DayTronic 3700 Series User manual

MODEL

3760

DC VOLTAGE CONDITIONER

SB.1.1

INSTRUCTION MANUAL

3700

Instrument Series

WARNING

Death, serious injury, or fire hazard could result from improper connection of this instrument. Read and understand this

manual before connecting this instrument. Follow all installation and operating instructions while using this instrument.

Connection of this instrument must be performed in compliance with the National Electrical Code (ANSI/NFPA 70-2014) of

USA and any additional safety requirements applicable to your installation.

Installation, operation, and maintenance of this instrument must be performed by qualified personnel only. The National

Electrical Code defines a qualified person as “one who has demonstrated the skills and knowledge related to the construction

and operation of the electrical equipment and installations, and who has received safety training on the hazards involved.”

Qualified personnel who work on or near exposed energized electrical conductors must follow applicable safety related

work practices and procedures including appropriate personal protective equipment in compliance with the Standard for

Electrical Safety Requirements for Employee Workplaces (ANSI/NFPA 70E-2012) of USA and any additional workplace safety

requirements applicable to your installation.

ADVERTENCIA

Una conexión incorrecta de este instrumento puede producir la muerte, lesiones graves y riesgo de incendio. Lea y entienda

este manual antes de conectar. Observe todas las instrucciones de instalación y operación durante el uso de este

instrumento.

La conexión de este instrumento a un sistema eléctrico se debe realizar en conformidad con el Código Eléctrico Nacional

(ANSI/NFPA 70-2014) de los E.E.U.U., además de cualquier otra norma de seguridad correspondiente a su

establecimiento.

La instalación, operación y mantenimiento de este instrumento debe ser realizada por personal calificado solamente. El

Código Eléctrico Nacional define a una persona calificada como "una que esté familiarizada con la construcción y operación del

equipo y con los riesgos involucrados."

El personal cualificado que trabaja encendido o acerca a los conductores eléctricos energizados expuestos debe seguir

prácticas y procedimientos relacionados seguridad aplicable del trabajo incluyendo el equipo protector personal apropiado

en conformidad con el estándar para los requisitos de seguridad eléctricos para los lugares de trabajo del empleado (ANSI/

NFPA 70E-2012) de los E.E.U.U. y cualquier requisito de seguridad adicional del lugar de trabajo aplicable a su instalación.

AVERTISSEMENT

Si l'instrument est mal connecté, la mort, des blessures graves, ou un danger d'incendie peuvent s'en suivre. Lisez

attentivement ce manuel avant de connecter l'instrument. Lorsque vous utilisez l'instrument, suivez toutes les

instructions d'installation et de service.

Cet instrument doit être connecté conformément au National Electrical Code (ANSI/NFPA 70-2014) des Etats-Unis et à

toutes les exigences de sécurité applicables à votre installation.

Cet instrument doit être installé, utilisé et entretenu uniquement par un personnel qualifié. Selon le National Electrical

Code, une personne est qualifiée si "elle connaît bien la construction et l'utilisation de l'équipement, ainsi que les dangers

que cela implique".

Le personnel qualifié qui travaillent dessus ou s'approchent des conducteurs électriques activés exposés doit suivre des

pratiques en matière et des procédures reliées par sûreté applicable de travail comprenant le matériel de protection

personnel approprié conformément à la norme pour des conditions de sûreté électriques pour les lieux de travail des

employés (ANSI/NFPA 70E-2012) des Etats-Unis et toutes les conditions de sûreté additionnelles de lieu de travail

applicables à votre installation.

Page 1

WARNUNG

Der falsche Anschluß dieses Gerätes kann Tod, schwere Verletzungen oder Feuer verursachen. Bevor Sie dieses Instrument

anschließen, müssen Sie die Anleitung lesen und verstanden haben. Bei der Verwendung dieses Instruments müssen alle

Installation- und Betriebsanweisungen beachtet werden.

Der Anschluß dieses Instruments muß in Übereinstimmung mit den nationalen Bestimmungen für Elektrizität (ANSI/NFPA

70- 2014) der Vereinigten Staaten, sowie allen weiteren, in Ihrem Fall anwendbaren Sicherheitsbestimmungen, vorgenommen

werden.

Installation, Betrieb und Wartung dieses Instruments dürfen nur von Fachpersonal durchgeführt werden. In dem nationalen

Bestimmungen für Elektrizität wird ein Fachmann als eine Person bezeichnet, welche "mit der Bauweise und dem Betrieb des

Gerätes sowie den dazugehörigen Gefahren vertraut ist."

Qualifiziertes Personal, das an bearbeiten oder herausgestellte angezogene elektrische Leiter sich nähern, muß anwendbare

Sicherheit bezogener Arbeit Praxis und Verfahren einschließlich passende persönliche schützende Ausrüstung gemäß dem

Standard für elektrische Sicherheitsauflagen für Angestellt-Arbeitsplätze (ANSI/NFPA 70E-2012) der Vereinigten Staaten

und alle zusätzlichen Arbeitsplatzsicherheitsauflagen folgen, die auf Ihre Installation anwendbar sind.

Safety Precautions

The following safety precautions must be followed whenever any type of voltage or current connection is being made to the

instrument.

oBefore connecting to electric circuits or pulse initiating equipment, open their related breakers or disconnects. It is

recommended NOT TO install any connection of the instrument on live power lines. Only Qualified Service personnel that

have demonstrated the abilities and received the proper safety training are capable of connecting to live circuits.

oConnections must be made to the instrument first, then connect to the circuit to be monitored.

oWear proper personal protective equipment, including safety glasses and insulated gloves when making connections to

power circuits.

oHands, shoes and floor must be dry when making any connection to a power line.

oBefore each use, inspect all cables for breaks or cracks in the insulation. Replace immediately if defective.

oIf the equipment is used in a manner not specified in this user’s guide, the protection provided by the equipment may be

impaired.

Page 2

Medidas de seguridad

Las medidas de seguridad siguientes deberán observarse cuando se realice cualquier tipo de conexión al instrumento.

