DAYLIFF SUNVERTER 3 Installation instructions

SUNVERTER 3

AC SOLAR PUMP CONTROLLER

Installation &

Operating Manual

CONTROLLER SPECIFICATIONS

1.

1

2.

SYMBOLS & WARNINGS 3

INDEX

© Davis & Shirtliff Ltd 2021

Contents herein are not warranted

2.1 Purchase Inspection 3

2.2 Installation 3

2.3 Wiring 4

2.4 Connection 4

3. INSTALLATION & WIRING 5

2.5 Running 4

3.3 Wiring Diagram

7

4.2 Panel Layout and Instruction 18

4.4 View Running Data 20

4.5 View Historical Data 21

4.6 View or Modify the Control Parameter 22

4.7 Function Parameter Description 23

3.1 Installation Direction 5

4. OPERATION & CONTROL 17

3.4 Electrical Connection

11

3.5 Single Phase Motor Wiring Installation

12

3.6 Water Level Switch Installation & Wiring Instruction

4.3 Panel Operation 20

13

4.1 Initial Settings before rst Operation 17

2.6 Hybrid Operation 5

2.7 Others 5

3.2 Installation Method 6

3.7 Others

14

3.8 Hybrid Installation

15

SERVICE & MAINTENANCE

6.

32

6.1 Routine Inspection & Maintenance 32

6.2 Requirement of Inspection & Maintenance 32

6.3 Main Points for Inspection & Maintenance 32

6.4 Inspection & Replacement of the Damageable

33

Part

6.5 Storage 33

TERMS OF WARRANTY

7.

34

5. TROUBLE SHOOTING 26

5.1 Fault Code Description & Solutions 26

5.2 Fault Page Display Description 26

5.3 Faulty & Abnormal Code Description 26

5.4 Faulty Inquiry & Reset 28

5.5 Important Note Description 29

5.6 Important Note Page Display Description 29

5.7 Important Note Code Description 29

1

1. CONTROLLER SPECIFICATIONS

Dayliff Sunverter 3 is the latest update of the established Sunverter range of advanced

AC/DC inverters specially designed for solar-powering AC motors in various water

pumping applications. As well as a general upgrade of the electronics and functionality

an important new feature is hybrid capability that enables concurrent operation with

direct AC power from mains or generator supply while prioritising solar supply. It is

adaptable to all AC motor types and can be retro fitted to existing AC supply

installations in solarisation projects. Particular features include;

• Hybrid capability with the option of DC solar power, generator or mains grid

power inputs

• Patented MPPT (Maximum Power Point Tracking) capability providing fast

response, good stability and up to 99% efficiency.

• Fully automatic operation with up to 8 years storage capacity of operating data.

• Supports motor soft start and gives full motor protection

• User friendly LCD display interface with comprehensive display information

• Integral remote monitoring and control capability activated by installing a

registered Sim Card with data plan or alternatively signing up to the unique

iDayliff Service

• Strong IP65 rated enclosure for enhanced component protection

Congratulations on selecting a Dayliff Sunverter3. It is manufactured to

the highest standards and if installed and operated correctly will give

many years of efcient and trouble free service. Careful reading of this

Installation Manual is therefore important, though should there be any

queries they should be referred to the equipment supplier.

Solar Water Pumping System Layout

Sunverter 3

Water Tank

Solar Panel

Pump

Generator

Grid

2

CONTROLLER FUNCTIONALITY

The controller offers the following control functions:

• Settable minimum and maximum frequency and open circuit voltage.

• Display of operating parameters including frequency, voltage, amperage, input

power and pump speed.

• Display of historical data including energy generation, maximum power and

operating times.

• Protection against over and under voltage, over current, system overload and

module over temperature.

• Fault detection with error code display.

