Tekin B1 User manual

NOTE: Before Radio Cali brating, e nsure speed control is

hoo ked up to the receiver, a c harged battery is properly con-

nected, and the transmitter is turned on. On your radio, set all

trim adjustments to the middle, throttle/brake EPAs set to max

and ensure that your throttle directio n is set to “normal” .

Calibration is really very simple, you just press and ho ld the

MODE button for 3 seconds to e nter radio calibrate, let the

speed control “find” your neutral, then let it “find” your full

throttle and full brake. If you are unsure how t o pe rform this

procedure, follow the detailed steps outlined below.

Congratulations on your purchase of the B1/B1-R, Tekin’s

High P erformance Mini Brushed Motor Electronic Speed Con-

trol. The QuickTunefeature allows the user t o quickly and

accurately adjust all critical operating parameters. Just connect

the speed control as described below, perform a quick radio

cal ibrate, and yo u are re ady to race!

B1

Forward / Brake

PROFESSIONAL MINI B RUSHED SPEED CONTROL

•Adjus table Drag Brake /Reverse Type

•Voltage Cutoff for LiPo Cells

•Push ( Anti-Drag Braking )

•QuickTuneDigital Setup

•Tempe rature Monitor

OWNER’S MANUAL

INTRODUCTION

The following statements ne ed to be understood before usi ng

the B1/B1-R:

1. Turn on the transmitter first to avoid uncontrollable noise

to speed control.

2. Dis connect battery from speed control when not in use.

3. Do no t hoo k-up the battery backwards! No reverse volt-

age protection.

4. Do no t operate speed control in or aro und water.

5. Insulate exposed wires with heat shrink tubing to prevent

short circuits.

6. The B1/B1R is intended for Mini vehicles only.

SOLDERING

IMP ORTANT: Use extreme care and observe proper safety

pre caut ions whe n s ol der ing. Al ways wear eye pr otec tion. Be

sure that both wires are disconnected from the battery before

soldering on the posts.

Never keep a hot solderi ng iron on the speed control solder

posts for more than 3 seconds—the sol der post may be come

de-soldered from the speed control and become damaged.

HINT: It should only take a few seconds to solder the wire to

the post. If you do not complete the solder joint in approxi-

mately 3 seconds, remove the iron, clean and tin the tip, then

repeat the procedure below. Applying a small amount of solder

paste flux can often help sol der flow on a stubborn surface.

SOLDERING CONT...

ATTACHING WIRES TO THE SPEED CONTROL:

1) Red Wires are usually used to connect the speed control

to the positive battery terminal and the positive motor

terminal. Black wire is typically us ed for the battery

negative t erminal, and blue is used for the ne gative motor

connection. Inspect the sticker on the speed controlor

refer to the diagrams to determine which color wire to

attach to each post.

2) Strip back the insulation of the wire by about 3/32” to

1/8” and “pre-tin” the wire by heating the end and apply-

ing solder until it is thoroughly covere d. You may shake

of any excess solder while it is still hot. Be very careful

not to splash yourself with hot solder.

3) If there is no solder on the post, place the tip of the iron in

the notch on top of the po st and apply a small amount of

solder to the post. When the solder has flowed, remove

the soldering iron, wipe the tip clean and apply a small

amount of fresh solder to it.

4) Hold the wire so t he tinned end is in co ntact with the

notch of the post. Now touch the iron tip to the wire and

the post. Wait about 2 seconds for the solder to flow, and

then remove the iron while still holding the wire. You

may le t go of the wire after a seco nd or two when the

solder sets.

For B 1 Co nnectio n Diagra m, Re fer to F igure 2 ,

For B1R Connection Diagram, Use Figure 3.

1) Placement: Choose a l ocation for the speed control that is

protected from debris. HINT: To prevent radio interfer-

ence place the speed control as far away from the radio

receiver as possible and keep the power wires as short as

possible. If possible plan on routing power and motor

wires away from the radio receiver and radio wires.

2) Mounting: For best results clean the bottom of the spee d

co ntrol and chassis. Using the doubled-sided tape,

(included) mount the speed control to chassis.

3) Using a small piece of double-sided tape, mount the ON/

OFF switch in a convenient place.