οCuando se haga conexiones a circuitos eléctricos o a equipo de activación por pulso, deberá abrirse sus respectivas cajas

de seguridad. NO deberá hacerse ninguna conexión del instrumento en líneas eléctricas bajo tensión.

οLas conexiones deberán hacerse primero al instrumento y, luego, al circuito a ser monitorizado.

οAl hacer conexiones a circuitos eléctricos, deberá utilizar anteojos y guantes protectores.

οSus manos, zapatos y el piso deberán estar secos en todo momento en que se haga una conexión a un cable eléctrico.

οVerifique que la unidad esté DESACTIVADA antes de conectar sondas en el panel posterior.

οPrevio a cada uso, deberá verificarse que los cables no estén rotos y que el material aislante no tenga rajaduras.

Reemplace de inmediato cualquier parte defectuosa.

Mesures de Sécurité

Les mesures de sécurité suivantes doivent être prises chaque fois qu’un type de connexion quelconque est effectué

sur l’instrument.

οOuvrir les disjoncteurs correspondants lors d’une connexion à des circuits électriques ou à des équipement de génération

d’impulsions. NE PAS effectuer de connexion d’instrument sur des lignes électriques sous tension.

οUne fois toutes les connexions de l’instrument effectuées, connecter au circuit à contrôler.

οPorter des lunettes de protection et des gants isolants pour effectuer des connexions aux circuits électriques.

οS’assurer que les mains, les chaussures et le sol soient secs lors de connexions à une ligne électrique.

οS’assurer que l’unité est ÉTEINTE avant de connecter les sondes au panneau arrière.

οInspecter tous les câbles, avant chaque utilisation, pour s’assurer que les isolants ne sont pas coupés ou fendus.

Remplacer immédiatement tous les équipements défectueux.

Page 3

Sicherheitsvorkehrungen

Die folgenden Sicherheitsvorkehrungen sind immer dann zu befolgen, wenn eine Verbindung zum Instrument hergestellt wird.

οÖffnen Sie beim Anschluß an elektrische Stromkreise oder Impulsauslösungseinrichtungen die entsprechenden

Unterbrecher. Es dürfen KEINE Anschlüsse an das Instrument unter stromführenden Spannungsleitungen montiert

werden.

οDie Verbindungen müssen zuerst am Instrument und danach an der zu überwachenden Schaltung hergestellt werden.

οTragen Sie Schutzbrillen und Isolierhandschuhe, wenn Sie Anschlüsse an den Stromkreisen vornehmen.

οHände, Schuhe und Fußboden müssen trocken sein, wenn Sie Anschlüsse an den Stromkreisen durchführen.

οStellen Sie sicher, daß das Gerät AUSgeschaltet ist, bevor Sie an der rückwärtigen Konsole Meßfühler anschließen.

οPrüfen Sie vor jedem Gebrauch alle Kabel auf Bruchstellen und Risse in der Isolierung. Wechseln Sie schadhafte Kabel

sofort aus.

Standard Accessories

Standard

accessories The following table lists the 3700 standard accessories.

Page 4

Description Part Number

*US Power Cord USSTDCORD (900744)

*European Power Cord EUROSTDCORD (115369-G1)

*United Kingdom Power Cord UKSTDCORD (115368-G2)

*Australian Power Cord AUSTDCORD (901347)

3760 Manual 92362.00

*User specified, one standard only.

3760 Quick Reference Guide 92367.00

5 Pin connector, analog signals

8 Pin connector, transducer

10 Pin connector, logic

25657-LF

25658-LF

25606.00

Desk top feet (4ea.) 35058.00

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

3760

1.A.0.3760

1

G

ENERAL

D

ESCRIPTION AND

S

PECIFICATIONS

The Model 3760 is a single-channel panel instrument for DC Voltage and 4-20mA sensors;

intended for applications involving single ended or differential DC Voltage signals with

ratings between 50 mV to 200.0 Vdc input full scale or 4-20mA inputs. The 3760 will

supply excitation, conditioning and provide a calibrated Engineering Unit's display and

analog output signals for the measurement of pressure, displacement, speed, load and other

parameters associated with DC based sensors. The 3760 is front panel configurable with

user selectable wide gain, zero, symmetry, and selectable analog output of voltage and

current signals. Display is user configured and independently adjustable for engineering unit

scaling up to ± 199950 independent of the analog full scale signal.

The Model 3760 can be calibrated by the “two-point (dead-weight)” process involving

known “zero” and “full scale” input parameters. A convenient “RCAL” front panel push

button or rear panel connection is available for calibration verification.

