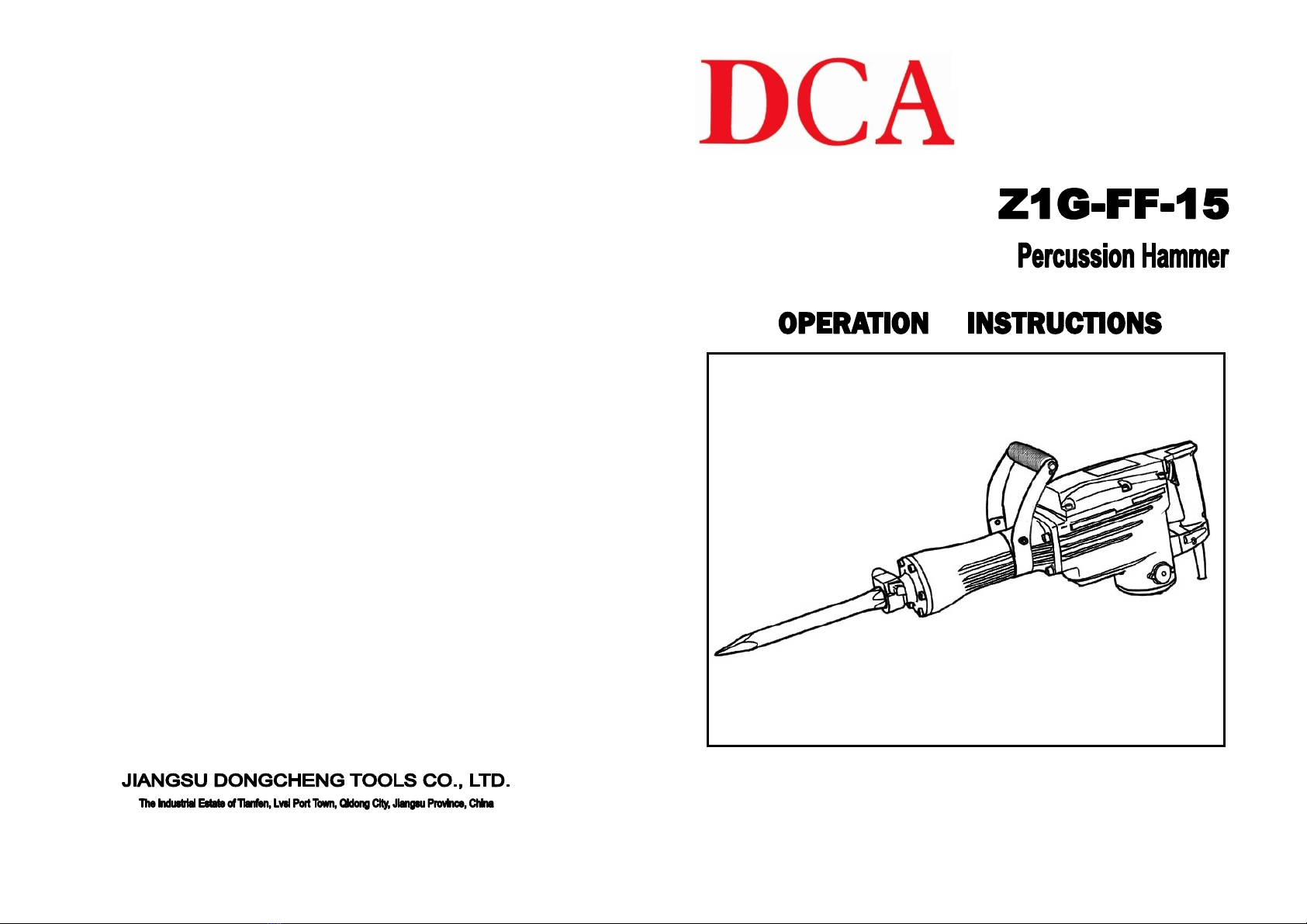

DCA Z1G-FF-15 User manual

Edition 2 July, 2011

Read through carefully and understand these instructions

before use.

GENERAL SAFETY RULES

(ForAll Tools)

WARNING! Read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire

and/or serious personal injury.