4) Determine how you would prefer to connect the motor

and battery pack to the speed co ntrol. Using connector

pairs is preferable for most applications as it allows you

to easi ly switch battery packs and change motors.

Whether using connec tors or direct soldering, consider

where yo ur battery pack sits and how much wire will be

needed to attach to the speed control.

HOOKUP INSTRUCTIONS

HOOKUP INSTRUCTIONS CONT...

NOTE: Make sure all wires are secure and a safe distance

from all moving parts—use the zip-ties in the accessory pack.

RADIO CALIBRATION

QuickTuneMODES

MODE RANGE DEFAULT

DRAG BRAKE

(DRG B) 1-11 1 (OFF)

NEUTRAL WIDTH

(NW) 1-11 5

CU R REN T L I MI TE R

(LIM) 1-11 11 (OFF)

PUSH CONTROL (ANTI DRAG)

(PC) 1-11 1 (OFF)

REVERSE TYPE—-B1R

(RT)

THROTTLE PROFILES-B1

(TP)

1-3

1-6

3

3

VO L TA GE C U TO FF

(VC) 1-4 1 (NONE)

PRECAUTIONS

DO NOT CONNECT BATTERY INCORR ECTLY TO

SPEED CONTROL, VERIFY THAT THE B ATTERY

POSITIVE WIRE WILL CONNECT TO THE SPEED

CONTROL POSITIVE WIRE BEFORE CONNECTING!

1) CONNECT SPEED CONTROL TO RECEIVER

Plug the speed control into the throttle channel of the receiver.

• Channel 1: Servo

• Channel 2: Speed Control

“REMEMBER: 1 to Turn, 2 to Burn”

3) CONNECT SPEED CONTROL TO MOTOR

Visually verify that the connector on the motor and the speed

control match the chart below, then connect.

Startup Sequence

When the power switch is turned ON the speed c ontrol begins

looking for the neutral signal. If a neutral signal is found the

Arming Sequence (flashes LEDs/chime) will occur followed by

LED3 on s teady. NOTE: If Arming Sequence does not occur

see Trouble Sho oting section of this manual before proceeding.

One Touch Radi o Cali bration

1) Turn on transmitter.

2) Turn on speed control.

3) Press and ho ld the MODE butto n on the speed co ntro l for

3 seconds. All LEDs will blink red 3 times with 3 chimes.

The speed control will make a pulsing chime as it loo ks

for a neutral signal—you do not need to do anything yet.

4) When NEUTRAL position is found and recor ded, LED3

will flash and a confirmation chime will sound .

5) The pulsing chime will begin again and LED6 will flash;

pull transmitter trigger to the full thro ttle positio n and

hold until t he confirmation chime sounds.

6) The pulsing chime will begin again and LED1 will flash;

push transmitter trigger to the full brake position and hold

until the confirmation chime sounds.

7) Release trigger to return to neutral position. LEDs will

flash and the arming sequence chime will sound.

8) LED3 is now on steady. Calibration is complete and you

are ready to dr ive!

NOTE: If any problems occur, repeat radio calibration.

HINT: Once calibrated, the LEDs on the speed control will

advanc e as the throttle or brake is applied.

Hairpin Trigger Response: If you wish to have a very short

trigger range, then only squee ze the thro ttle/brake trigger

partially during the radio calibration proce dure. Throttle/Brake

response will not be quite as s mooth, but yo u can pull full

throttle very quickly.

QuickTune:

1) Press the MODE button to access the desired setup mode.

The LED starts blinking to indicate that mode selection is

under way. Each time the MODE button is pressed and

released, the LED advances. For example, to get to the

Voltage Cutoff adjustment, simply press and release the

MODE button 6 times. NOTE: Do not wait longer than

5 seconds to adjust the selected MODE or the speed con-

trol will return to normal operation.

2) Press and release the INCR button to adjust the value.

The first time INCR button is pressed, the LED(s) will

display the existing setting. Each time the INCR button is

pressed the value will advance, then after maximum, start

over again at the lowend of the scale. If two LEDs are

on at once, it indicates a value mid-way between the

LEDs.

QuickTune Exampl e: Le t’s say you want to us e a 2 cell LiPo

battery. To change the Voltage Cutoff from the default setting

(1 = None) to setting 2 (2 = 6.0 Volt Cutoff), first followstep 1

above by pre ssing and re leasing the MODE butto n 6 times.

