Daystrom HEATHKIT HP-20 Installation instructions

Assem bly

and

Operation

of the

UTILITY

POWER

SUPPLY

MODEL HP-?O

-

HEA-- CCMPANY,

i d ^- : . .

lr^

I EIAY

IrJ STROM

IIEATIrKTT"

fl-ir-..-:

I DAYSTROM, : \coRpoRArEo

Lfl 12/7 /62

TABLE OF CONTENTS

Specifications. .

Introduction... .....

Theory of Operation. . . .

Construction Notes.

Parts List. .

Proper Soldering Techniques

Step-By-Step Proeedure.

Step-By-Step Assembly. . .

Testing The HP-20 power Supply.

Operation.

In Case Of Difficulty. . .

Service Information. . . .

Service.

Replacements.

Shipping Instructions. . . .

Warranty.

Schematic.

tFold-out from this page.

2

2

3

3

4

6

B

I

15

t7

77

1B

1B

19

19

20

7,N

A11 prices are subject to change without notice. The Heath

company reserves the right to discontinue instruments and

to_change specifications at any time without incuming any

obligation_to incorporate new ieafures in instrum""i"!""-

viously sold.

Copyrisht 1960

Heoth Compony

Page 2

SPECIFICATIONS

Power Requirements:. .

Overall Height:.

Total Continuous DC OutPut

Filament Power:.

Regulation (5070 load to 10070 load, from

hieh voltagetap):.....

Net Weight:. . .

Shipping Weight:.

11? volts AC, 50/60 cycles, 200 watts.

9" long, 4-3f 4" wide, 2-lf 4" high,

6" (with cover and four rubber feet).

1. 120 watts - 600 volts at 200 milliamperes

- or-

120 watts - 600 volts at 150 milliamperes

and 300 volts at 100 milliamPeres.

2. Bias - 130 volts at 30 milliamperes.

(Available in addition to above.)

6. 3 volts at 11 amperes, or

12. 6 volts at 5.5 amperes.

Approximately L0%.

12 lbs.

15 Ibs.

INTRODUCTION

The HEATHKIT Model HP-20 Utility Power

Supply was designed primarily to furnish all the

necessary power for HEATHKIT Mobile Trans-

mitters and Receivers, when they are used as

fixed station units.

Being a utility power supply allows it tobe used

to supply power to many other makes and types

of amateur equipment as well.

The Model HP-20 will supply a full 120 watts

of power, 600 volts at 200 milliamperes. A half

voltage tap (300 volts) is available for supply-

ing the receiver, or low leve1 stages of the

transmitter. In addition, 130 volts of negative

bias is available at a current rating (30 ma)

consistent with voltage regulator service. This

feafure allows use of the HP-20 Ydth SSB

equipment requiring regulated bias voltage.

The loads on the high and low voltage termi-

nals of the supply should be adjusted so that

the total power drain will not exceed 120

watts. A typical example would be a drain of

600 volts at 150 milliamperes from the high

voltage tap, which equals 90 watts. This would

leave 30 watts available at the low voltage tap,

or 300 volts at 100 miiliamperes. The total of

the two will equal the 120 watt rating of the

supply.

In event of a comptete short circuit in any of

the secondary circuits of the suppiy, two fuses

of the proper current rating afford adequate

proteetion.

The supply features excellent static regulation,

combined with the advantages of good dynamic

regulation, achieved through the use of high

value filter capacitors.

A full-wave voltage doubler circuit affordsgood

efficiency along with circuit economy. The

resultant ripple frequency is twice the source

frequency and, therefore, is easi.er to filter. A

further advantage is that each capacitor in the

doubler circuit requires a DC rating of only

half the output voltage, since the capacitors are

in series.

r^

DAYSTROM

rJ

IIEATI{ITIT'

i

|r^

I E,AYST

IrJ ROM

EEATEIKIT'

VAC

VAC RMS

voc

FREOUENCY

-l 30 E

FREOUENCY

OPERATION

the output voltage is concerned.

Page 3

600

6.3

12.6

THEORY OF

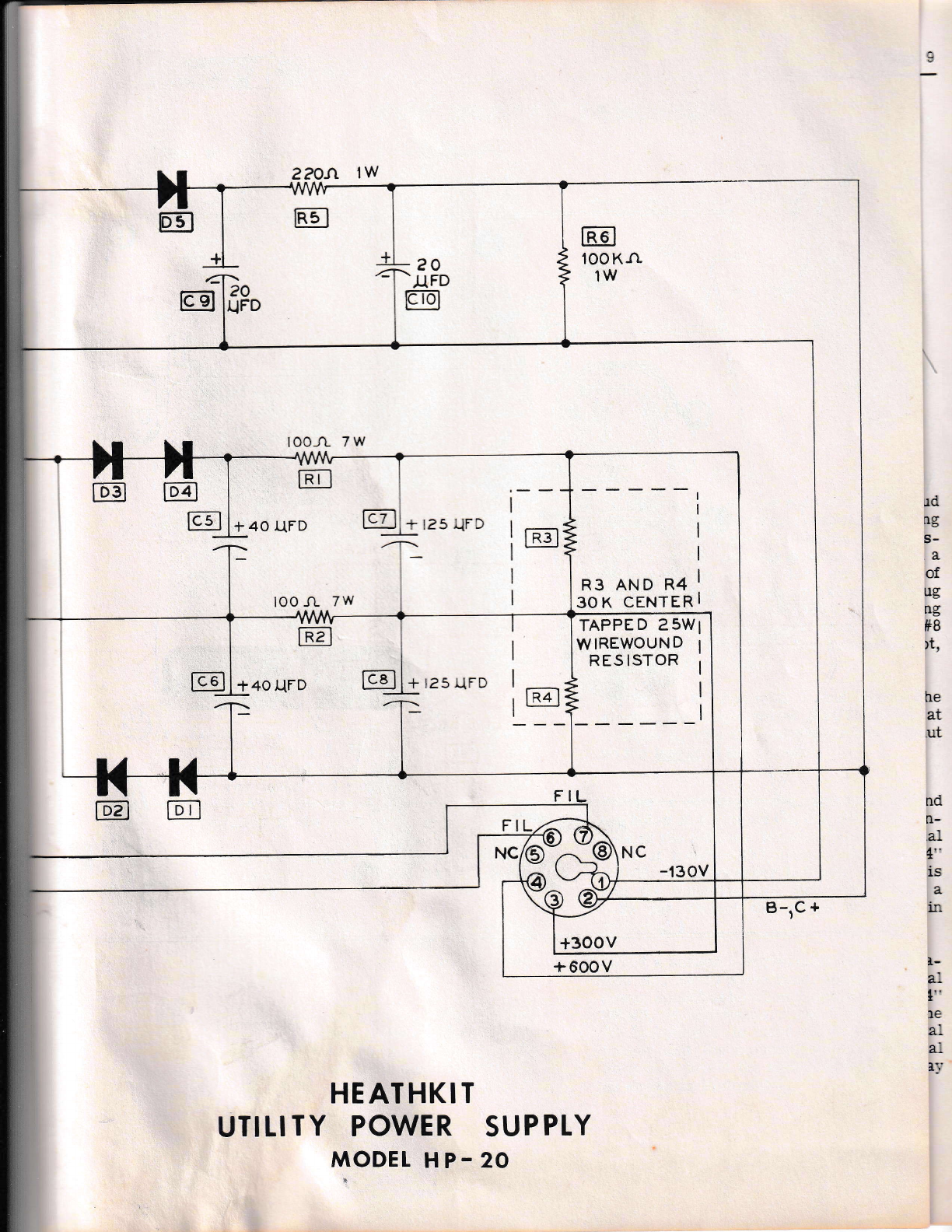

The conventional voltag+-doubler circuit used in

this power supply ha.s been chosen because of

its efficiency, economy and circuit simplicity.

