 (1) P 3 ( 0)

230v 0.0A 1 . 0 @

MAN () AUT (* ) P 1 1

6

The Dayliff EXPRESS panel features a host of internal functions.

There are basically 8 operating modes developed for various types of application as

described below.

5.1 FUNCTION 1 - Draining with oats/pressure switches

This operating mode is used for drainage applications using floats or pressure switches,

enabling the control of one or more pumps.

On selection of mode 1, all relative parameter fields for this function are enabled.

5. FUNCTIONS AND SETTINGS

4.2 Activation of load in manual mode

On start-up, the panel starts in automatic mode, as confirmed by the asterisk (*) displayed

alongside the text AUT on the display of each motor, or according to the previous status set

before shutdown.

The operating mode can be changed by pressing the UP arrow to change to Manual

mode, or the DOWN arrow to change to Automatic mode. Therefore, to enable

operation in Manual mode, press the UP arrow (the asterisk (*) is displayed alongside the

text MAN) and then press and hold OK.

The display then displays current absorption of the motor and the cos-phi power factor

values in real time. On release of the OK button, the motor is shut down.

In manual mode, the load is activated and bypasses all alarms,

but in the event of a fault the display ashes.

CAUTION

Programming Menu

To select the panel operating logic, access the programming menu by pressing the buttons

SETUP, UP and DOWN at the same time on the main screen of the panel.

User Menu

On completion of panel operation programming, enter the setup menu to configure the

various data for motor start-up. To access the user menu, press the button SETUP for 4

seconds in the main screen of the panel.

Language

0 ITA / 1 ENG/ 2 FRA

Number of Pumps

This parameter enables selection of the number of pumps in the system

(when 1 single pump is selected, the parameters pump rotation enabled and

float star/stop function are disabled).

DESCRIPTION OF PARAMETER VALUE

Operating Logic

0

FAULT

0

1-

1-4 As per order

Pump rotation enabled

This parameter enables activation of pump exchange on each demand

from floats or pressure switches. Also, if the main pump thermal cutout

(current overload) trips, the second pump is enabled (if set to N,

parameter 5 is disabled).

Float start/stop function (self-holding)

This parameter enables deactivation of active pumps only on opening of

the contact MIN.F. (min./stop float).

Minimum level alarm output

This parameter enables removal of the minimum level alarm from the

cumulative alarm output.

Y or N Y

Y or N N

Y or N Y

7

8

Minimum Voltage

Set by default at -10% .

Modifications to operating limits beyond the default parameters will

i m m e d i a t e l y r e n d e r t h e w a r r a n t y n u l l a n d v o i d .

Maximum Voltage

Set by default at +10% .

Modifications to operating limits beyond the default parameters will

i m m e d i a t e l y r e n d e r t h e w a r r a n t y n u l l a n d v o i d .

DESCRIPTION OF PARAMETER VALUE

207 (230)

FAULT

360 (400)

-

-

253 (230)

440 (400)

Maximum Current P1 / P2 / P3 / P4

This parameter enables entry of the maximum current for each motor.

Enter the maximum current value, increasing it by 10-15% with respect to the

rated motor value.

Modifications to operating limits beyond the parameters stated on the model

data plate will immediately render the warranty null and void.

Display brightness on standby

This parameter enables entry of the brightness setting applied when the

d i s pl a y s et s t o s t an d b y ( w a i t 9 s e c o n d s f o r a p r e v i e w ).

Time For Entry To Set-up

This parameter enables entry of the time to keep the SETUP button

pressed for access to the set-up menu.

1 - … A As per order

0-9

3 Sec

4

2 - 30 Sec

5.2 FUNCTION 2 - Draining with level sensors and oats/pressure

switches

This operating mode is used for drainage applications using level sensors and floats or

pressure switches, enabling the control of one or more pumps.