Work Area

1. Keep work area clean and well lit. Cluttered areas and benches invite

injuries.

2. Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away while operating a power

tool. Distractions can cause you to lose control.

Electrical Safety

4. Power tools must be plugged into an outlet properly installed or

grounded in accordance with all codes and ordinances. Never modify

the plug in any way. Do not use any adaptor plugs with grounded

(earthed) power tools. The original plug and proper outlet may reduce the

risk of electric shock.

5. Avoid body contact with grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your

body is grounded.

6. Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

7. Do not abuse the cord. Never use the cord to carry the tools or pull the

plug from an outlet. Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords immediately. Damaged or entangled

cords increase the risk of electric shock.

8. When operating a power tool outside, use only extension cords intended

for outdoors use. These cords may reduce the risk of electric shock.

Personal Safety

9. Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating power tools may

result in serious personal injury.

10.Dress properly. Do not wear loose clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

11.Avoid accidental starting. Be sure switch is off before plugging in. Carrying

tools with your finger on the switch or plugging in tools that have the switch on invites

accidents.

12.Remove adjusting keys or wrenches before turning the tool on. A wrench or a

key that is left attached to a rotating part of the tool may result in personal injury.

13.Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the tool in unexpected situations.

14.Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

Ordinary eye or sun glasses are NOT eye protection.

15.If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properlyused. Use of dust collection

can reduce dust-related hazards.

Tool Use and Care

16.Do not force tool. Use the correct tool for your application. The correct tool will

do the job better and safer at the rate for which it is designed.

17.Do not use tool if switch does not turn it on or off. Any tool that cannot be

controlled with the switch is dangerous and must be repaired.

18.Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

19.Store idle tools out of reach of children and other untrained persons. Tools

are dangerous in the hands of untrained users.

-1- -2-

20. Maintain tools with care. Keep cutting tools sharp and clean. Properly

maintained tools with sharp cutting edges are less likely to bind and are

easier to control.

21. Check for misalignment or binding of moving parts, breakage of parts,

and any other condition that may affect the tools operation. If damaged,

have the tool serviced before using. Many accidents are caused by poorly

maintained tools.

22. Use only accessories that are recommended by the manufacturer for

your model. Accessories that may be suitable for one tool, may become

hazardous when used on another tool.

Ser ice

23. Tool service must be performed only by qualified repair personnel.

Service or maintenance performed by unqualified personnel could result in a

risk of injury.

24. When servicing a tool, use only identical replacement parts. Follow

instructions in the Maintenance section of this manual.

Use of

unauthorized parts or failure to follow Maintenance instructions may create a

risk of electric shock or injury.

VOLTAGE WARNING:

Before connecting the tool to a power source (receptacle, outlet, etc.), be sure the

voltage supplied is the same as that specified on the nameplate of the tool. A

power source with voltage greater than that specified for the tool can result in

SERIOUS INJURY to the user, as well as damage to the tool. If in doubt, DO NOT

PLUG IN THE TOOL. Using a power source with voltage less than nameplate

rating is harmful to the motor.

SPECIFICATIONS

Rated Power Input 1240 W

Blows per Minute 1400 …/min

Net Weight 16 kg

※Due to the continuing program of research and development, the specifications

herein are subject to change without prior notice.

ADDITIONAL SAFETY RULES

1. Be sure to wear a safety helmet. Also wear ear protectors, safety glasses, face

shield and/or thickly padded gloves when necessary.

2. Check and ensure that the bit be correctly installed and secured before operation.

3. Hold tools by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

4. Vibration will be occurred in normal operation according to the design. That will

cause the screws easy to be loosened and invite damages and accidents. Check

tightness of screws carefully before operation.

5. In cold weather or when the tool has not been used for a long time, let the tool

warm up for a while by operating it under no load. This will loosen up lubrication.

Without proper warm-up, hammering operation is difficult.

6. Always be sure to have a firm footing. Use safety belt and be sure no one is below

when using the tool in high locations.