A voltage-doubler circuit wiII deliver a DC

output voltage approximately twice the rms

value of the secondary winding of the trans_

former. Under very high current drains, the

output voltage may be slightly under twice the

secondary voltage.

In operation, the filter capacitors Cb and C6

are each chargedto thepeak voltage of the trans-

former secondary on alternate traf cycles, but

with polarities such that the DC voliages de_

veloped across the capacitors add, in so far as

Due to the low ripple content existing in the

waveform immediately after rectification (the

ripple frequency being doubled, as well as the

voltage), a minimum of filtering is required.

This is accomplished with a simple resistance

1$ capacity network, consisting of Rl, R2,

C7, and C8. A half-wave rectifier is used in

the bias supply. The blas supply filter network

c.onsists of C9, R6, and C10 with R? serving as

the bleeder resistor.

Ia order to provide good dynamic regulation,

high value output filter capacitors are used.

CONSTRUCTION NOTES

This manual is supplied to assist you in every

rl'a:,- ro complete your kit with the teast possibll

cha-nce for error. The arrangement shown is

rhe result of extensive experimentation and

tr:al. Ii followed carefully, the result will be a

stalle instr:ument, operating at a high degree

:: :::;:.:a'bi1it"'. we suggest that you retain the

*-;--:' i- -'-.,* fil

_-- --.- _. .. _ ..: rrres for future reference, both

rr- *_r-: _s; _: :he instrument andfor its main_

--l;; -.-i: :*: ::T C.Tfi.EFULLY AND CHECK

:.:-_i-: :-r:.: .. ^..:.-,il THE PARTS LIST. Lr so

: :..: .: :;:ai.nted with the parts.

Refer to the charts and other information on the

inslde covers of the manual to help you identify

the components. If some shortage or parts

damage is found in checking the parts List,

please read the REPLACEMENT section and

supply'the inJormation called for therein. Include

all inspection slips in your Ietter to us.

R-esistors generally have a tolerance rating of

10/6 unless otherrvise stated in the parts List.

Tolerances on capacitors are generally even

greater. Limits of +tO1Vo and -2070 are common

for electrolytic capacitors.

L JNE

F IL TER STEP-UP

TRANSFORMER VOLTAGE-DOUBLER

RECTIFIER RESISTANCE

CAPACITANCE

FILTER

HALF- WAVE

RECTIFIER RESISTANCE

CAPACITANCE

FILTER

117 VAC

RV5 6C-,

Il

t-

Page 4

We suggest that you do thefollowingbefore work

is started:

1. Lay out all parts so that they are readily

available.

2. Provide yourself with good quality tools.

Basic tool requirements consistof ascrew-

driver with a t/4" blade; a small screw-

driver with a 1/8" blade; Iong-nose ptiers;

wire cutters, preferably separate diagonal

cutters; a penlmife or a tool for stripping

insulation from wires; a soldering iron (or

gun) and rosin core solder. A set of nut

drivers and a nut starter, while not neces-

sary, will aid extensively in construction

of the kit.

Most kit hrilders find it helpful to separate the

various parts into convenient categories. Muffin

tins or molded egg cartons make convenient

trays for small parts. Resistors and capac-

itors may be placed with their iead ends in-

serted in the edge of a piece of corrugated

PARTS

cardboard until they are needed. Values

be written on the cardboard next to each

component.

IMPORTANT NOTE: The #57-20 silicon diodes

supplied in this kit will meet all circuit re-

quirements, but may appear different than shown

in the parts pictorial and other sections of the

manual. The accompanying illustration shows

some of the silicon diode types that may be

supplied.

ANODE ENDS

, NE6ATLVE (-)

CATHODE ENI

POSiTIVE +)

PART

No. PARTS

Per Kit DESCRIPTION

220Alwattresistor

(red-red-brown)

100 KC} 1 watt resistor

(brown-black-ye11ow)

100O7wattwire-wound

1070 resistor

30 KO 25 watt wire-wound

center tapped resistor

.001 prfd GMV 1400 V disc

ceramic capacitor

125 p,fd 450 V twist prong

electrolytic capacitor

40 pfd 450 V electrolytic

hrbular capacitor

20+20 ptfd 150 volt capacitor

1-lug terminal strip

Z-Lug terminal strip

4-lug terminal strip

5-Iug terminal strip

3-lug terminal strip

3-1ug terminal strip, #B foot

Octal socket

L IST

PART

No.

346- 1

346-10

347-18 1

Metal Parts

200-M279F396

204-M198

205-M168F

Hardware

250-B 8

250-18

2 50- 56

250-89

250- 12 3

252-3

252-4

252-30

PARTS DESCRIPTION

Per Kit

Resistors-Capacitors

1A-19

1A-28

3G-9

3Y-3

2L-71

25-34

25-36

25-80

1

1

2

1

4

2

2

1

Plus-socket-Terminal Strips (Cont' d.)

438-11 1 Plug, AC fused

438-22 1 Octal plug

Wire-Cord-Sleevinq

ffiinecord

344-1 4 Length hookuP wire

Choke - Switch- T ransf ormer

45-L7 2 Line choke

54-109 1 Power transformer

61-1 1 SPST toggle switch

Plug- Socket- Ae t rI!44 J!!4_q

1

2

1

1

1

7

6

4

1

(1 each-black, orange,

yellow, red)

Length insulated sleeving

Length 3/8" fiber glass

sleeving

Length 8-conductor cable

C-:assis

[lounting bracket

Bottom plate

#6 x 3/8" BH sheet metal

screw

8-32 x 3,/8" RHMS

6-32 x 1/4" BHMS

6-32 x 3/8" BHMS

10-24 x 2-l/4" slotted hex

head screw

6-32 x 1,/4" nut

8-32x3 B"nut

10-2i :ex nut

431-1

431-2

431- 5

431-1 1

43t-27

431-33

434-39

1

1

3

2

1

1

1

10

11

1

I

IIEATIII(rT'

-

-

I

,I

Ir^

I EIAY

ltJ STROM

ETAIIIIilT'

2)3-7 I

.,1=4,_/., ?

