DAYLIFF DSTEAM90 Installation instructions

Steam Generator

STEAM GENERATOR

SPECIFICATIONS

1.

1

2.

SYMBOLS & WARNINGS 2

4. INSTALLATION 7

4.3 Water & Steam Connection 9

4.4 Installation for Controller

10

4.1 Steam Room Design 7

6. TROUBLE SHOOTING 14

8. TERMS OF WARRANTY 17

© Davis & Shirtliff Ltd 2022

Contents herein are not warranted

5. OPERATION 12

7. MAINTENANCE 16

5.2 Setting Time & Temperature 13

5.3 Descaling Process

14

5.1 Steaming Control 12

5.4 Flushing & Draining

14

3.

DESIGN DETAILS 2

4.2 Equipment Installation 8

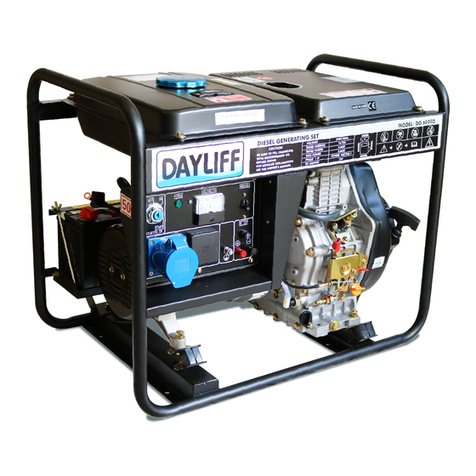

DAYLIFF steam generators are high specification units with a number of design features

that provide exceptional performance. They are fitted with multiples of 3kW elements

depending on size for improved reliability ensuring steam freshness and selectable

manual/auto drain. A remote control panel is included that gives a digital display of

temperature and timer settings with indicator lights showing various operating

conditions. Remote switches are included in the controller for cabin lighting and

ventilation. One controller may be used to control one or up to 3 units. A demand switch

is included that is installed inside the steam room for extending steam release for 30min.

Units are supplied complete with all installation accessories including a steam head and

auto drain valve. Provision for auto-descaling is provided.

OPERATING CONDITIONS

Water Pressure: Min 0.25Bar, Max 8Bar

Water Quality: Hardness less than 50ppm CaCo above which regular de-scaling is

2

necessary. If hardness exceeds 100ppm a water softener and a cartridge prefilter is

required to ensure efficient operation on the water inlet

Congratulations on selecting Dayliff Steam Generator. They are

manufactured to the highest standards and if installed and operated

correctly will give many years of efcient and trouble free service.

Careful reading of this Installation Manual is therefore important,

though should there be any queries they should be referred to the

equipment supplier.

1. SPECIFICATIONS

Dimensions(mm)

Model Size

(kW)

Heating

Elements

(kW)

Phase/

Current

(A)

Room

Volume

3

(m )

Weight

(Kg)

L W H

DSTEAM90 9 3x3 1-39/3-13 6-10 210 370 14

530

DSTEAM120 12 4x3 3-17 8-12

240 460

DSTEAM150 15 5x3 3-22 12-17 18

1

STEAM GENERATOR

2. SYMBOLS AND WARNINGS

This appliance must be connected to an all pole isolator.

WARNING

Disconnect the power supply before making any electrical

connections.

WARNING

Ensure correct voltage for single and three phase steam

generator.

WARNING

This equipment must be installed by a qualied technician.

WARNING

The steam inlet nozzle should be set at approximately 300mm

from the oor and at least 200mm from wall.

WARNING

The steam generator should be installed in an accessible place

where both the electrical power and water supply can be

isolated in an emergency.

WARNING

The minimum water inlet pressure is 0.25 bar and a maximum

of 8 bar, working pressure should not exceed 5 bar.

WARNING

The steam pipe length from steam generator to steam room

should be kept to a minimum, pipes longer than 5 meters

should be insulated to prevent heat loss. Steam pipes are hot

during use and must be protected against accidental contact.