Motor Clicson

Motor 2/ Duty

Float/ Pressure

Switch

Earthing Grounding

Motor Output

Starting Capacitor

(1-phase)

Supply Input

(T for 3-phase)

Alarm Float

Switch

Motor Clicson

Motor 1/ Exchange

Float/Pressure Switch

Min Level Input

Cumulative Alarm

Output

Earthing Grounding

Motor Output

Supply Input

(T for 3-phase)

Starting Capacitor

(1-phase)

9

Programming Menu

To select the panel operating logic, access the programming menu by pressing the buttons

SETUP, UP and DOWN at the same time on the main screen of the panel.

User Menu

On completion of panel operation programming, enter the setup menu to configure the

various data for motor start-up. To access the user menu, press the button SETUP for 4

seconds in the main screen of the panel.

Language

0 ITA / 1 ENG/ 2 FRA

Number of Pumps

This parameter enables selection of the number of pumps in the system

(when 1 single pump is selected, the parameter PUMP ROTATION

ENABLED is disabled).

DESCRIPTION OF PARAMETER VALUE

Operating Logic

0

FAULT

0

2-

1-4 As per order

Pump rotation enabled

This parameter enables activation of pump exchange on each demand

from floats or pressure switches. Also, if the main pump thermal cutout

(current overload) trips, the second pump is enabled.

Sensor Sensitivity (Sa - Sb - Sc - Sd)

This parameter enables display of sensor sensitivity. With the contacts open,

if a value of 99 is displayed, and a value of 45 is displayed with water

present, set sensitivity to an intermediate value, such as 75.

Minimum Level Alarm Output

This parameter enables removal of the minimum level alarm from the

cumulative alarm output.

Y or N Y

0-99 75

Y or N Y

10

Minimum Voltage

Set by default at -10% .

Modifications to operating limits beyond the default parameters will

i m m e d i a t e l y r e n d e r t h e w a r r a n t y n u l l a n d v o i d .

Maximum Voltage

Set by default at +10% .

Modifications to operating limits beyond the default parameters will

i m m e d i a t e l y r e n d e r t h e w a r r a n t y n u l l a n d v o i d .

DESCRIPTION OF PARAMETER VALUE

207 (230)

FAULT

360 (400)

-

-

253 (230)

400 (400)

Maximum Current P1 / P2 / P3 / P4

This parameter enables entry of the maximum current for each motor.

Enter the maximum current value, increasing it by 10-15% with respect to the

rated motor value.

Modifications to operating limits beyond the parameters stated on the model

data plate will immediately render the warranty null and void.

Display brightness on standby

This parameter enables entry of the brightness setting applied when the

d i s pl a y s et s t o s t an d b y ( w a i t 9 s e c on d s f or a p re v i e w ) .

Time For Entry To Set-up

This parameter enables entry of the time to keep the SETUP button

pressed for access to the set-up menu.

1 - … A As per order

0-9

3 Sec

4

2 - 30 Sec

5.3 FUNCTION 3 - Drainage with "COS-Phi" power factor control

This operating mode is used for drainage applications with dry running safety control,

obtained from the power factor (where "Phi" is the timing angle between current and

voltage), without the need for external commands (float or pressure switch), enabling the

control of one or more pumps.

On selection of mode 3, all relative parameter fields for this function are enabled.

Motor Clicson

Motor 2/ Duty

Float/ Pressure

Switch

Earthing Grounding

Motor Output

Starting Capacitor

(1-phase)

Supply Input

(T for 3-phase)

Alarm Float

Switch

Motor Clicson

Motor 1/ Exchange

Float/Pressure Switch

Cumulative Alarm

Output

Earthing Grounding

Motor Output

Starting Capacitor

(1-phase)

Supply Input

(T for 3-phase)

11

Programming Menu

To select the panel operating logic, access the programming menu by pressing the buttons

SETUP, UP and DOWN at the same time on the main screen of the panel.

User Menu

On completion of panel operation programming, enter the setup menu to configure the

various data for motor start-up.

