DAYLIFF SUNFLO-S 150 Installation instructions

Installation &

Operating Manual

SOLAR PUMPING SYSTEMS

INDEX

© Davis & Shirtliff Ltd 2020

Contents herein are not warranted

SPECIFICATIONS

1.

1

2.

EQUIPMENT INSTALLATION 2

2.1 Module Positioning

1.1 Pump

2

1

2.2 Pump Installation

1.2 Power Outputs

3

1

2.3 Electrical Wiring

1.3 Pump Data

4

2

2.4 Low Water Level Protection 7

4. SYSTEM OPERATIONS 8

2.5 High Water Level Tank Sensor 7

4.2 Controller 8

4.1 Pump 8

5. TROUBLE SHOOTING 11

6. TERMS OF WARRANTY 12

3. BATTERY SYSTEMS 7

4.2.1 Suno-S 8

4.2.2 Suno-A 9

4.2.3 Suno-B 9

1

1. SPECIFICATIONS

Congratulations on selecting a Dayliff SunFlo Solar Pumping System.

They are manufactured to the highest standards and if installed and

operated correctly will give many years of efcient and trouble free

service. Careful reading of this Installation Manual is therefore

important, though should there be any queries they should be

referred to the equipment supplier.

1.1 PUMP

Solar Pumping Systems are available with several pump options as follows:-

SunFlo-S: Pumps are of positive displacement three-chamber diaphragm design and

can run dry without damage. An internal by-pass is incorporated to prevent damage in the

event of delivery cut-off.

Pump components are manufactured from high quality engineering plastic with

santoprene used for the diaphragm and EPDM for the valves. Casings are plastic for the

150 and stainless steel for the 300.

PV connection is either direct or through a charge controller that is connected to a battery

for 24hrs operation.

SunFlo- A: Pumps are of rotary screw design, the screw being made of stainless steel with

a rubber stator. They feature an in-built controller for starting and running the pump which

incorporates over and under current and voltage protection.

SunFlo-B: Pumps are of either rotary screw or centrifugal design depending upon model.

Material of construction for rotary screw design is stainless steel screw with rubber stator

while centrifugal pumps feature noryl impellers and stainless steel chambers.

Pumps are supplied with a self-contained multifunction MPPT (Maximum Power Point

Tracking) controller that provides high efficiency output, typically +25% higher than

conventional pumps of a similar water output. The controller also protects for over current,

over and under voltage and low water level (with provided electrode) and features

indicator lights that give the pump's operating status. The system can be optionally

installed with batteries so the pump operates when there is insufficient solar irradiation.

1.2 POWER OUTPUTS

2

Typical performance figures are given at standard test conditions of 1000W/m solar

0

irradiance and 25 C. Output will vary throughout the year depending upon prevailing

irradiation levels. For indicative purposes, factors of 1.1 can be applied for hot arid areas

and 0.9 for temperate high altitude areas in East Africa. Output will vary throughout the

day as a proportion of the estimated hourly irradiation as shown in Graph 2.

2

2. EQUIPMENT INSTALLATION

Before commencing installation check all systems components that should include the

pump with cable, safety rope, DC Isolator, controller (if applicable), supply cable for PV

module array to pump controller/isolator, pipe fittings and PV solar modules.

Also required will be the necessary length of piping, surface pipe fittings and module

support which is not included in the systems but is available from the pump supplier on

request.

2

Average Daily Irradiation Values (Kwhr/m)

Graph 1

Jan Feb Mar Apr May Jun Jul Aug Sep 11

Oct Nov Dec

5.6

6.3 6.5

6.0 5.8 5.6 5.7 5.9

6.5

5.8

5.1 5.3

% Daily Output

Graph 2

6 7 8 9 10 12 13 14 15 16 17 18

Time (hrs)

