DC Power Solutions B-COOL9000RM-12V User manual

INDEX:

Introduction & Company information...............................................................4

Safety instructions.............................................................................................. 5

Parts List .............................................................................................................. 6

B-COOL 9000 Specifications ............................................................................. 7

Parts List .............................................................................................................. 8

Installation............................................................................................................ 9

Technical & Install Specifications............................................................... ...10

Fault analysis.................................................................................................... 11

Operating Instructions......................................................................................12

Compressor / Trouble shooting ......................................................................13

Air Conditioner /Trouble shooting..................................................................14

Refrigerant Leakage..........................................................................................15

Maintenance.......................................................................................................16

SALES

OFFICE: 604-599-9200

MOBILE: 778-233-3905

For Sales Information:

Introduction

B-C OOL9000 is a fully self-contained –one piece - roof mount AC unit, available in 12 and 24 volts with

an inside cab air diffuser, ready to connect wire harness / battery cable and fuse block and comes pre-

charged with R134a refrigerant.

In other words –our roof mount air conditioner comes ready to go.

DC Power Solutions provides this document for informational purposes only. DC Power Solutions has

devoted significant time and effort to compile manuals (Installation, Maintenance and Trouble-shooting) to

assist customers with the installation of the AC and product usage. However, DC Power Solutions makes

no representations warranties expressed or implied with respect to the information, recommendation s

and descriptions contained within this and other documents. Information from the manuals should at no

time be regarded as covering all contingencies. If you are in need of additional information, contact DC

Power Solutions directly.

DC Power Solution’s warranty shall not apply to any product which has been installed, maintained,

repaired or altered in a manner as to affect the product’s integrity. Any alteration of these products and

deviation from suggested installation process without written approval will void DC Power solution’s

warranty.

DC Power Solutions accepts no liability to any person or entity for personal injury of any kind, property

damage, or any other direct, indirect, special, or consequential damages whatsoever arising out of the

use of the manuals or deriving from any information, recommendations or descriptions contained in the

manuals.

To ensure the durability of DC Power Solutions products, please follow and understand the instructions

within the manuals.

Recycle and dispose of the air conditioning unit properly to help keep the environment healthy.

There are Federal, Provincial and State regulations regarding the disposal of refrigeration /AC machines.

Consult a professional and ensure they follow the laws when disposing of the refrigeration/AC unit.

4

Recommendations / Safety instructions

The installation must be performed by a qualified

professional.

Switch off / disconnect the battery before installation

and performing maintenance work.

Wear goggles and gloves for the installation of this

product or disassembly an item for repair.

ATTENTION: The unit must be cooled before any work

is performed. Some parts are hot and can cause burns.

ATTENTION. Do not remove any protection provided

on the unit. This could cause serious injury.

ATTENTION: The unit is heavy. Do not handle or

install the unit alone.