254-1 10

254-2 11

255-41 4

90- 10 1

261-6

391- 7

472-10

421-2

440-l

481-3

Miscellaneous

=10 fiber shoulder washer

t/2" x 3/16" flat rvasher

=6 I:.cr'.','asher

:6 iC,:..'.','a She r

Sj.licor recr,ifier (500 ma)

3/8" rui:oei {ronlmet

i / 16" rui,.'rel grommet

.:-R,T PARTS DESCRIPTION

I'r Per Kit

H=r'dware (Cont'd. )

PART PARTS DESCRIPTION

N!. Per Kit

Miscellaneous (Cont' d. )

Page 5

Cabinet cover

Rubber feet

Nameplate

Neon pilot light

3 amp fuse

Octal plug cap

Capacitor mounting wafer

(fiber)

Solder

Manual

1/4'' SPACER

#255-41

3/16" x 5/16"

RUBBER GFOMMET

s 13-4

1

4

1

1

2

1

2

57-20

?3- 1

73-4 1

5

1

1336- 1

595-363

o

6-32 NUT 8-32 NUT

#252 4

r - :, .i ::::: j10-24 NUT

#252-30

DUAL 20 pFD 150V

ELECTROLYTIC CAPACITOR

#25_80

OCTAL SOCKET

!434-39

r

F=+250-E!

fhss!

" 8-32 x 3 /8" RH-\IS

#250-18

$$sssn$ss$$sfifi$$ r

10-21 x 2 1/4"

SLOTTI]D HEX

HEAD SCREW

*250-723

@@

#10 FIBER

-

1 "2 s : -: .: :ri;:l ffi

iFs* #6 x 3/B, BH

SHEET MET,{I SCRE\I'

#250 B

lOOO?WATTRESISTOR

#3G-9

OCTAL PLUG CAP

4440-7

--t-r-_ ;-'- a

--: =l=01:nl

. '!. t.-i.l,ti

3/8" x9/32,'

RUBBER GROMMET

001 lLfd

DISC 1400 voLT

CERAMIC

CAPACITOR

40 -::-: -

... H

\*r-f-''--. i,-, -l.:::-alaIEF

--r:-:

12r -id{50 VOLT

Eii.TFO LYTIC CAPACITOR

-25 34

@

:1.,:=:-' a,: - -

ffi

] :::;:I]

G L-r. S: : - : a 1,-I\ G

'311-:0 1-LUC

TERMINAL STRIP 3-LUG

TERMINAL STRIP

#431-27

d!H!}

L,

r ILG

:J]:];.\I STRIP

'-M 11

4-LLG

?ERM1NAL STPIP

*431 t3_LUG

TERMINAL STRIP

#B Foot #431-33

2 LUG

TERMiNAI STRIP

4131-2

o

l,-rT i-:---, l,:il.

(-, =)

L^l

U

ROM

trA

I oAYST

ltJ

ITEATIIKTT'

PROPER SOLDERING

OnIv a small percentage of HEATHKIT e$rip- 3'

;;tit;;ffi;s'ers find it necessarv to return an

i;;i;"il;;a for factorv service' of-these instru-

'#i"ltE,' uv ; ^i- tr, " r i" ri e s t p o r t i on-o-t m alf uncti on s

are due io poor or improper soldermg'

If terminals are brightandcleanandfree of wax'

f";;;a insulation *a ott'u' foreign substances'

""'oiiii""itv will be experienced in soldering'

Correctly solderecl connections are essential if 4'

the performance engineered ilto .a kit is to be

irirv--*"tiir"a. If you are .a .le,sinner with no

"ruLri"""" in solaering, a haU hour's practice

*iif, "o*" odd lengths of wire may be a worth-

while investment.

For most wiring, a 30 to 100 watt iron or its

"q,ri"-"i&t in a so*idering gun is very satisfactory'

A'1o**" wattage iron than this may not heat the

"t""u"tio" eno'ugh to flow the solder smoothly

or.* tfr" joint. Keep the iron tip clean and bright

tr- *ipi"! it from time to time with a cloth' 5'

Page 6

CIIASSIS WIRING AND SOLDERIhG

1

2.

TECHNIQUES

Leads on resistors, capacitors- a,nd similar

components are gene"afly much longerthan

il;y ;;;A to be "to mat<e the required con-

,r""lio"t. In these cases, theleadsshouldbe

ffi;;fier length before thepartis added

io -ttt" "fr""sis. t: general' the.leads -:,l?y]d

te lust long enough to reach their termrn-

ating points.

Wherever ttrere is apossibility r:f 'bar* teads

;h;"ti"g to other p*its o: ':r:rthe*ha*sis'the

i;;;t lhould be eove;eil x'rt!:: irrsulating

"i""ti"s. where the use oi sieeviug- is spe-

Iiircriiv'i"tended, the phrase "use sleeviRg"

i" it"i,ia"a in the asiociated construetion

step. Il:I any case where there is the pos-

tiuiirtv oi "r" unintentional short circuit'

;i;;;ils strouto be used. Extra sleeving is

provided for this Purpose'

Crimp or bend the lead (or leads) aroundthe

t-e*minri to form a good ioint without re-

iil;-;; solder for phvsical strength' If

iiJ'"*ir- it too iarge to allow lrending or if

;il; ;i;p siates trrat ttre wire is not to be

;;i*p-e, position the wire so that a good

t"iau" connection can still be made"

Unless otherwise indicated, all. wire used

;'th" type with colored insulation (hookup

;J, ttre size of the conductor is thesame

i;; ;n ;;;; of hookuP wires furnished with

it i" Lit. Inpreparing a Iength of hookup wire'

I /i" of insutation should be remcved from

"'""r, "rri ""Iess directed otherwise in the

construction steP.

To avoid breaking internal connect'ions when

"iripptns insulati-on frorn the leads of trans-

;;;;;#"r similar components,. ga1e should

;;iai<;; not to pu1l directlv on the igld' h-

"i""d,-iirfO the lead with pliers while it is

being striPPed.

6. Position the work, if possible, 3o that gravity

*iir r,.rp to keep ihe-solder where yor: want

it.

Place a flat side of the solciering iron tip

**ri".i *,. joint to be soldered until it is

;:;;- suttrcienttY to melt the solder'

Then place the solder against the heated

i""*i"tf and it rrill immediately flow over

7

iI

B"

ll\

I oAYSTR

IrJ OM

EEATHITIT'

IRemove the sold:r -i ihen the iron from

the completed j'.rr.c::-:. Use care notto move

the leads unril ::r s - iler is solidiJied,

CRIMP WIRES HEAT CO\}'ECTIO\ APPLY SOLDER

the joint; use only enough solder to thor-

oughly wet the junction. It is usually not

necessarj/ to f i11 the entire hole in the

terminal. cith solder.

COLD SOLDER JOINT

CO\f E C TIO\ INSUFFICIENT LY

HE.{TED

Page 7

A poor or cold solder joint wiII usually Iook

crystalline and have a grainy texfure, or the

solder will stand up in a blob and will not have

adhered to the joint. Such joints should be re-

heated until the soider flows smoothly over the

entire junction. In some cases, it maybeneces-

sary to add a little more solder to achieve a

smooth bright appearance.