13.5%

7%

10%

12%

13% 13%

12%

10%

7%

0%

2% 2%

0%

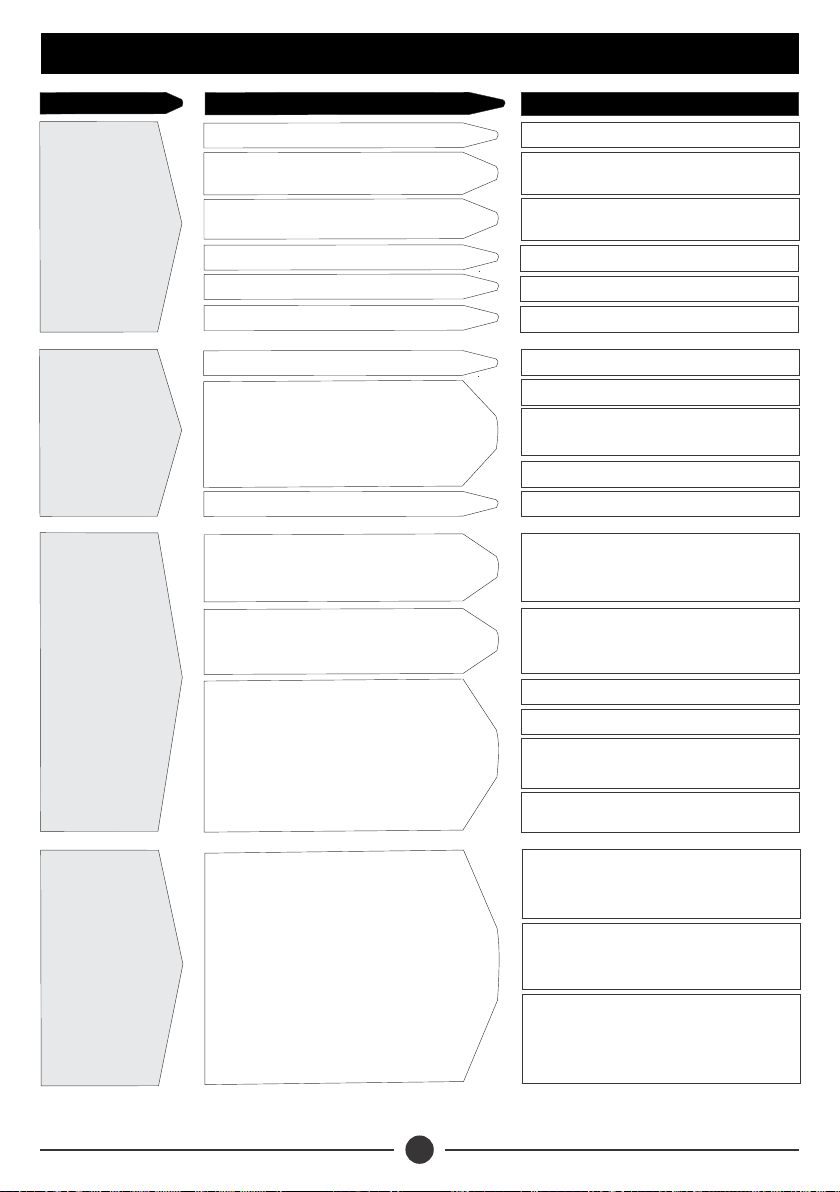

1.3 PUMP DATA

SunFlo-A

SunFlo-S

SunFlo-B

H

104mm

13.8mm

H

SUNFLO-S 150

SUNFLO-S 300

SUNFLO-A 150H

SUNFLO-A 270H

SUNFLO-A 600H

SUNFLO-B 120H

SUNFLO-B 500C

SUNFLO-B 1000C

1m /day at 30m

3

3m /day at 60m

3

2m /day at 30m

3

3m /day at 50m

3

4m /day at 70m

3

3m /day at 30m

3

3

6 4m /day at 0m

12m /day at 70m

3

12024

30024

15024

27036

60048

12024

50048

1000110

Pump Model Indicative

Performance

24 1x200W

2x200W

1x200W

2x200W

4x200W

1x200W

4x200W

8x200W

60m

50m

70m

30m

40m

70m

30m

30m

½”

¾”

1”

1¼”

Outlet

Size

Cable

length,

2

2.5mm

PV

Modules

Peak

Voltage

(V)

Motor

Rating

Watts

Open

Circuit

Voltage

(VoC)

≥20

≥30

≤50

≤50

≤100

≤125

≤200

≥30

≥60

≥112

Input

Voltage

(V)

≤60

3

0

The PV module array should be positioned ideally on an East-West axis at 15 from the

horizontal facing North in the Southern hemisphere and South in the Northern

hemisphere. It is essential that modules are fully exposed to direct sunlight as any shading

will greatly reduce performance.