WARNING

Bends and elbows should be kept at a minimum. The pipe line

should be kept simple and straight to prevent condensate from

gathering and causing blockage.

WARNING

There must be no valve or other blockage in the steam pipe.

WARNING

2

The steam pipes should be metallic or of any other material

which can withstand 150°C temperature, copper pipe is

recommended.

WARNING

Steam generator should be installed on level ground.

WARNING

The Steam generator should not be in close proximity to

hazardous substances.

WARNING

The size of heater required to heat a particular size of steam

room is dependent on type of material used for construction,

the height of the steam room and the ambient temperature.

NOTE

3

Frame and functions of the Steam Generator

Fig 4

3. DESIGN DETAILS

No.

1

5

Automatically controls the water flow (maximum pressure

2bar)

2

3

4

Part Description

Water Inlet Valve

Controlled by controller turn on or turn off to drain water

Drain Valve

The entry route of power wire

Power Entry

The entry route of control cable

Control Cable Entry

BoilerStainless Steel Tank

6Reduce the loss of the boiler heat

Insulation Material

7Detect the water levelWater Level Probe

8Steam OutletSteam Outlet

9

13

Operates if the pressure in the boiler exceeds 10.2bar

10

11

12

Pressure Relief Valve

0

To protect boiler when temperature exceeds110 C

Overheat Switch

Control Centre

Main Circuit Board

Connect and control the heat element

Accesorial Circuit

Board

Connection for power supply

Terminal

4

No. Part Description

14 Connection for earth wire Earth Wire Plug

15 Descaling liquid inlet (1/2 inch)Descaling Liquid Inlet

16 Electrical ElementHeat Element

OC-B Controller Display

Fig 5

No.

1Switch ON & OFF

2

3

Part Description

Dual function button push to select steam on demand mode

or to drain the generator manually when not steaming

On

Off

On

Off

Light

Light

Temperature Display

Time Display

Push to operate lights

Drain

Drain

Fan

Mode

Mode

Enter

4Dual function button used when steaming to set the

time/temperature

5

6Decrease button

Increase button

Set

Clean

Set

Clean

5

1

2

5

4

16

15

9

14

13

3

6

7

17

10

8

11

12

Light

Clean

Fan

Water Drain Mode Heating Overheating

No. Part Description

7Dual function button switches the fan on and off also used

to confirm

Fan

Enter

8Display the resting and operating time of the steam

generator

Time Display

Window

9Display the detected temperature of steam room

Temp Display

Window

10 Indicator LED for the lamp of steam room

Light LED

11

Indicator LED for water level .Red means water is filling,

green means ideal water level is reached. If the LED is

always in red (exceed 5 minutes). Check water supply and if

water level valve is blocked.Otherwise the water level inlet

valve may be damaged .

Water LED

12 Indicator LED for draining – shows red for manual draining

and green for automatic draining at the end of the cycle.

Drain LED

13 Operation mode indicator red is for steam on demand

mode and green for conventional timing.

Mode LED

14 Green indicates heating is on, red indicates the required

temperature

Heating LED

15 Indicator LED for over heat, red means the steam generator

has been cut off due to heat element being too hot

Overheat LED

16 Indicator LED for fan in operation

Fan LED

17 Indicator LED shows descaling in operation.

When the switch is operated the LED indicator inside the switch turns red and steam is

generated for 30 minutes. At the end of 30 minutes or if the switch is operated again, the

light will go off and the steam will stop. (Notice: Long Press the “Drain/Model” button for

5 seonds, the time display will show ”Long”, then enter “OC-S” mode).

Clean LED

In order for the generator to operate in steam on demand

mode the steam on demand button must be connected.

