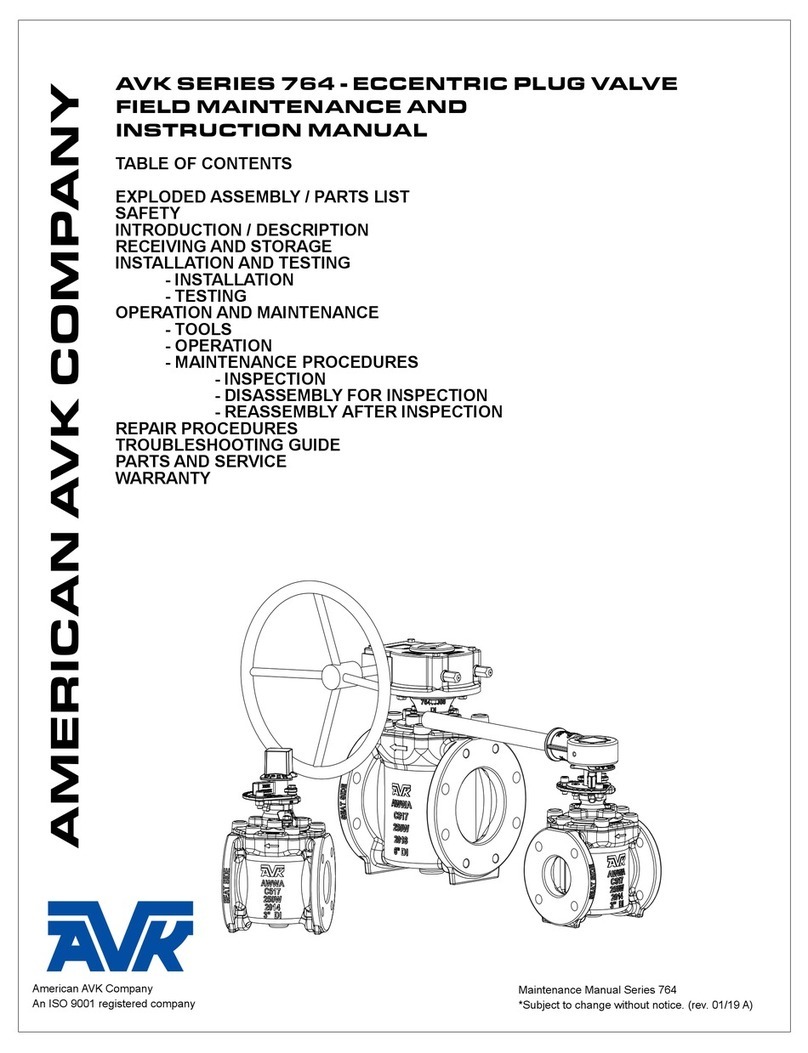

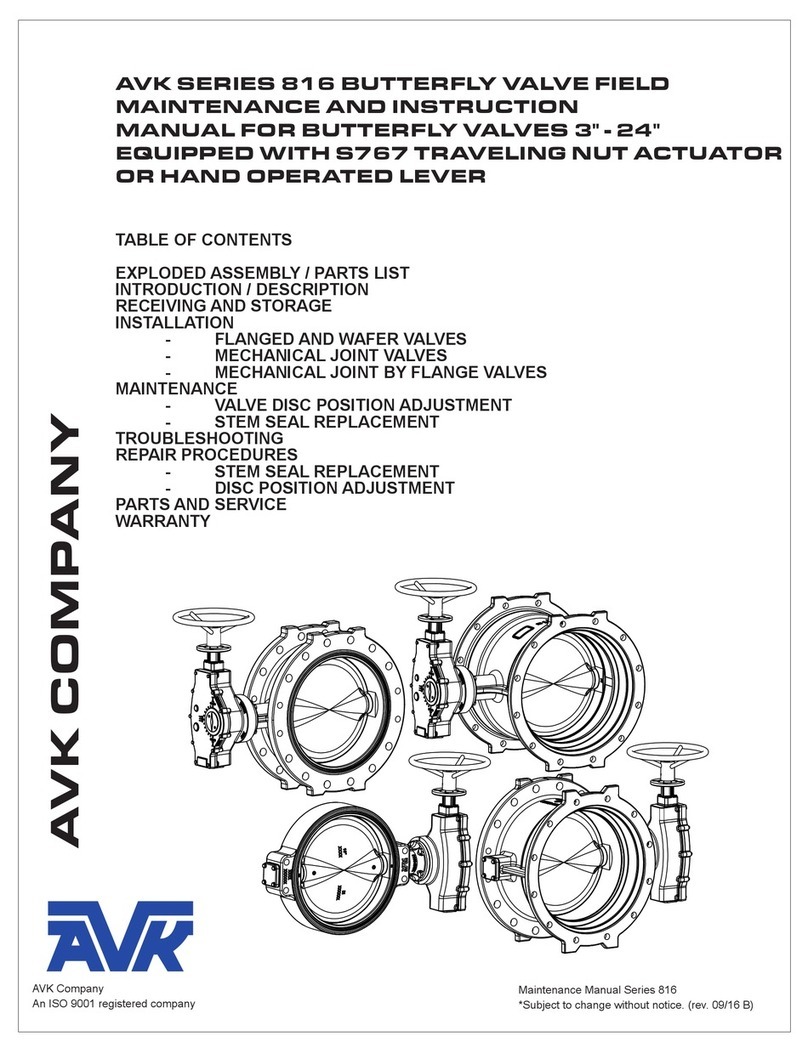

INSTALLATION, OPERATION AND MAINTENANCE MANUAL – ORIGINAL VERSION

AVK GATE VALVES FOR WATER AND FIRE PROTECTION

SERIES 145

Page 10/12 MI GateValve 145 rev. AC 2020 GB

7.2 OS&Y VALVE REPAIRS

7.2.1 HANDWHEEL REPLACEMENT (Fig. 5A and 5B)

WARNING

To perform the following steps, make sure that the water

main supply line has been shut off and that the pressure has

been bled off!

NOTE

As most OS&Y valves are used in fire protection applications,

verify that any alarm system has been disabled prior to

performing any maintenance or repair.

1. Remove the hot melt glue that covers the bonnet bolts

(F216) using a small, flat bladed screwdriver (Fig. 5A).

2. Once the hot melt glue has been removed, use a 5/16”

(8mm) Allen wrench to remove the DN65 valve bonnet

bolts (F216) and a 3/8” (10mm) Allen wrench for valve

sizes DN80-200.

3. Turn the remaining part of the handwheel (F202) in the

closing direction. This will lift the yoke/bonnet (F263)

head assembly, allowing removal of the upper stem nut

(F201) from the stem assembly (F215).

4. Remove the upper half of the stem nut (F201) from the

handwheel and place it in the new handwheel (F202).

NOTE: The stem nut pair is keyed with different sized

lugs. Make sure to align the lugs in the correct location

(Fig. 5B)!

5. Align the upper stem nut (F201) with the lower stem nut

(F205), and ensure that there is full engagement of the

lugs.

6. Carefully turn the handwheel (F202) in the opening