5

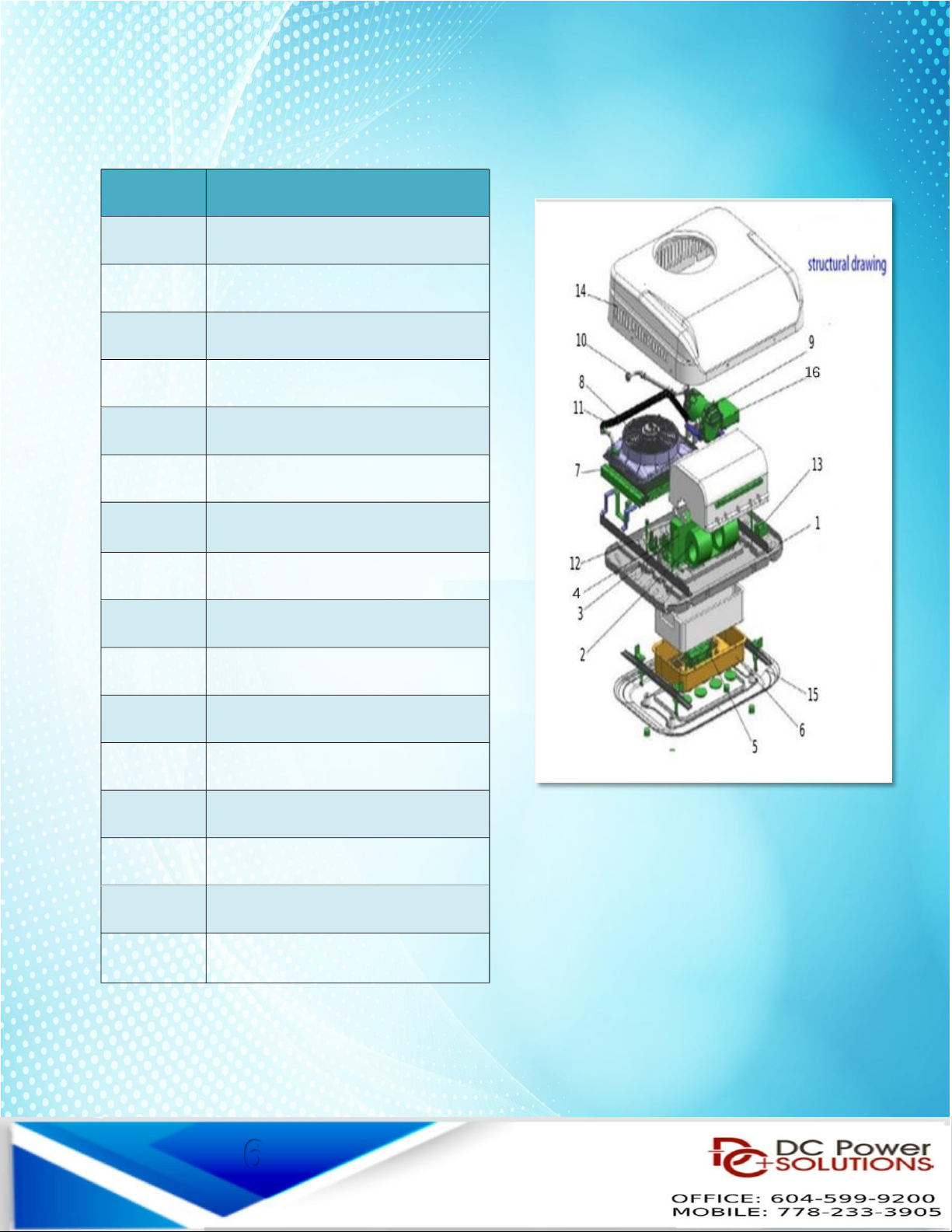

Parts List

6d

Item PART LIST

1 ase frame

2 lower motor

3 External Motor assembly

4 Expansion valve

5 Evaporator

6 Internal cover

7 Condenser

8 Condenser fan 12V/24V

9 Compressor 12V/24V

10 Piping

11 Hose

12 Dryer

13 Thermostat

14 Top cover

15 Decorative Cover

16 Compressor Controller

6

-Cool 9000 - Fully Self-Contained - 100% Electric

MODEL # -COOL9000RM12V -COOL9000RM24V

Voltage 12V 24V

Compressor type 25cc Electric scroll

compressor

25cc Electric scroll

compressor

Max. current 70amps 40 amps

Working current 50-70 amps 15-40 amps

Freon type R134a R134a

Freon amount 650g 650g

Cooling capacity 10,230 TU/h 10,230 TU/h

Evaporator air

flow

800m³/hr (470cfm) 800m³/hr (470cfm)

Condenser air

flow

2400m³/hr (1410cfm) 2400m³/hr (1410cfm)

Climate controller yes yes

Remote

controller

yes yes

AC roof top

dimensions

96cm L x 72cm W x 16.5cm H

(37.8 x 28.35 x 6.5 inches)

96cm L x 72cm W x 16.5cm

H (37.8 x 28.35 x 6.5

inches)

AC inside cabin

dimensions

50cm L x 34cm W x 11.4cm H

(19.7 x 13.4 x 4.5 inches)

50cm L x 34cm W x 11.4cm

H (19.7 x 13.4 x 4.5 inches)

AC unit net

weight

34.5 kg (76 lbs.) 34.5 kg (76 lbs.)

AC unit gross

weight

38 kg (83.75 lbs.) 38 kg (83.75 lbs.)