ALLOW SOLDER

TO FLOW

PROPER SOLDER

CONNECTION COLD SOLDER JOINT

CONNECTION MOVED

WHILE COOLING

RosL\ Llar:.: :o--r:P. HAS BEEN SUPPLIED WITH THIS KIT. THIS TypE oF soLDER

\ltsf :: -,-::; FoF. .{LL SOLDERNG IN THIS KIT. ALL GUARANTEES ARE voIDED

A\D 'N'' ',i:- - \OT REP.{IR OR SER\IICE EQUIPMENT IN WHICH ACID CORE SOLDER

OR P.{S.: TI LXES HAVE BEEN USED. IF ADDITIONAL SOLDER IS NEEDED, BE SURE

TO PL?.CL:--ir RO'SINCORE (60:40 or 50:50 TIN-LEADCONTENT)RADIOTYPE SOLDER.

ri

\I

Page 8

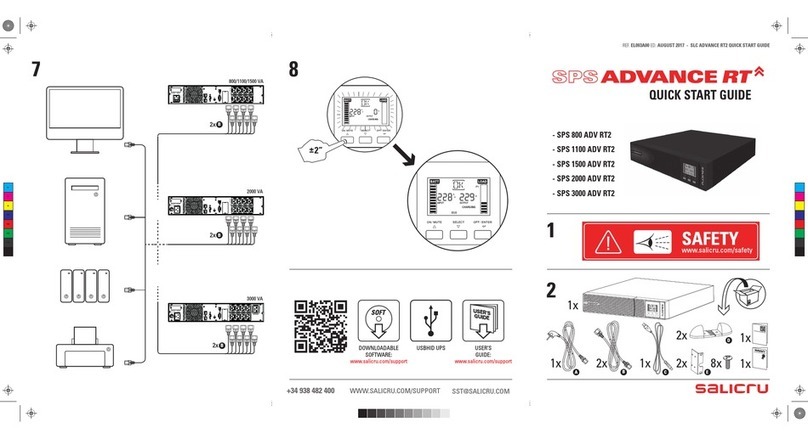

STEP-BY.STEP PROCEDURE

The following instructions are presented in a

logieal step-by-step sequence to enable you to

complete your kit with the least possible con-

fusion. Be sure to read each step all the way

through before beginning the specified operation.

Also read several steps ahead of the actualstep

being performed. This will familiarize you with

the relationship of the subsequent operations.

When the step is completed, check it off in the

space provided. This is particularly important

as it may prevent errors or omissions, espe-

cially if your work is interrupted. Some kit

builders have also found it helpful to mark each

lead in colored pencil on the Pictorial as it is

added.

The fold-out diagrams in this manual may be

removed and attached to the waII above your

working area; but, because they are an integral

part of the instructions, they should be returned

to the manual a.fter the kit is completed.

In general, the itlustrations in this manual

correspond to the actual configuration of the

kit; however, in some instances the illustra-

tions may be slightly distorted to facilitate

clearly showing all of the Parts.

The abbreviation 'tNS, indicates that a con-

nection should not be soldered yet as other

wires will be added. When the iast wire is

installed, the terminal should be soldered and

the abbreviation "S" isusedto indicate this. Note

that a number will appear after each solder

instruction. This number indicates the number of

leads that are supposed to be connected to the

terminal in point before it is soldered. For

example, if the instruction reads, "Connect a

lead to lug 1 (S-2)," it will be understood that

there wilt be two leads connectedtotheterminal

at the time it is soldered. (In cases where a lead

passes through a terminal or lug and then con-

nects to another point, it will cotmt as two leads,

one entering and. one leaving the terminal.)

The steps directing the installation of resistors

include color codes to help identify the parts.

Also, il a part is identified by a letter-number

designation on the Schematic, its designation

wiil appear inthe construction step which directs

its installation.

EEAASET

lt7 v.

50-50 \

LI

3 AMP FUSE LINE CHOKE BLACK

PI LOT

LICHT

.oot .ool UFD

.oot UFD .00t urD

3 AMP FUSE LINE CHOKE L|NE SwtTCH BLACK

L2 S1

BROWN

BROWN

RED

'i--:,t-3-rE

EEN

t2.6V.-4 A.

JUMPER

6 3V-

JUve6P

lA

I o:,-EA I

ll r/PFg

25a =t,,S 5 A-

a3"-4A

E

E

I

lI

cro

E

E

?o

@UFD

?o

,TIFD

D3 D4

C7 + 125 LlFD

+ 40 UFD

loo J1 7w

roo_n- 7 w

+600v

+300v

EE

100KJt

1w

R3 AND R4

30K CENTER

TAPPED 25W

W IREWOUN D

RES ISTOR

c6

R2

DI

+ l2s UFD

+40 UFD

NC -'130v

F

E

z?On lw

HEATHKTT

UTILITY POWER SUPPTY

MODET HP.20

he

at

ut

ud

NG

s-

a

of

ug

ng

#B

)t,

nd

n-

dL

4"

is

,

ix

I.

dL

1"

1e

ar

tr:,'

B-rc +

E

EE

-T.

@@

@

@

ffi

o

@

@

A,)

w

KEYWAY

Pictorial 1

L

BLACK

Figure 2

,!

-4

BLUE

YELLOW

BLUE-YELLOW

YELLOW-GREEN

BROWN

@

6

t8-3? NUT (4)

+e locxwasHen (a)

{sro.rn 1o;

e

e

L

: - i'

o

,s

a.

MOUNTING

FOOT

sJ) \\

0

@

o

I

Figure 3

lr\

I DAYST

ltJ FIOMEEATHITIT' Page 9

Ref er to Figure 1 f or the f ollowing step.

( ) Insert the r'*'o sruds of the namepiate in

the two hoies in the chassis f ace side,

orierrting as shosr. \\hile holdingthe name-

plate tight to the :l-.assis, melt the studs

do*n with a hot s:-i:::::E i.ron r.rntil a smali

fiat retaininq 'ceai :s :::=ed.

STEP.BY.STEP ASSEMBLY

o

Refe

(r4 r to Pictorial 1 :,:r :he i--li:*ing steps.

Mount a 4-Iug re:'r::-a- sr:i: a: -_caricn CC.

Orient the termi::ai sir:: as s::atl. Use a

6-32 x 1/4" Brnder Hra;. ]Ia::i:re Screw

(BHMS) through the c:assis. r:rE n:.c.-:rting

foot of the terminal. sir::. a =6 l:lk-r,asher

and secure with a 6-32 n;i.

e

NOTE: The plastic nut holder sill be found

convenient in the mounting of these con:ptnenrs.

(:i ) Mount a 4-Iug terminal strip at locatic::.DD

and a 2-1ug terminal strip at locatr:n EE

(on the same screw). Face the ter::inal

strips as shorm in Pictorial 1 anri F:.i.r.:.re

6. Use a 6-32 x L/4,, BHMrS thrc'qh -Jre

chassis, the two mounting feet. a 16 -;ck-

washer, and secure with a 6-32 nut.