7. Always use the auxiliary handle and hold the tool firmly with both hands.

8. Keep hands away from the rotating parts.

9. Do not leave the tool running. Operate the tool only when hand-held.

10.Do not point the tool at anyone in the area when operating. The bit could fly out and

injure someone seriously.

-3- -4-

11. Do not touch the bit or parts close to the bit immediately after operation; they

may be extremely hot and could burn your skin.

12. Some material contains chemicals which may be toxic. Take caution to

prevent dust inhalation and skin contact. Follow material supplier safety

data.

SAVE THESE INSTRUCTIONS.

WARNING! MISUSE or failure to follow the safety rules stated in this

instruction manual may cause serious personal injury.

INSTRUCTIONS FOR OPERATION

1.

..

.

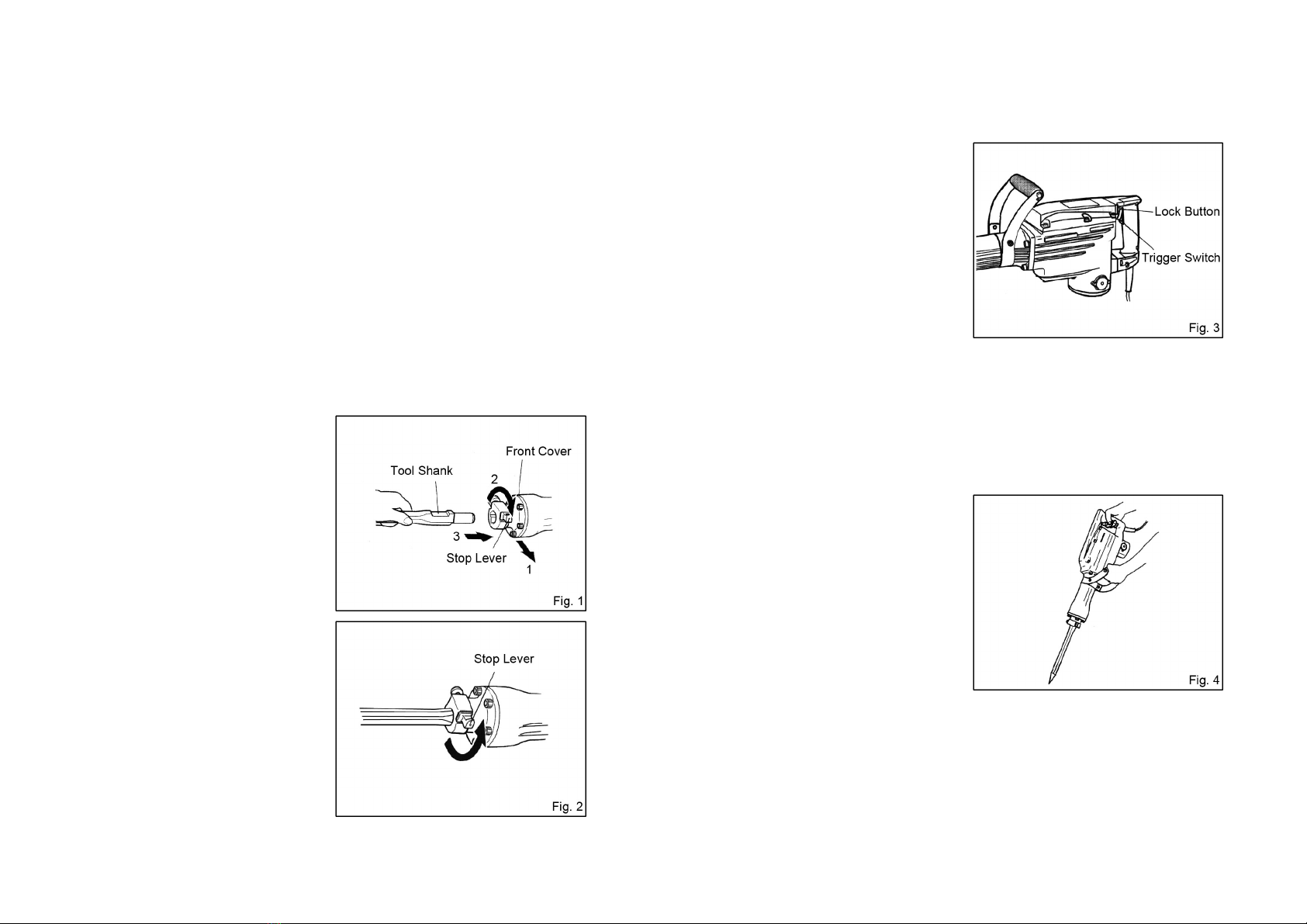

Installing or Remo ing the Bit

CAUTION: Always be sure that the tool is switched OFF and unplugged

before installing or removing the

bit.

Clean the bit shank and smear it

with grease or machine oil before

installation.

To install the bit, rotate the stop

lever 180°in a clockwise direction

while pulling it toward you. Then

insert the bit shank into the

hexagonal hole on the front cover.

(Fig. 1)

Clamp the tool by turning the stop

lever by half a turn in the opposite

direction. (Fig. 2)

To remove the bit, follow the

installation procedure in reverse.

2.

..

.

Switch Operation

CAUTION: Before plugging in the tool, always check to see that the trigger switch

actuates properly and returns to the “OFF” position when released.

To start the tool, simply pull the switch

trigger. Release the trigger to stop. For

continuous operation, pull the switch

trigger and then push in the lock button.

To stop the tool from the locked position,

press the switch trigger fully, then

release it. (Fig. 3)

3.

..

.