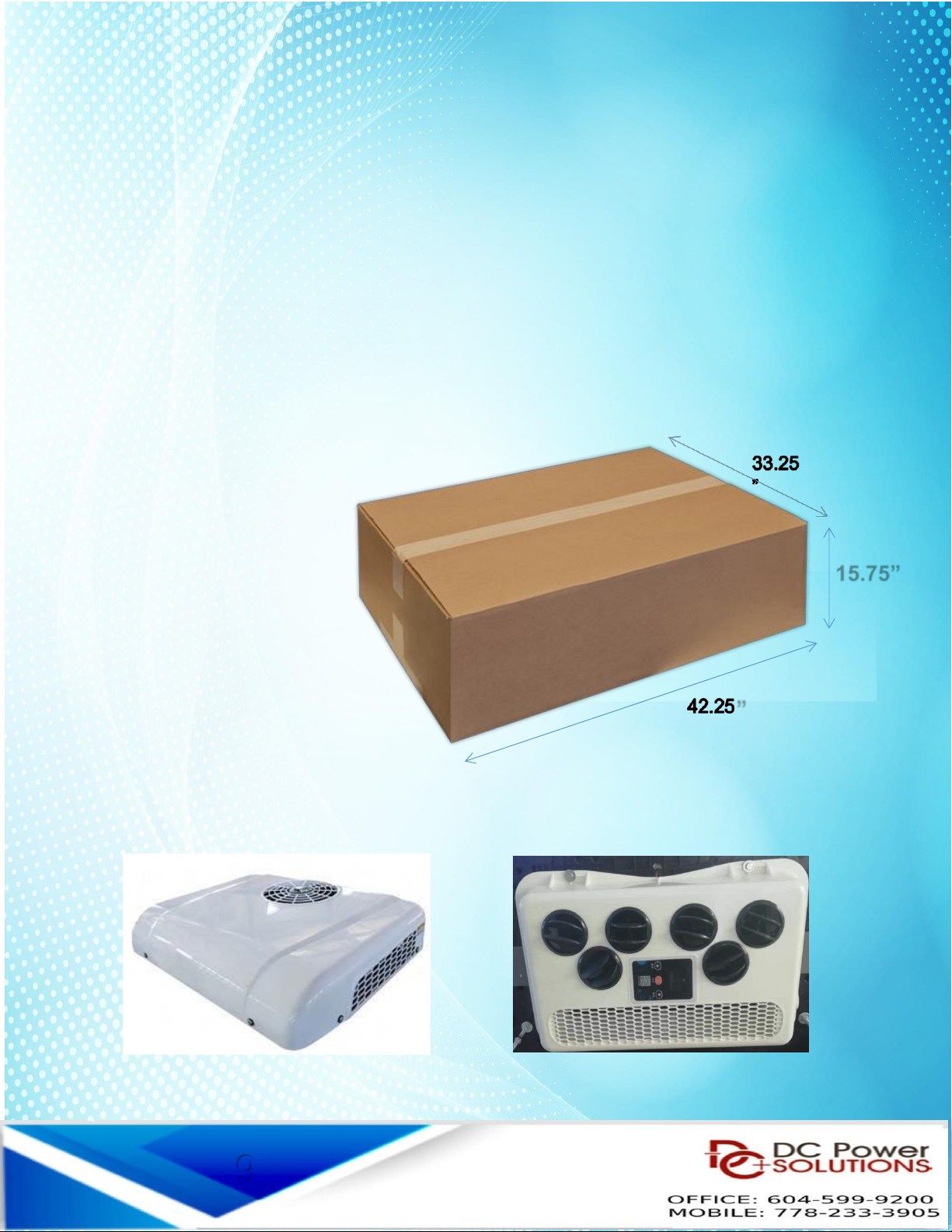

AC shipping box 107.5cm x 84.5cm x

40cm (42.3 x 33.25 x

15.75 inches)

107.5cm x 84.5cm x

40cm (42.3 x 33.25 x

15.75 inches)

7

Parts List & Numbers

8

Installation

Installation Conditions:

1. Read the Installat on sect on to understand how the un t s mounted and nstalled before start ng.

2. Mount ng surfaces must be clean and free of debr s.

3. Gather all equ pment needed for the nstallat on.

4. Ver fy roof s strong enough to support the roof mount AC un t and the we ght.

5. Please look to techn cal spec f cat ons for we ght and space requ rements

6. Make sure there s no nterference w th any OEM electr cal w r ng, supports, etc. before

dr ll ng or cutt ng nto the veh cle.