PV modules are light and simple to fix, frame mounting being recommended. This can be

sited either on a roof or on a ground structure. Frames are available on request.

2.2 PUMP INSTALLATION

For borehole installations it is important to ensure adequate

water availability as damage can occur in the event of dry

running. This should be checked from the Driller's report if

available or by careful testing during commissioning.

WARNING

Pumps can be installed in wells or boreholes and should be provided with fittings as

indicated in Fig1. Piping options are Dayliff PVC for deep wells, galvanized steel or HDPE.

The latter is recommended for shallower wells due to simplified lowering. When installing

the pump ensure to fit the safety rope which can be used to lower the pump down. The rope

should be secured at the well head.

When lowering, it is recommended that the drop cable, electrode cable (if fitted) and rope

are secured to the drop pipe by the tape provided and are not left loose.

ŸA wide range of pump models are available and the pump selected must be matched

to the well/borehole output to provide optimal operating performance. This should

be done with reference to the borehole drillers report in consultation with a borehole

installation specialist where applicable. As a rule pump output should not exceed

65% of maximum tested borehole yield.

ŸMinimum Borehole Diameter 3”pumps-84mm, 4” pumps-110mm.

ŸMaximum Pump Immersion Depth SunFlo-S- 30m, SunFlo-A/B - 20m.

ŸPumped liquid should be clean, thin and non-explosive containing no solid particles

or fibres. Sand content should not exceed 50gm/m or else pump life will be reduced

and any warranties will be invalidated .

0

ŸLiquid temperature should not exceed 40 C in order to preserve rubber components.

ŸPumps can be installed either vertically or at an angle, though if installed at an angle

0

the discharge outlet should never fall below 10 to the horizontal plane as shown in

Fig. 2. For all angled installations a flow sleeve should be used with a minimum of

0.5m water depth above the pump to prevent the formation of a vortex.

2.1 MODULE POSITIONING

When positioning the PV Modules avoid all shade .

WARNING

Fig. 2 Pump Axis Limits

Allowed

Not

Allowed

0

Min 10

2.3 ELECTRICAL WIRING

Cover modules during connection to avoid electric shocks,

Connections should be done in the early morning or late

afternoon when irradiation is low.

WARNINGWARNING

4

Fig. 1 Pump Installation Arrangement

Ensure input power is isolated before wiring and connection

WARNINGWARNING

WARNING

Ensure secure earth grounding of the system to avoid

dangerous power surges.

WARNINGWARNING

Ensure tight cable connections as loose connections are the

most common source of system failures.

WARNINGWARNING

Ensure that the Isolator and Controller are mounted adjacent

and close to the PV module array. Distance between controller

and PV module should not exceed 10m or pump performance

will be impaired. They must be well protected from rain and

weather.

WARNINGWARNING

Electrical connection should be carried out by an authorized

Electrician in accordance with local regulations.