Language

0 ITA / 1 ENG/ 2 FRA / 3 ESP

Number of Pumps

ThThis parameter enables selection of the number of pumps in the system

(when 1 single pump is selected, the parameter PUMP ROTATION

ENABLED is disabled).

DESCRIPTION OF PARAMETER VALUE

Operating Logic

0

FAULT

0

3-

1-4 As per order

Pump rotation enabled

This parameter enables activation of pump exchange on each demand

from floats or pressure switches. Also, if the main pump thermal cutout

(current overload) trips, the second pump is enabled.

Minimum Level Alarm Output

This parameter enables removal of the minimum level alarm from the

cumulative alarm output.

COS-Phi Alarm Output

This parameter enables removal of the dry running alarm from the

cumulative alarm output.

Y or N Y

Y or N Y

Y or N Y

Minimum Voltage

Set by default at -10% .

Modifications to operating limits beyond the default parameters will

i m m e d i a t e l y r e n d e r t h e w a r r a n t y n u l l a n d v o i d .

Maximum Voltage

Set by default at +10% .

Modifications to operating limits beyond the default parameters will

i m m e d i a t e l y r e n d e r t h e w a r r a n t y n u l l a n d v o i d .

DESCRIPTION OF PARAMETER VALUE

207 (230)

FAULT

360 (400)

-

-

253 (230)

440 (400)

Maximum Current P1 / P2 / P3 / P4

This parameter enables entry of the maximum current for each motor.

Enter the maximum current value, increasing it by 10-15% with respect to the

rated motor value.

Modifications to operating limits beyond the parameters stated on the model

data plate will immediately render the warranty null and void.

Minimum COS-Phi P1 / P2 / P3 / P4

This parameter establishes the minimum Cos-Phi power factor value for

each motor

Enable operation in manual mode, activate in no-load conditions (dry

running), check the power factor reading (e.g. 0.65) and enter the

minimum power factor, increasing it by approx. 0.05.

Automatic Reset On Dry Running Alarm

In the event of a dry running alarm (minimum power factor) the panel

may attempt to reset automatically, which can be programmable in

minutes.

4 reset times can be set, in which the system automatically restarts after

being blocked; By default these values are set as shown below:

The first reset attempt is performed 5 minutes after the dry running alarm.

The second reset attempt is performed 10 minutes after the alarm.

The third reset attempt is performed 15 minutes after the alarm.

The fourth reset attempt is performed 20 minutes after the alarm.

Sequential Reset On Dry Running Alarm

If the value 0 (zero) is set, all automatic resets are blocked after the fourth

attempt; if the value is set to 1 (one) at the end of the fourth attempt, the

reset cycle is repeated continuously;

The system protecting the panel against dry running conditions activates

the reset cycle according to the time intervals set, and resumes the same

reset cycle each time water is detected for more than 10 seconds.

Display Brightness On Standby

This parameter enables entry of the brightness setting applied when the

display sets to standby (wait 9 seconds for a preview).

Time For Entry To Set-up

This parameter enables entry of the time to keep the SETUP button

pressed for access to the set-up menu.

1 - … A As per order

0.15-1.00

1° 5 Min

2° 10 Min

3° 20 Min

4° 30 Min

0.8

1-240min

12

0 or 1 0

0-9 4

2-30 Sec 3 Sec

5.4 FUNCTION 4 - Pressurisation with analogue signal and

oats/pressure switches

This operating mode is used for pressurisation applications managed via analogue

signals and floats or pressure switches, enabling the control of one or more pumps.

On selection of mode 4, all relative parameter fields for this function are enabled.

Language

0 ITA / 1 ENG/ 2 FRA / 3 ESP

Number of Pumps

This parameter enables selection of the number of pumps in the system

(when 1 single pump is selected, the parameter PUMP ROTATION

ENABLED is disabled).