7. D scuss w th customer or cons der appl cat on, keep ng mportant spaces open and enough

clearance at doors / roof for easy use of the system.

8. Prepare add t onal mount ng hardware s nce there are d fferences between veh cle types,

models, and appl cat ons.

Useful tools & equipment

• Tape measure

• Ut l ty kn fe

• Dr ll/Impact gun

• Dr ll b t set

• Angle gr nder

• Wrench set

• Pl ers

• W re cutters

• W re cr mpers

Installation (Roof-top Unit)

Ma n components of One-P ece a r cond t oner

8

”

15.75”

9

Installation Instructions For B-COOL9000

MODEL #

B-COOL9000RM12V & B-COOL9000RM24V

Roof top hole - MAXIMUM. cut size

75cm x 50cm (29.5in. x 19.7in.)

Roof top hole - MINIMUM cut size

62cm x 36cm ---OR--- 24.4 x 14.2 inches

Once the cut is made, clean the area around the hole.

Remove all dust & dirt.

Apply sealant tape around the cut hole

Make sure there are no wrinkles or twist in the sealant tape

Before Installation

Place the air conditioner on the roof.

Keep in mind - the unit weighs 34.5kg or 76lbs. Get someone

to help you.

Fit the air conditioner over the cut-out area.

Attach the air conditioner with the 2 cross bars provided.

Last, install the decorative cover with the parts provided.

Connect the power wire to the automotive battery.

Run the power cables from the main or auxiliary batteries.

Check the polarity before installing the cables

Use the provided 100A Maxi type fuse between the vehicle

battery and the positive main wire

10

1

ERROR Codes displayed on the controller

If, while the air conditioner is running, any of the following codes appear on the

controller screen, please take the following steps as the code may indicate a serious

problem

1: STOP THE AIR CONDITIONER & POWER OFF.

2: AFTER 10 MINUTES POWER ON & START A/C

3: IF THE CODE PERSISTS - STOP A/C & POWER OFF

4: CONTACT REPAIR CENTER.

E01 - Voltage is too low - Charge the battery or Start the Eng ne

E02 - Evaporator blower is not operating. Check w r ng and voltage of the supply w r ng and repa r.

Also check blower and replace f defect ve.

H22 / H23 - Check evaporator nlet sensor by power ng down the a r cond t oner and restart the a r

cond t oner. If the code reappears t means that the sensor s defect ve or has become d slodged from the

evaporator co l.

E04 - Temperature sensor of the plenum

E05 - Compressor over temperature indicator. Th s w ll power off the un t unt l to compressor cools

down so as not to damage the un t. Th s may happen f the amb ent temperature s very h gh. Once the

compressor cools the un t w ll restart aga n.

E06 / E07 - Condenser fan is not operating. Check the w r ng and voltage. Also check fan as t may be

defect ve and needs to be replaced

E09 - Condenser fan control board s defect ve and should be replaced.

E10 - Condenser fan fa lure - Replace the condens ng fan motor

E11 - The condenser fan is not operating. Check the w r ng for damage.

NOTE: If the number flashing on the indicator is not shown in this table, please replace the

compressor control panel

11

OPERATING INSTRUCTIONS

Functions of the Control panel & the Remote Control

Turn on A/C: Press On / Off button to turn on A/C (long press)

Check H gh/Low Pressure

Normal range: H/P 1.2 - 1.4 L/P 0.2 - 0.25

Temperature setting:

A) Cl ck the Temp. button (Arrow down) to set the temperature after

start ng the A r Cond t oner

B) After cl ck ng the down button, cl ck the DOWN button

or the UP button to set des red temperature (18°C [66°F] – or h gher)

Speed setting:

A) Cl ck the Speed button (Arrow up) to set speed after start ng the A r

Cond t oner

B) After cl ck ng the up button, cl ck the DOWN button or

the UP button to adjust the speed

Voltage setting:

A) After start ng the A r Cond t oner, cl ck the ON / OFF

button 3 t mes to enter the voltage sett ng

B) Cl ck the DOWN button or the UP button to set the

voltage

NOTE: Sw ng Flap, T med off , T med on – NO FUNCTION

12

Compressor Troubleshooting

Flash 1x

Standby

5x

Compressor Case temperature is too high- Lack of

refrigerant or dirty condenser

6x

Open circuit of cooling fan - Bad contact of

electromagnetic fan plug

7

x

Short circuit of cooling fan - Short circuit in the motor or

short circuit in the connection line.