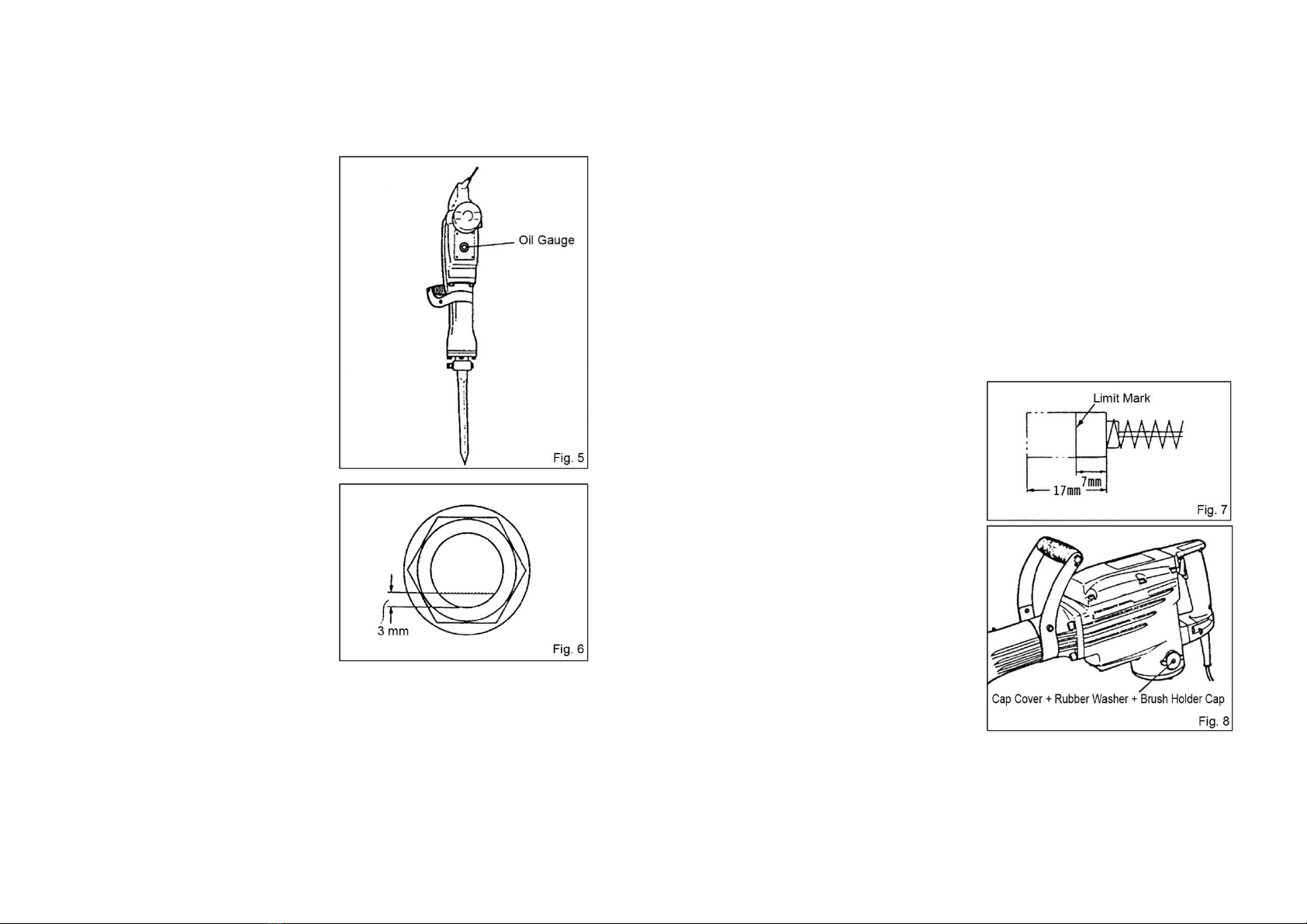

Chipping/Scaling/Demolition

Pull the trigger switch after applying the tip of the bit to the crushing position. In

some cases, it is necessary to punch the tip of the bit against the crushing position

forcibly in order to begin the striking motion. This is not due to malfunction of the

tool. It means that the safe guard

mechanism against no-load striking is

working.

Operate the tool by utilizing its empty

weight. The performance will not be

better even if the tool is pressed or

thrust forcibly against the work surface.

Hold the tool with a force just sufficient

to counteract the reaction. (Fig. 4)

CAUTION:

Sometimes the tool does not begin the striking motion even when the motor

rotates because the oil has become thick.

If the tool is used at low temperatures or if it is used after a long time idle, the

tool should be used running in for five minutes in order to warm it up.

-5- -6-

4.

..

.

Oil Feeding

CAUTION: Prior to oil feeding, always disconnect the plug from the

receptacle.

Since an oil chamber is built in this

tool, it can be used for approximately

20 days without replenishing

lubrication oil, assuming that the tool

is used continuously 3-4 hours daily.

(Fig. 5)

Feed oil into the oil tank as

described below before using this

tool.

Just before the oil level, which

can be visible in the oil gauge

window, is decreasing lower

than 3 mm when the power tool

is held upright, feed oil without

fail. (Fig. 6)

Before feeding oil, use the

provided wrench to remove the

oil gauge. Be careful not to lose

the rubber packing attached

below the oil gauge.

After feeding oil, securely clamp

the oil gauge.

Check the oil level once a day, confirming that oil is filled.

NOTE:

As an optional accessory, the oil is sold separately. Shell Oil Co. ROTELLA

#40 (engine oil) can also be used. This oil is sold as Shell gasoline stations

most anywhere.

MAINTENANCE AND INSPECTION

CAUTION:

Always be sure that the tool is switched off and unplugged before attempting to

perform inspection or maintenance.

1.

..

.

Inspecting the Bit

Since use of a dull bit will degrade efficiency and cause possible motor malfunction,

sharpen or replace the bit as soon as abrasion is noted.

2.

..

.

Inspecting the Mounting Screws

Regularly inspect all mounting screws and ensure that they are properly tightened.

Should any of the screws be loose, retighten them immediately. Failure to do so

could result in serious hazard.

3.

..

.