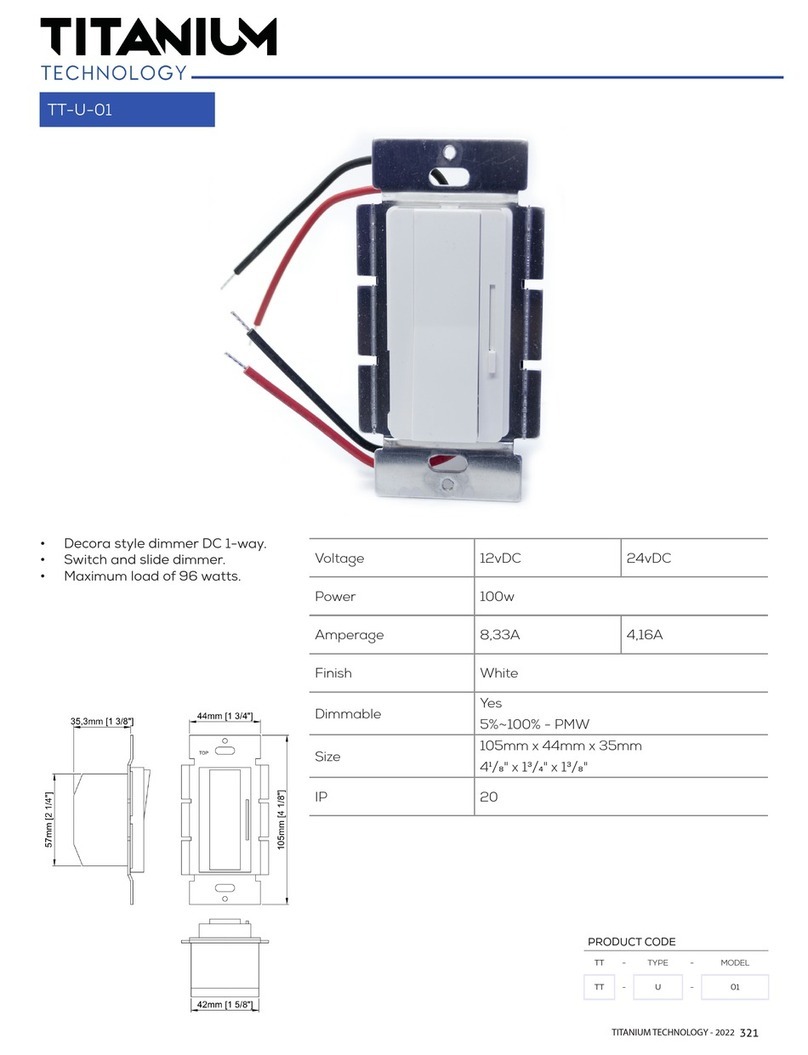

FRONT PANEL VIEW OF 3760 CONTROLS (Front Display Cover Removed)

1 2 3 4 5 6 7

CF

CCFF

1 . X . X . X . X 0

FINE ADJUST

ZERO SPAN 1.X.X.X.X 0

ZERO SPAN

WIDE ADJUST

5000

10000

20000

SYM

DISPLAY SPAN

TARE

RCAL

1 2 3 4 5 6 7

ANALOG CTRL

FINE ADJUST

COARSE ZERO

FINE ZERO

COARSE SPAN

FINE SPAN

WIDE ADJUST

ZERO

SPAN

DISPLAY CONFIGURATION

Sw 1,2,3,4 DECIMAL POINT PLACEMENT

Sw 5 DUMMY ZERO

Sw 6 & 7 DISPLAY RESOLUTION

RCAL Remote Calibration

TARE

ANALOG CONTROL SETTINGS

1 – VOLTAGE OUTPUT – 5.0 or 10.0 VDC

2 - CURRENT OUTPUT – 4-20 mA

3 - ANALOG FILTER – 20 / 200 Hz

4 - ANALOG FILTER – 20 / 2 Hz

5 - CURRENT INPUT – 4-20 / 4-12-20

6 - VDC INPUT RANGE SELECT

7 - VDC INPUT RANGE SELECT

DISPLAY SPAN

COARSE

FINE

SYMMETRY

OFF

Page 5

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

3760

SPECIFICATIONS

Measurement Range: Adjustable; 0.050 mV to 200 VDC; or 4-20 / 4-12-20 mA nominal full-scale.

Transducer Types: DC Voltage or mA Current out (potentiometer, DC to DC LVDT)

Excitation: ± 12.0 Vdc (24 Vdc), up to 50 mA.

Power Supply: Voltage 90 - 250 VAC, 47 -63 Hz

Amplifier

Normal - Mode Range: ±5 V RMS operating; ±28 V without instrument damage

Input Impedance: Differential 200 kΩ

Offset: vs. Temperature: ±30 ppm µV/°C; vs. Time: ±10 ppm/month

Gain Accuracy: Limited only by calibration accuracy

Gain Stability: vs. Temperature: ±30 ppm/°C; vs. Time: ±10 ppm/month

Linearity: better than ± 0.03% of full scale

Filter: 3-pole modified Butterworth; 3 dB down at 2 Hz, 20 Hz or 200 Hz; selectable.

Fast output always enabled, 5 KHz response (J3 Pin 3).

Common Mode:

Range C-M Range

(Vf.s.) (+/- V)

0.050 - 0.400 5

0.400 - 3.200 40

3.200 - 25.00 200

25.0 0 - 200.0 200

Step-Response Settling Times for the 3760 (in milliseconds)

3db Frequency To within 1% within .1% within .02%

Fast Output 5000 Hz 0.14 0.10 0.08

Selectable Output 200 Hz 3.7 5.0 5.6

20 Hz 37 50 56

2 Hz 370 500 560

1.a

P

ANEL

M

OUNTING

You can easily mount the instrument in your own precut panel. Cutout dimensions for a

panel-mounted unit are standard

DIN

; panel thickness should not exceed 6 mm (0.24

in).Simply unscrew the two rear-panel CLAMP SCREWS and slide the CLAMP

SLIDES rearwards out of their grooves (THE FRONT BEZEL NEED NOT BE REMOVED).

Insert the unit through the panel cutout, from the front of the panel (if the unit has rubber

feet, these will have to be removed). Then reinstall the CLAMP SLIDES, and tighten the

CLAMP SCREWS until the instrument is securely mounted.

Page 6

Consumption 10 Watts

Physical Parameters: 5. 68” W x 2. 84” H x 7. 06” D; weight - 3. 25 Lbs.

Analog Output: selectable; ± 5, ±1 0 VDC, 4 -20 mA or 4 -12 -20 mA (20 % over -range on voltage outputs only)

Operating Temperature: 0 to +55 Degrees C, 5 to 95% relative humidity, non-condensing

Altitude: 2000m (6560 ft) maximum

Installation Category: Installation Category II, Pollution Degree 2

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

2

C

ONNECTIONS

The Model 3760 I/O CONNECTIONS are via removable screw terminals which will accept wire sizes

from AWG 12 to 26. NOTE:The recommended transducer cabling would be twisted pair,

individually shielded - wired as indicated (Fig. 6). Table 1 denotes screw terminal assignments