NOTE

OC-S Steam on Demand Switch

6

Commercial Mode Instruction (OC-B+OC-S )

If OC-B is under domestic model, only the OC-B controls the steam generator .OC-S will

not work. When OC-B is used on commercial model, the steam generator will be under

waiting status (the time window shows “Long” and on circuit board the LED will be

flashing) , press OC-S to operate steam generator , every press will make the steam

generator keep working for intervals of 30 minutes , the temperature control will depend

on the OC-B controller’s setting.

4. INSTALLATION

7

4.1 Steam Room Design

As a guide; For lightweight materials such as plastics and laminates, 1 kW will heat up to

3

1m of air. For dense materials such as stones and ceramics which conduct heat more

3

rapidly allow for up to 2kW per m of air. Hot air rises so restricting the height to around 2

meters will ensure the user is sitting in the steam. For higher ceilings, ensure to increase

the power requirement.

If greater power is required one OC-B controller may be used to control two or more

steam generators, e.g. if a 30kW steam generator is needed, one OC-B controller can

control two 15kW steam generator or three 10 kW steam generators .

Fig 1: Schematic Layout Multiple Generator

Temperature Sensor

Master

OC-B Controller

To Next Slave

Slave 1 Slave 2

Temperature

Sensor

OC-B Controller

Fig 2: Schematic Wiring of Multiple Generators

Master Slave 1

To Slave

Slave 2

To Next Slave

From Master

Filter

Fig 3: Typical Layout of Multiple Generators

0

The OC-B controller has a working window of 10-240 minutes and 30-60 C. When the

time is not set, the generator operates continuously until switched off.

An OC-S demand switch may be included in the controller to set working times in regular

intervals of 30minutes.

The steam generator should be installed in a dry well ventilated place in close proximity to

the steam room. It can be placed on the floor or hung from a wall.

4.2 Equipment Installation

Fig 6: Typical Room Layout

Insulation

Closet

Basement

Steam Nozzle

Under Washing Basin

Steam Generator

OC-B Controller

(can be either in or

outside the steam room)

8

Fig 7: Minimum Setting Dimensions

1. The water supply pipe and steam pipe should comply with local standards.

2. Connect the water inlet valve of the generator to the 15mm mains water supply using

a flexible hose with 1/2 inch fittings.

3. Steam outlet (1/2 inch or 3/4 inch) should use the same dimension copper pipe for

ease of connection

4.3 Water & Steam Connection

Fig 8: Accessory Installation Layout

T h e s te a m n o z z l e

sh o ul d be 3 00 m m

away from the ground .

For user comfort it

s h o u l d b e a t t h e

farthest place from the

seat.

STEAM GENERATOR

Valve

Water Level Probe

Overheat Switch

According to the location it may be necessary to attach an

additional length of pipe to the pressure relief valve in order to

divert the steam ow to a safe direction should the valve

operate.

NOTE

9

315mm - 9/12kW

215mm

415mm - 15kW

215mm

ŸTo hang the generator on a wall drill 3 holes 8mm in diameter as below image and

use the wall plugs and screws provided.

ŸFix the top 2 screws in place first then hang the generator by the 2 keyhole shaped

holes in the back plate.

ŸThen with the front cover removed fix the third screw to secure the unit in place.

4.4 Installation of Controller and Temperature Probe

Steam generator controller is water proof and can be installed inside or outside the steam

room according to customer preference.

1. The control panel should be installed at a height of approximately 1200mm for ease

of use.

2. To Install: drill a Φ40mm hole on wall. Open the front cover of steam generator. Fix

the control cable (6 core) and temperature sensor cable (2 cores) to the relevant

ports. Put the protruding back of controller in the hole at the bottom of controller press

close to the wall and place back the cover.

Control panel installation: Screw one end to circuit board ports in steam generator

and connect the other to the controller's cable.

Fig 9: Controller Installation

118mm

Temperature probe installation: The temperature probe is installed inside the

steam room at approximately 1.2 to 1.5 meters high and away from the door respective.

Use a Φ4mm screw to fix it in place and connect to the wire from the controller.