Rope

Pressure Gauge

Cable

Outlet

Check

Valve

Ball

Valve

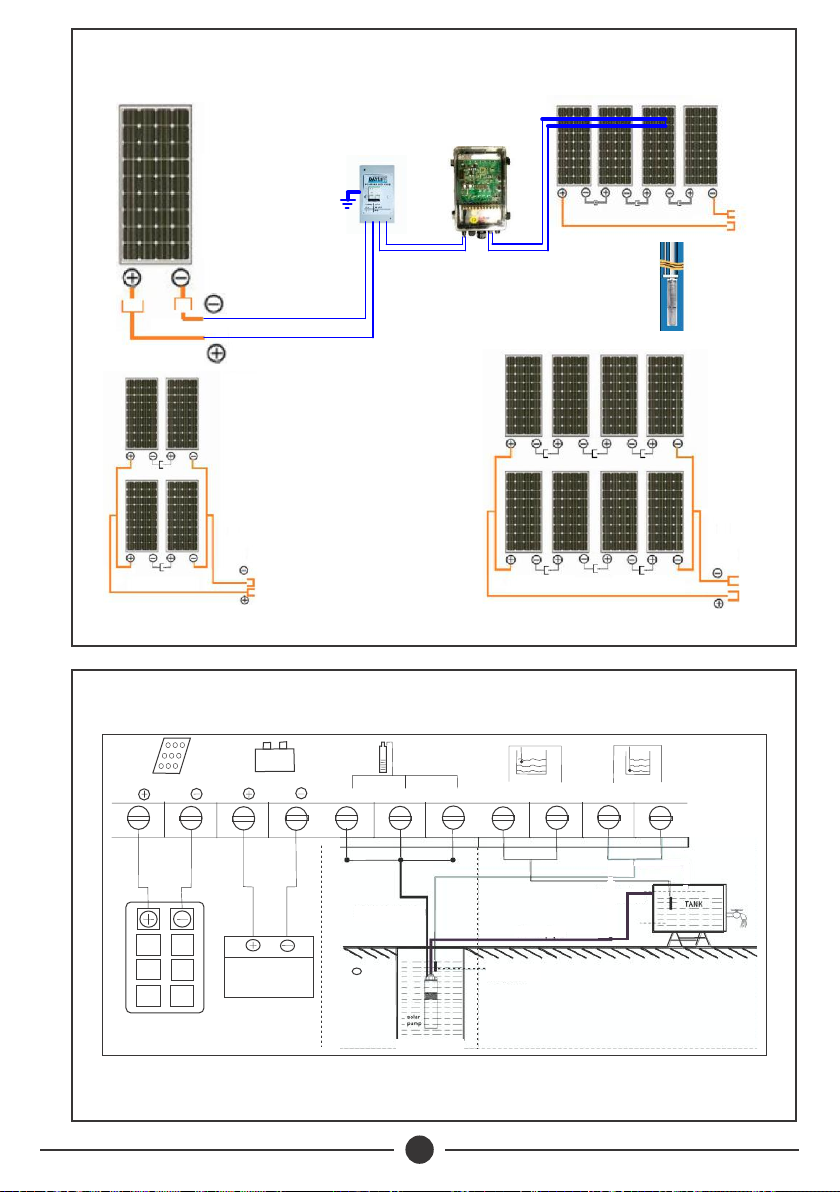

Modules should be wired as per the arrangement shown in Fig. 3,4 & 5 depending on

system. Note most systems are series connected +ve to -ve terminals, though larger

systems include parallel arrays. All module cables should be firmly connected with the

provided plugs to avoid short circuits.

The module connection cable should be connected to the PV Isolator that is provided with

MCB overload protection. All wiring connections should be made with the isolator 'off'.