Nowpress and releasethe INC button, the LED should show

the current setting of 1. Press and release the INC button again

and the LED will move to position 2, indicating that Voltage

Cutoff is now set to 6.0 Volts. Wait 5 seconds and the ESC

returns to normal operation.

HINT: If you wish to s et another Program Feature, press the

MODE but to n again. After 5 seco nds paus e, the values you

selected will be saved in memory and the speed control will

res ume normal o peration.

P IT TUN IN G : If you are in the pit area and cannot use your

transmitter you may use pit tuning mode to adjus t settings by

following this pro cedure: Unplug the steering servo from the

receiver to avoid servo damage. Hold down either MODE or

INCR button while turning the power switch on. An LED se-

quence will occur indic ating you are in pit tune mode. The

user settings will be active, but the motor will no t run and the

speed control will not respond to receiver signals. Turn the

speed control po wer off and back on to resume nor mal opera-

tion.

LED1: DRAG BRAKE control provides immediate braking

action i n the neutral zone. This gently slows the car down

when yo u let off the trigger. Drag Brake can pro vide a better

cornering approach . Higher values increase the degree of drag

braking.

QuickTune

Tekin’s QuickTuneelectronic setup feature allows users to

change every criticaloperating parameter in a quick, easy, and

accurate fashion. The basic operat ion is describe d as:

•Use MODE button to sc roll to a Program Feature.

•Use INCR (increment) button t o vie w/adjust the Feature.

The B1 series has a built-in self-test mode that checks all major

sys tems on the speed control. Before using the se lf-test mode,

be sure the re ar wheels are free to spin (off the ground). To

activate the self-test, turn the speed control on, then press and

hol d both MODE and INCR butto ns simultaneousl y for 5

sec onds. After 5 seconds, the LEDs will ramp up in sets of

two. Circuits inside the speed control are tested to see if any

problems have o ccurred. If the unit passes self-test, t hen LED3

will s t ay o n s teady.

If probl ems occ ur turn the power off to the unit and verify all

ot her connections are clean/tight/correct (motor, receiver, bat-

tery, plugs, etc). After verification, power the unit back on.

NOTE: Activating the self-test mode also resets all the user-

programmable settings and parameters to their default values.

The user’s radio calibration settings are also reset to defaults.

SELF TEST

B1-R

Forward / Brake /

Reverse

ESC MOTOR

(M -) Blue Wire (-) Negative

(M +) Red Wire (+) Positive

2) CONNECT SPEED CONTROL TO BATTERY

Visually verify that the connector on the battery pack and the

speed control match the chart below., then connect.

DANGER: If the battery wires touch during the plug installa-

tion. It will cause an electrical short circuit resulting in damage

to the pack and possibly a fire hazard. Tekin reco mmends the

use of high quality battery connectors, such as Dean’s P lugs, to

improve po wer transfer and minimize the risk of short-circuits.

ESC BATTERY

(B-) Black Wire (-) Negative

(B +) Red Wire (+) Positive

Pit Tune Mode

SPEED CONTROL SPECIFICATIONS

Controls, B1 Fwd/Br k

Input Power (Cells)

4-8 NiCd/NiMh

2-3S LiPo

Motor Limit Si ze 370 Size or smaller

Motor Limit Turns None

ON Resistance

B1

B1-R

0.0013 Ohms

0.0052 Ohms

Max Current

B1

B1-R

60 Amps

30 Amps

BEC 5 Volts,1.5 Amps

Power Wires 16 GASilicone

Dimensions 1.0 x 0.9 x 0.25 In.

(25.4 x 23 x 6 .3 mm)

Weight (with wires) 0.28 Oz (8g)

Controls, B1-R Fwd/Br k/Rev

The following items are neede d to co nnect your s peed control:

•Soldering Iron

•60/40 Electric Grade Solder (or silver solder)

•4 pieces 16 Ga. Wire (Included)

•Motor/Battery co nnectors (2 pair)

MOUNTING

SOLDERING, TOOLS NEEDED

SOLDERING CONT...

ATTACHING WIRES TO THE BATTERY:

The same techniques described i n the preceding sec tion may be

used to solder the wires to the battery connectors.