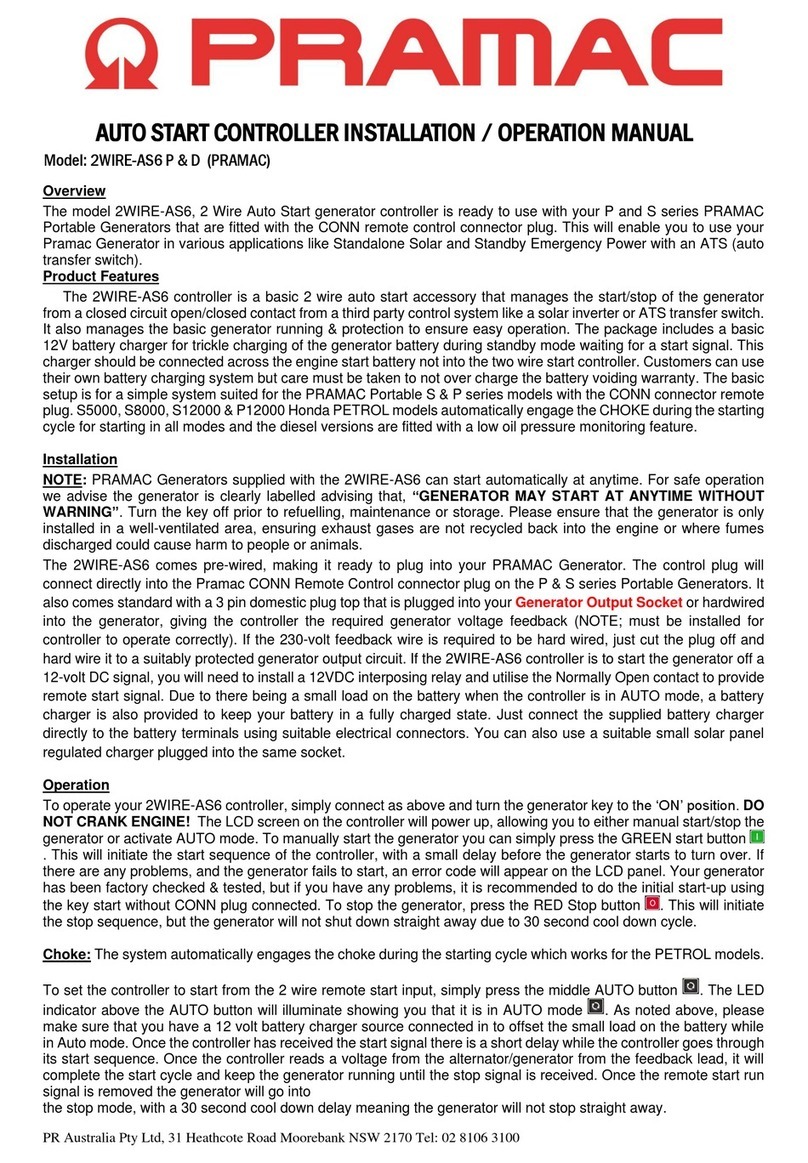

Rear Panel Connections

HOLD

TARE

LOGIC COM

TARE ENABLE

EXCITATION

EXCITATION

mA ENB

SIGNAL

SIGNAL

EXC COMMON

SHIELD

VDC COM

V OUT SEL

V OUT FAST

4-20 mA COM

4-20 mA OUT

+

_

_

+

N/C

N/C

R CAL

3760

CM FAULT

N/C

N/C

mA

_

Table 1

Connector Screw Terminal Line

Number Terminal Label Function

J1 1 N/C

J1 2 N/C

J1 3 HOLD

J1 4 TARE

J1 5 TARE ENABLE

J1 6 LOGIC COM

J1 7 R CAL

J1 8 N/C

J1 9 CM FAULT

J1 10 N/C

No connection

No connection

Input Analog Hold command

Input Analog TARE command

External TARE enable input

Logic Common

Remote Calibration Command

No connection

Common Mode Fault output

No connection

J2 1 + EXCITATION

J2 2 - EXCITATION

J2 3 mA ENABLE

J2 4 - mA

J2 5 + SIGNAL

J2 6 - SIGNAL

J2 7 EXC COMMON

J2 8 SHIELD

+ Excitation Power

- Excitation Power

Jumper Connection to Enable mA input

- Negative 4-20 mA Input Signal from sensor

+ Signal Input (VDC or mA)from sensor

- Signal Input from sensor

Excitation common

Case Shield for cable termination

J3 1 V OUT COM - Signal Output Voltage Common

J3 2 V OUT SEL + Signal Output Voltage – Filter Select

J3 3 V OUT FAST + Signal Output Voltage – 5 kHz Filter

J3 4 4-20 mA COM Current Output Common

J3 5 4-20 mA OUT Current Output Signal

Page 7

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

2

C

ONNECTIONS

J1 – RCAL Command Connections.

Connection is used to remotely activate the positive

calibration command from the rear panel. When the RCAL terminal is connected to LOGIC COM

via a switch or relay, the 3760 meter will generate 80% of the full scale value as configured.

Fig. 4

RCAL Command

Connections

J1 - RCAL Activation

Connections

Connecting LOG COMMON to the R CAL

terminals will activate an internal voltage

reference in place of the sensor’s signal for

simulated calibration & verification check of

the 3760 settings and input operation.

LOGIC COM

R CAL +

N/O

Switch

J2 - HOLD & TARE Connections.

Connection is used when external control of the "HOLD" and

"TARE" features of the unit are enabled and are controlled by an external switch, PLC or relay. The

LOG COM signal is used to activate the analog HOLD or Analog TARE (offset) to the meter's

display and analog output signals present on J3.

Fig. 5

J1 Logic Controls

HOLD IN Activates Analog HOLD when connected to LOGIC COMMON

TARE IN Activates Analog TARE when connected to LOGIC COMMON

TARE ENABLE Enables remote TARE and disables front panel TARE when connected to LOGIC COMMON

LOGIC COMMON Connection to enable rear panel features

COMMON MODE FAULT Logic Output. True when the input signal’s Common Mode exceeds specifications.

Push Button, Contact Relay,

Switch…..