• Selectable hybrid modes that prioritise solar supply as well as maximise output

through optimal blending of both power supplies

INSTALLATION

Dayliff Sunverter 3 controllers are surface mounted and should be provided with a

housing for water and heat protection. They must also be provided with a circuit

breaker between the PV modules and controller. Due to the high operating voltages

proper earthing is essential, which must be done by a qualified electrician. As a rule, all

PV powered solar pumping systems should be provided with a solar module array with a

nominal output about 30% greater than the motor size. In hybrid applications, higher

array MPP voltage is specified to allow achievement of larger solar supply share of

hybrid power supply. The arrays should be wired in a combination of series and parallel

connections to ensure that the correct voltage is available into the inverter. It is

important that the connection arrangement is approved by the pump supplier.

OPERATING CONDITIONS

0 0

Ambient Temperature: -20 C to 60 C Frequency: 0-60Hz

Relative Humidity: 0-90% (Non-Condensing) Altitude: 0-2000m***

CONTROLLER DATA

Model

Motor

Rated

Power

(kW)

Output

Rated AC

Current

(A)

5.5

3.7

2.2

3.0

11

15

18.5

22

Weight

(kg)

SV3/7.5T

SV3/11T

SV3/15T

SV3/18T

SV3/3.7M

SV3/5.5T

Dimensions (mm)

WH D

17

9

13

18

24

30

39

45

315

458 300

143

175

5.5

8

11.5

Max

DC

Input

Voltage

VDC

450

850 500-700

SV3/3.7T

1.1

SV3/1.5M 8.6 150-360

1.5

SV3/2.2M

Rated

Voltage

3x415V

1x240V

11

310-370

219

MPP

Voltage

VDC,

Solar

MPP

Voltage

VDC,

Hybrid

600-700

150-360

324-370

SV3/22T

***If the altitude is over 2,000m, the rated output current of the inverter should be derated by 10% for every 1500m increase in height.

Rated

AC

Input

(A)

22.5

17.5

35

12

30

39

45

54

14

23

Current

416 257 158

3

All dimensions in mm

W

H

D

2. SYMBOLS AND WARNINGS

Check the inverter before installation. Do not install if it is

damaged or with missing parts, else may cause accidents.

CAUTION

To ensure good cooling effect, the inverter must be installed

vertically with atleast 10cm space at the sides and 30cm at

the top and bottom.

CAUTION

2.1 Purchase Inspection

2.2 Installation

CAUTION

Sunverter is normally wall mounted. Ensure that the

mounting backplate can support the weight of the inverter.

Misuse will result in re, serious injury to persons or even

death.

WARNING

Misuse will cause low or middle-level injury to person or

equipment damage.

CAUTION

CAUTION

Suitable for indoor installation with sufcient ventilation. Do

not install under direct sunlight. Keep away from dust and

moisture.

4

2.3 Wiring

Wiring must be performed by a qualied electric

professional, else may cause electric shock or re.

WARNING

Always ensure input power is isolated before wiring and

connection; else may cause electric shock or re.

WARNING

Earth terminal must be reliably grounded, or else inverter

enclosure may be electried.

WARNING

2.5 Running

Do not change wiring and connection when the inverter is

powered, else may cause electric shock.

WARNING

CAUTION

Before operation, adjust the function parameters according

to the steps indicated in this manual. Do not change the

function parameters of the inverter randomly, else may cause

damage to the equipment.

CAUTION

The temperature of heat sink is normally high during running

and it should not be touched, else may cause burns.

Make sure all the wiring and connection are correctly

connected before powering on, or else may damage the PV

disconnect box or cause re.

CAUTION

Ensure to fasten terminal with specied torque, or else may

cause re

CAUTION

Do not connect capacitor or phase-advanced LC/RC noise

lter with inverter output.

CAUTION

2.4 Connection

The selection of solar array, motor and inverters should be

reasonable, in case of doubt, consult nearest dealer.

NOTE

5

3. INSTALLATION AND WIRING

CAUTION

For areas with altitude over 2000m, the inverter output

current should be derated at 10% for every 1500m increase in

altitude.