5

SunFlo-S System Layout

Fig.3

SunFlo-A System Layout

Fig.4

SunFlo-S 150 - 1 PV MODULE

SunFlo-S 300 - 2 PV MODULES

DC Isolator

Outlet

Batteries

PV MODULES

Charge

Controllers

PV MODULES

DC ISOLATOR

OUTLET

MODULE CONNECTIONS

SunFlo-A 150H - 1 PV MODULE

SunFlo-A 270H - 2 PV MODULES

SunFlo-A 600H - 4 PV MODULES

6

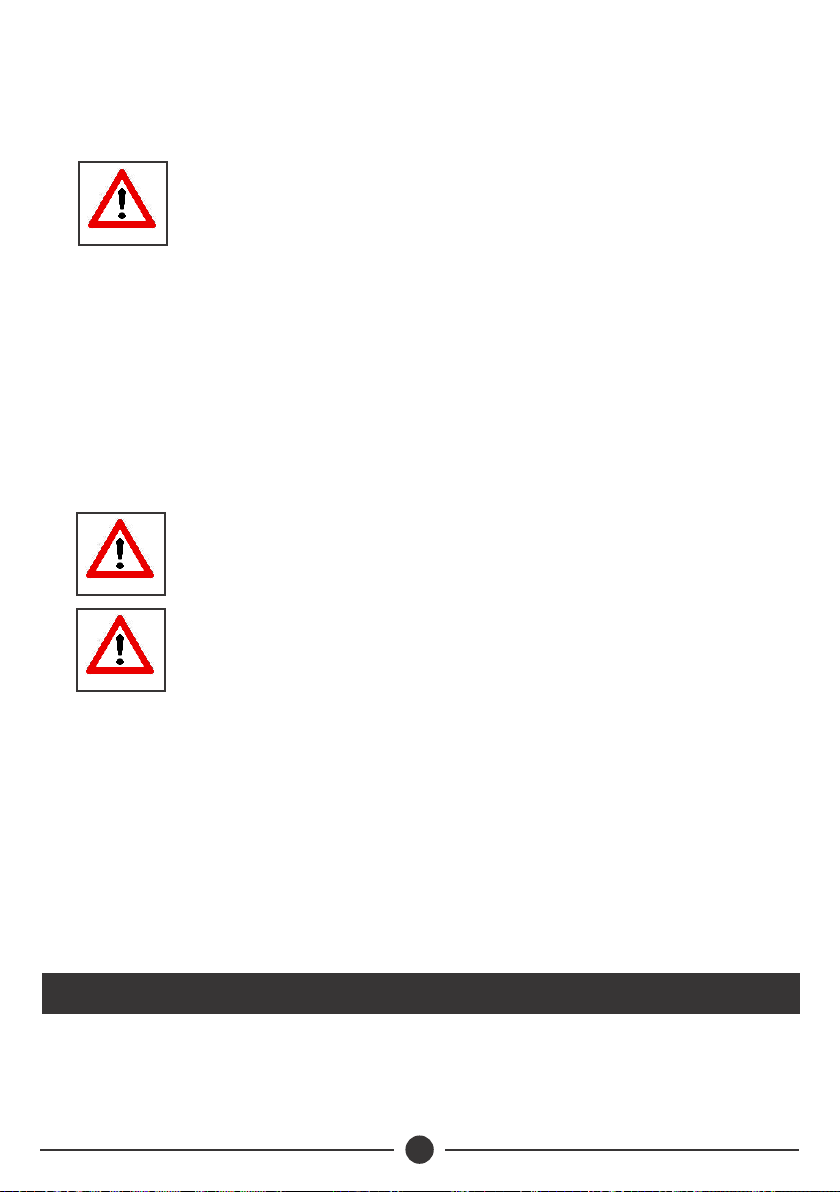

SunFlo-B System Layout

SunFlo-B Controller Connection

Fig.5

Fig.6

Solar Battery

L1 L2 L3

Motor

Tank Well

COM2

Solar Panel

Battery

TH WH

COM1

Water Pipe

Electronic water

level sensor

Well

PV MODULES

MODULES CONNECTIONS

DC ISOLATOR

OUTLET

MPPT PUMP CONTROLLER

SunFlo-B 120H - 1 PV MODULE

SunFlo-B 500C - 4 PV MODULES

SunFlo-B 1000C - 8 PV MODULES

When provided, separate Controllers should be located adjacent to the Isolator and care

taken to ensure correct connections to the terminal block. The controller isolator must be

'off' during connections.

2.4 LOW WATER LEVEL PROTECTION

7

Water level sensors are unnecessary when there is no risk of

draw down to the pump.

CAUTION

The total length of cable used for water level sensors should not

exceed 200m.

CAUTION

The water level sensor should be installed not less than 100mm

above the pump suction.

CAUTION

2.5 HIGH WATER LEVEL TANK SENSOR

A high level sensor is also provided that can be used to control the pump when the

pump output is delivered to a high level tank. In the event of this being fitted it should

be connected to the terminals as shown in Fig 6 and also the timer delay controlled by

Switch B must be set to approx. 20 mins.

SunFlo-A

A paddle type float switch is provided on the main pump cable that is suitable for large

diameter well installation where there is sufficient space for paddle operation.

If installed in a borehole the paddle should be removed by cutting the cable and the

three cable ends bared, joined together and bound by insulation tape to the main

drop cable. Care should be taken to ensure a tight connection so the switch leads are

in closed circuit.

SunFlo-B

A separate level probe is provided that should be connected to the Controller as

indicated. When fitted it is important to set the timer delay on Switch B (see section

4.2) to protect the pump from cycling as the water level rises. When no low level

sensor is fitted terminal COM1 and WH should be directly connected with a looped

cable.