IMP ORTANT: Take precautions if removing factory battery

co nnectors. Connecting the battery backwards will cause dam-

age, an d will void warranty. When soldering connect ors to a

battery pack, cut only one wire ofthe battery pack at a time to

ensure that the e xposed wires cannot short to gether.

HINT: If you are using Dean’s c onnectors for both the batter y

and the moto r, make sure that you have a male and a f emale

attache d to the speed control wires. That way, you canno t acci-

dentally connect the battery to the motor wires or vice versa.

1) If using a connector betwee n battery and speed control

make sure that the ends will be mated together correctly,

male to female, and that the wire colors match—red to

red and black to black.

2) Solder the wires from the speed control to each of the

connectors, then solder wires from the battery to each

connector’s mate.

ATTACHING WIRES TO THE MOTOR:

The same techniques described in section 5 may be used to

solder the wires to the motor.

1) If using a c onnector between motor and speed control

make sure that the ends will be mated together correctly,

male to female, and that the wire colors match—red to

red and blue to blue.

2) Solder the wires from the speed control to each of the

connectors, then solder wires from the motor to each

connector’s mate.

REMOVING WIRES:

1) Have a hot iro n and the speed co ntrol secured. Clean the

tip of the i ron and apply a small amount o f solder. While

the tip is still smoking from the flux in the solder, touch

the tip of the iron to the top of the post.

2) As the solder on the po st melts, pull on the wire yo u wish

to remove.

HINT: If there is excess solder remaining on the post, you

may remove it by heating the po st until the solder just starts to

melt, then quickly tapping the speed control against the

workbench to knock off the excess sol der.

SOLDERING CONT...

Listed below are a number of tips to ensure that you will get

year s of trouble-free performance from your Tekin speed

control.

LED2: NEUTRAL WIDTH adjusts your deadband around

the neutral point. A low ne utral width value pro vides more

sensitive trigger re sponse around neutral.

LED3: CURRENT LIMITER adjusts the throttle response

during acceleration to control annoying wheelspin. Low values

allow low amounts of current to pass to the motor, higher val-

ues allow higher amounts of current. The top value (11) turns

OFF current limit.

LED4: PUSH CONTROL or ANTI-DRAG BRAKING

overcomes the natural drag of the motor when you return to

neutral. Racers refer to this as “creep” , this setting eliminates

the need to trim the throttle forward to create a coasting

(pushing) effect. Lo w values give you a shor t duratio n push,

higher values a longer duration push

LED5: BRAKE/REVERSE TYPE **B1R ONLY**

1) Proportional Brake with Reverse Lockout (LED1 ON).

Proportional brake will be applied during reverse throttle.

2) Forward to Brake to Reverse (LED1-2 ON). The car will

operate freely in forward and reverse. (Brakes to a stop

before switching into reverse)..

3) Proportional Brake with Reverse Delay (LED1-3 ON).

The car will only go in reverse if the trigger has been in

neutral for 1 second, otherwise it operates like

proportional brake with no reverse.

NO LIGHTS COME ON

Check for de ad batteries . Check the connections between the

batteries and the speed controller and that the switch is in the

“ON” position. Verify that there are no bad connections at the

speed controlle r. Check for reverse battery connection.

ALL LE Ds F L ASH IN G

No r adio signal can be f ound. Check rece iver connection and

verify that ESC is plugged into correct channel. Verify trans-

mitter and r eceiver are functioning properly.

BOTTOM OR TOP 3 LEDs FLASHING

Radio signal found, but neutral point from transmitter is out of

expected range. Speed control not calibrated properly or radio

setti ngs have been changed. Recalibrate speed co ntrol as de-

scribe d in the Radio Calibr ation section.

ADJUSTMENT MODES CONT...

Before sending your B1/B1-R in for service, please review the

Instruc tions and Troubleshoo ting sections. After reviewing

these instructio ns, if your speed co ntrol still requir es service,

please contact our customer service department for additional

assistance. To obtain the most current product service options

and pricing, consult the following:

WEBSITE: (www.teamtekin.com) Follow the instructions

from the Service Request section of our website.

PHONE/FAX: Contact our customer service department.

WARRANTY SERVICE: For warranty work, you MUST

CLAIM W ARRANTY on A COMPLETELY FILLED OUT

PRODUCT SERVICE FORM and include a VALID CASH

REGISTER RECEIP T with purchas e date, dealer name &

phone # on it, or an invoice from previous service. If warranty

provisions have been voided, there will be service charges.