direction until the yoke/bonnet (F263) is fully down and

resting on the body (F219).

CAUTION: When lowering the head assembly back on

the body, ensure that the bonnet gasket (F218) is not

damaged.

7. Install the bonnet bolts (F216), ensuring they are inserted

through the bonnet gasket (F218) and tighten in a

diametrically opposite pattern.

8. To replace the protective hot melt glue over the bonnet

bolts, use any EPA approved caulk or hot melt glue.

9. Repressurise the system. If there is a leak around the

stem seal O-ring area, make sure that the upper gland

follower bolts (F261) are screwed down evenly into the

bonnet/yoke (F263). Tighten the nuts 1/4 turn each until

the leak stops.

NOTE: Since UL, ULC and FM approvals are for the

manufacturer, this procedure will have no effect on

listings or approvals.

page 10

OS&Y (Outside Stem & Yoke) VALVE REPAIRS:

HANDWHEEL REPLACEMENT (Figs.6A,6B)

WARNING: To perform the following steps, be sure the Water

Main Supply Line has been shut off, and that the pressure has

been bled off!

NOTE: As most OS&Y valves are used in fire protection

applications, verify that any alarm systems have been

disabled prior to performing any maintenance or repairs.

1. Using a small, at bladed screwdriver, remove the hot melt

glue that covers the Bonnet Bolts (F216).

( See Fig. 6A )

2. Once the hot melt glue has been removed, use 5/16", or 8mm

Allen wrench to remove the 2½" valve Bonnet Bolts (F216),

and a 3/8”, or 10mm Allen wrench for valve sizes 3"- 8".