CAUTION

Do not switch off DC or AC power to the inverter while the

pump is running. The disconnect switch and/or MCB should

only be operated after the inverter is in stop mode otherwise

there will be damage .

2.6 Hybrid Operation

2.7 Others

WARNING

Maintenance and inspection must be performed by a

qualied technician.

WARNING

Do not disassemble the inverter during operation. The

inverter must be powered off atleast 5 minutes before

conducting maintenance and inspection and this is to avoid

the residual voltage of electrolytic capacitor in major loop

causing personal injuries.

CAUTION

Reverse engineering is not permitted.

WARNING

At the end of its design life, the inverter should be disposed

as industrial waste. During incineration, the electrolytic

capacitor may explode and some parts may produce toxic

and harmful gas.

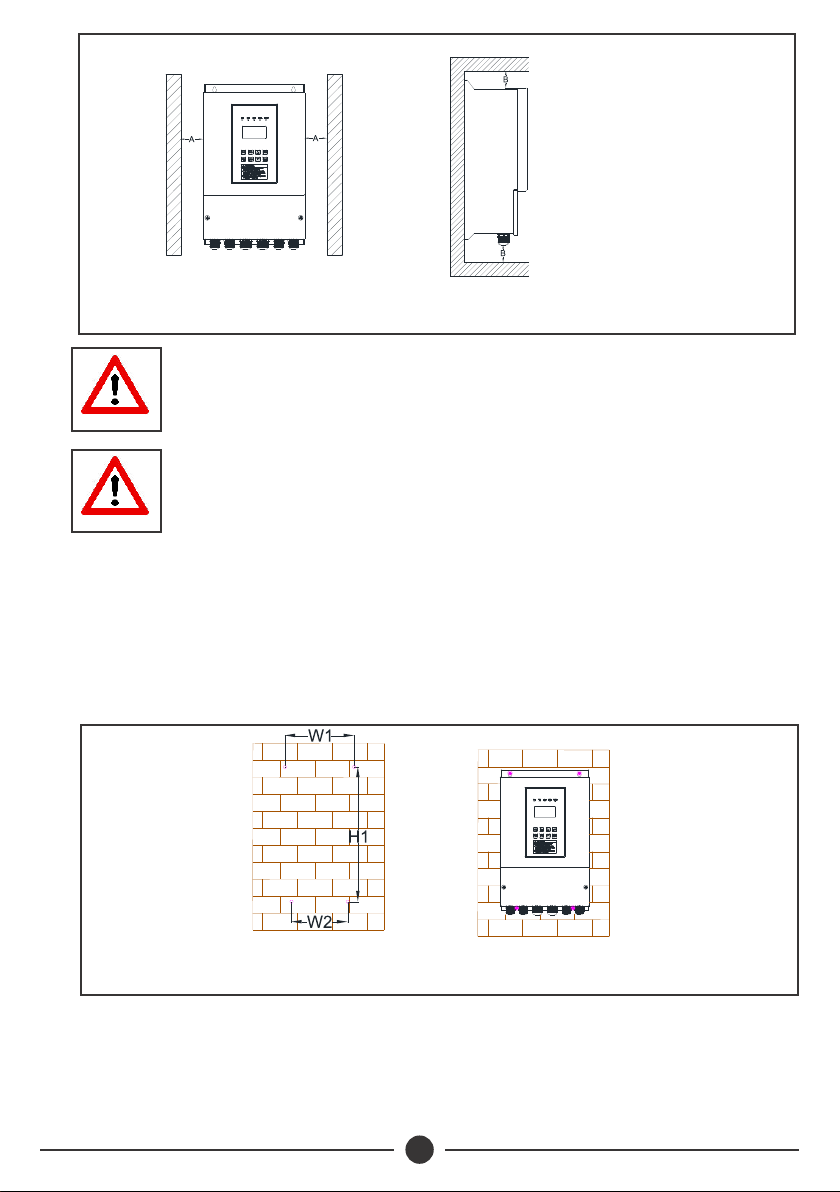

3.1 Installation Direction

ŸLeave enough installation space between inverter and other objects nearby to

ensure good ventilation and heat dissipation. As shown on Fig 1, please install the

0

invert vertically or backwards with maximum 10 inclination angle do NOT install it

horizontally or transversely.

