DBA LaneWalker User manual

DBA LaneWalker Table of Contents

153-3000C (Rev 6:99)

Section I · Introduction ...................................................................................................... 1

A. OVERVIEW ...................................................................................................................................................................1

B. MACHINE SPECIFICATIONS ...........................................................................................................................................1

C. CARE AND SAFETY PROCEDURES .................................................................................................................................2

Section II · Machine Description ....................................................................................... 3

A. BUFFING END /DUSTER END /RIGHT SIDE /LEFT SIDE................................................................................................3

B. KEYPAD .......................................................................................................................................................................4

C. BUFFING END COMPONENTS ........................................................................................................................................6

D. DUSTER END COMPONENTS.........................................................................................................................................7

E. UNDERSIDE COMPONENTS (BOTTOM) ..........................................................................................................................9

Section III · Pre-Installation Suggestions....................................................................... 10

Section IV · Operating Instructions ................................................................................ 11

A. TURNING THE UNIT ON..............................................................................................................................................11

B. MENU SELECTIONS AND OPTIONS..............................................................................................................................11

C. KEYPAD DISPLAY.......................................................................................................................................................14

1. Operator’s Menu...................................................................................................................................................14

2. Lino Control Menu................................................................................................................................................17

3. Odometer Menu.....................................................................................................................................................18

4. Override Auto Program ........................................................................................................................................19

5. Change Program Settings.....................................................................................................................................19

6. Change Auto Program Select................................................................................................................................23

7. Change Lane-to-Lane Distances...........................................................................................................................25

8. System Control Lino Duster..................................................................................................................................27

9. Clear Maintenance Messages ...............................................................................................................................28

Section V · Adjustments .................................................................................................. 29

A. BUFFING BRUSH REPLACEMENT AND ADJUSTMENT...................................................................................................29

B. DUSTER CLOTH REPLACEMENT AND ADJUSTMENT....................................................................................................29

C. DUSTER CLOTH COUNTER..........................................................................................................................................30

D. FILLING OF CONDITIONER TANK.................................................................................................................................30

E. WICKING ADJUSTMENTS.............................................................................................................................................30

Section VI · Maintenance................................................................................................. 31

A. CARE OF THE POWER CORD .......................................................................................................................................31

B. WICKING PADS ...........................................................................................................................................................31

C. BUFFING BRUSH.........................................................................................................................................................32

D. SENSORS ....................................................................................................................................................................32

E. LANE-TO-LANE WHEELS ............................................................................................................................................32

F. DRIVE WHEELS...........................................................................................................................................................32

G. “HOPPING”WHEELS...................................................................................................................................................32

H. INSIDE MACHINE ........................................................................................................................................................32

I. AUTOMATIC MAINTENANCE CHECKS ..........................................................................................................................33

Section VII • DBA LaneWalker Maintenance Inspections..............................................34

