DAYLIFF ULTRASUN UFS Installation instructions

Installation &

Operating Manual

ULTRASUN UFS

Flatplate Solar Systems

SPECIFICATIONS

1.

1

4.

SITING 5

INDEX

© Davis & Shirtliff Ltd 2020

Contents herein are not warranted

5.

INSTALLATION 6

6.

SYSTEM COMMISSIONING 21

7.

USAGE 21

8.

MAINTENANCE 21

9.

TROUBLE SHOOTING 22

10.

TERMS OF WARRANTY 24

3.

WARNINGS & SYMBOLS 4

2.

EQUIPMENT SPECIFICATIONS 2

1

1. SPECIFICATIONS

Ultrasun UFS Flatplate Solar hot water systems are economical effective heaters that

provide excellent performance, good value and guaranteed long life. They are of Open

Loop thermosyphon design with water flow circulating through the collector and being

stored in the tank ready for use.Features include;

• Heavy duty storage tank comprising SUS304 stainless steel inner cylinder

encased in a plastic painted insulated galvanized steel casing complete with

2.4kW electric heater, thermostat and a sacrificial anode to protect against

corrosion

• Ultra high efficiency solar collectors incorporating capillary copper pipes

ultrasonically welded on a black chrome backplate covered by high transmittance

glass

• Insulated copper pipe complete with necessary compression fittings, pressure

release valve and a drain cock

• Galvanised mounting frame

Ultrasun UFS Flatplate Systems are available in three sizes to suit domestic and small scale

institutional applications. They are effective and robust products designed for many years

of trouble free operation with a 5 year guarantee to demonstrate product quality.

OPERATING CONDITIONS

Water quality: Water outside the following limits should be appropriately pre-

treated. Clarity: Clear, TDS:<600mg/l, Hardness:<200mg/l,CaCo3

Saturation Index: >0.8

0

Max. Operating Temperature: 150 C

Max. Operating Pressure: 6bar

Congratulations on selecting a Ultrasun UFS Flatplate Solar Hot Water

System. They are manufactured to the highest standards and if installed and

operated correctly will give many years of efcient and trouble free service.

Careful reading of this Installation Manual is therefore important, though

should there be any queries they should be referred to the equipment

supplier.

2

DESIGN FEATURES

Direct Tank

1. Copper Aluminum fin absorbing plate

2. High Transmittance Glass

3. Polyester Fibre Insulation

4. EPDM Sealing Gasket

5. 6063 Aluminium Alloy Frame

Solar Collector

1

2

3

4

5

123

445

1. Steel outside casing coated by electrostatic

0

powder coating baked at 220 C to protect the

tank from outdoor conditions and UV rays

2. Direct-injected, CFC-free polyurethane foam

Insulation in 40mm thickness

3. Stainless steel hot water tank

4. UV resistant plastic cap

5. 2.4kW electric heater

2. EQUIPMENT SPECIFICATIONS

The equipment supplied comprises of two principal components, the tank and the

collectors which are mounted together on a frame. The units work on the thermosyphon

principal whereby the temperature differential between the top and bottom of the system

creates water circulation thus facilitating the heating process. A schematic layout of the

circulation arrangement is shown below:-

Priming Cock

Hot Water Out

Pressure Release Valve

Drain Plug

¾” Ball Valve

Cold Water In

¾” Non return Valve

Model

Typical Household (People)

UFS 150D UFS 200D

5 7 10

150 200 300

System Tank Size (Litres)

UFS 300D

Flat Plate Collectors

Max Heat Output/Day (kWhrs)

Collector Fluid Capacity (litres)

Min Heat Output/Day (kWhrs)

Collector Weight (kgs)

2

Collector (m )

2000

2 2.4 4

65 75 105

215 275 405

11 14.3 22.3

1000

2600

1400 2100

1170 1480 2300

32 38 64

12 15 24

7.4 9.6 14.9

A

B

C

D

E

Full Weight (kgs)

Empty Weight (kgs)

Dimensions(mm)

F

1xFCP2.0 1xFCP2.4 2xFCP2.0

520

620

3

Open-Loop (Direct) Systems

I n s u l a t e d

copper pipe

Plug

Solar CollectorSolar Collector

Security

Valve

8 Bars Hot

Water

Outlet

Open - Loop Enameled Storage Tank

One-way

Valve

Nipple

Filter

Cold Water Inlet T Nipple

SPECIFICATIONS

4

NOTE

Maximum heating output is based on average

2

irradiation levels of 6000W/m /day prevailing in

September- March and minimum Heating output is

2

basedon average irradiation levels of 4000W/m /day

prevailing in June/July and are for indicative purposes

only.