3. BATTERY SYSTEMS

SunFlo-S and SunFlo-B installations can be provided with auxiliary batteries to

provide extended pump operation. Batteries must be connected through the

controller provided to the terminals indicated. They should not be connected directly

to the pump. Batteries should be sized according to the table below:

8

Pump Power,

Watts

120

Pump

Voltage

Battery Capacity Series Connection

300

500

24

24

48

2No. 18Ah/12V

2No. 35Ah/12V

4No. 35Ah/12V

2No. 35Ah/12V

2No. 100Ah/12V

4No. 100Ah/12V

4. SYSTEM OPERATIONS

4.1 PUMP

Generally pump operation is fully automatic with pump flow starting with low output at

around 8am building to a peak at mid-day and stopping around 5pm. Output will vary

with conditions with low output during rainy or clouded periods. Equipment is water

lubricated and requires no maintenance though periodically it is important to clean the

module surface of dust and debris and check the installation for damage.

4.2 CONTROLLER

4.2.1 SunFlo-S

For battery operated systems a charge controller (supplied in the system) is required. The

controller must not be used for systems without batteries as performance will be impaired.

Charge controllers are fitted with LED indicators for fault, battery and working status;

automatic 12/24 identification, overload protection and anti-reverse protection.

Units

PV

BAT

LOAD

Battery

Charging

at daytime

Load

LCD Icon Indicated Item

Solar Panel Parameter

Status

Output

Parameter

Indicator

Charge Controller Display

Battery Parameter

Load discharging

Parameter

Daytime or Charging

Night recognition

Load short-circuit or

overload

Load turned on

Load turned off

Battery in normal state

Over discharge

Over voltage

Steady on

Steady on

Steady on

Steady on

Steady off

Quick Flashing

Steady on

Steady off

All lighting up

Only the frame flashing

The frame and 3 dashes

all flashing

2hrs 5hrs

Indicator Lights

Label Denition Instruction

SYS

Pump

MPPT

ERR_I

LOW_POWER

Tank_F

WELL_L

System

Power

Pump running

Maximum

Power Point

Tracking

Current

Error

Voltage

Error

Tank Water

Level Alarm

Well Water

Level Alarm

Solar Mode: Indicator light is always on (not battery mode)

Battery Mode: Green indicator light blinking

Green indicator light will turn on after the pump starts running

Green light, monitor the power input from the solar arrays and adjust the

voltage and current to gain the highest performance from the pump

Red light is always on: Overload error

Red light blinking : Over current error :

Yellow light continuously on indicates the system voltage is too low

Green light, the tank is full

Green light, the well is empty

If the light is blinking, system is in time-delay mode

9

4.2.2 SunFlo-A

Pumps are controlled by an internal motor controller with no external monitoring or

adjustment provisions. However, pumps must be connected through the PV Isolator that

also provides over-current protection.

4.2.3 SunFlo-B

All SunFlo-B pumps are provided with an advanced MPPT controller that enhances pump

performance by up to 25%. The controller includes an isolator switch, protection from

over/under voltage, overcurrent, low level control (optional), indicator lights for pump

operating status and provision for high level floatswitch.

10

No Indicator Lights System Status

1

2

3

All the indicator lights blink once

‘SYS’ Blinking

‘SYS + Pump + MPPT’ Blinking System starts charging mode

System in self-check mode

System powered

Time delay

Speed button

Solar battery diverter switch

Speed Control – Modulates the pump speed by regulating pump efficiency. Turn fully

clockwise for 100% efficiency and fully anti-clockwise for minimum 30% efficiency. This

function allows PV module output to be shared between the pump and battery charging

according to the set proportion and for reduced pump output in the event of over-

pumping. For full output pump operation it should be set to 100% efficiency.

Speed Time Delay – Controls the delay on the low level cut-out re-start with up to

30mins delay being available. The WELL indicator will blink when the delay is activated. If

no delay is required the control should be set to '0', the recommended setting unless the

well has very poor output.

Solar/Battery Mode Selector Switch – A three position switch that selects solar

operation, system isolation or battery operation.

When operating in 'Solar' mode all power from the PV modules will be used for the pump

operation and the battery will be isolated. For non-battery systems the switch should

always be in this position

When operating in 'Battery' mode the system will be powered by hybrid battery/PV module

output according to power available and the battery is charged by surplus PV module

output controlled by the Speed Control. Also when there is insufficient irradiation the

charged battery will power the pump.

