Controlli W554C User manual

Other Controlli Controllers manuals

Controlli

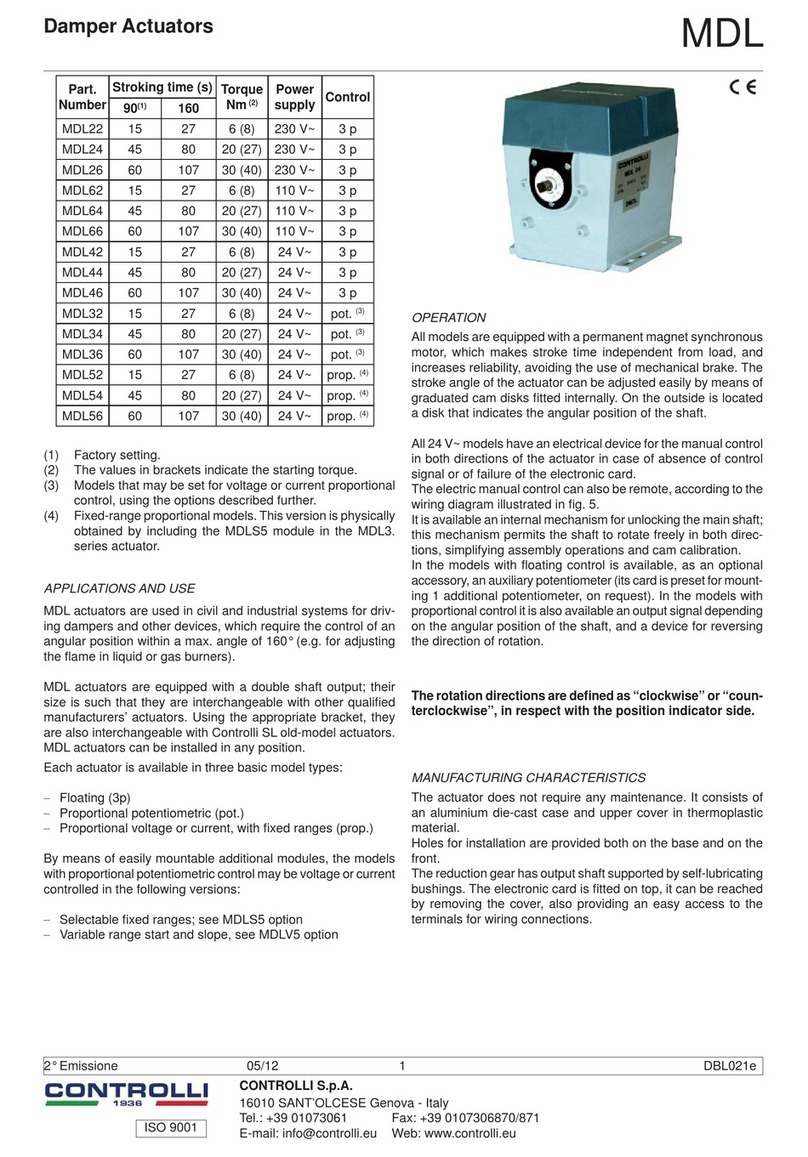

Controlli MDL46 User manual

Controlli

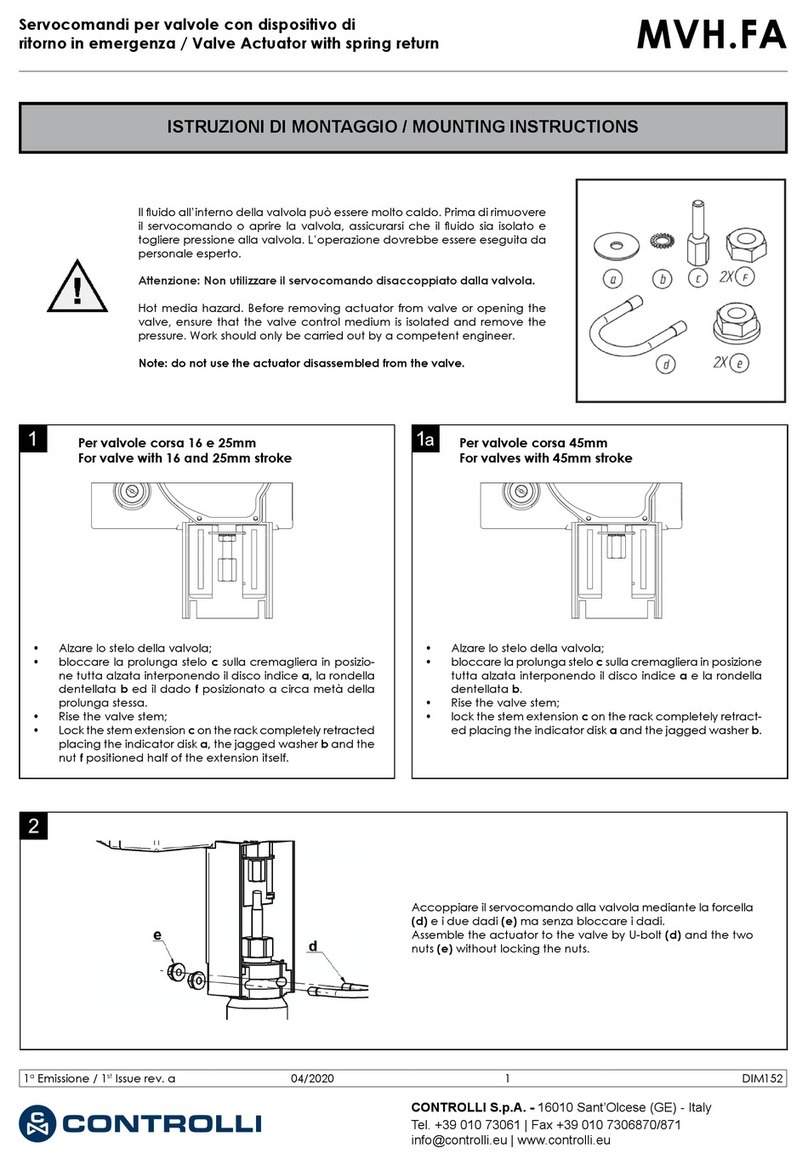

Controlli MVH User manual

Controlli