9x

Condenser fan controller failure

10x

Condenser fan failure

11x

Condenser fan lost contact

13

Troubleshooting - Air conditioners

If any of the following situations occur during the use of air

conditioners, please find out a solution by following the index

If it’s a fault, Please contact the tech. / repair center.

Condition Solution

If the cooling

effect is not good

Select the right mode and set proper temperature and speed.

Check if there is any obstruction at the air inlet and outlet

Check if the surface of the condenser is too dirty

Check if it is short of refrigerant and if the high and low

voltage is within the normal range

There is water on

the surface of

indoor unit

When running in an environment with high humidity, water

drops may form on at the air outlet and core surface, which

is a normal physical phenomenon

Check battery for low voltage and verify the power source is

either DC 12V or 24V

The indoor unit

displays voltage

fault

Check if the low voltage protection value is too high

Check if the sensor at air inlet / outlet is plugged in correctly

The indoor unit

displays sensor

fault

Check if the display temperature is higher than normal

ambient temperature. If it is, change the sensor.

The indoor

unit displays fan

fault

Check if the fan is correctly plugged in. Connect the fan with

a separate 12V or 24V DC power source. If the fan doesn’t

work, replace fan.

Installation and User Manual for vehicle Electric Air – Conditioners

The indoor unit

displays outdoor unit

fault

Check if it is short of refrigerant.

Check if the high and low voltage is within the normal range.

Check if the condenser is too dirty - so that heat dissipation

is adversely affected.

14

The -COOL9000 unit comes pre-charged. However, should a leak or an

Incident occur during shipping, the following steps must be taken.

Leak Testing

1 - Refr gerant volume (check w th level glass)

2 - If volume s low or s lower than the prev ous check, nvest gate poss ble

leak by look ng for traces of o l.

3 - Attach the n trogen tank to the low s de port.

4 - Perform a leak test by pressur ng the system to 200 ps and then check for leaks

at each f tt ng and connect on and throughout the evaporator and condenser co ls.

5 - The system should hold pressure for at least 15 m nutes.

6 - Somet mes, but rarely, the un t could be damaged dur ng sh pp ng.

7 - If there are no leaks, evacuate the system.

Evacuate System

Evacuate the ent re system wh le meet ng local refr gerant handl ng standards.

We recommend at least 30-45 m nutes vacuum before charg ng.

After the un t s empty, move to charg ng the system and charge t w th 650g of

R134a refr gerant.

Charge the System

The system should be charged by a qual f ed A/C techn c an and

follow the gu del nes for R134a Freon.

15

Maintenance:

Before beg nn ng clean ng, make sure the a r cond t oner s

turned off, powered off

1) Surface Cleaning of inside unit:

W pe w th a clean damp cloth.

The cloth can be d pped n a m ld clean ng solut on f the un t s very d rty.

2) The core of evaporation chamber is too dirty.

Check for d rt and debr s n the evaporator, clean w th compressed a r f

necessary.

3) Outdoor unit cleaning:

Remove the top cover and clean the condenser w th compressed a r.

Pay attent on not to damage the condenser co l.

4)Long time not in use:

Unplug the a r cond t oner and wrap the outdoor un t to avo d any phys cal

damage

5) Using after long time not in use:

Clean the un t body condenser and evaporat on un t. Check for s gns of any

fore gn matter at the a r nlet or outlet of the un t. Check f the dra n s clear;

Install remote controller, make nspect on and power t on.

Tips:

Maintain the AC unit frequently - at least once every 2 months,

If you operate the AC in a dusty - dirty environment more

frequent cleaning will be required.

Check for blockage on top and bottom of the condenser fan,

the condenser coil and air flow before and after the evaporator

blower.

16

Other manuals for B-COOL9000RM-12V

1

This manual suits for next models

1

Table of contents

Other DC Power Solutions Automobile Accessories manuals