Controls

11

For SunFlo-B pump

shutdown with red

LED ON for ERR_1

Clean all solids or sand out of the pump

and reset by switching the pump OFF

then ON again

Motor or pump is blocked and very hard

to turn

Check the PV array is facing the sun and

remove any shading. Otherwise wait for

optimum sunshine conditions

Low irradiation

Check and correct wiring

Incorrect wire connections

Check controller wiring is well done

Inspect the controller for any burnt parts

and repair/replace

Check earthing connections are well

done

For SunFlo-B pump

shutdown with red

LED ON for

LOW_POWER

Insufficient power reaching the controller.

A solar-direct (non-battery) system should

start once there is sufficient sunshine

Low voltage on the system which is

insufficient to power the pump

A battery system should start if the battery

supply voltage is higher than what the

pump requires

If the pump was recently connected (or

reconnected) to the controller, it may be

running in reverse direction due to wiring

error

Check power supplyIncorrect power supply

Incorrect wire connections

Pump will not

operate

Insufficient sunshine

Check for tripped MCB & reset

Check electrical wiring

Check for corrosion and looseness and

correct

Wait for sufficient sunshine conditions

PROBLEM POSSIBLE CAUSE SOLUTION

Check solar irradiationLow voltage

No water at pump level

Pump operates with

no flow or reduced

flow

5. TROUBLE SHOOTING

Pump located too deep

Clogged filter screen

Water flow restricted

Loose connections or punctured hose

Remove filter screen and rinse

Check for crimped hose or blocked pipes

Check hose clamps or replace hose

Ensure the pump is installed below

the lowest water level

Correct installation to the recommended

level

6. TERMS OF WARRANTY

i) General Liability

ii) Standard Warranty

ŸIn lieu of any warranty, condition or liability implied by law, the liability of Dayliff in

respect of any defect or failure of equipment supplied is limited to making good by

replacement or repair (at the Company’s discretion) defects which under proper use

appear therein and arise solely from faulty design, materials or workmanship within a

specified period. This period commences immediately after the equipment has

been delivered to the customer and at its termination all liability ceases. Also the

warranty period will be assessed on the basis of the date that the Company is

informed of the failure.

ŸThe warranty applies solely to equipment supplied and no claim for

consequential damages, however arising, will be entertained. Also the warranty

specifically excluded defects caused by fair wear and tear, the effects of careless

handling, lack of maintenance, faulty installation, incompetence on part of the

equipment user, Acts of God or any other cause beyond the Company’s reasonable

control. Also, any repair or attempt at repair carried out by any other party invalidates

all warranties.

If equipment failure occurs in the normal course of service having been competently

installed and when operating within its specified duty limits warranty will be provided as

follows:-

ŸUp to one year - The item will be replaced or repaired at no charge.

ŸOver 1 year, less than two years - The item will be replaced or repaired at a

cost to the customer of 50% of the Davis & Shirtliff market price.

The warranty on equipment supplied or installed by others is conditional upon the

defective unit being promptly returned free to a Davis & Shirtliff ofce and collected

thereafter when repaired. No element of site repair is included in the warranty and any site

attendance costs will be payable in full at standard charge out rates. Also proof of

purchase including the purchase invoice must be provided for a warranty claim to be

considered.

12

INS420A-05/19

www.davisandshirtliff.com

This manual suits for next models

7

Table of contents

Other DAYLIFF Inverter manuals

Popular Inverter manuals by other brands

AIMS Power

AIMS Power PE200012230S user manual

Sungrow

Sungrow SG36KTL-M user manual

Haier

Haier AS50XCAHRA Service manual

Statpower

Statpower Portawattz 400 Installation & operation guide

Fuji Electric

Fuji Electric FRN0001C2S-2AFRN0002C2S-2AFRN0004C2S-2AFRN0006C2S-2AFRN0010C2S-2AFRN0012C2S-2AFRN0020C2S-2AFRN0025C2S-2AFRN0033C2S-2AFR instruction manual

Deye

Deye SUN-8K-G03-LV user manual