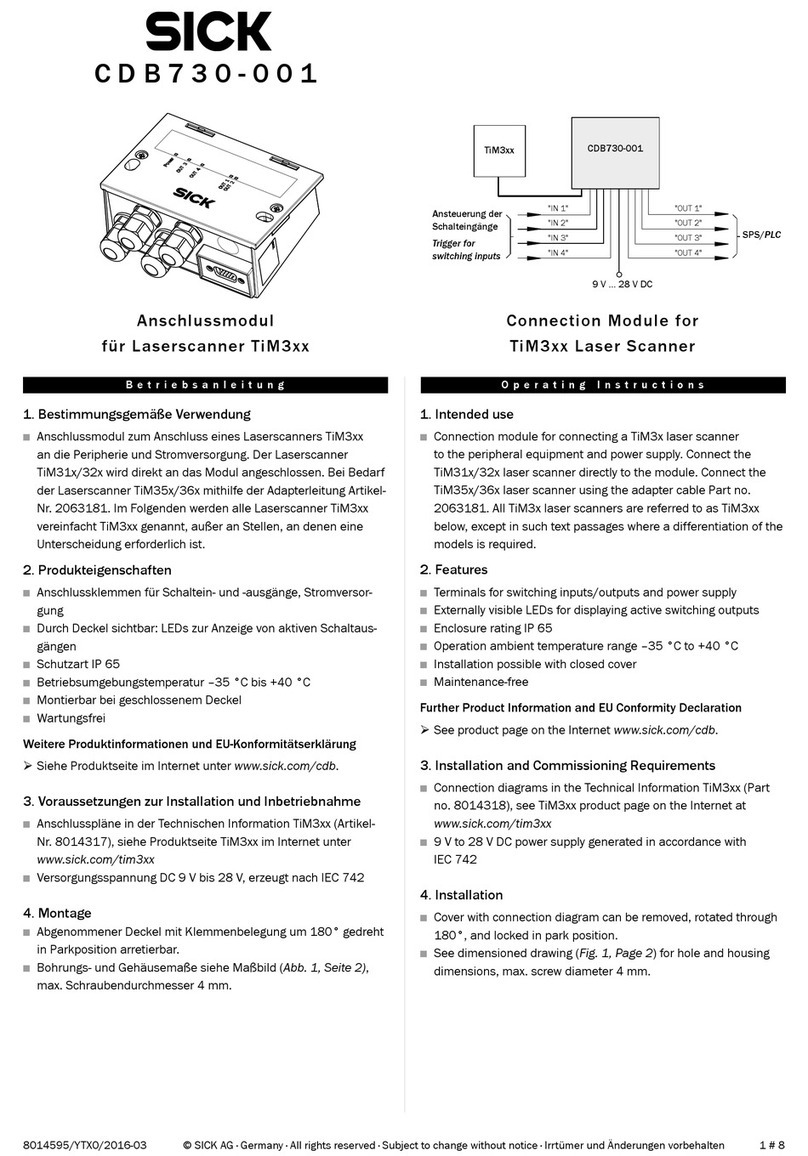

Section VIII • Inputs and Outputs ....................................................................................39

• Inputs ..............................................................................................................................40

1. LDS (LANE DISTANCE SENSOR) .................................................................................................................................40

2. ADS (APPROACH DISTANCE SENSOR) ........................................................................................................................40

3. WPS (WHEEL POSITION SENSOR)...............................................................................................................................40

4. CORD HOLDER SHUT-DOWN SWITCHES......................................................................................................................41

5. ON THE LANE SWITCH................................................................................................................................................41

6. WIND UP MICROSWITCH.............................................................................................................................................41

• Outputs............................................................................................................................42

1. WICKING PAD SOLENOIDS...........................................................................................................................................42

2. CR1 CONTROL RELAY #1............................................................................................................................................42

3. CR2 CONTROL RELAY #2............................................................................................................................................42

4. CR3 CONTROL RELAY #3............................................................................................................................................42

5. CR4 CONTROL RELAY #4............................................................................................................................................42

6. LANE TO LANE MOTOR ..............................................................................................................................................42

7. BUFFER MOTOR ..........................................................................................................................................................42

Section IX · Troubleshooting...........................................................................................43

Section X · Error Messages .............................................................................................44

Section XI · Worksheets...................................................................................................45

A. LEFT-TO-RIGHT TRAVEL WORKSHEETS ......................................................................................................................46

B. RIGHT-TO-LEFT TRAVEL WORKSHEETS.......................................................................................................................48

C. FACTORY-SET CONDITIONING PROGRAMS &GRAPHS...............................................................................................51

Section XII · Mechanical Drawings....................................................................................1

1999 The Kegel Company, Inc.

DBA LaneWalker Model C Operating Manual ·Page 1

Section I · Introduction

A. Overview

The DBA LaneWalker “Model C” represents advanced technology in automated lane

conditioning. Through the use of an on-board programmable computer, a “user-friendly”

keypad to input data and information, and a patented conditioner transfer system, the

LaneWalker allows the bowling center to maintain consistent bowling conditions.

With the expandability of the LaneWalker’s Programmable Computer, future

upgrades are possible, assuring that your LaneWalker will not become obsolete.

IT IS EXTREMELY IMPORTANT THAT THE OPERATOR

THOROUGHLY READ AND UNDERSTAND THIS OPERATING

MANUAL BEFORE USING THE LANEWALKER.

Should you have any questions regarding any procedures pertaining to the proper

operation of this machine, please contact your authorized Distributor.