LOGIC COM

HOLD

TARE

TARE ENABLE

CM FAULT

Page 8

Common Mode: Is the voltage level at which the input signal can be "floating" from earth common

which the 3760 can function properly. If this level is exceeeded, the "CMF" (terminal 9, J1) will go true

(to ground), giving the user a remote status of the Common-Mode condition of the 3760 unit.

Static condition of terminal 9 is TTL (+ 5 Vdc).

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

2

C

ONNECTIONS

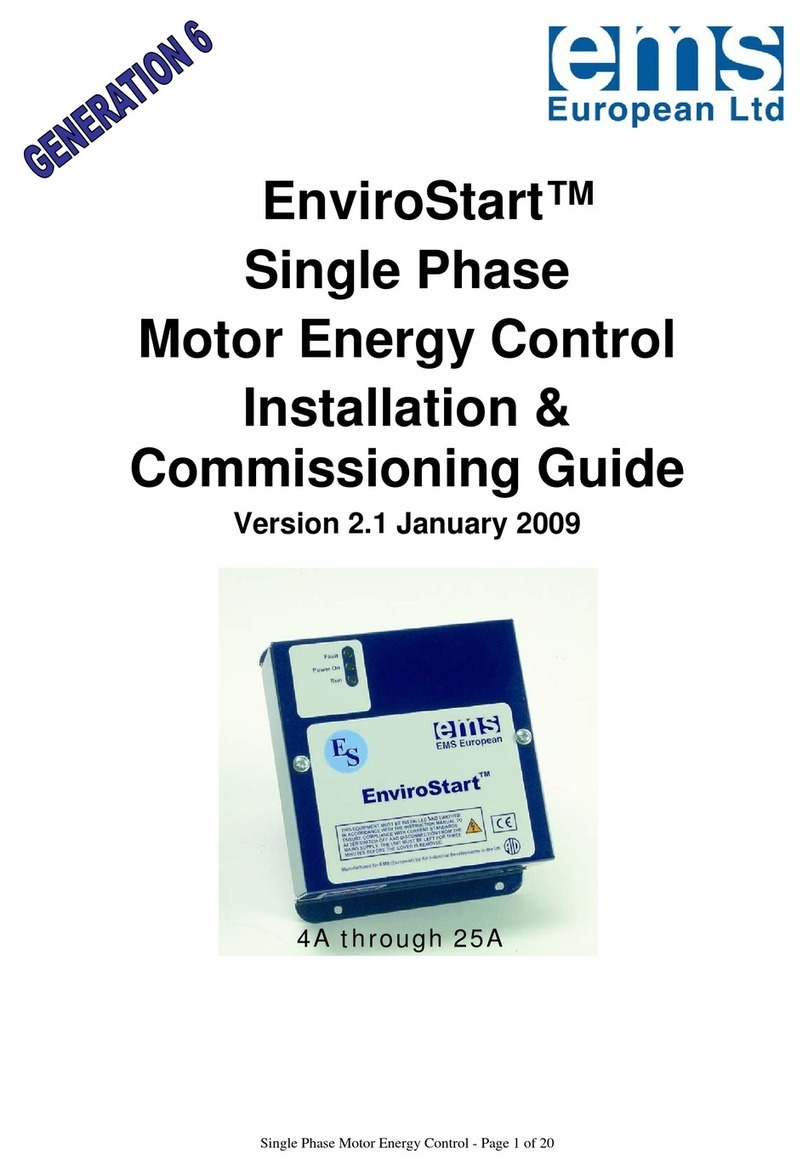

Fig. 6 - Transducer Cabling – DC Voltage Input- J2 Connector

EXCITATION

EXCITATION

SIGNAL

SIGNAL

+

_

_

+

SHIELD

EXC COMMON

+ Power

- Power

+ Signal

_

DC Powered

Sensor

24 Vdc

DC – DC LVDT

DC Load / Pressure Sensors

Amplified Sensors

mA

mA ENB

EXCITATION

EXCITATION

SIGNAL

SIGNAL

+

_

_

+

SHIELD

EXC COMMON

Linear

Potentiometer

Sensor

Linear Potentiometers

Zero Centered for

Bi-Directional output

_ mA

EXCITATION

EXCITATION

SIGNAL

SIGNAL

+

_

_

+

SHIELD

EXC COMMON

Linear

Potentiometer

Sensor

Linear Potentiometer

With Uni-Directional output

mA

_

EXCITATION

EXCITATION

SIGNAL

SIGNAL

+

_

_

+

SHIELD

EXC COMMON

mA

_

Linear

Sensor

Linear Transducer

With 4-20mA output

+ Power

- Power

- Signal

+ Signal

Page 9

mA ENB

mA ENB

mA ENB

WARNING

Qualified personnel who work on or near exposed energized electrical conductors must follow applicable safety

related work practices and procedures including appropriate personal protective equipment in compliance with the

Standard for Electrical Safety Requirements for Employee Workplaces (ANSI/NFPA 70E-2012) of USA and any

additional workplace safety requirements applicable to your installation.

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

2

C

ONNECTIONS

J3 - Analog Connections Provides analog outputs from the meter's signal conditioning area in the form of

± 5 Vdc or ± 10 Vdc (selectable via the front panel controls) and 4-20 mA (or selectable 4-12-20 mA).

Full scale output is referenced to the display "range" selected (5000, 10000, or 20000). I.e. If range

10000 is selected, the analog output will be 5 Vdc or 10 Vdc, as determined by the front panel controls

(or 20 mA FS) when in the default – UP position.

12345

Analog Voltage

Output

+/- 5 Vdc or +/- 10 Vdc with

fixed cutoff filter @ 5 KHz

Analog Voltage

Output

+/- 5 Vdc or +/- 10 Vdc with

front panel selectable cutoff

filter @ 2/20/200 Hz

Analog Current

Output

4-20mA, 4-12-20mA

at selected cutoff filter

+ SIGNAL

- SIGNAL

- SIGNAL

+ SIGNAL

+ SIGNAL

- SIGNAL

J3 - Analog Output Connections

Pin 1 V Out Common (- Signal out) reference for Pin 2 and Pin 3 + Signal Voltage Output.