NOTE: Hobby dealers or distributors are not authorized to

replace TEKIN products thought to be defective.

Tekin, Inc.

McCall, Idaho

(20 8) 634-5559 / (208) 634-5569 (FAX)

www.te amtekin.c om

WARRANTY

TEKIN, INC. guarantees speed controllers to be free from fac-

tory defects in materials and workmanship for a period of 120

days from date of purchase, when verified by sales re-

ceipt. This warranty does not cover: suitabilit y for specific

application, co mponents worn by use o r improper voltage,

tampe ring, misuse, or shipping. Our warranty liabili ty shall be

limited to repairing unit to our original specifications. Because

we have no control over the installati on or use of this product,

in no case shall we be liable for damages.

Additionally, these items void the warranty:

1) Using the same polarity connectors on the battery and

motor wires from the speed controller.

2) Allowing water or moisture into the speed controller.

3) Incorrect wiring.

4) Use inconsistent with the instructions.

OPERATING TIPS

LED5: THROTTLE PROFILES **B1 ONLY**

1) Mildest profile, concave (LED1 ON)

2) Mild profile, concave (LED1 -LED2 ON)

3) Linear profile (LED1-LED3 ON)

4) Aggressive profile convex (LED1-LED4 ON)

5) More aggressive profile, convex (LED1-LED5 ON)

6) Custom— User Adjustable Using Tekin HotWire PC

Connection (LED1-LED6 ON).

LED6: VOLTAGE CUTOFF

1) NONE (LED1 ON)

NiCd/NiMh Cells.

2) 6 Volts (LED1-LED2 ON)

2 Cells LiPo (2S)

3) 9 Volts (LED1-LED3 ON)

3 Cells LiPo (3S)

4) Custom (LED1-LED4 ON)

User Adjus table Cutoff, requires Tekin HotWire PC

Connection.

IMPORTANT: If using Lithium Polymer (LiPo) batteries, DO

NOT operate your vehicle with the factory default Cutoff Volt-

age setting (None).

PROPER ON/OFF PROCEDURE

Always turn your transmitter on first and then turn on your

speed control. At the c onclusion o f your run, simply reverse

the above procedure.

BATTERY P OLARITY

It is extremely impor tant to e nsure the battery pack is

co nnected to t he speed control properly. Co nnecting the m

back wards could cause severe damage to the battery pack and/

or speed control.

DO NOT JAM THROTTLE

This will cause tremendous reduction in run time and excessive

heat build-up.

RADIO INTERFERENCE

Try to keep the r eceiver at l east 1-2 inc hes away from any mo-

tor or battery wires.

RECEIVER BATTERY

The built-in BEC (Battery Eliminator Circuit) is stro ng enough

for 1 standard se rvo. If you are using a high po wer ser vo you

may need a separate receiver battery (see Receiver Battery

section).

NO REVERSE

QuickTune mode, Brake/Re verse Type is set to o ptio n 1.

QuickTune mode, Brake/Re verse Type is set to o ptio n 3

(transmitter trigger must be in neutral position for 1 s econd

before reverse is enabled). Speed control is a B1, not a B1R

(not a reversing type).

MOTOR WILL NOT SHUT OFF OR RUNS SLOWLY

Inco rrect radio calibration or throttle trim setting on transmit-

te r. Check transmitter se ttings and rec alibrate s peed control.

Moisture in speed control: Unhook batteries and le t the s peed

co ntrol dry.

MOTOR CUT OUT/RADIO INTERFERENCE /POOR

RANGE

Transmitte r batteries are low o r damaged. Mismatched c rys-

tals. The three-wire cable from speed control to receiver may

also be too long; 6 inches is the maximum. This speed control

radiate s very low noise and you shoul d have no trouble with

interference. If you do have interference , mount the speed

control in the pan, and mount the receiver andantenna at the

top of the shock tower. Try to keep the receiver away from the

batteries, power wires, metal or graphite.

TROUBLESHOOTING

NOTE: Optional. Connect a separate battery pack to the

receiver using the “B” or “BAT” socket on your receiver. A

small switch should be used on the receiver pack to operate the

radio., and the receiver pack should have no more than 5 cells.