{1Mount a third 4-1ug terminal strip ar -:-

cation LL, as shown. Use a 6-32 x I .i"

BHMS, #6 lockwasher and 6-32 nut.

\/) Locate the powertransformer (r54-109) a:r:

refer to Figure 2. Measuring straight out

from the transformer bottom shell. cut the

two red leads and one of the brosrr leads

to A-Lf 4". Trim approximately b,, 16" of the

insulation off the ends.

NOTE: In the following steps, when instructions

are given to strip the ends, strip b/16" of in-

sulat/bn in each case.

( fI Cut one black lead to 3" in length and the

other to 2-L/2" i:r length. Strip the ends,

Save the two pieces of excess wire as they

will be used later.

Figure 1

( ,) T1. Slip a L/4,, spacer onto each 8-'32 stud

and seat the transformer into its mounting

position. See Figure 3. Secure the trans-

former on the chassis bottom side with a

#8 lockwasher and an B-32 nut on each of

the three sfuds, as shown. Mount a 3-tug

terminal strip at QQ (has an 8-32 mounting

foot) on the transformer stud, Use a #B

lockwasher first, then the mounting foot,

and the 8-32 nut last.

( ) 51. Refer to Pictorial 1 and mount the

single-pole single-throw (SPST) switch at

location A, with the lockwasher and one nut

on ttte inside of the chassis.

( ) Scrape or sandpaper any paint from around

the holes at locations GG and IIH on the in-

side of the ehassis. Mount a b-tug terminal

strip at location GG, using a B-52 xL/4,,

BHMS, #6 lockwasher between the chassis

and the mounting foot, and secure with a

6-32 nut. Orient the strips as shown in

Pictorial 1.

( ' .'I'Mount a seeond 5-Iugterminal strip at loba-

tion HH. At the same time, mount the octal

power socket at location P'using 6-82xL/4,,

BHMS, #6 lockwashers and 6-82 nuts, The

#6 lockwasher is used between the octal

socket and the mounting foot of terminal

strip HH. Orient the socket with the keyway

as shown in Pictorial 1.

Cut each of the remaining five colored

leads (blue, brown, yellow, blue-ye11ow,

and ye1Iow-green) to Z-g/4,, in lgngth.

Strip the ends. Save these piecesof wirefor

use later.

({

Page 10

a-szrf'nr.rus (s)

q..

G.

lr3

2"t6 FLAT WASHER (3)

,8 LOCKWASHER (3)

NUr (3)

#6 LOCKWASHER (4)

NUr (4)

igure 4

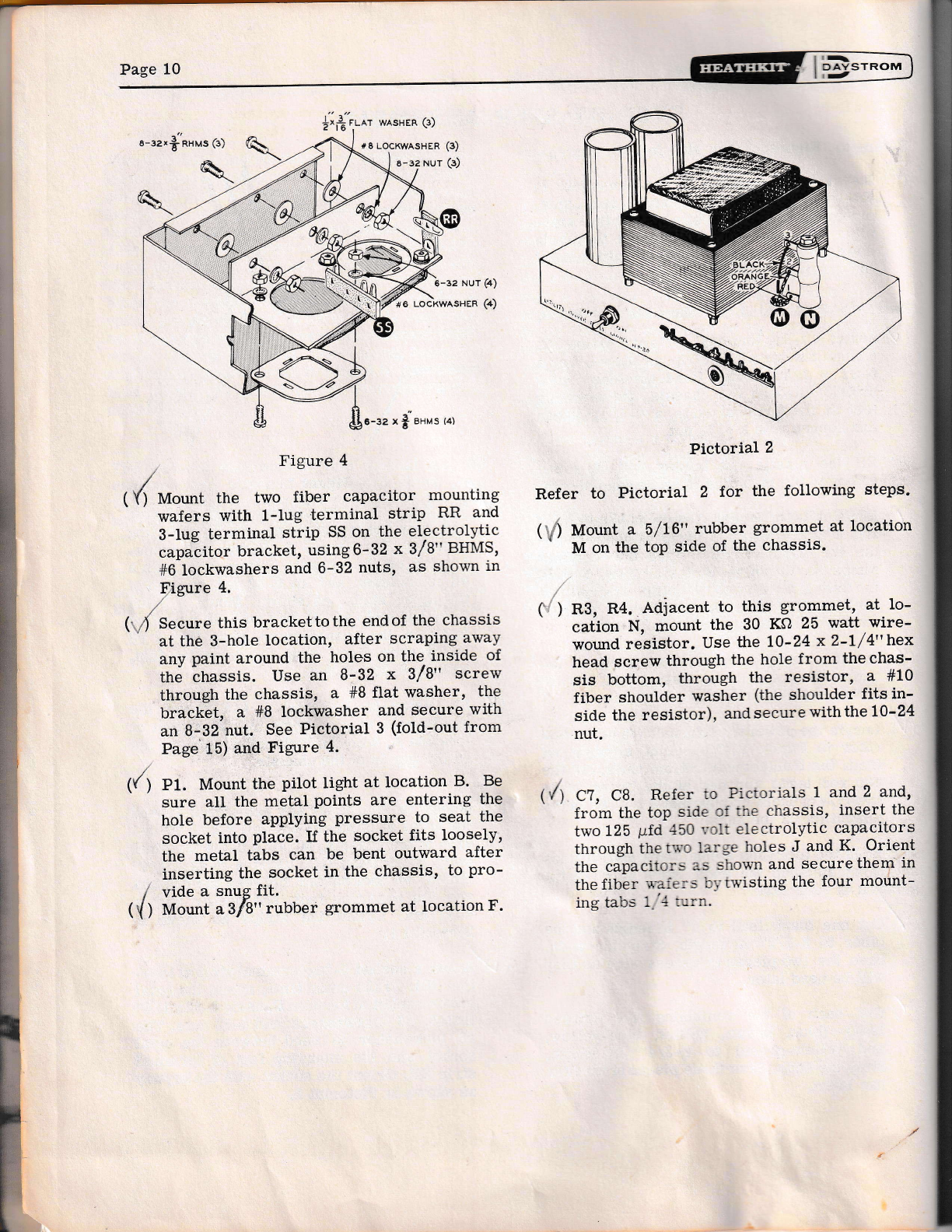

( () Mount tire two fiber capacitor mounting

wafers with 1-Iug terminal strip RR and

3-Iug terminal strip SS on the electrolytic

capa;itor bracket, using6-32 x 3/8" BHMS,

#6 lockwashers and 6-32 nuts, as shown in

Figure 4.

(.-4 Secure this brackettothe endof the chassis

at the 3-hole location, after scraping away

any paint around the holes on the inside of

the chassis. Use an B-32 x 3/8" screw

through the chassis, a #B flat washer, the

bracket, a #B lockwasher and secure with

an B-32 nut. See Pictorial 3 (fold-out from

Page'15) and Figure 4.

-.. r $'u.,u. ,ot

({) Pl. Mount the pilot light at location B. Be

sure aII the metal points are entering the

hole before applying pressure to seat the

socket into place. If the socket fits loosely,

the metal tabs can be bent outward after

inserting the socket in the chassis, to pro-

, vide a snug fit.