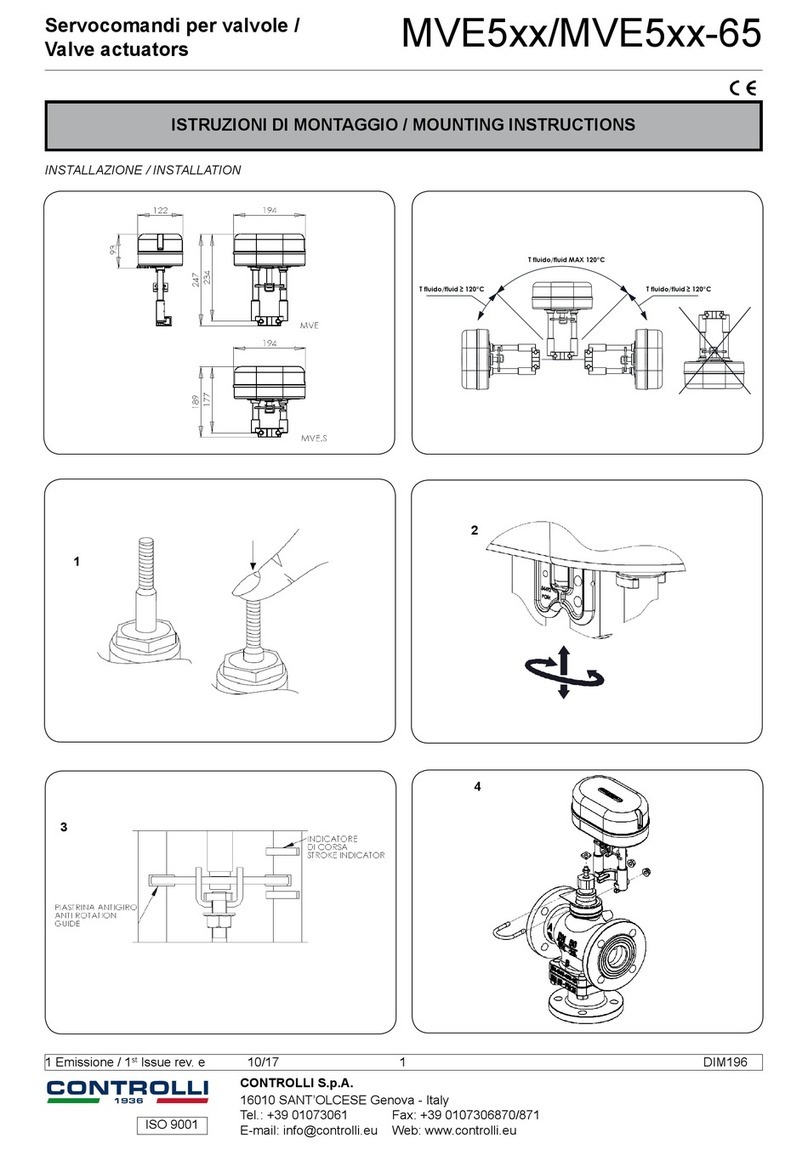

Controlli MVE5 Series User manual

Controlli

Controlli Energon NR9001 User manual

Controlli

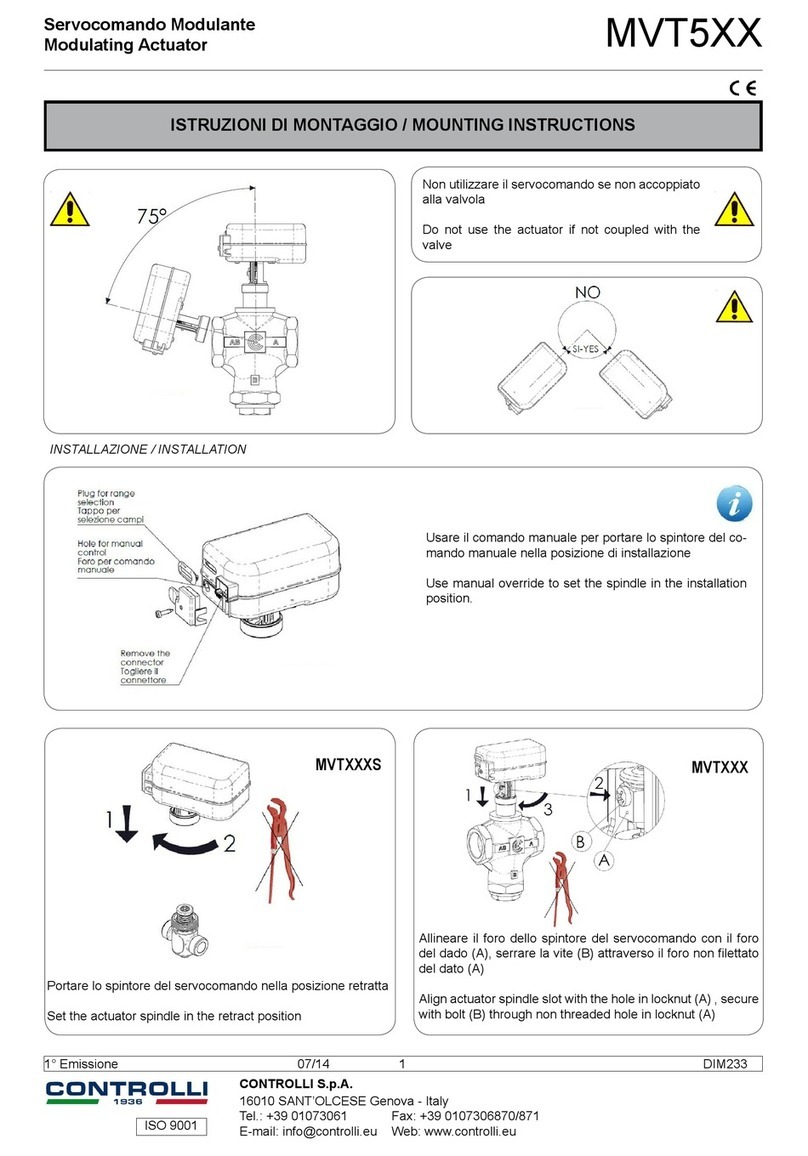

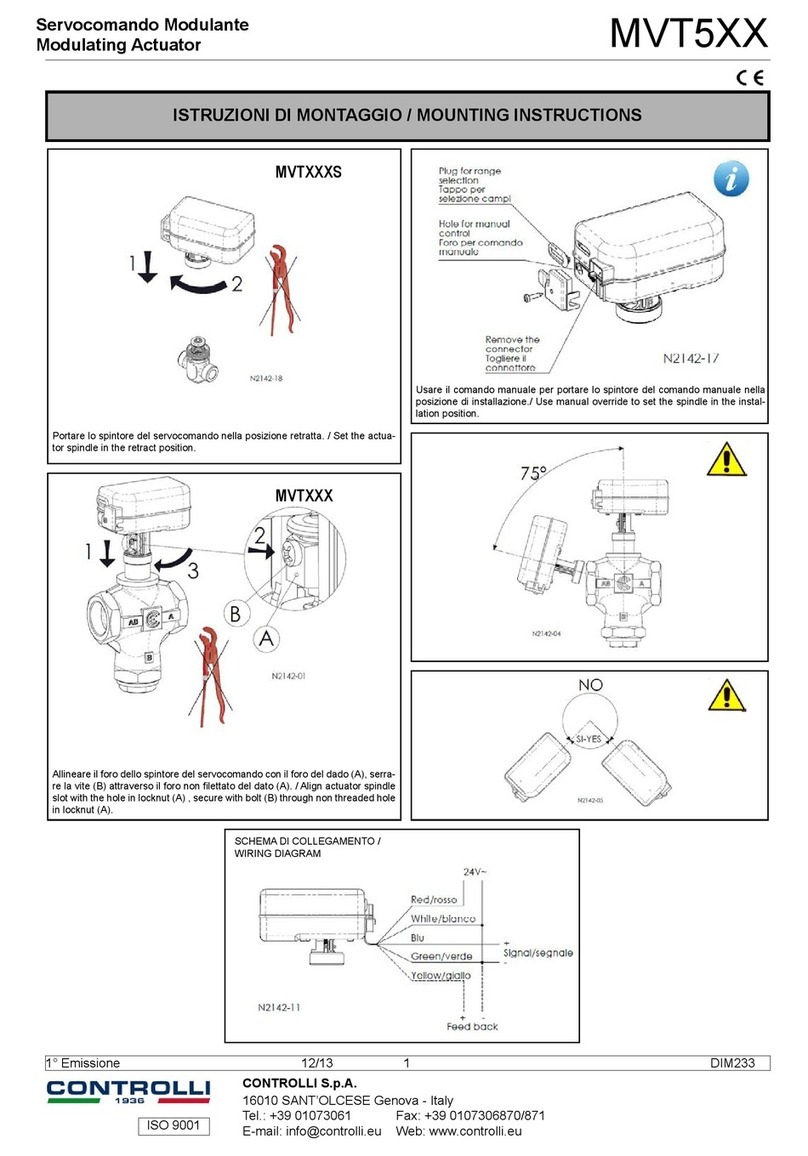

Controlli MVT5 Series User manual