A

DE

B

3. WARNING AND SYMBOLS

The installation of the solar system must be in accordance with

the relevant requirements of the local authority building

regulations as well as regulations for the prevention of

accidents when carrying out works such as solar installation. It

is necessary to do so in a safe and professional manner, taking

due care of any aspects of the works that could result in injuries

to the person, buildings as well as general public.

Work should be preceded by a risk assessment covering all

aspects of health and safety risks, or training requirements

that are reasonably foreseen.

These instructions describe mounting and installation of

thermosiphon solar water heaters. All installations must be

done by qualified people.

Installers must adhere to the valid work protection regulations,

in particular when working on the roof. Anti-fall protection

must be employed whenever there is a risk of falling.

To avoid the risk of being burned or scalded by hot

components, Installation and replacement of collectors or

parts should be done on cloudy days. Installation work on

sunny days should be carried out only in the morning or

evening or with the collector covered.

To avoid the risk of being burned or scalded by hot solar fluid

or components, fill and flush the solar system when the

collectors are cold. The collectors should be covered while

doing so.

5

Steam can escape from the expansion relief valve of the solar

pump unit if the system is shut down. To avoid injuries an

expansion relief valve must be connected to a collecting

container with a hose line

In order to ensure a seamless operation of the product, the

safety valve should be cleaned periodically and checked for

proper functions. In areas with very calcareous water the calk

residuals on the valve should frequently be cleaned off.

The product shall be installed in an area where children cannot

access.

Immersion heater is intended as standby device for water

heating and should not be used simultaneously.

In areas with hard water hot water temperature should not

0

exceed 45 C to avoid calcification.

This product is designed for water heating purposes using

solar energy and it may not be changed or modified in any

way. It should be installed by a qualified person, who should

observe the applicable local regulations and the building

code.

4. SITING

Correct siting is critical for the effective operating of a solar water heater, the following

being important guidelines:-

• Orientate the principal axis of the units in a North/South direction, with the collector

facing the equator. This orientation is important to maximise sun exposure on the

collector as it tracks on its East /West axis throughout the day.

0

• Tilt at approx 15 . In order to optimise irradiation and also assist in the thermosyphon

process. Heater units should never be laid flat.

• Avoid any shade, especially between 10am and 4pm. Shade reduces system

efficiency.

Preferably, solar panels should be installed on roofs where solar irradiation is highest and

they are also less exposed to damage. If this is not possible, a protected ground sitting is

acceptable.

NORTH

EASTWEST

SOUTH

Hot Water OutCold

Water In

NORTH

EAST

WEST

SOUTH

Hot Water Out Cold

Water In

ORIENTATION OF SYSTEM

NORTH OF THE EQUATOR

ORIENTATION OF SYSTEM

SOUTH OF THE EQUATOR

5. INSTALLATION

Ultrasun UFS solar heaters are provided with drilled frames incorporating a support cross

bar. On roofs the preferable mounting arrangement is by means of hooks affixed to the

cross bar and secured to an appropriate mounting point on the roof beams. Suspension

from the hooks is generally sufficient and fixed location is not necessary.

For ground installation rear support legs are available which should be mounted on small

concrete feet as shown below:-

ROOF INSTALLATION

TRUSS

GROUND INSTALLATION

6

Two types of installations are available: A pitched roof installation and a flat roof

installation. The pitch roof bracket is provided for all installations while a flat roof

conversion kit is available to convert the pitched roof bracket into a stand.

Approximate weights for systems should be taken into account to ensure that roof structure

is able to bear the weight before the installation commences. The longitudinal beams

should coincide with the rafters of the roof where the structure is most rigid.

7

The units can be installed using a gravity system or pressurised supply. Pressurised systems

are preferable as they give higher line pressures up to a maximum of 3 Bar. Note that in the

case of pressurised supply hot and cold lines must be pressurised at the same pressure to

ensure even temperature control. The systems are easy to plumb being provided with two

piping connections only, the inlet and outlet. It is important to fit a non-return valve and

isolating valve on the inlet line. Suggested installation layout arrangements are shown

below:-

Cold In

Cold

Water

Supply

Hot

Water

Supply

Cold In

Cold

Water

Supply

Cold

Water

Supply

Hot

Water

Supply

Cold

In

Cold In

PUMPED SUPPLY

FROM TANK

DIRECT PUMPED SUPPLY

WITH COLD WATER STANDBY

HEADER TANK

GRAVITY SUPPLY

Hot

Water

Supply

All units are fitted with 3kW electric booster heaters which should be connected to the

mains supply via 20A fuse or MCB by a qualified electrician. Manual control is suggested

with the switch mounted in a convenient place.