( { ) n{ount asf9" rubber grommet at location F.

Pictorial 2

Refer to Pictorial 2 for the following steps.

( ; ) Mount a 5f L6" rubber grommet at location

' M on the toP side of the chassis.

rl

(

R3, R4. Adiacent to this grommet, at 1o-

cation N, mount the 30 KO 25 watt wire-

wound resistor. Use the tO-24 xZ-lf 4"trex

head screw through the hole from the chas-

sis bottom, through the resistor, a #LO

fiber shoulder washer (the shoulder fits in-

side the resistor), and secure with the 10-24

nut.

'/1 Cl, Ca. Refer to Pictorials 1 and 2 and,

from the top side :f rhe chassis, insert the

two 125 p.fd -150 ''';1t electrolytic capacitors

through the t'i,'o large holes J and K. Orient

the capacitor> 3s shoun and securethem in

the fiber -*-aie:'5 r--'1,-trvisting the four rnount-

ing tal-.s 1.'l t;rn.

tr-

I DAYST

lt- ROM

EEATEET

I

lr=

I DAYST

ltJ ROM

Er!{TfIIilT" Page 11

i

tl

f

{l

f

];OTE: Refer to pictorial 3 (fold_out from page

1 5) for the following sreps unless otherrvise noted.

( r ) Conneet the longer black lead from the

transforn:er tl lug 2 of rhe SpST s*itch at

location A (\-S).

( .') Connect one pitcr l:;ht Iead to the sar:e lug

.2 of the SpST sr:r::. S_2 .

(/) Strip both er-:s :j -.:-: -::.:::;i:ce :: c-ack

wire u.hich a.as ,.,.=----a= _,t :h: Iralts_

former. Ccn::e:: _:. =:l:- -.. 1 :::n= SpST

switch (S-1). R:_:e -_:.= _-r... :nj C_rn

along ttre chass:s a:.1 . ::-:--::: :: :: -*: i ,:,f

terminal strip HH ,-:-S .

( ) C+. Cut both lead-c :: ..--- _:: _i_, -,,.,1t

disc ceramic capaciicl r_ j a .- ';-;th

Connect one end to 1ug i ,: :=.=^-.. .;rip

HH (NS). Connect thJct;: =-.: :: -..:* 3

of terminal strip HH (NS).

(') L2. Cut both leads of a line ct:.:. t-- t 2,,

in length. While retaining the er: :*:rs of

the coil by holding them *ttir :arr_,;._:ose

pliers, bend both ieads axia_ll,,. t: f a::.:rare

mounting, as shown in pictoi:.- 3. SLi:: a

piece of the latge 3/9,' sleer.irs :-,,=r -,*,re

choke coil. Cormect one end t: -.:: i of

terminal strip GG (NS). Comecr r.e- _:hEr

:nd to lug 4 of terminal strip HH S_ 3).

Trim off excess lead length.

( ) Connect the remaining black leac frci:: rhe

transformer to lug 2 of terminal. s::-:r HH

(NS).

(.. ) Route the remaining pilot Iight ieaC,.::rder

the line choke, as shown, andlonnecr tothe

same tug 2 of terminal strip HH (NS).

(") C:. C-:r rhe leads on another .001 =id 1400

volt d"isc ceramic capacitor to 3 g,,in

Iengt. C,tl:-iCr one end to lug 2 of terminal

strip IiH \ S . C onnect the other end to Iug B

of ter=r.a- s:i-:: HH (S_2).

( ) Lt. Cut both leads on another line choke to

l/2,, in 1ength, form the leads axially as

before, and slip_a piece of B/8,, steeving

over the choke. Connect one end to lug 2 oi

terminat strip GG (NS). Connect the oth""

end to lug 2 of terminar strip HH (S_4).

(' ) Cut a piece of the remaining blue-yellow

wire to 2,, in length and strip the ends.

Connect one end to lug 1 of terminal strip

LL (NS). Conneet the other end to lug ? ot

the power output socket (S_1). Use cale in

soldering to avoid shorting this lead to the

socket frame.

( {Connect the blue-yellow lead from the trans-

former to lug 1 of terminat strip LL (NS).

( t ) Connect the blue lead from the transformer

-!o lrg 2 of terminal strip LL (NS).

( "/) Connect_ the green-yellow lead to lug 3 of

terminal strip LL (NS).

(i ) Conneet the ye1low lead to 1ug 4 of termi_

nal strip LL (NS).

) Cut a piece of the leftover yellow trans-

former lead to B-l/2,, in tengtfr. Strip the

ends.Tin one end Iightly with solder and route

this lead down under the other filament

leads and connect to lug 4 of terminal

strip LL (NS). Connect thi remaining lead

to lug 6 on the power output socketis_f l.

NOTE: Now decide whether this supply is to

deliver 6.3 volts AC at 11 amperes or LZ.6

volts AC at b.5 amperes forthefitamentcireuii.

ff, the supply is to be used with the HEATHKIT

Mode1s MR-l and MT_1, select the filament

voltage for which the transmitter and receiver

have been wired.

SELECT AND PERFORM THE STEPS FOR ONLY

ONE, NOT BOTH, VALUES OF FILAMENT

VOLTAGE.

fr:

,x

il

I

Page 12

Detail 3A

FOR 6.3 VOLTS AT B AMPERES (See Detail 3A )

( .) Cut pieces of the leftove and green-

leads to 2- length. Strip the

ends tin lightl Connect ttre green-

yellow Iafrom iug 1 (S-3)

to lug 3 (S-2) rminal strip LL.

( ) Connect .ue a jumper from 1ug

2 (s-2) lug 4 (s-3) strip LL,

This cthe wiring for 6.3 ilament

FOR 12.6 VOLTS AT 4 AMPERES (See Pictor-

ial 3):

(t4 Cut one piece of the remaining blue lead to

Z-l/2" in length. Strip the ends and tin

lightly. Connect this lead from Iug 2 (S-2)

to lug 3 (S-2) on terminal striP LL.

(."') Solder lue 1 (S-2) andlug.! (S-2)of terminal

strip LL.

(ly) Cut a piece of black hookup rj.re 6" in

length. Strip the ends. Connect one end to

lug 2 of the power output socket (S-2).

Connect the other end to lug 1 on the 125

prfd capacitor at location K (NS). Route wire

. as shown.

/

This completes the wiring for 12.6 voltfilament

operation.

( \) Strip a short length of hookup wire and con-

nect this bare wire fiom lug 2 of the power

output socket (NS) to the adjacent socket

ground lug (S-1).

) Cut a piece of orange wire to 2't/2" in

length. Strip the ends. Connect one end to

Iug 3 on the power output socket (S-1).

Connect the other end to lug 4 of the 125

pfd capacitor at location J (NS).