Pin 2 Voltage Output Selected (+Signal out) reference to Pin 1. The Full Scale Voltage is

determined by the position of switch 1 -VDC on the Conditioner Controls. Output

response is determined by the position of switch 3-FIL and 4- FIL on the Analog

Controls.

Pin 3 Voltage Output Fixed. (+ Signal out) reference to Pin 1. Full Scale Voltage is

determined by the position of switch 1-VDC of the Conditioner Controls. Filter

response is fixed at the highest analog signal response of 5 KHz.

Pin 4 4-20 mA Current Output Common (- Signal) reference for Pin 5 Current Output.

Pin 5 4-20 mA Current Output (+Signal) reference to Pin 4 Current Output Common. The

Current Output is selectable for 4 - 20 mA or 4-12-20 mA as determined by the

position of switch 2 -mA of the Conditioner Control switch(s) on the front panel.

Page 10

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

3

C

ONTROLS

Display Range and Decimal Point Selection

Switch 1 -

selects decimal point for position

X.XXXXX

Switch 2 -

selects decimal point for position

XX.XXXX

Switch 3 -

selects decimal point for position

XXX.XXX

Switch 4 -

selects decimal point for position

XXXX.XX

Switch 5 -

enables dummy zero display digit

XXXXX

0

Switch 6 & 7 -

selects Display Full Scale Range

Range will equate to an analog output value of ± 5 Vdc or ± 10 Vdc per Analog Control

switch placement. Selection is set for 1 count in 5000, 2 counts in 10000 and 5 counts in 20000.

Analog Zero and Span Adjustments

Coarse Zero - 22 Turn potentiometer adjustment forbalance control ofanalog offset signal

Fine Zero - 25 Turn potentiometer for fine balance control ofanalog offset signal

Coarse Span - 22 Turn potentiometer adjustment for analog control ofgain (approx. +/- 11% authority)

Fine Span - 25 Turn potentiometer adjustment for analog control of fine gain

Page 11

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

3

C

ONTROLS

Analog Wide Span and Zero Controls

16 Position switch for wide control adjustment of the analog output signal from the 3760 meter, this in turn

affects the digital readout for engineering units adjustments as determined by the display settings.

Wide Zero -

16 position switch to adjust wide zero-balance authority, approx. 13% /position

Wide Span -

16 position switch to adjust wide range gain for 0.050 mV to 200 Vdc sensors

Display Span

Adjustments

The Display Span Adjustment is used to adjust the digital readout of the 3760 meter; the user

calibrates the analog output for a specific span value and then adjusts the readout for proper

engineering units display. “OFF” position indicator defines the default position. i.e. 5.000 Vdc for

the analog outputs equals to 5000 counts on the display.

Display Coarse Span -

16 position switch to adjust wide span / gain authority for the display

Display Fine Span -

25 Turn potentiometer for fine span / gain control of display reading

Display “OFF” –

switch position “F” which disables the Adjustable Span feature of the display

Page 12

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

3

Controls

Analog Control Settings

Front panel controls configure the main parameters of the Signal conditioner for input type,

mode of the analog output signal, low pass filter characteristics and full scale voltage input

range.

1 – 5 Vdc Output - UP sets the analog output FS to 5 Vdc, DOWN is 10 Vdc

2 – 4 - 20 mA Output - UP sets the analog current output for 4-20 mA , DOWN is 4-12-20ma

3 – 20/200 Hz - UP selects 20 Hz filter. DOWN selects 200 Hz filter

4 – 20/2 Hz - UP selects 20 Hz filter. DOWN selects 2 Hz filter

5 – 4-20 mA Input – UP selects 4-20 ma Input. DOWN selects 4-12-20 mA Input

6 – VDC Input – Full Scale Range Select switch, 50 mV to 200 Vdc

7 – VDC Input – Full Scale Range Select switch, 50 mV to 200 Vdc

With all switches in the UP position, the unit will have the following settings:

•5 Vdc Analog voltage output full scale

•4-20 mA Analog current output full scale

•The Analog low pass filter will be set for 20 Hz

•4-20 mAinput is selected – requires proper input wiring. Refer to page 5 for diagram

•VDC Input Range set for 3.20 to 25.0 Vdc input

Analog Control Settings for Conditioner Configuration

1– VDC OUT

2 – mA OUT

3 – FILTER

4 – FILTER

5 – mA IN

5

4-20

20 Hz

20 Hz

4-20

Up 10

4-12-20

200 Hz

2 Hz

4-12-20

Down

Function

RANGE VDC INPUT 67

0.05 – 0.40

0.40 – 3.20

3.20 – 25.0

25.0 – 200.0

Analog Control Settings

Switch 6 and 7 are used to select one of the

four expected DC Voltage Input Ranges of the

meter. The adjustability within the selected

range will be accomplished via the Wide Span,

Coarse Span and Fine Span controls.

When the input is4-20mA, the

correct input Range is auto-selected

Page 13

1

2

3

4

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

3

Controls

Analog Symmetry, RCAL, TARE

SYM Symmetry - Adjust the negative gain slope for symmetrical analog adjustment and

display reading with reference to the positive span value. 20 Turn potentiometer, with

approx. +/- 2% full scale authority

RCAL Remote Calibration – Activates thePositive voltage calibration reference. Value is

determined by the rear rotary switch located behind the rear panel. See details after

Section 4 - calibration.

TARE Push / Push switch. When enabled, offsets the present sensor signal input to "Zero". When

activated, a green LED light will illuminate. During activation process, LED will light

Yellow. If disabled, or out of range, LED will be RED. TARE maybe remotely activated via

rear J1 connections. Front panel TARE can be disabled via J1 Pin 5 connected to Logic

Common, Pin 6.Maximum TARE capability is approx. 60% of full scale reading.

Page 14

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

4. CALIBRATION

This section contains the instructions for calibrating the 3760. Included is a functional description of the

instrument front-panel (see Page 1). To perform calibration, proceed as follows.