ŸLeave enough space in front of the inverter, install the inverter at a height that is

convenient to operate device and read information in the LCD display screen

NOTE

Installation of the inverter according to the specied

environmental conditions is the precondition for ensuring

long-term normal and stable operation of the inverter.

6

Fig 1: Installation Direction Diagram

A >100mm

B>200mm

B>300mm for 11kW

NOTE

The installation surface should be at and closely attached to

the inverter bottom surface to ensure good heat dissipation.

NOTE

If multiple inverters are to be installed in the same cabinet, it

is recommended to adopt side by side installation. If two

inverters are to be installed longitudinally, a guide plate

should be added in the middle.

3.2 Installation Method

ŸChoose the installation place and drill holes according to the size and shape of

support plate, the recommended diameter of holes is 8±1mm with 60±5mm

depth.

ŸFasten the support plate on the wall with 35Nm tightening torque expansion

bolt.

Fig 2: Mounting Hole

Diagram

Fig 3: Inverter Mounting

Installation Diagram

ŸHang the mounting groove in inverter back on the support plate, when inverter

is reliably hung up, fasten the screw nuts between the support plate and

inverter.

47

Model

SV3/7.5T

SV3/11T

SV3/15T

SV3/18T

SV3/3.7M

SV3/5.5T

Dimensions (mm)

W2W1 H1

139

215 193

288

423

SV3/3.7T

SV3/1.5M

SV3/2.2M

SV3/22T

200 162 387

NOTE

Do NOT install the inverter on rocks or thin wooden panels

with toggle bolts.

NOTE

The expansion bolts provided by manufacturer are suitable

for installation on concrete walls. If the inverter is to be

mounted on wooden walls, select the expansion bolt suitable

for wooden wall mounting, and ensure the expansion bolts

are long enough to penetrate at least 1/2 of the wall

thickness.