( ,) R2. Cut one lead of a 100 Q 7 watt resistor

(#3G-9) to 5f 8" in length. Cover the other

lead with a piece of insulated sleeving 1-

lf 4" in length. Connect the short leadtolug

1 of terminal strip HH (NS). If the resistor

supplied is the square body type, face the

"filled" side of the resistorupward, or away

from the power output socket, otherwise rest

the resistor body against the socket. Con-

nect the insulated lead to tug 4 of the 125

trrfd capacitor at location J (S-2).

) Cut a piece of black hookup wire 9" in

length. Strip the ends, Connect one end to

lug 5 of terminal strip GG (NS). Connectthe

other end to lug 1 of the 125 pfd capacitor

at location K (NS). Route wire as shown.

( ,) Cut another piece of black wire 6-1/2" in

length. Strip the ends. Connect one end to

1ug 5 of terminal strip GG (NS), routing

close to the chassis. Connect the ottrer end

to lug 1 of terminal striP DD (NS).

) Cut another piece of black wire 6-1/2" in

length. Strip the ends. Connect one end to

Iug 3 of the 30 KA 25 watt bleeder resistor

(S-1). Route the other end throughgrommet

M close to the chassis and connect to Iug 1

of terminal strip DD (NS).

) Cut a piece of orange wire L-L/Z" in

length. Strip the ends. Connect one end to

1ug 3 of the 125 pfd filter capacitorJ (S-1).

Connect the other end to lug 5 of the 125

prfd fitter capacitor K (S-1).

STROM

-

DAY

J

rIE:aI'rrrtr"

-

t

lr-

I E,AYST

ItJ ROM

f,EATIIKIT'

Cut a piece of ,trarrie l,L-,,-rtup u-it'e 10" in

length. Strip tle e:is. Fl'o:r the botton-) slde

of the chass;s, -:s.r': -r: ir-d ull th1'ough the

5/16" rui,r-'ter =:- r:1::-:: -'',- :.ilacent to the 30

Kf,) bleeciei :'.srs:-:'. ---:'.i:Jnn.c: to Iug 2

of the bleecer- t'.:-i:-: S- i Route the other

Iead end clos€ :-, ::.: , :: i-:. ncitl tell:tinal

strips GG and ii:.. ..:. j _:::-ecl ii 1ui 1 of

the 125 -icl::-:... ..: . : ;: -. rr-,ir J

+

CATHODE

Page 13

ANODE

/c- r

\v rr,

(') Cut a -r::=:= -: -:' LEA

s

in lenfl:. S:: -: :.-.. .:'. r:, ? - i:a ::;i efld

down r.mde: ::-: -:..= .. --::-i. . --s: t- Ihe

chassis, an.l --:j-:-, : --: : -: t;r:::inal

strip QQ (r.-S; --:-< 1 -:-.: I .:'= :,i used).

Comect the :.,:.=: :..t :- -'.- - -::::ntinal

strip HH (S-2 .

Cut a piece c: t:: .-. -i:--* ';::': :-1 2" in

length. Strip tre =..:=, I -.-..=:: ---= =nd to

Iug 4 of the r-;:r -:- -: -i ..:-: S-1).

Connect the other c:"1 :: ,lu

filter capacitor J );S ,

(o4 Cut another piece :: ::-- ..:-.:-'- ',i::. 11"

' in length. Strip L:.= :..-:. I. .:. -:.: :od

down close to the ci:ass:s. --. t::' :.-.a -_:',i'er

output socket, under tar:--::-.a- s::-::s i:i{ and

GG and uptolugl ontEr::::...- s::-. E: \S).

Conneet the other end t: --;: -: --.. -:; -fd

filter capacitor J (S-2).

( '') Cut another piece of rec. :.- -.:-, ^.:.= i rn

Iength. Strip the ends. Fr'_l: :"-.: :-assis

bottom side, insert one r:; -1 ,-.: -:t-, rhe

5/16" rubber grommet M ai:: : -:-'.: -::: Iu3

1 of the bleeder resistor 'S- 1 P. _ -:= lhe

other end close tothe chassis a:--. -: : -:g 1

on terminal strip EE (NS). Luq 2 :s :. _: -sed.

NOTE: Maintain the diode bodies at r.= r-rid-

point between terminal strips CC anC DD. Do

not allow the diodes to touch the is -: =ach

othet

('.') D4. Refer to Detai.l 4A for diode p:Iarity

irrdication. C;t rre leads on four :: the

dj.odes tc 1" i: -en5h. measuring f:,m rhe

diode b:c.,,' as sho\rn. ilIount the firsl ,Ci,:de

with rhe ;-sitir-e (*) Iead connected tc -:g .4

of tern:i:a- strip DD (NS). Connect rhe

negative ,- -ead to 1ug 4 of terminal strip

cc (NS).

Detail rtA

(l/) oS. hr a similar manner, mount a second

diode with the negative (-) end connected to

lug 3 of terminal strip DD (NS) and the

positive G-) end connected to tug 3of termi-

nal strip CC (NS).

( zf Connect a 1" tength of bare wire (a clip-

ping from one of the components) between

Iug 3 (S-2) and lug 4 (S-2) of terminal strip

CC, as shown in Figure 44-

) D2. Connect the positive (+) end of a third

diode to lug 2 of terminal strip DD (NS).

Connect the negative (-) lead of this same

diode to lug 2 on terminal strip CC (NS).

4

6

4

D1. Install the fourth diode withitsnegative

(-) lead connected to Iug 1 onterminalstrip

DD (S-3). Conneet the positive (+) Iead of

this same diode to lug 1 on terminal strip

cc (NS).

Connect a 1" length of bare wire between

lug 1 (S-2) and lug 2 (S-2) of terminal strip

CC, as shown in Detail 44'

) Corurect al-l / 4" length of bare wire between

lug 2 (NS) and lug 3 (S-2) on terrninal strip

DD.

Page 14

n

Pictorial 4

( l) Corurect the nearest red lead ii:,m the

transformer to lug 2 on terminal srrip DD

(s- 3).

€) 6?iis) d

@Connect the remaining red lead from the

transformer to lug 3 of terminal strip QQ

(s-4).

Refer to Pictorial 3 for the following steps.

( ;rl-Connect the shorter brown lead from the

transformer to lug 3 of terminal strip SS

(NS).

1V; nl. Cut one lead of a 100 e ? watt resistor

(#3G-9) to l-7/4,'in length, Cover this lead

with a piece of insulated sleeving 1,' in

length. Cover the longer lead with a piece

of sleeving 1-t/4,,in length.

( 'i) Place this resistor in the corner of the

chassis, as shown in pictorial 4. Connect

the longer lead to lug 4 on terminal strip

DD (NS). Connect the other lead to lug 1

on terminal strip EE (S-3).

1l ) C5. Cut both teads on a 40 pfd 450 volt

filter capacitor to L-l/4,,in length. position

the capacitor as shown in pictorial 4,

aliowing l/8,, to \/4,, of space between the

capacitor and the transformer shell. Con-

nect the positive (+) Iead to lug 3 on termi-

nal strip aa (NS). Connect the negative (-)

lead to lug 5 on terminal strip GG (S-3).