Controlli

Controlli MVH.FC User manual

Controlli

Controlli MVHFA User manual

Controlli

Controlli MVE2-65 Series Owner's manual

Controlli

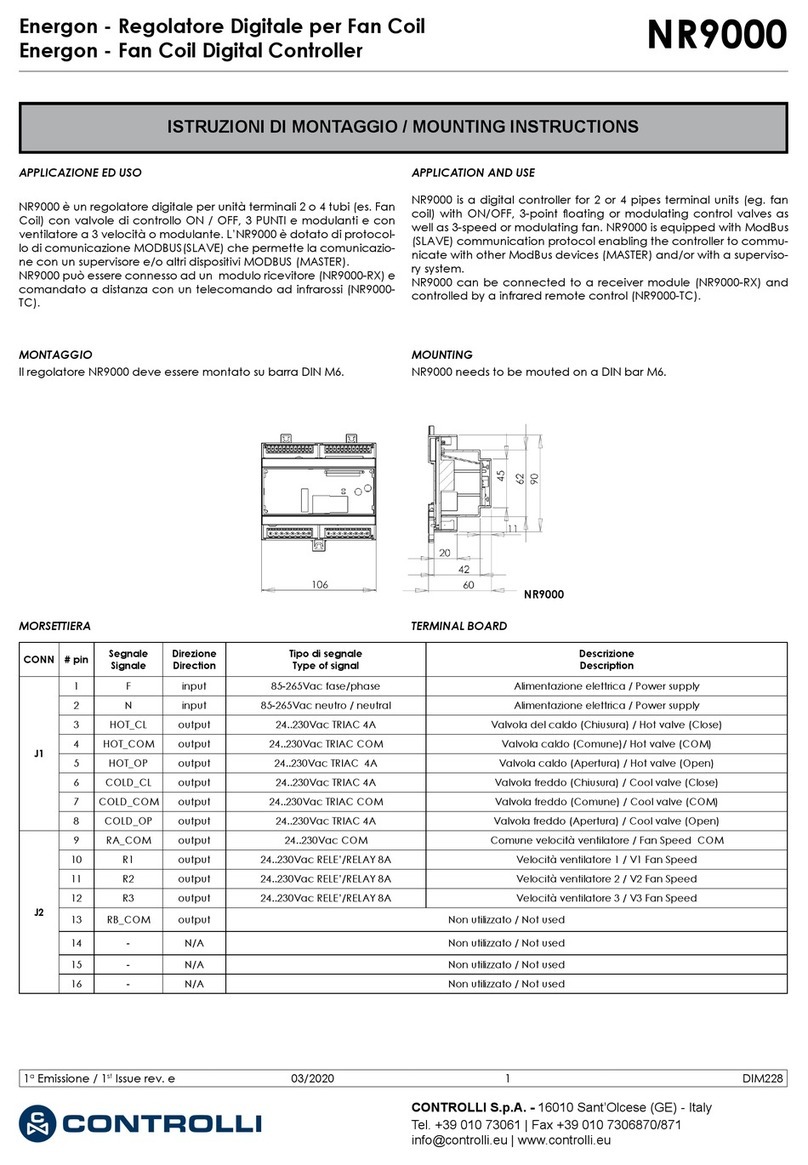

Controlli NR9000 User manual

Controlli

Controlli MVE2 Series User manual

Controlli

Controlli MVE5-65 Series User manual

Controlli

Controlli MVH56E User manual

Controlli

Controlli NR9000 User manual

Controlli

Controlli SH 2 Series User manual

Controlli

Controlli MVC503R-MB User manual

Controlli

Controlli Energon NR9001 User manual

Controlli

Controlli MVH56EA User manual

Controlli

Controlli MVE5 R Series User manual

Controlli

Controlli Energon User manual

Controlli

Controlli MVC503 User manual