PV

Disconnect

Solar Input

MCB

SV3

INVERTER

Tank Water Level Signal

Well Water Level Signal

Tank

AC Input

Water

Level

Switch

Water

Level

Switch

Well

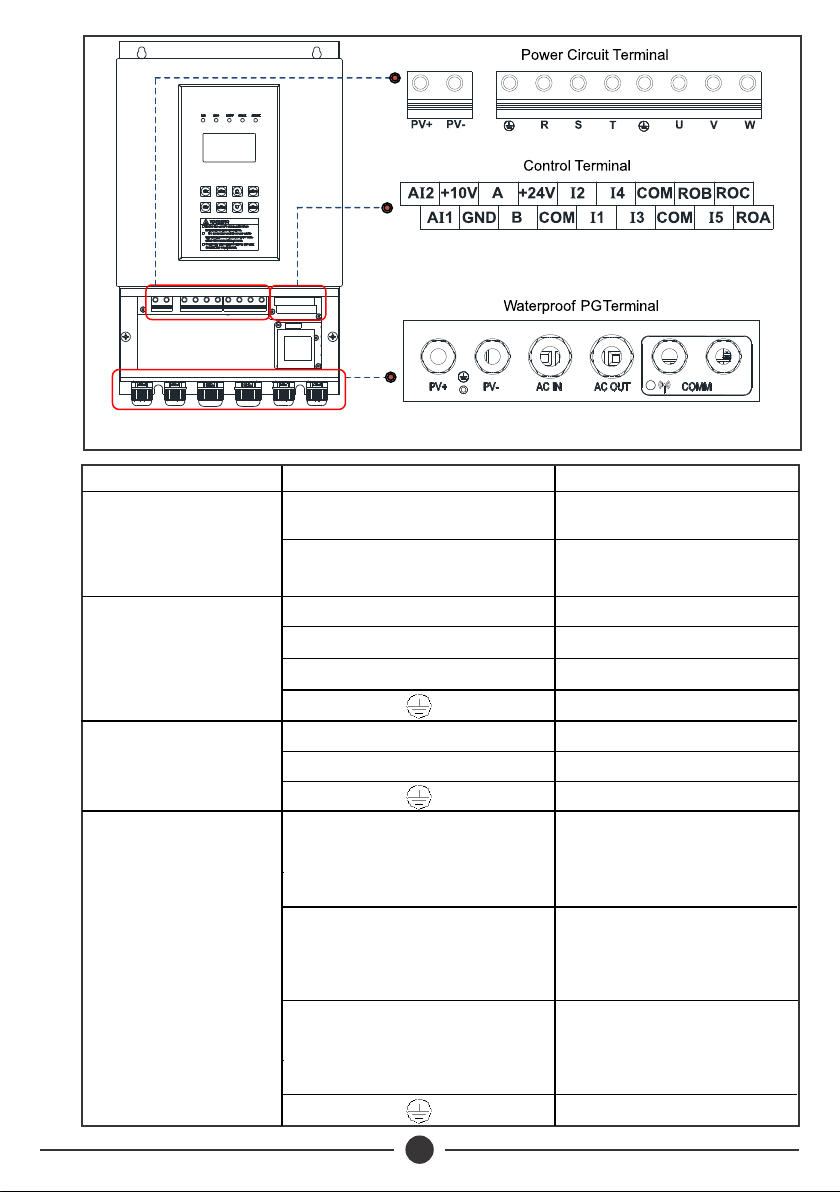

3.3 Wiring Diagram

Fig 4: System Wiring Diagram

8

Fig 5: Wiring Terminal Diagram

4

DC Input

C o n n e c t e d t o p o s i t i v e

electrode of solar pv array

PV+

Socket Terminal Description Connection Description

PV-

Three - Phase

AC Input

R

Connected to earth cable

Connected to R phase of grid

U/A

Connected to U phase of

three-phase motor/auxillary

winding access terminal A of

single-phase motor

C o n n e c t e d t o n e g a t i v e

electrode of solar pv array

SConnected to S phase of grid

TConnected to T phase of grid

Single - Phase

AC Input

LConnected to L phase of grid

NConnected to N phase of grid

Connected to earth cable

AC Output Connected V phase of three

phase motor/main winding

access terminal M of single-

phase motor

V/M

W/C

Connected to W phase of

three -phase motor/main

winding access terminal C of

single-phase motor

Connected to earth cable

49

CAUTION

The input/output sockets are different for models, subject to

the silk screen on the inverter sockets and the terminal

description.

NOTE

For single-phase pumps, remove the external capacitor

before wiring

Switch input terminal 1

Tank water level signal input, open circuit is normal,

short circuit is abnormal. Function setting through

Pr15, default value 7

I1-COM

Terminal Terminal Name Function Description

Switch input terminal 2 Reserved. Function setting through Pr16, default

value 0.

I2-COM

Switch input terminal 3

Well water level signal input, open circuit is

abnormal, short circuit is normal. Function setting

through Pr17, default value 6.

I3-COM

Switch input terminal 4 Reserved. Function setting through Pr18, default

value 0

I4-COM

Switch input terminal 5 Woltman water meter signal input. Function setting

through Pr19, default value 3.

I5-COM

+24V power supply 24V power supply, maximum output current 300mA;

can be used as power supply of communication

module, external sensor or miniature relay

+24V-COM

+10V power supply

10V power supply, maximum output current 50mA;

can be used as power supply of an external

potentiometer with resistance value range of 1k

Ω~5kΩ

+10V-GND

RS485 communication

interface

Interface for communication with wired external host

or inbuilt wireless communication module. (Default

setting enable the communication with inbuilt

imodule, if needed for external host, relevant

advanced parameter must be modified)

A-B

Analog input terminal 1 Water level sensor signal input (default current type).