B. Machine Specifications

Power Supply: Class I –Single Phase

110-120 Volts, 50/60 Cycle, 10 Amps

Dimensions: Width - 57-¾”

Height - 13”

Length –29-¾”

Weight - 300 pounds

DBA LaneWalker Model C Operating Manual ·Page 2

C. Care and Safety Procedures

This machine is manufactured of the highest quality materials, but keep in mind that

the DBA LaneWalker is a sensitive piece of equipment. Care should be taken to see that it

is not dropped, knocked around, or handled roughly. Doing so may damage the

programmable computer, its components, or the conditioner transfer system.

For care and safety reasons, see that the following precautions are exercised:

· AVOID SPILLING ANY LIQUIDS OR CHEMICALS INSIDE OF THE MACHINE

· DO NOT OPERATE THE LANEWALKER WITH AN EXTENSION CORD OR

POWER CORD OTHER THAN THE ONE PROVIDED

· DO NOT OPERATE THE LANEWALKER WITH POWER CORD SHUT-DOWN

SWITCHES DISCONNECTED

· MAKE SURE THAT THE POWER OUTLET USED PROVIDES THE CORRECT

VOLTAGE AND AMPERAGE

· DO NOT ATTEMPT TO MAKE ANY WIRING MODIFICATIONS

· DO NOT ATTEMPT TO RE-PROGRAM THE COMPUTER

· DO NOT OPERATE THE LANEWALKER IN AN UPRIGHT POSITION

Not following the above recommendations may cause damage to the LaneWalker,

its computer, those persons operating it, or void the warranty.

Persons assigned the responsibility of operating the DBA LaneWalker should be

trained in its use by an authorized factory-trained Distributor.

DBA LaneWalker Model C Operating Manual ·Page 3

Section II · Machine Description

A. Buffing End / Duster End / Right Side / Left Side

With the machine sitting on the approach in a position ready to be operated on the

first lane, the following descriptions will be used:

· BUFFING END: The BUFFING END shall be the end of the machine closest to the

operator and nearest the approach, where the buffing brush is located.

· DUSTER END: The DUSTER END shall be the end opposite the buffing end and

nearest to the pins, where the DMR duster assembly is located.

· RIGHT SIDE: The RIGHT SIDE of the LaneWalker shall be the side where the

keypad is located, to the right of the operator as they face the pins.

· LEFT SIDE: The LEFT SIDE of the LaneWalker is the side opposite the right, to

the left of the operator as they face the pins.

· REAR: Items in or toward the buffing end are in the REAR of the LaneWalker

(toward the approach).

· FRONT: Items in or toward the duster end are in the FRONT of the LaneWalker

(toward the pins).

DBA LaneWalker Model C Operating Manual ·Page 4

B. Keypad

Located on the right side of the buffing end of the LaneWalker is the computer

keypad. This keypad is used to enter all programming information, as well as to start the

machine on the first lane.

The keypad consists of 10 input keys and a two-line Liquid Crystal Display (LCD)

where the menu items and prompts appear.

The following keys are used on the keypad:

· NEXT: Use this key to advance within a main menu from one menu prompt to the

next.

· ENTER: This key is used to complete an entry of data or information requested

by a menu prompt.

· MAN or MANUAL: This key starts the manual modes accessed in the

LaneWalker’s programs, such as manually walking across the approach.

· LAST: This key will return the user to the last menu prompt within a main menu.

· START: This key will start the LaneWalker.

· MENU: This key will display and advance the available main menus for the

operator.

· UP & DOWN ARROWS: Use of these keys will increment or decrement numbers

asked for in certain menu prompts, such as starting lane number, walking distance

from one lane to the next, etc.

· LEFT & RIGHT ARROWS: Use of these keys will input left or right movement

during manual operation on the approach. They also can be used when entering the

starting and ending lane numbers from the OPERATORS MENU. The left arrow will

display “Lane #1”, while the right arrow will display the last lane in the center.