DESCRIPTION OF PARAMETER VALUE

Operating Logic

0

FAULT

0

4-

1-4 As per order

Pump rotation enabled

This parameter enables activation of pump exchange on each demand

from floats or pressure switches. Also, if the main pump thermal cutout

(current overload) trips, the second pump is enabled.

Minimum Level Alarm Output

This parameter enables removal of the minimum level alarm from the

cumulative alarm output.

Type Of Analogue Signal

This parameter enables selection of the type of analogue signal on input

to the panel: 0 = 0-10 V 1 = 4-20 mA

Unit Of Measurement

This parameter enables selection of the measurement unit of the

analogue signal on input to the panel.

Full Scale Of Analogue Signal

This parameter enables selection of the full scale of the analogue signal

on input to the panel.

Y or N Y

0 or 1 As per order

Y or N Y

13

Programming Menu

To select the panel operating logic, access the programming menu by pressing the buttons

SETUP, UP and DOWN at the same time on the main screen of the panel.

% + or % -

m or bar As per order

1.0 - 999.9 As per order

Motor Clicson

Earthing Grounding

Motor Output

Starting Capacitor

(1-phase)

Supply Input

(T for 3-phase)

Alarm Float

Switch

Motor Clicson

Analogue Signal

Min Float/Pressure

Switch

Cumulative

Alarm Output

Earthing Grounding

Motor Output

Starting Capacitor

(1-phase)

Supply Input

(T for 3-phase)

User Menu

On completion of panel operation programming, enter the setup menu to configure the

various data for motor start-up. To access the user menu, press the button SETUP for 4

seconds in the main screen of the panel.

5.5 FUNCTION 5 - Pressurisation with analogue signal and level sensors

This operating mode is used for pressurisation applications managed via analogue

signals and level sensors, enabling the control of one or more pumps.

On selection of mode 5, all relative parameter fields for this function are enabled.

Minimum Voltage

Set by default at -10% .

Modifications to operating limits beyond the default parameters will

i m m e d i a t e l y r e n d e r t h e w a r r a n t y n u l l a n d v o i d .

Maximum Voltage

Set by default at +10% .

Modifications to operating limits beyond the default parameters will

i m m e d i a t e l y r e n d e r t h e w a r r a n t y n u l l a n d v o i d .

DESCRIPTION OF PARAMETER VALUE

207 (230)

FAULT

360 (400)

-

-

253 (230)

440 (400)

Maximum Current P1 / P2 / P3 / P4

This parameter enables entry of the maximum current for each motor.

Enter the maximum current value, increasing it by 10-15% with respect to the

rated motor value.

Modifications to operating limits beyond the parameters stated on the model

data plate will immediately render the warranty null and void.

Set Point

This parameter enables entry of the set point for pressure (bar), level

(metres) or percentage to be maintained on the system.

The maximum settable value depends on the "ANALOGUE SIGNAL FULL

SCALE" set in the ASSISTANCE menu.

Threshold P1 / P2 / P3 / P4

In the case of pump P1, this indicates the restart value of the first pump

(master) on decrease or increase of the previously entered set point.

In the case of pumps P2, P3 and P4, this indicates the start and stop

values of the pumps used as backup units.

The maximum settable value depends on the "ANALOGUE SIGNAL FULL

SCALE" set in the ASSISTANCE menu.

Display Brightness On Standby

This parameter enables entry of the brightness setting applied when the

display sets to standby (wait 9 seconds for a preview).

Time For Entry To Set-up

This parameter enables entry of the time to keep the SETUP button

pressed for access to the set-up menu.

1 - … A As per order

0.0 - 999.9

-

0-9 4

2-30 Sec 3 Sec

0.0 - 999.9

-

14

15

Programming Menu

To select the panel operating logic, access the programming menu by pressing the buttons

SETUP, UP and DOWN at the same time on the main screen of the panel.