Range: DC 4~20mA

A11-GND

Analog input terminal 2 Pressure sensor signal input (default current type)

Range: DC 0~10V

A12-GND

Normal open relay contact Contact drive capability:

AC250V, 3A, cosØ = 0.4

DC30V, 1A

ROA - ROC

Normal close relay contact

ROB - ROC

410

NOTE

In order to ensure communication quality, use twisted

shielded pair cable as communication cable.

NOTE

All cables, analog, digital, power and signal should be

separated to avoid entanglement.

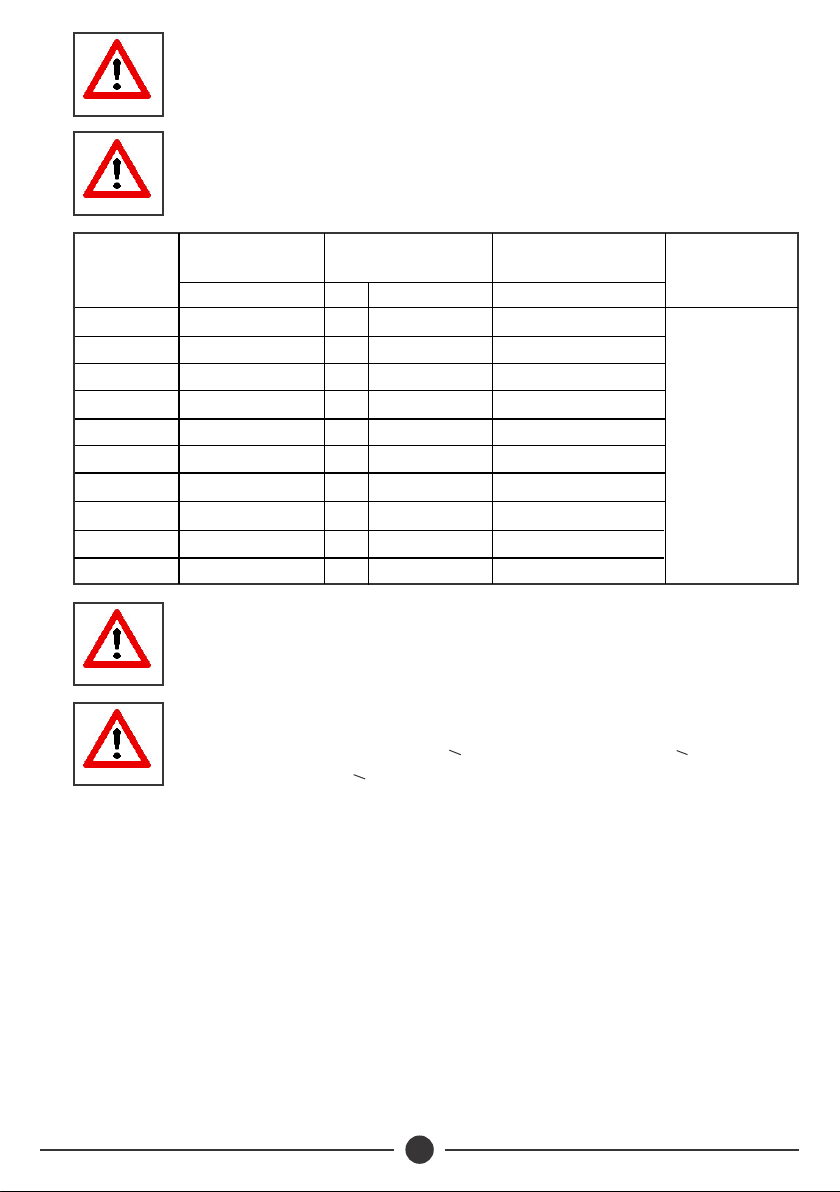

Model Solar Array

2

Cable (mm )

2

AC Cable (mm )

SV3/7.5T

SV3/11T

SV3/15T

SV3/18T

SV3/3.7M

SV3/5.5T

SV3/3.7T

SV3/1.5M

SV3/2.2M

SV3/22T

CAUTION

To ensure the system works normally, the cable size should be

selected according to the table above.