3. Turn the remaining part of the Handwheel (F202) in the

closing direction. This will lift the Yoke/Bonnet (F263) head

assembly, allowing removal of the Upper Stem Nut (F201),

from the Stem Assembly (F215).

4. Remove the upper half of the Stem Nut (F201) from the

handwheel and place it in the “new Handwheel” (F202).

NOTE: The Stem Nut pair are keyed with different sized lugs.

Be sure to align the lugs in the correct location!

(See Fig. 6B)

5. Align the Upper Stem Nut (F201), with the Lower Stem Nut

(F205), And insure that there is full engagement of the lugs.

6. Carefully turn the Handwheel (F202) in the opening direction

until the Yoke/Bonnet (F263), is fully down and resting on the

Body (F219).

CAUTION: When lowering the head assembly back on the body,

take care to ensure that the Bonnet Gasket (F218), is not

damaged.

7. Install the Bonnet Bolts (F216), taking care to ensure they are

inserted through the Bonnet Gasket (F218), and tighten in a

diametrically apposed pattern.

8. To replace the protective hot melt glue over the Bonnet Bolts,

use any EPA approved caulk, or hot melt glue.

9. Repressurize the system. At this time, if there is a leak

around the Stem Seal O-ring area, be sure that the upper

Gland Follower Bolts (F261) are screwed down evenly in to

the Bonnet/Yoke (F263). Tighten the nuts 1/4 turn each until

the leak stops.

NOTE: Since UL , ULC and FM Approvals are for the

Manufacturer, this procedure will have no effect on

listings or approvals.

Fig. 6A

Fig. 6B

F201

F202

F263

F215

OS&Y Stem Nut Pair (F201

andF205) are drilled and

tapped as a pair

F201

F205

F205

F219

Fig. 5A

page 10

OS&Y (Outside Stem & Yoke) VALVE REPAIRS:

HANDWHEEL REPLACEMENT (Figs.6A,6B)

WARNING: To perform the following steps, be sure the Water

Main Supply Line has been shut off, and that the pressure has

been bled off!

NOTE: As most OS&Y valves are used in fire protection

applications, verify that any alarm systems have been

disabled prior to performing any maintenance or repairs.

1. Using a small, at bladed screwdriver, remove the hot melt

glue that covers the Bonnet Bolts (F216).

( See Fig. 6A )

2. Once the hot melt glue has been removed, use 5/16", or 8mm

Allen wrench to remove the 2½" valve Bonnet Bolts (F216),

and a 3/8”, or 10mm Allen wrench for valve sizes 3"- 8".

3. Turn the remaining part of the Handwheel (F202) in the

closing direction. This will lift the Yoke/Bonnet (F263) head

assembly, allowing removal of the Upper Stem Nut (F201),

from the Stem Assembly (F215).

4. Remove the upper half of the Stem Nut (F201) from the

handwheel and place it in the “new Handwheel” (F202).

NOTE: The Stem Nut pair are keyed with different sized lugs.

Be sure to align the lugs in the correct location!

(See Fig. 6B)

5. Align the Upper Stem Nut (F201), with the Lower Stem Nut

(F205), And insure that there is full engagement of the lugs.

6. Carefully turn the Handwheel (F202) in the opening direction

until the Yoke/Bonnet (F263), is fully down and resting on the

Body (F219).

CAUTION: When lowering the head assembly back on the body,

take care to ensure that the Bonnet Gasket (F218), is not

damaged.

7. Install the Bonnet Bolts (F216), taking care to ensure they are

inserted through the Bonnet Gasket (F218), and tighten in a

diametrically apposed pattern.

8. To replace the protective hot melt glue over the Bonnet Bolts,

use any EPA approved caulk, or hot melt glue.

9. Repressurize the system. At this time, if there is a leak

around the Stem Seal O-ring area, be sure that the upper

Gland Follower Bolts (F261) are screwed down evenly in to

the Bonnet/Yoke (F263). Tighten the nuts 1/4 turn each until

the leak stops.

NOTE: Since UL , ULC and FM Approvals are for the

Manufacturer, this procedure will have no effect on

listings or approvals.

Fig. 6A

Fig. 6B

F201

F202

F263

F215

OS&Y Stem Nut Pair (F201

andF205) are drilled and

tapped as a pair

F201

F205

Fig. 5B