The following keys may also be used on the keypad when trouble-shooting or

updating the program:

· SHIFT

· HR

· DM

· CHANNEL

· CONTACT

DBA LaneWalker Model C Operating Manual ·Page 5

· CHANGE

· SET

· MONITOR

· RESET

· UP

· CLEAR

· WRITE

· DOWN

LaneWalker Keypad Overlay

DBA LaneWalker Model C Operating Manual ·Page 6

C. Buffing End Components

Located on the buffing end of the LaneWalker are the following components:

· DISTANCE WHEELS: Located on the outside rear wall of the buffing end and

mounted on the ends of the lifting handle are the distance wheels. These wheels measure

the distance the LaneWalker travels down the lane. This is done through the use of an

infra-red sensor mounted near the center of the counting shaft.

· POWER SWITCH: Mounted on the right side of the rear wall under the buffing end

hood is the power switch. This switch also controls which power inlet on the LaneWalker

will be “live”. Flip the switch in the direction of travel to activate the correct inlet. For

example, if lanes are being conditioned from left to right, flip the switch to the right and the

left inlet will become “live”.

· FUSES: Mounted near the power switch are two fuses. One fuse protects the PC

COMMON (6 Amp) and one fuse protects the DC Speed Control Board (4 Amp - Ceramic).

Replace with Slow Blow fuses of the same type and amperage size.

· CONDITIONER TANK: Under the lid located towards the rear of the buffing end is

the conditioner tank and fill tube assembly. This tank, including wicks, holds slightly under

¾ gallon of lane conditioner when full.

· WICKING PADS: Located on the front edge of the oil tank are the six wicking pad

assemblies. Each individual wick sits inside the conditioner tank and draws conditioner

through the wick to pass on to the transfer roller. There are two pads which are

approximately 10 lane boards wide, two pads which are approximately 7 boards wide, and

two pads approximately 3 boards wide. From right to left, these pads shall be referred to

as Right Outside (7 boards), Right Track (3 boards), Right Inside (10 boards), Left Inside

(10 boards), Left Track (3 boards), and Left Outside (7 boards).

· TRANSFER ROLLER: Resting against the wicking pads is the conditioner transfer

roller. This stainless steel roller is chain driven and pulls conditioner off the wicking pads

and transfers it onto the buffing brush.

· BUFFING BRUSH: Located near the rear wall as you open the buffing lid is the

buffing brush assembly. The belt-driven buffing brush removes conditioner from the

transfer roller and places it onto the lane surface.

DBA LaneWalker Model C Operating Manual ·Page 7

D. Duster End Components

Descriptions are given when looking into this compartment from the front wall of the

LaneWalker. The following components are located under the lid on the duster end of the

LaneWalker:

· LIFTING DUSTER ASSEMBLY: Located nearest the operator across the duster

end is the patented DMR (Dual Motor Ratcheting) duster cloth assembly. The DMR

assembly operates by means of two duster motors: the first which unwinds cloth; and the

second which winds up used cloth onto the used core. This dual action simulates that of a

ratcheting duster, helping to eliminate dirt lines during a conditioning run. The system also

better controls cloth usage, and has no clutch mechanism to adjust.

The LaneWalker should ALWAYS be operated with duster cloth in the machine!

This will prevent excess dirt and dust build up on the wicking pads and the lane. Operating

without cloth will also cause unnecessary drag on the LaneWalker and its motors.

The LaneWalker can use DBA Red Edge Cloth #8443 or #8441.

Approximately 1-1/2” to 1-3/4” of cloth is used per lane

depending on the distance of travel.

· DUSTER UNWIND MOTOR: Mounted on the far left hand side of the duster

assembly is the duster unwind motor. This motor supplies fresh duster cloth before the

LaneWalker travels down the lane.

· DUSTER WIND-UP MOTOR: Mounted on the far right hand side of the duster

assembly is the duster wind-up motor. This motor takes up the used cloth and lifts the

cushion roller off the lane.

· PROGRAMMABLE COMPUTER: Located near the center of the duster end is the

LaneWalker Programmable Computer (PC).

WARNING: The PC contains a Lithium battery. When it is replaced, the old battery

should be discarded in accordance with local regulations.

· DRIVE MOTOR: On the left side of the duster end is the drive motor. This two-

speed motor drives the LaneWalker up and down the lane and onto the approach. The

drive motor also drives the transfer roller.