NOTE

(+)/(-) L/N R/S/T, U/V/W

2

Earth Cable (mm )

PE

Signal Cable

2

(mm )

4

6

10

10

4

4

2.5

2.5

4

10

6

2.5

4

4

6

10

10

6

4

2.5

2.5

4

10

1.5

2.5

4

6

6

2.5

2.5

2.5

1.5

1.5

10

The recommended cable should be used under the conditions

0

of ambient temperature < 40 C, cable length <100m and

working current < rated current.

411

3.4 Electrical Connection

Step 1 : Prepare all the input/output cables as shown in Fig 6.

Step 2: Open the cover of the inverter wiring area, pass the cable through the

waterproof PG terminal and fasten the corresponding cable connector with

a slotted screw driver. The tightening torque is 10Nm for the PV/AC terminal

and 7Nm for the signal terminal as shown in Fig 7.

Fig 6: Wire Process Diagram

Single Core Cable

Stripping Diagram

Multi Core Cable

Stripping Diagram

Single-Core Strip 10mm at A

DC Cable

Solar Array

Cable Type Process Description

Multi-Core Strip 50mm at A, Strip 10mm at B

AC Cable

Multi-Core Strip 50mm at A, Strip 5mm at B

Control

Signal

Cable

Fig 7: Wiring Diagram of Inverter Wiring Area

412

Step 3: Upon completion tighten the bottom waterproof PG terminal, close the wiring

area cover and lock it with a tightening torque between 10Nm and 12Nm.

Step 4: Fix the earth cable to the ground screw at the bottom of the shell as shown in

Fig 8.

Step 5: Wired Sunverter shown in Fig 9.

Fig 8: Grounded Connection Diagram

Fig 9: Wiring Complete Diagram

3.5 Single Phase Motor Wiring Instruction

ŸAs shown in Fig 10, remove the external capacitor on the single phase pump

and connect the inverter and single phase motor according to wiring

instruction.

413

Fig 10: Single phase Inverter Wiring Diagram

CAUTION

Ensure to connect the wires according to the instructions,

incorrect connection may lead to abnormal operation of the

system.

Wiring Reminder

In case single phase pump motor connection parts cannot be recognized, perform the

following steps to identify

Step 1: Test the resistance between each pair of the connection parts with a multi-

meter, the two ports with largest resistance value should be the main winding

M and auxiliary winding A, so the other one is common port C.

Step 2: Test the resistance between C and the other 2 ports, the resistance between C

and M should be relatively less and the resistance between C and A should

be much bigger.

Step 3: If the measured resistance in step 2 appears to have little difference, then

compare water flow during operation to determine if the wiring is correct.

Keep C port wiring unchanged, exchange the wiring of A and M and observe

the water flow. The wiring with bigger water flow should be the correct wiring.

From the above steps, the connection ports A, M,C of single phase motor can be

confirmed

3.6 Water Level Switch Installation and Wiring Instruction

The water level switch is installed in the well for dry running protection or installed

in the water tank for overflow protection.

Water level switch requires vertical installation with maximum 10° inclination

angle. The installation position should be slightly higher than the pump outlet

position in the well, while in the water tank it should be slightly lower than highest

water level as shown in Fig.11.

414

To wire for well application, pass the water level switch cable through the

waterproof PG terminal and connect to the I3 and COM terminals(remove the

short-circuit strip between the two first), for tank application, connect to the I1 and

COM terminals as shown in Fig. 12.

Fig 11: Water Level Switch

Installation for Well/Tank

Fig 12: Water Level Switch

Wiring Diagram

ŸA DC circuit breaker should be installed as protection switch for solar DC input.