(a) Connect Sensor and Analog terminals as required. Connect and apply power to the unit. The

front-panel digital display should light indicating the application of the AC input power. Allow

10 minutes of warm up for stabilization of transducer characteristics. Remove the front cover of

the 3760 unit by removing the two small Phillips screws on the front panel. TARE button should

not be activated.

(b) Center the Zero and Fine Span potentiometers by rotating the potentiometers CW until you feel

the “end stop” or by the number of turns accomplished (Coarse is 22 turns, Fine is 25 turns).

Rotate the potentiometer back to the middle of their range (Coarse 11 turns, Fine 12-13 turns).

This will establish the mid-authority adjustment of the potentiometers.

(c) Position the front panel switches to the desired settings for the application. Refer to Section 3 for

details.

(d) Relax the sensor or voltage input to “zero” and adjust the Wide Zero and Fine Zero controls

until the meter reading is achieved at the point which will be the “zero” value reference.

(e) Once the Zero position has been established, apply a known input to the meter. With the input

active and stable, adjust the Wide Span, Coarse Span and Fine Span controls until the display

reading required is achieved.

(f) Return the sensor to the "Zero" position and re-adjust the Coarse Zero and Fine Zero controls for

the desired reading or analog output of the unit. Repeat the Span (step e) adjustment as

necessary to achieve the proper reading or analog output. Note that changes in Span (Gain) will

affect Zero. Span and Zero re-adjustments may need to be repeated to obtain the desired reading.

(Note that the 3760 meter also has independent display adjustment capability to where the

digital display can be adjusted independently to the analog output signal of the unit so as to

achieve maximum analog output levels from the meter.)

(g) Once the Zero and the Gain (SPAN) adjustments have been accomplished, if needed -the user

can adjust for Negative non-symmetrical value (as referenced by the positive SPAN value) by

utilizing the front panel Symmetry control when the input to the meter is Negative - adjust the

symmetry control for the correct readout or analog output signal required. Note the Symmetry

control has approx. ± 2 % full scale authority.

(h) Once completed, record the position of the "Wide Span" control setting (0 thru F). This setting

position will be used to set the internal RCAL switch as described below under

"Front Panel Calibration (RCAL) setting" instructions.

Display Calibration

The 3760 instrument display has separate adjustment controls that are independent of the

analog output controls - allowing the user to alter the display reading to a value that is suited for the display

while maintaining the flexibility to adjust the analog signal as needed for external devices. In the standard –

default switch position (as marked on the Coarse Span control area), the display has a fixed full scale reading set

by the display range switches of 5000, 10000 or 20000 counts. At theses settings the full scale analog output

signal will be 5 Vdc or 10 Vdc, as selected. To accomplish the display adjustment change, the user would first

set the desired display range and decimal location using the display dip switches, adjust the analog output to the

desired level and then adjust the Display Coarse and Fine span controls for the required digital readout.

(i) Replace thefront display lens cover to the original position and ensure proper shielding and

grounding have been done tothe meter.

Page 15

M

ODEL

3760

DC VOLT & 4-20mA PANEL METER

Tech Tip on use of wide range settings for the DC Voltage Conditioner

Due to multiple amplifier stages within the 3760 instrument, attention to the proper gain setting and understanding of

the sensor inputs should be reviewed to produce a linear- amplified analog output signal and display reading.

The wide span – gain control (as shown in the front panel diagram) has 16 positions to amplify the incoming signal by

incremental steps. Each step is positioned so the Coarse and Fine Span potentiometer controls overlaps each step to

provide a continuous linear gain of the signal from 50 mVdc to 200Vdc full scale. Below is a table of each wide gain

steps, indicating the nominal low and high input signal range per position – full scale in millivolts DC to the meter.

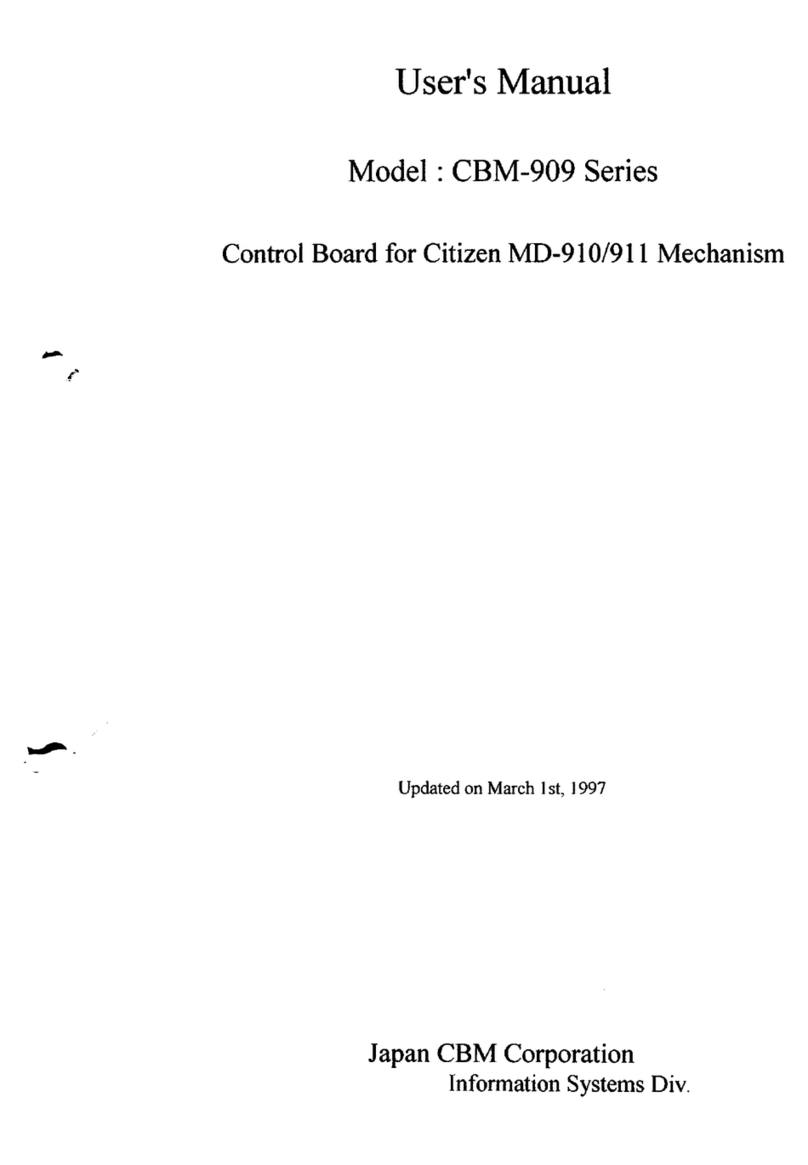

Wide Span

Control

Wide Span Control table for Low and High Input DC Voltage adjustment per Front panel Range selection