· LANE-TO-LANE MOTOR: Mounted on the outer right side of the duster end is the

lane-to-lane motor. This motor drives the LaneWalker on the approach from one lane to

the next.

DBA LaneWalker Model C Operating Manual ·Page 8

· BUFFING MOTOR: Just to the left of the lane-to-lane motor is the buffing motor.

This motor drives the buffing brush.

· PC POWER SUPPLY: Located just to the left of the buffing motor is the

PC Power Supply. This power supply converts 115V AC into the 24V DC needed to

operate the PC.

· SPEED CONTROLS: Located between the PC and the PC Power Supply is the

Drive Motor Speed Control Assembly. The trimpot nearest the Power Supply is the HIGH

Speed Control, and the trimpot nearest the PC is the LOW Speed Control. The LOW

Speed Pot regulates the motor speed as the LaneWalker moves from the lane onto the

approach. The HIGH Speed Pot regulates the speed of travel on the lane surface itself.

This control is normally set at its highest speed, but can be used to slow down the Drive

Motor to achieve more “buffs per foot”, thus creating a different conditioning pattern.

· BUFFING MOTOR CONTACTOR: Just in front of the PC Power Supply is the

Buffing Motor Contactor. When actuated under power, it will operate the buffing motor.

· POWER CORD HOLDER: Mounted on the center wall is the power cord holder.

The holder can be swiveled either to the right or left side of the machine depending on

the direction in which lanes are being conditioned.

· POWER CORD SHUT-DOWN SWITCHES: Mounted on both the right and left

outside walls of the duster end are the power cord shut-down switches. Under normal

operation, the power cord holder will rest on one of these switches. In the event the cord is

stepped on, or caught on a foul light or capping, the cord holder will actuate the switch,

immediately shutting down the machine.

· WICKING SOLENOIDS: Mounted on the center wall across the duster end from

right to left are the six wicking solenoids. Each solenoid controls one wicking pad. The

pads are designated as Right Outside, Right Track, Right Inside, Left Inside, Left Track,

Left Outside.

DBA LaneWalker Model C Operating Manual ·Page 9

E. Underside Components (Bottom)

Located on the underside of the LaneWalker are the following components:

· DRIVE SHAFT: Located toward the center of the bottom, close to the duster cloth

assembly is the drive shaft. This shaft is driven by the drive motor. An infra-red sensor

mounted near the drive sprocket indicates the position of the walking wheels.

· DRIVE WHEELS: Mounted on the drive shaft approximately ¼ of the way in from

the side walls are the two drive wheels. These wheels are powered by the drive shaft and

drive the LaneWalker up and down the lane.

· WALKING WHEELS: Located on each end of the buffing brush are two of the

walking wheels; two additional walking wheels are located on end of the drive shaft. The

walking wheels move the LaneWalker off the lane surface and onto the approach area.

· LANE-TO-LANE WHEELS: Located on the far right and far left side, near the

buffing brush, are the lane-to-lane wheels. The left-side lane-to-lane wheel is chain-driven

by the lane-to-lane motor and moves the LaneWalker from one lane to the next. The other

lane-to-lane wheel (on the right side) counts the distance traveled on the approach with an

infra-red sensor.

· LANE-TO-LANE CASTERS: Located toward the bottom of the underside, slightly

to the middle are two lane-to-lane casters. These casters stabilize the LaneWalker as it is

driven from one lane to the next by the lane-to-lane wheels.

· GUIDE ROLLERS: Located on either side of the drive shaft are four UHMW guide

rollers. These spring-loaded rollers help guide the machine as it travels on the lane.

DBA LaneWalker Model C Operating Manual ·Page 10

Section III · Pre-Installation Suggestions

Preparation of the Bowling Lanes

Prior to operating the LaneWalker for the first time, it is highly recommended that a

thorough inspection of the bowling lane and approach area take place. All loose foul lights,

divisions, cappings and adapter blocks should be tightened, repaired or replaced.

The machine is equipped with a shut-down switch in the event the power cord gets

caught on loose items. However, continued operation of the LaneWalker on improperly

prepared lanes could cause damage or malfunction. Please contact your Distributor

should you need assistance with repair or replacement of these items.