IMPORTANT: You must remove the red wire from the speed

co ntrol servo plug and cover it with heat shrink tubing.

The On-Board Temperature Monitor wor ks to provide you with

important feedback on speed control temper ature, he lping you

to adjust gearing and avoi d long term heat damage. To use;

1) The spe ed control must be calibrated to yo ur radio and

the r adio must be in the neutral po sit ion.

2) The middl e LED will be on steady, and should blink out

ever y 2 seconds.

3) At the moment that the center LED blinks out,one or

more of the other LEDs will light up.

4) LEDs 1-3 lit is typical of light loads or a stoc k motor.

LEDs 1-5 lit indicates heavy loads and is typical when

running mod moto rs. LEDs 1-6 lit indicates high internal

temperatures approaching thermal shutdo wn. Dis con-

tinue use until the speed co ntrol returns to normal o perat-

ing temperature.

SERVO WORKS, THROTTLE DEAD

Spee d control not adj usted correctly. May be in Pit Tune

mode. If LEDs are flickering, may indicate that Voltage Cutoff

is set above battery pack voltage. Check that cutoff is cor-

rec tly set and that batte ry is fully charge d. Motor or connec-

tions to motor are bad. Receiver plugor connections are bad.

Spee d control not plugged into throttle channel o n receiver.

STUTTERING UNDER HEAVY ACCELERATION

Receiver is getting magnetic field interference. Try mounting

receiver on its side and/or spacing it 3/16 inch up from the

chas sis. If t his does not work, try mounting it on its other side.

Move power wires away from receiver. Check for low current

limiter setting. Check for incorrect Voltage Cutoff setting.

BRAKES DO NOT WORK AT ALL

Speed control or radio transmitter improperly adjusted. Adjust

EPAs on transmitter all the way out and recalibrate speed con-

trol to radio.

AU TO CO UN T N O T W O RK IN G

Mount transponder at front of c ar away from batteries and

wires.

SERVO AND THROTTLE DEAD

Check for dead batt eries, bad co nnections to s peed cont rol,

dad receiver plug co nnection. Switch may need replac ing.

Bro ken wires, bad crystal, bad radio equipment.

THROTTLE WORKS, SERVO DEAD

Bro ken servo. Wiring of plug is bad or incorrectly wired.

TEMPERATUREE MONITOR

TROUBLESHOOTING CONT... SERVICE AND REPAIR

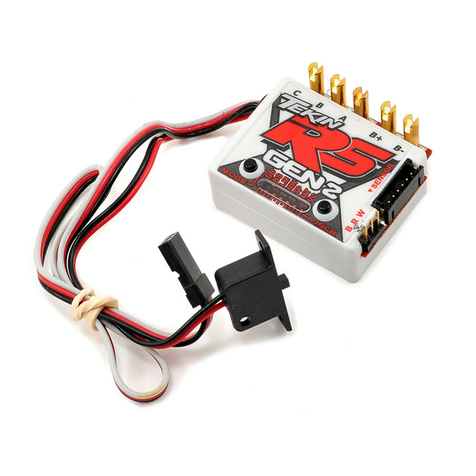

Figure 2.

B1 Connection Diagram

TROUBLESHOOTING CONT...

ADJUSTMENT MODES CONT...

Figure 3.

B1R Connection Diagram

RECEIVER BATTERY

This manual suits for next models

1

Other Tekin Controllers manuals

Popular Controllers manuals by other brands

KWC

KWC AQUA3000OPEN Installation and operating instructions

Dormakaba

Dormakaba RAC5 XT installation guide

Siemens

Siemens Synco 700 operating instructions

Toshiba

Toshiba TE Series instruction manual

YASKAWA

YASKAWA MP2200 user manual

Carrier

Carrier VVT 33ZC Installation, Start-Up and Configuration Instructions

Reliance electric

Reliance electric GV3000SE Hardware reference, installation, and troubleshooting manual

Adaptec

Adaptec AIC-6915 Programmer's manual

Mitsubishi

Mitsubishi AL-6MR-A Hardware manual

Siko

Siko AG02 Translation of the original installation instructions

PMA

PMA KS40-1 operating manual

ACO FUNKI

ACO FUNKI M-8525 Mounting instruction