3Bar solar pressure relief valve must be installed on the primary circuit (between heat

exchanger of the tank and collector) to avoid challenges with over pressure and over

temperature.

Oxidation may be seen on the galvanised parts of mounting sets if installation is very close

to the sea or humid areas.

l Open the 3 Bar relief valve on the tank.

l Unplug the endcap on the side of solar collector.

l Connect the filling hose to the bottom right of the collector.

l Raise hose above the tank and fill tank with fluid

l Close the top left collector plug when thermal fluid starts to leak out.

l Continue filling the thermal fluid until it leaks out of the 3 Bar relief valve which is an

indication it is full

l Unplug the filling hose and close the bottom right of collector.

The various installations are shown below:

Single Panel Installation

Flat roof Installation Pitch Installation

8

Pitch Roof Bracket Assembly

Step 1

Fit the top part of the solar tank bracket to channel 3 using M8 x 25 screws as shown.

9

Step 2

Select the holes in the angled section that are required for the specific installation. It is

suggested that the holes be marked according to the specific type of installation required.

Two types of angled sections are provided, a set for a single panel installation and a set for

a double panel installation. The holes required for each type of installation are shown

below:

Single Panel Angled Section

150 litres 200 litres

200 litres 150 litres

Double Panel Angled Section

300 Litres

200 Litres

300 Litres

200 Litres

Step 3

After selecting which angled section to use and which holes to mount it with, in order to fit

the required system, the top angled section can be fitted to both solar tank brackets using

M8 x 25 screws as shown below:

10

Step 4

Select which slotted holes the bottom angled section should be bolted onto. The selection

should be based on the size of the solar collectors supplied. Two sizes are available:

Ÿ2.0m² - Approximately 2000 mm in length

Ÿ2.4m² - Approximately 2000 mm in length

The correct slotted holes on longitudinal channel are indicated below:

Step 5

Fit the second appropriate angled section to the bottom of the channel on both sides as

shown below:

2

2.0m Panel 2

2.4m Panel

11

Step 6

Remove the tank feet supplied as shown below:

Step 7

Fit the tank to the completed bracket frame as shown below on both sides. This step is to

confirm that the two longitudinal channel beams are appropriately spaced to

accommodate the tank.

12

Step 8

Fit the collectors to the bracket by placing them between the angled sections as shown

below. Adjust the bottom angled section position by means of the slotted holes in order to

fit the panel/s closely. Fasten the panels through the 6mm holes by means of the M5 x 16

self drilling screws.

Step 9

Remove the collectors for installation to the roof. The completed frame should be fastened

to the roof as appropriate.

Tin Roofs

It is suggested to fasten the assembly through the longitudinal channel by means of an

appropriate fastener by earthing the roof and sealing the entry point.

Tiled Roofs

Six metals strips are supplied and can be fastened by all M8 x 25 screws as shown below:

The strips can be used to fit the system to the battens of the roof to provide additional

support. Please note that longitudinal channel should coincide with or be as closely

located to the rafters of the roof structure as possible. The strip fastening method is

depicted below in section view. Use all six fastening points to support the structure.

13

After the bracket system is securely fastened to the roof, the tank can be re-fitted. Use the

straight compression couplers to connect collectors in parallel for double panel systems

and re-fit the collectors between the angled sections and fasten with screws.

Step 10

Connect piping as shown on Fig 1. Use appropriate roof seals supplied to seal off any

pipe entry points into the roof.

Step 11

Apply pipe insulation to all exposed pipes.

14

Flat Roof Conversion

Fig 1

Assemble the structure as described for pitched roof installations up to step 5. Do not

tighten all screws initially in order to attain proper alignment of the entire structure before

final tightening.

300L HOT

WATER CYLINDER

150 OR 200L

HOT WATER

CYLINDER

Hot Water

Outlet

Vacuum

Breakers

T&P Safety

Valve

Hot Water

From

Panel

Anti-siphon Loop

T&P Safety

Outlet (Metallic)

300mm

Cold Water

From Cylinder

1978

Pressure Control Valve

Stopcock

Mains Pressure

2100

1000/1400

Single Panel Double Panel

Electrical Cover

Solar

Draincock

A

15

Step 12

Turn the structure upside down and fasten channel 2 to the top part of channel 3 using M8

x 65 screws and long spacer tubes as shown below on both sides:

Step 13

Fit the two longitudinal channels using M8 x 65 screws and long spacer tubes on both

sides as shown below:

Step 14

Fit channel 4 to channel 3 using M8 x 65 screws and long spacer tubes on both sides as

shown below:

16

Step 15

Mount channels 1, 2 and 4 together using M8 x 65 screws and long spacer tube on both

sides as shown below:

Step 16

Two types of braces are included in the kit. Short braces are used for 150 and 200 litre

installations and long braces for 300 litre installations. It should be decided at this stage of

the assembly which braces and which mounting holes should be used. This dictates the

distance between the two trusses and which hot water system will fit. It is suggested that the

braces and fitment holes be marked for the specific installation required.