DBA LaneWalker Model C Operating Manual ·Page 11

Section IV · Operating Instructions

A. Turning the Unit On

Carefully set the LaneWalker in the operating position on the approach. Line up the

machine on the approach so that the side walls will enter the lane area an equal distance

or flush with the foul lights on both sides. The LaneWalker should be completely on the

approach, with the duster end being approximately 3 to 4 feet behind the foul line.

Connect the power cord to the LaneWalker, and attach the cord to the power cord

holder. The power cord holder should be swiveled to the side of the LaneWalker which will

be opposite the direction of travel from lane to lane. For example, if you are conditioning

lanes from left to right, the cord should be located on the left side of the machine. Be

certain that the power cord holder is resting correctly on top of the shut-down switch on the

side being used.

Connect the power cord into a suitable outlet. MAKE SURE THAT THE OUTLET IS

SUPPLYING THE CORRECT VOLTAGE AND AMP RATING. Connecting the power cord

into an outlet located towards the center lanes of the establishment will allow more lanes to

be conditioned without changing outlets. The 180 foot power cord supplied with the

LaneWalker will allow 48 lanes to be conditioned without changing outlets.

(To accomplish conditioning 48 lanes the LaneWalker should be plugged into an outlet at

approximately Lane 20. This will allow enough cord to be placed out of the LaneWalkers

path as it conditions lanes 1-20.)

Open the buffing end lid of the LaneWalker and turn the power switch to the correct

position, pointed toward the direction of travel. Both the green LED and the menu screen

on the keypad will illuminate indicating power to the machine. Now the LaneWalker is

ready to run.

B. Menu Selections And Options

The operation of the DBA LaneWalker is controlled by a series of selectable

programs located within the memory of the programmable computer. These programs and

settings may be changed or modified by following a simple sequence of prompts within the

available menus displayed on the keypad. This section will lead the operator step-by-step

through each menu and prompts.

The LaneWalker PC is equipped with a Lithium 5-year rated battery for back-up and

retention of information which is input into the memory. Dispose of used battery properly.

To make this section easily understandable, the operator should be familiar with the

keypad as detailed in Section II of this manual.

DBA LaneWalker Model C Operating Manual ·Page 12

DBA LaneWalkerOperators Menu Selections

* OPERATORS *

0600 MENU LW4.2

* LINO CTRL&RSET *

0600 HIT MAN ENT

ODOMETER

0000 FT 0000 MI

STARTING LANE ?

01 01

LAST LANE ?

00 00

RUN LAST PROGRAM

01 00 00

DBA LaneWalker Model C Operating Manual ·Page 13

DBA LaneWalkerManagers Menu Selections

* OVERRIDE AUTO

PROGRAM?

* CHANGE PROGRAM

SETTINGS

* CHANGE AUTO

PROGRAM SELECT

* CHANGE

LN TO LN DIST?

* SYSTEM CONTROL

LINO DUSTER

* TO CLEAR MAINT

MESG HIT MAN KEY

CHOOSE PROGRAM #

00 00

CHANGE PROGRAM #

00 00

MON AM1 PRGRM#00

LANES 00 THRU 00

L-R HIT RT ARROW

R-L HIT LF ARROW

PRESENT DUSTER

09 UNWND TIME 09

PRESS MAN KEY

RUN LINO DUSTER?

01 1-YES,0-NO 01

MON AM2 PRGRM#00

LANES 00 THRU 00

LAN00TO LANE 00

0000 COUNTS 0000

DEFAULT DUSTER

09 UNWND TIME 09

TRAVEL DIST.

00 00

MON AM3 PRGRM#00

LANES 00 THRU 00

CONTINUES

LINO EMPTY # LNS

0600 DEFAULT0600

RO OIL DIST.

00 00

MON PM1 PRGRM#00

LANES 00 THRU 00

FOR

RT OIL DIST.

00 00

MON PM2 PRGRM#00

LANES 00 THRU 00

EACH

RI OIL DIST.

00 00

MON PM3 PRGRM#00

LANES 00 THRU 00

LANE

LO OIL DIST.

00 00

CONTINUES

LT OIL DIST.

00 00

FOR

LI OIL DIST.