Language

0 ITA / 1 ENG/ 2 FRA / 3 ESP

Number of Pumps

This parameter enables selection of the number of pumps in the system

(when 1 single pump is selected, the parameter PUMP ROTATION

ENABLED is disabled).

DESCRIPTION OF PARAMETER VALUE

Operating Logic

0

FAULT

0

5-

1-4 As per order

Pump rotation enabled

This parameter enables activation of pump exchange on each demand

from floats or pressure switches. Also, if the main pump thermal cutout

(current overload) trips, the second pump is enabled.

Minimum Level Alarm Output

This parameter enables removal of the minimum level alarm from the

cumulative alarm output.

Sensor Sensitivity (Sa - Sb - Sc - Sd)

This parameter enables display of sensor sensitivity. With the contacts

open, if a value of 99 is displayed, and a value of 45 is displayed with

water present, set sensitivity to an intermediate value, such as 75.

Type Of Analogue Signal

This parameter enables selection of the type of analogue signal on input

to the panel: 0 = 0-10 V 1 = 4-20 mA

Unit Of Measurement

This parameter enables selection of the measurement unit of the

analogue signal on input to the panel.

Y or N Y

0 - 99 75

Y or N Y

0 or 1 As per order

% + or % -

m or bar As per order

Motor Clicson

Earthing Grounding

Motor Output

Starting Capacitor

(1-phase)

Supply Input

(T for 3-phase)

Alarm Float

Switch

Motor Clicson

Analogue Signal

Min Level Input

Cumulative Alarm

Output

Earthing Grounding

Motor Output

Starting Capacitor

(1-phase)

Supply Input

(T for 3-phase)

Full Scale Of Analogue Signal

This parameter enables selection of the full scale of the analogue signal

on input to the panel.

DESCRIPTION OF PARAMETER VALUE

1.0 - 999.9

FAULT

As per order

User Menu

On completion of panel operation programming, enter the setup menu to configure the

various data for motor start-up. To access the user menu, press the button SETUP for 4

seconds in the main screen of the panel.

Minimum Voltage

Set by default at -10% .

Modifications to operating limits beyond the default parameters will

i m m e d i a t e l y r e n d e r t h e w a r r a n t y n u l l a n d v o i d .

Maximum Voltage

Set by default at +10% .

Modifications to operating limits beyond the default parameters will

i m m e d i a t e l y r e n d e r t h e w a r r a n t y n u l l a n d v o i d .

DESCRIPTION OF PARAMETER VALUE

207 (230)

FAULT

360 (400)

-

-

253 (230)

440 (400)

Maximum Current P1 / P2 / P3 / P4

This parameter enables entry of the maximum current for each motor.

Enter the maximum current value, increasing it by 10-15% with respect to the

rated motor value.

Modifications to operating limits beyond the parameters stated on the model

data plate will immediately render the warranty null and void.

Set Point

This parameter enables entry of the set point for pressure (bar), level

(metres) or percentage to be maintained on the system.

The maximum settable value depends on the "ANALOGUE SIGNAL FULL

SCALE" set in the ASSISTANCE menu.

Threshold P1 / P2 / P3 / P4

In the case of pump P1, this indicates the restart value of the first pump

(master) on decrease or increase of the previously entered set point.

In the case of pumps P2, P3 and P4, this indicates the start and stop

values of the pumps used as backup units.

The maximum settable value depends on the "ANALOGUE SIGNAL FULL

SCALE" set in the ASSISTANCE menu.

Display Brightness On Standby

This parameter enables entry of the brightness setting applied when the

display sets to standby (wait 9 seconds for a preview).

Time For Entry To Set-up

This parameter enables entry of the time to keep the SETUP button

pressed for access to the set-up menu.

1 - … A As per order

0.0 - 999.9

-

0-9 4

2-30 Sec 3 Sec

0.0 - 999.9

-

616

This manual suits for next models

4

Table of contents

Other DAYLIFF Controllers manuals