The various layouts for the different braces are shown below:

150 Litre

Tank

200 Litre Tank

300 Litre Tank

Step 17

Fit the brace ends using M8 x 25 screws on both sides as shown below:

Step 18

Fasten the braces' centre holes using M8 x 25 screws and short spacer tube as shown

below:

17

This manual suits for next models

3

Popular Water Heater manuals by other brands

DeDietrich

DeDietrich Kaliko TWH 300EH Installation and service manual

STIEBEL ELTRON

STIEBEL ELTRON SBS 800 W Operation and installation

STIEBEL ELTRON

STIEBEL ELTRON CF 12 KW Operation and installation

ATL

ATL SWH 15H M5 instruction manual

Ariston

Ariston ABSE VLS PRO PW 100 quick start

Galmet

Galmet SGW(S) Maxi 250 Installation and operating manual

State Water Heaters

State Water Heaters SUF-100-250 instruction manual

Celsior

Celsior 35 BF Installation and operating instructions

Pitco

Pitco L22-303 Service manual

Ariston Thermo

Ariston Thermo SGA X 120 EE Installation and maintenance instructions

Bosch

Bosch GWH 2400 ES NG manual

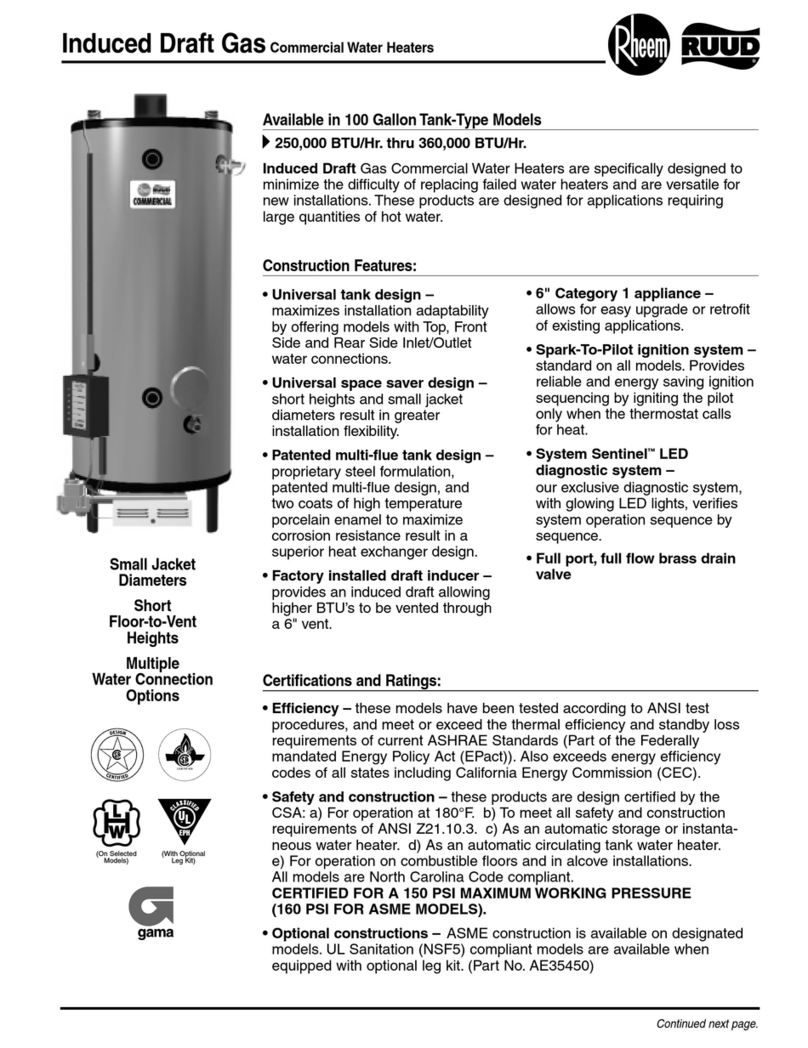

Rheem

Rheem Induced Draft Specifications