Avoid burning the insulation on other ad-

jacent wiring.

( ) C6. Cut both leads on another 40 prfd filter

capacitor to L-l/z,, in length. Connect the

negative (-) lead to lug 3 on terminal strip

aa (NS). Conneet the positive (+) Ieadtotug

4 on terminal strip DD (S-3).

V) Connect the remaining br,own lead to lug 2

of terminal strip RR (NS).

\

( l{ Cut all three leads of the dual 20 prfd elec-

,troiytic capacitor to 3/4,, in length.

( ") Connect the negative (-) capacitor lead to

lug 2 of terminal strip RR (S-2).

(..,) Cg, C10. Connect the nearest positive (+)

capacitor lead to 1ug 1 of terminal strip

SS (NS) and the otier positive (+) Iead to

Iug 2 of the same terminal strip (NS).

( ,) R6. Cut both leads of a 100 KO 1 watt

(brown-btack-ye1Iow) resistor to l/2,, in

length. Connect one lead to 1ug 1of terminal

strip RR (NS). Corurect the other lead to

1ug 3 of the 125 prfd capacitor at location

K (s-1).

( ' ) R5. Cut both leads of a 220 ohm 1 watt

(red-red-brorm) resistor to 3/4,, in length.

Connect one lead to lug 1 of terminal strip

SS (NS). Coru-iect the other lead to lug 2 of

the same terminal strip (NS).

( i) D5. Cut both leads of the remaining silicon

diode to 37'4" and connect the positive (+) lead

to lug 2 of terminal strip SS (S-3). Connect

the negative (-) Iead to tug 3 of termi-

na1 strip SS (S-2).

1 -') Cut a piece of black hookup wire to l-l/2,,

in length and strip both ends. Connect one

end to lug 1 of terminal stripSS(S-3). Con-

nect the other end to lug 1 of the 125 1tf.d

capacitor K (S-3).

'l::l

fl, too

4

oor .l_(FD

1400 V

STROM

t^

I DAY

I,J

EEATEXIT

++

40 qFD

450 V

tt

40 UFD

450 v

L

-

ROM

l1-

I DAYST

IrJ

EEATI{ITIT'

1 Cut a piece of ',-ell.:-.'.' :o:r:;uil \,rir.e ro B" in

length. Strip 'i:::- e:'-ds, C:rnect one end

to lug L of t-l':---:.t-- -.:t':,, ?P (S-2 r. Con-

nect the:::er::,i :'r --:= i ri ih.e itc',,.-er

socker P /S-1r.

P.efer to Pi:::, r'ial : - - :: = - -,,',,,',-.: s:e:t_,

) Sepalate tle ,=*l: * - : - ...-. : --.= --:-= --tt cl

for a ciist::-a _- - .'. :'_-_ -:: at-. ls _ '= ;iild

tin light--. '.'.':::. . -:=-' '.a-:: ..= _:.=1--.:.ecl

endsthlou::::-.=: : -_ ,:- _t -.-.ti-,:.ia:d

tle a slnlL,i€ -----_:. :.: -i-..",-. _: F-_: t.:- +.

( ) Connect one re.-:l -: :-. -,'- j - . -:- l,tf

terminal strip Gl l.: _ :-:---.:-- ,:l-.er"

Lead to lug 2 ol :.t':.. -.--: - ::. -:_ -:-l ].S r.

( ) C2. Cut the lead: ;:- .- i : - .1. -_ _ . _l

ptfd 1400 volt disc r=: -. .'_ j_ .,, . _ r-i ro

3/8" in length. Coru-t-: - -.=. _ _:.: of

these capacitors to lug ; _:. :=:....- .:t.i1t

GG (NS)- Connect the Jr,-e:. -=.-- . , -: i tn

the same terminal strip (S-: .

,'

('r/f U. Connect one lead of the rer:a::-:::; .001

pfd disc capacitor tc iug 2 of re:::i:.:-- srrip

GG (S-3). Connect tiie ,::her Iea::: -::3 on

the same terminal sti.rp (S-2).

If an ohmmeter is available, nta-te:l-: :_--_-,i.ing

resistance checks beti,re appi,,-ir: .: _.,;, ::., i\-ith

the negative (-) lead on outpur s,_cl;:: .=::tinal

2, a resistance of more than 20.0_: -:.::-_. sr,:rulci

be read at terminat 4. With the n==-.::-. - _ r lead

on terminal 1, a resistance of nt,_r= .:-.:-. , r.000

ohms should be read at terminal 2, _ =-,rer of

these readings are zero, or verv i,:-,,... . short

circuit exists" Refer to the IN CASE r,: l,IF_

FICULTY section (Page 1?). If the rea,ri:-.--q are

normal. proceed as follows.

Be certain that the two 3 ampere fuses are in

the power plur and insert the plug into a wail

receptacle. T:.::'n the power supply line switch

to the Oli pcsit::r,

The pilot lig:: srould glow. (If it does not, see

the IN C*lqa OF DIFFICULTy section.) A

point to pci;:: -,',_).tage check should be done

before the supp-'.' is used with any equip-

ment. A high resisrance voltmeter (geneially

2000 to 20,000 orms per volt) wittr at leasi

0-?50 volt scale is used for voltage checking.

AND TIN LIGHTLY

Page 15

SECURE LEADS

UNDER TERMINAL

scREws.

<

o<.

SEPARATI THE LEADS

BAcK ?il1 srRtp s/6", REMovE scREw ANo NUT

TESTING THE HP-20 FOWER SUPPLY

CAREFULLY INSERT LEAOS

ANO TERMINALS. REASSEMBLE THE PLUC ANO

INSERT TWO FUSES,

Figure b

) Refer to Figure 5 and mount the fused

power plug on the free end of the line cord.

Sepanate the two leads for 2". Strip the ends

5/8" and tin lightly with solder. Secure the

two leads under the screw terminals of the

p1ug. Insert the two 3 ampere fuses.

NOTE: The top and bottom chassis covers are

mounted aJter testing the Supply.

A HEATHKIT Volt-Ohm-Milliammeter would

be ideal. Connect the common (ground) lead to

terminal 2 of the power output socket. The

voltage at terminal 3 should be approximately

+365 volts with no load on the supply other than

the self-contained bleeder resistor.

T'}:e voltage measured at the high voltage termi-

ns.i 4 on the power plug should be approximately

+?30 volts, with no load. The voltage measured

at terminal 1 should be approximateiy -1b0

volts, with no load. These voltages drop to their

rated values under proper load current. NOTE:

A line voltage variation of more or less than

11? volts will reflect itself in slightiy higher

or lower readings of the power supply's out-

put voltages.

On the low range AC scale of thetest rneter, the

filament voltage rneasured from terminal 5 to 6

of the power output socket should read 6.3 volts

or 12.6 volts, depending on which waythesupply

was wired.

@

@B

t

o

lr.

5

o

a

,(

fv

BLAC K

i+

?20 GRE

,..

o

UJ

g.

2

I

Y

O

o

:

uJ

(,

z

tr

o

loo o 7W L INt

o

LL

il