ŸThe inverter has one pair of DC input terminals. If the solar modules are multi-

paralleled, an additional solar combiner box is necessary.

ŸThe inverter must be grounded reliably and the grounding cable properly sized and

as short a possible. If possible, the inverter should be grounded separately.

ŸIn areas with high incidence of lightning, it is recommended to install an external

surge protector at the power input of the inverter.

ŸIf the inverter is far from the motor (>200m), it is recommended to install on output

reactor or filter.

ŸIt is recommended to install input and output reactors, dedicated filters and

magnetic rings at the input and output of the inverter which can effectively reduce

the noise and avoid interference with other components.

ŸConsult nearest Davis & Shirtliff dealer for the extra accessories such as PV

disconnect switch/DC breaker, combiner, surge suppressor and reactors.

3.7 Others

4

Model

SV3/7.5T

SV3/11T

SV3/15T

SV3/18T

SV3/3.7M

SV3/5.5T

SV3/3.7T

SV3/1.5M

SV3/2.2M

SV3/22T

AC Breaker (A) DC Breaker

40

50

63

63

50

25

25

25

40

100

25A/1000VDC

40A/1000VDC

63A/1000VDC

63A/1000VDC

25A/750VDC

25A/1000VDC

16A/1000VDC

16A/750VDC

25A/750VDC

80A/1000VDC

415

3.8 Hybrid Installation

SV3 series solar pumping inverter provides PV and AC hybrid power input

function, as shown below, PV input is connected to bus circuit through anti-reverse

diode. Through anti-reverse diode and AC power input is rectified through rectifier

bridge then connected to bus circuit. Two kinds of power can be connected with

the inverter at the same time, and the hybrid power drives the water pump to work.

Hybrid Power Supply Main Circuit

Three Phase

AC Power Input

PV Array Input

Inverter

Bridge

PV+

R

U

PV-

SV

T

W

Fig 19

Hybrid Mode

Solar priority mode (Pr6=1) default.

Where there is both AC and PV power inputs, inverter adjusts pump running speed

prioritising solar power and only blends with AC power when there is insufficient

solar power. Insufficient solar power is detected when the pump speed falls to the

set value 30Hz.

AC+PV blending (Pr6=0)

When there is both AC and PV power inputs, inverter drives the pump running at

rated speed. Solar power usage is much higher when the solar irradiance is high

2

(near 1000 W/m )

Model SV3-M SV3-T

AC Input Voltage (VAC) 1PH/220V - 240V 3PH/380V - 415V

Recommended PV array voltage conguration:

As shown below, if the value of maximum power point voltage (Vmp) of the PV

array is equal to value of the bus voltage (Vdc) when the system is running, the PV

array will output the maximum power (Pmax). If Vmp deviates from Vdc, the more

the deviation, the less PV array power output. Therefore, in order for the PV array

to output the maximum power as much as possible, it is recommended to

configure the Vmp of the PV array to be near the bus voltage value Vdc. The Vdc

can be determined by the following formula: Vdc= √2 ∗V rms

416

NOTE

Vrms is the effective voltage value of AC power, such as 1PH

220V/3PH 380V

PV Array Curve

Voltage

Power

Pmax

Vmax V

Imax P

I

Model

Motor

Rated

Power

(kW)

Solar

Max

Input

Power

(kWp)

Output

Current

(A)

7.5

5.5

2.2

3.7

11

15

18.5

5.0

5.0

8

11

16

22

28

17

9

13

18

24

30

39

Max DC

Input

Voltage

Vmax

MPP

Voltage

VDC

450

850 600-700

1.1 2.2 8.6

1.5 3.3 11 150-360

Rated

Voltage

Output

1x220-240V

3x380-415V

324-370

22

SV3/7.5T

SV3/11T

SV3/15T

SV3/18T

SV3/3.7M

SV3/5.5T

SV3/3.7T

SV3/1.5M

SV3/2.2M

SV3/22T 32 45

Table of contents

Other DAYLIFF Inverter manuals