10

Temperature

Sensor 4

Screw

Installation for Power Supply and Control Cable

1. Confirm the correct voltage of power supply and the wires.

2. Remove the knock out for the power cable entry and use a rubber grommet to protect

the cable, connect the conductors to the correct terminals. For single phase power

use the copper bridge connectors.

3. Ensure the power supply wire and control cable remains separated to prevent

magnetic field of power supply wire from interfering with control cable signal.

4. Connect the drain outlet to a suitable drain via a copper pipe with the appropriate

fittings.

5. Make a secure connection between steam nozzle & steam pipe.

6. Use non corrosive hose with ½ inch unions to connect between the descaling liquid

container and the inlet valve; note the descaling liquid container must be mounted at

least 500 mm above the steam generator.

Fig 10

11

9kW Steam Generator Circuit Diagram

12/15kW Steam Generator Circuit Diagram

Fig 11

12

Steam on Demand Function

Commercial operators may wish to take advantage of the steam on demand function

which allows bathers to press the steam on demand button located inside the steam room

after which the generator will operate for 30 minutes then stop until activated again.

To operate the steam on demand function install the controller inside the plant room

alongside the generator then fit the push button supplied in a convenient location inside

the steam room and connect to the controller with the cable provided.

5. OPERATION

Once the installation has been completed and checked, turn on the power and water

supply and carry out the following procedure

1. On the control panel press the “ “ key , the key has a time-lapse function, long

press for 1 second, the time and temp windows will display the data.

2. Open the water inlet valve and water will enter the boiler, the indicator LED turns red.

When the water level rises to the low water sensor level the elements will switch on and

the heating indicator LED will turn on. When the high water sensor is reached the

water inlet indicator LED changes to green and the water inlet valve will turn off.

3. After a few minutes of operation the generator will begin steaming, for small steam

generator 2-3 minutes and about 3-5 minutes for larger generators.

4. Press the “ “, key again and the controller turns off. The display turns off and

steam stops being generated there will also be no data on display.

5. Press the “ “ key once more (temp and time display again) after a few seconds the

generator will begin producing steam again. Let the generator operate for a short

while until the water level falls to the low water level, check that the water inlet valve

opens automatically and the water inlet indicator LED turns red. Cold water then

enters the boiler and the steam generator starts to produce steam once the high water

level is reached. The water inlet valve will close and the LED will turn green.

6. The timer will then count down to show the remaining time and when it reaches 0 the

steam generator will stop.

7. Once the steam generator has operated for 10 minutes or more and turns off

(manually or automatically) it prepares for automatic drain down cycle. Once the

0

temperature of the water falls below 80 C, drain and flush are carried out and

steaming can begin.

On

On

Off

Off

On

Off

5.1 Steaming Control

The water will only start draining once the temperature has

fallen below 80 ℃.

NOTE

13

8. “ “This button has 2 functions; if the generator is off this button can be used to

drain the generator manually. If the generator is switched on it can be used to select

the steam on demand operating mode.

9. When the preset temperature for the steam room is reached 2 of the 3 elements will

switch off allowing just 1 to continue heating to maintain the temperature. Elements

will cycle on and off to maintain the temperature to within approximately 2.5 degrees

above or below the preset requirement.

10. Boil dry protection – If the water supply is discontinued the water level indicator LED

turns red and the steam generator stops immediately.

11. The “ “ button can output AC230V to power the transformer for a 12V steam

room lamp.

Drain

Model

Light

12. “ “ button has 2 functions; it can be used to power a fan if fitted and can also be

used during the temperature or time setting procedure to confirm the settings (see

further details below).

13. “ “ button has 2 functions; it is used to set the time and temperature settings and to

start the descaling operation (see further details below).

14. The display temperature can be changed from Celsius (default) to Fahrenheit by

altering the settings of the JP1 pins on the circuit board.