00 00

EACH

RO RETURN OIL

00 00

DAY

RT RETURN OIL

00 00

OF

RI RETURN OIL

00 00

THE

LO RETURN OIL

00 00

WEEK

LT RETURN OIL

00 00

LI RETURN OIL

00 00

2ND RUN TRVL DST

00 00

2ND RT OIL DST

00 00

2ND RI OIL DST

00 00

2ND LT OIL DIST

00 00

2ND LI OIL DIST

00 00

DBA LaneWalker Model C Operating Manual ·Page 14

C. Keypad Display

The keypad display is a two line LCD (Liquid Crystal Display). During operation and

selection of programs, various prompts, which are simply questions or data requests, will

appear in the display, along with possibly some numbers. The prompts will request the

operator to input or change data or information within the selecting menu. The numbers

will display conditioning program numbers, distances (feet) or “counts”. What the prompts

and numbers mean for each menu is explained under each menu heading in this section.

When the numbers appear, there will often be two numbers, both the same,

displayed in the LCD. When this occurs, both numbers refer to the current setting for that

particular prompt. When changing the setting with the use of the UP or DOWN ARROWS,

only the number on the right side of the display will change. The number on the left will

remain at the previous setting until the ENTER key is pressed, at which time both numbers

will change to the new setting.

THE FOLLOWING MENU SELECTIONS

CAN BE ACCESSED BY THE OPERATOR

1. Operator’s Menu

The Operators Menu will display the time remaining on the current duster cloth roll,

the conditioning program being used, and allow the operator to select the starting and

ending lane number. The LaneWalker is also started from this menu.

Once the LaneWalker is turned on, OPERATORS MENU will appear on the two-line

LCD of the keypad. Also appearing will be a four digit number on the left hand side of the

second line. This number designates the number of lanes of usable cloth remaining on the

current duster roll. It will appear similar to the following:

* OPERATORS MENU *

0045 MENU LW4.2

The “0045” means that approximately 45 lanes are left on the current roll of cloth.

The “4.2” refers to the program version of Kegel ThoughtWare currently installed in the

LaneWalker PC.

DBA LaneWalker Model C Operating Manual ·Page 15

To begin operation of the LaneWalker, press NEXT on the keypad. The following

prompt will appear:

STARTING LANE ?

00 00

The LaneWalker is asking the operator to input the starting lane number. Also

appearing in the LCD Display will be two numbers, one on the lower left side and one on

the lower right side. These numbers indicate the starting lane number the last time the

LaneWalker was operated. If these numbers are not the starting lane numbers for this

conditioning run, they must be changed.

To change the starting lane number, push either the UP ARROW or DOWN

ARROW. The number on the lower right hand side of the LCD will change, while the

number on the left side will remain the same. (The left number will always remain the

same while the right number is being changed until the ENTER key is depressed.)

NOTE: When entering the starting lane number, depressing the Left Arrow key on

the keypad will automatically input “Lane #1” as the starting lane. Depressing the Right

Arrow key will input the number of the last lane in the center.

Once you have reached the desired starting lane number, press ENTER. Now both

the right and left side numbers should be the same as the new starting lane number you

selected. If this is correct, depress the NEXT key.

The following prompt will appear:

LAST LANE ?

00 00

Now you must input the number of the last lane to be conditioned. Appearing with

the above prompt will again be two numbers, this time displaying the number of the last

lane conditioned during the previous run of the LaneWalker. If these numbers are

incorrect, you must enter the correct number. Using the UP or DOWN ARROWS again,

change the number to the number desired. Once again, only the right side number will

change.

NOTE: When entering the last lane number, depressing the Left Arrow key on the

keypad will automatically input “Lane #1” as the starting lane. Depressing the Right Arrow

key will input the number of the last lane in the center.

DBA LaneWalker Model C Operating Manual ·Page 16

Once you reach the desired number, depress ENTER, and both numbers will

change to the one you selected. If this is correct, depress the NEXT key.

At this point, this prompt will appear:

RUN LAST PROGRAM

01 24 01

Along with this prompt, the starting lane number, last lane number and conditioning

program number will appear in the LCD. (The example above shows the LaneWalker

starting on lane #1, ending on lane #24, and applying conditioning program #1.)