0.05 - 0.400

Range 1

0.40 - 3.20

Range 2

3.20 - 25.0

Range 3

25.0 - 200.0

Range 4

Front Panel Range Switch Settings (refer to page 9)

1– VDC OUT

2 – mA OUT

3 – FILTER

4 – FILTER

5 – mA IN

5

4-20

20 Hz

20 Hz

4-20

10

4-12-20

200 Hz

2 Hz

4-12-20

Up Function Down

RANGE VDC INPUT 67

0.05 – 0.40

0.40 – 3.20

3.20 – 25.0

25.0 – 200.0

1

2

3

4

Page 16

Model 3760 DC VOLT & 4-20mA PANEL METER

Page 17

The 3760 contains a "calibration switch" which is accessed by removing the rear panel of the instrument.

This switch is used to set the range of the front panel pushbutton (and rear remote control) of the CAL /

Remote CAL function of the 3760 instrument. The "calibration" switch is recommended to be set at the

same value (0 thru F) as the front panel's "Wide Span" control. At this setting, the internal votlage

reference will produce approx. 80% of the full scale value of the calibrated unit. This allows the user to

produce a reference check of the instrument's calibration integrity.

FRONT CALIBRATION (RCAL) setting

Procedure should be done once the instrument has been calibrated per the instructions above.

To access the "calibration switch":

1) Remove power from the instrument.

2) Record the postition of the front panel "Wide Span" control....... 0 thru F position.

3) Remove the 4 phillips head screws retaining the back panel of the instrument

4) Remove the rear panel (with slides) and rotated away from the instrument. Locate the blue

rotary switch to the bottom right of the instrument and set the switch to the "Wide

Span" control position as noted in Step 2.

When complete, re-assemble the back panel and slides.

Re-energize the instrument.

With your "zero" input active, depress the front "CAL" button, or the rear panel "Remote CAL" logic and

record the value on the display. This will be your calibration reference number. If any changes are made to

the front panel controls, this reference number will change reflecting a "calibration" change has occurred to

the 3760 unit.

Rear Panel 3760

5. FUSE REPLACEMENT

Should you suspect a blown fuse proceed as follows.

WARNING

Installation, operation and maintenance of this instrument must be performed by qualified personnel

only. The National Electrical Code defines a qualified person as “one who has the skills and knowledge

related to the construction and operation of the electrical equipment and installations, and who has

received safety training on the hazards involved.”

a) Disconnect all power sources and cables connected to the instrument before servicing the instrument.

b) On the rear panel remove the (2) clamp slide retaining screws and remove the clamp slides from both sides of the

instrument. Next remove the (4) corner screws that retain the rear panel to gain access to the instrument.

c) Open the rear panel and replace the fuse(s) as required , replace only with same type T Slow Blow, 1A, 250V

(Littelfuse 218001.HXP, 1 A). The fuseholder wire conductors are appropriately labeled “L” for Line and “N” for

Neutral on both halves of each of the fuseholder wires. When reassembling the fuseholder(s) make sure “L” and

“L” are connected together and “N” and “N” labeled wires are connected together properly.

d) Mate the rear panel to the enclosure and replace the clamp slides back in position and secure the clamp slides

with the (2) screws previously removed from the instrument. Next, replace the (4) corner screws to secure the

rear panel and ensure that all screws have been adequaetely tightened.

e) Power ON the instrument with the appropriate power cord and verify the instrument is functioning properly

before reconnecting the instrument to your installation.

WARNING

For continued protection against risk of fire or shock replace only with the same type and rating

of fuse.

ADVERTENCIA

Para la protección continua contra el peligro de incendio o descarga, cambie sólo por fusibles

del mismo tipo y capacidad nominal.

AVERTISSEMENT

Pour assurer une protection continue contre les risques d’incendie ou de choc, ne remplacez que

par un fusible du même type et de la même valeur nominale.

WARNUNG

Zum anhaltenden Schutz gegen Brand oder einen elektrischen Schlag nur gegen eine Sicherung

desselben Typs und mit demselben Nennwert austauschen.

Page 18

Model 3760 DC VOLT & 4-20mA PANEL METER

WARNING

Do not replace fuse again if failure is repeated. Repeated failure indicates a defective condition that will not clear

with replacement of the fuse. Refer condition to a qualified technician.

ADVERTENCIA

No reemplace el fusible nuevamente si se repite la falla. La repetición de las fallas indica una condición defectuosa

que no se subsanará con el cambio del fusible. Acuda a un técnico calificado para evaluar la condición.

AVERTISSEMENT

Ne remplacez pas le fusible une nouvelle fois si la défaillance se répète. Une défaillance répétée indique une

condition défectueuse qui ne disparaîtra pas avec le remplacement du fusible. Consultez un technicien qualifié.

WARNUNG

Die Sicherung nicht erneut austauschen, wenn der Fehler noch einmal auftritt. Ein wiederholtes Auftreten des

Fehlers weist auf einen Defekt hin, der sich nicht durch Austauschen der Sicherung beheben läßt. Den Defekt

einem qualifizierten Techniker mitteilen.

Page 19

Model 3760 DC VOLT & 4-20mA PANEL METER

Other manuals for 3700 Series

1

This manual suits for next models

2

Table of contents

Other DayTronic Controllers manuals