Fan

Enter

Set

Clean

5.2 Setting Time and Temperature

0

The steam generator default settings are 40 C temp and 1 hour of operation which can

be adjusted as follows;

The memory is lost and reverted back to the factory default

settings when the power is cut off.

CAUTION

Fan

Enter

Fan

Enter

Set

Clean

Set

Clean

1. To set time: press “ “ key and the time display window will flash - press “ “ or “ “

to adjust the time, every press increases or reduces by 5 minutes, once the desired

setting is achieved press “ “ the window will stop flashing. Time may be adjusted

from 10 to 240 minutes. Exceeding 240 minutes the display will show “NO”

meaning no time limit.

2. To set temperature press “ “ twice. The temperature window will flash, enter the

required temperature by pressing “ “ or “ “ to adjust - every press will increase or

reduce by 1 ℃ . Temperature is adjustable from 30℃-60℃ , press “ “ key and

the window will stop flashing.

3. Auto-descaling can only operate when the steam generator is in OFF mode i.e. the

boiler has finished steaming; the water has drained and flushed, the drain LED will be

off. Before auto-descaling can commence, a supply of dilute citric acid liquid must

be connected from a storage vessel positioned at least 500mm above the steam

generator. For the dilution ratio refer to the information supplied with the citric acid.

14

Do not use strong acids or high concentrations as these may

attack and destroy the element or other metal parts of the

boiler.

NOTE

Set

Clean

1. To start the process press the “ “ key for 5 seconds, “Clean” LED light will come on

and time window display last setting time (default setting is 8 hours).

2. Press “ “ or “ “ for 5 seconds, to change display into hours, increase or decrease

to set the required time, each button press will increase or decrease 1 hour, maximum

is 24 hours, minimum is 1 hour.

3. Once the setting is done the flashing will stop and the process will begin automatically

by opening, the inlet valve for the boiler to fill with the descaling solution. The inlet

valve will then close and the solution will remain inside the boiler for the preset time.

5.3 Descaling Process

5.4 Flushing and Draining

1. At the end of the sequence, the drain valve will open and the boiler will drain and then

flush with clean water; when the cycle is complete the drain LED will go off.

2. Ensure there is sufficient descaling solution in the container to completely fill the boiler

- when liquid level reaches set point , the LED on circuit board will light up.

If during descaling the power supply is interrupted do not

operate the steam generator until either the descaling process

has been reset or the acid solution has been drained and the

boiler ushed with clean water – minimum 3 ushes.

CAUTION

6. TROUBLE SHOOTING

Fault

1. Check power supply voltage.

2. If Indicator LED of power supply on

circuit board is not in red then check

transformer.

3. If the LED is red, remove controller, use

circuit board and turn the steam

generator If steam generator doesn’t

work .then circuit board is faulty, change

circuit board.

4. If the circuit board is ok and the steam

generator works normally, Check the

control cable port and controller.

Cause Solution

1. No Power Supply

2. Transformer faulty

3.Main Circuit Board

faulty

4. Control Cable or Port

faulty

There is no

display on the

control panel

w h e n t h e

on/off switch

is pressed

Faulty Cause Solution

1. If indicator LED for water level is red.

check water supply and turn on water

inlet valve.

2. Check the connection of water level

probe.

3. Check grounding connection of circuit

board and boiler.

4. If indicator LED for water level is green

check circuit board.

5. Check if overheat switch is disconnected

6. Check heating elements.

1.Water Supply valve is

not turned on.

2.Water inlet valve faulty

3.Water Level Probe

Faulty

4. Earth Wire of Boiler

and Circuit Board

Faulty.

5. Circuit Board Faulty.

6. Heat Element Faulty.

The controller

is on,

Indicator LED

of heating is

not on and

there is no

steam being

produced

1. Replace main circuit board

2. Replace relay circuit board

3. Replace heating elements

1.Main Circuit Board

Faulty

2.Relay Circuit Board

Faulty

3.Heating Element s

Faulty

S t e a m

generator is

turned on but

there is no

steam output

Check connection or change water level

probe.