If the starting and ending lane information is incorrect, depress the LAST key until

you return to the starting and ending lane number prompts. If the conditioner program is

incorrect, it will be necessary to access the Managers Menus to change the program

selection. Once all information is acceptable, depress the START key and the LaneWalker

will begin its operation. (IMPORTANT! The “ENTER” key MUST be depressed to accept

starting and ending lane information, even if new starting and ending lane numbers are not

needed. If the “ENTER” key is not depressed, the LaneWalker will not start.)

NOTE: Manual operation of the LaneWalker can also be done from the

Operators Menu.

To manually operate the LaneWalker in the forward, reverse, right or left direction,

depress the “MAN” key while OPERATORS MENU is displayed on the screen.

The following will appear:

* MANUAL OVERIDE

ONE HOP-ONE LANE

Depress the “RIGHT” arrow to move the LaneWalker to the right, the “LEFT” arrow

to move to the left, the “UP” arrow to move forward, or the “DOWN” arrow to move

backwards. The LaneWalker will move side to side approximately one lane, or one “hop”

forwards or backwards, depending on the directional key depressed.

For continuous manual operation, depress the NEXT key while in the above screen.

The following will appear:

DRIVE RPM 0000

CONTINUOUS RUN

Now when a directional key is depressed, the LaneWalker will move in that direction

until stopped. To stop the LaneWalker, simply depress any key on the keypad or pull on

the power cord holder to actuate the cord-holder shut-down switch.

DBA LaneWalker Model C Operating Manual ·Page 17

When the LaneWalker is operated in the manual mode, a tachometer is available to

assist in adjusting the high and low speed settings of the drive motor. The tachometer

appears on the first line of the keypad screen during a continuous run.

When adjusting for low speed travel on the approach, the tachometer should read

between 42 and 46. If the speed is set too slow, an error message may occur. If too fast,

crooked approach travel or pre-mature wheel wear may occur.

2. Lino Control Menu

Depress the MENU key until the following appears on the screen:

* LINO CTRL&RSET

0600 HIT MAN ENT

To reset the cloth counter, depress the MAN then ENTER keys while this screen is

displayed. Be certain to perform this procedure each time a new roll of duster cloth is

installed in the LaneWalker. When reset, the counter will read “0600”.

NOTE:If usable duster cloth still remains after counting down from “0600”, reset the

counter, then note how many additional lanes can be conditioned before cloth runs out.

After noting the additional lanes of cloth, access the SYSTEM CONTROL LINO DUSTER

Menu. Within this menu access the LINO EMPTY # LANES DEFAULT screen. By using

the Up or Down Arrow, change the default value to the correct number of lanes of cloth.

When this screen is displayed, the UP and DOWN ARROWS will NOT operate the

duster motors. A red push button on each Model C duster plate will operate the motor

when depressed. These buttons will work any time power is applied to the machine.

DBA LaneWalker Model C Operating Manual ·Page 18

3. Odometer Menu

Depress the MENU key until the following screen appears:

ODOMETER

0000 FT 0000 MI

The Odometer will display the feet and miles the LaneWalker has traveled up to that

point.

THIS CONCLUDES ALL MENUS AND FUNCTIONS

ACCESSIBLE BY THE OPERATORS PASSWORD!

TO ACCESS THE FOLLOWING MENU SELECTIONS, IT WILL BE

NECESSARY TO INPUT THE MANAGERS PASSWORD!

The Managers Password is a series of three key entries on the keypad which will

allow access to the LaneWalker Manager Menus. To enter the password, the keypad LCD

must be displaying the LINO CTRL&RSET screen. The factory-set password information

is recorded in the Quality Control Inspection envelope which is included with this manual.

To have the Managers Password changed, please contact your Authorized LaneWalker

Distributor.

Table of contents

Popular Control Unit manuals by other brands

Nortek

Nortek GoControl PS15EMZ5-1 instructions

DX Engineering

DX Engineering DXE-RCA8C-SYS-4P manual

Agilent Technologies

Agilent Technologies 355C Installation, operating and service manual

SEI Industries

SEI Industries BAMBI MAX Service manual

DRAGONFRAME

DRAGONFRAME DMC-16 Z-Turn instructions

Bradley

Bradley EFX 125 Installation