Wa t e r l e v e l p r o b e

connection faulty

T e m p .

w i n d o w

display “LC”

15

1. Check water level probe connection

2.Check controller if it is has shorted

circuited

Water level probe is

short circuited

T e m p .

w i n d o w

display “HC”

Clean and change water inlet valve

Water inlet valve faulty

Water flows

from steam

nozzle when

s t e a m

generator is

off

Change circuit board or water inlet valve 1.Water Inlet Valve

Faulty

2. Circuit Board Faulty

When power

is cut off water

continues to

flow

Faulty Cause Solution

Disconnect power supply and contact

nearest Dayliff retailer

1. Circuit Board Faulty

2. Controller Faulty

3 . Fa ult y Re l a ys o n

a c c e sso r y c i rc ui t

board

4. Water Level Probe

S t e a m

generator is

turned off but

c o n t i n u e s

working

Turn off the steam generator manually and

press the drain button ,when the steam

generator finishes draining, the drain valve

will close , and then turn on the steam

generator.

Last cycle of draining

curtailed due to power

loss

When steam

generator is

t u r n e d o n ,

water comes

off the valve

16

7. MAINTENANCE

The single biggest problem with steam generation is the build up of scale resulting from

dissolved solids within the water. Scaling can cause the elements to fail, the water level

sensors not to function and premature failure of the O-rings resulting in leaks from

around the elements. The extent of the problem will vary according to the degree of

hardness in the local water supply.

It is recommended to use water softener.

NOTE

All commercial and domestic uses must ensure a regular maintenance routine for

descaling the generator. The frequency of this will vary according to the degree of

hardness in the local water supply and the amount of time the generator is used. Check

the water for hardness and arrange the descaling routine accordingly.

Faults arising from a failure to descale the generator are not

covered by warranty.

NOTE

Because heating and cooling cause expansion and contraction it is important to inspect

all the water and steam inlets and outlets as well as their pipes and connectors on a

regular basis to ensure there are no leaks.

Clean the filter net in the magnetic valve according to the water quality in the location.

Wiring and electrical integrity of the generator should be checked regularly at least once

a year.

8. TERMS OF WARRANTY

ii) Standard Warranty

General Terms

If equipment failure occurs in the normal course of service having been

competently installed and when operating within its specified duty limits

warranty will be provided as follows:-

• Up to 1 year - The item will be replaced or repaired at no charge.

• Over 1year, less than 2 years - The item will be replaced or repaired

at a cost to the customer of 50% of the Davis & Shirtliff market price.

The warranty on equipment supplied or installed by others is conditional upon

the defective unit being promptly returned free to a Davis & Shirtliff

ofce and collected thereafter when repaired. No element of site repair is

included in the warranty and any site attendance costs will be payable in full at

standard chargeout rates. Also proof of purchase including the purchase

invoice must be provided for a warranty claim to be considered.

I) General Liability

• In lieu of any warranty, condition or liability implied by law, the liability of

Davis & Shirtliff (hereafter called the Company) in respect of any defect or

failure of equipment supplied is limited to making good by

replacement or repair (at the Company's discretion) defects which

under proper use appear therein and arise solely from faulty design,

materials or workmanship within a specified period. This period

commences immediately after the equipment has been delivered to

the customer and at its termination all liability ceases. Also the warranty

period will be assessed on the basis of the date that the Company is

informed of the failure.

ŸThis warranty applies solely to equipment supplied and no claim for

consequential damages, however arising, will be entertained. Also the

warranty specifically excludes defects caused by fair wear and tear, the

effects of careless handling, lack of maintenance, faulty installation,

incompetence on the part of the equipment user, Acts of God or any other

cause beyond the Company's reasonable control. Also, any repair or

attempt at repair carried out by any other party invalidates all

warranties.

17

This manual suits for next models

2

Table of contents

Other DAYLIFF Portable Generator manuals