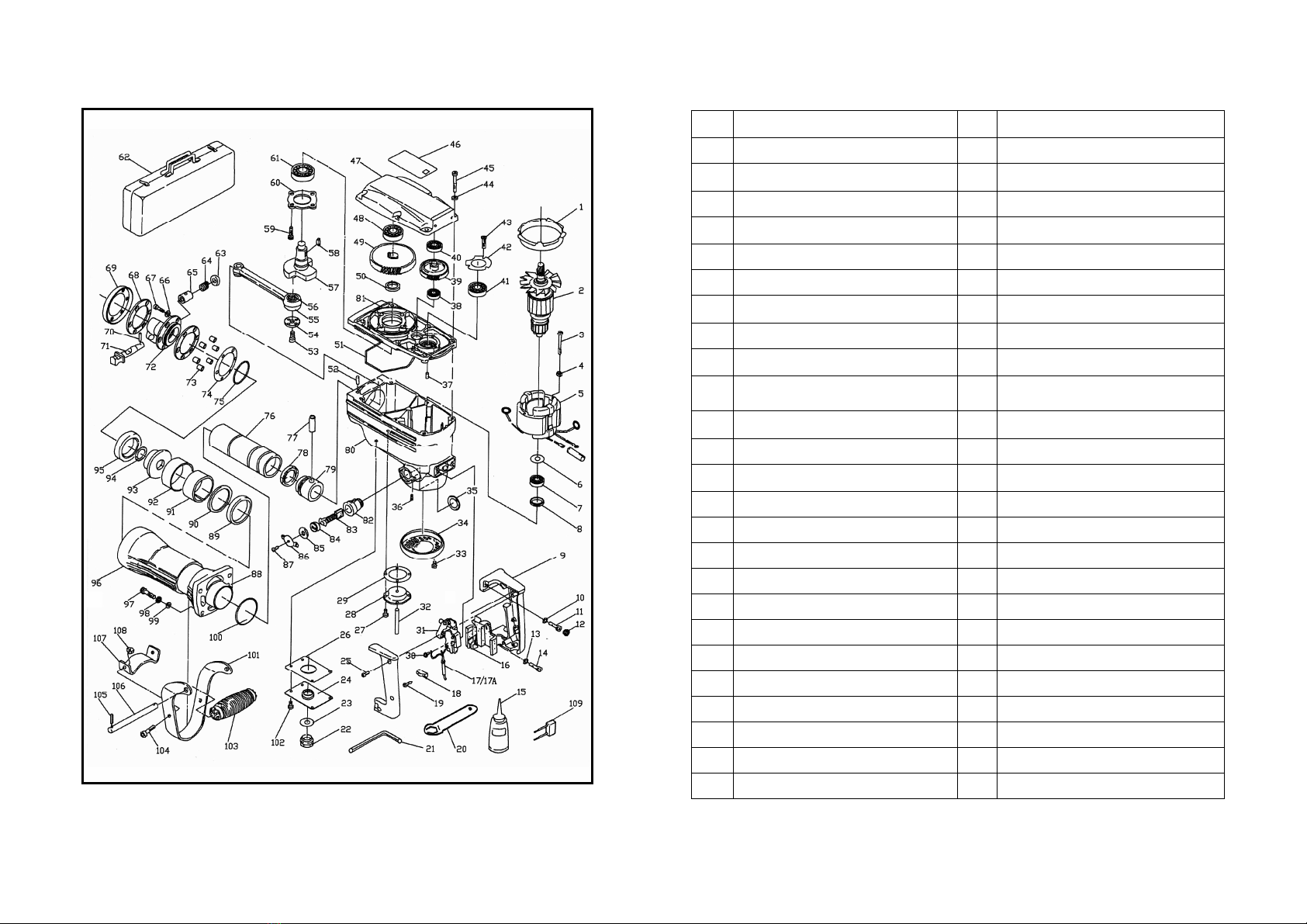

Inspecting and Replacing Carbon Brushes

Remove and check the carbon brushes

regularly. Replace when they wear down

less than 7 mm (Fig. 7). Keep the carbon

brushes clean and free to slip in the

holders. Both carbon brushes should be

replaced at the same time. Use only

identical carbon brushes.

Loosen the screw of the cap covers,

remove the cap covers, rubber washers

and brush holder caps in order. Take out

the worn carbon brushes, insert new ones

and secure the brush holder caps, then

mount the rubber washers and cap covers

securely. (Fig. 8)

※

※※

※ To maintain product SAFETY and RELIABILITY, repairs, any other maintenance or

adjustment should be performed by authorized centers, always using original

replacement parts.

-7- -8-

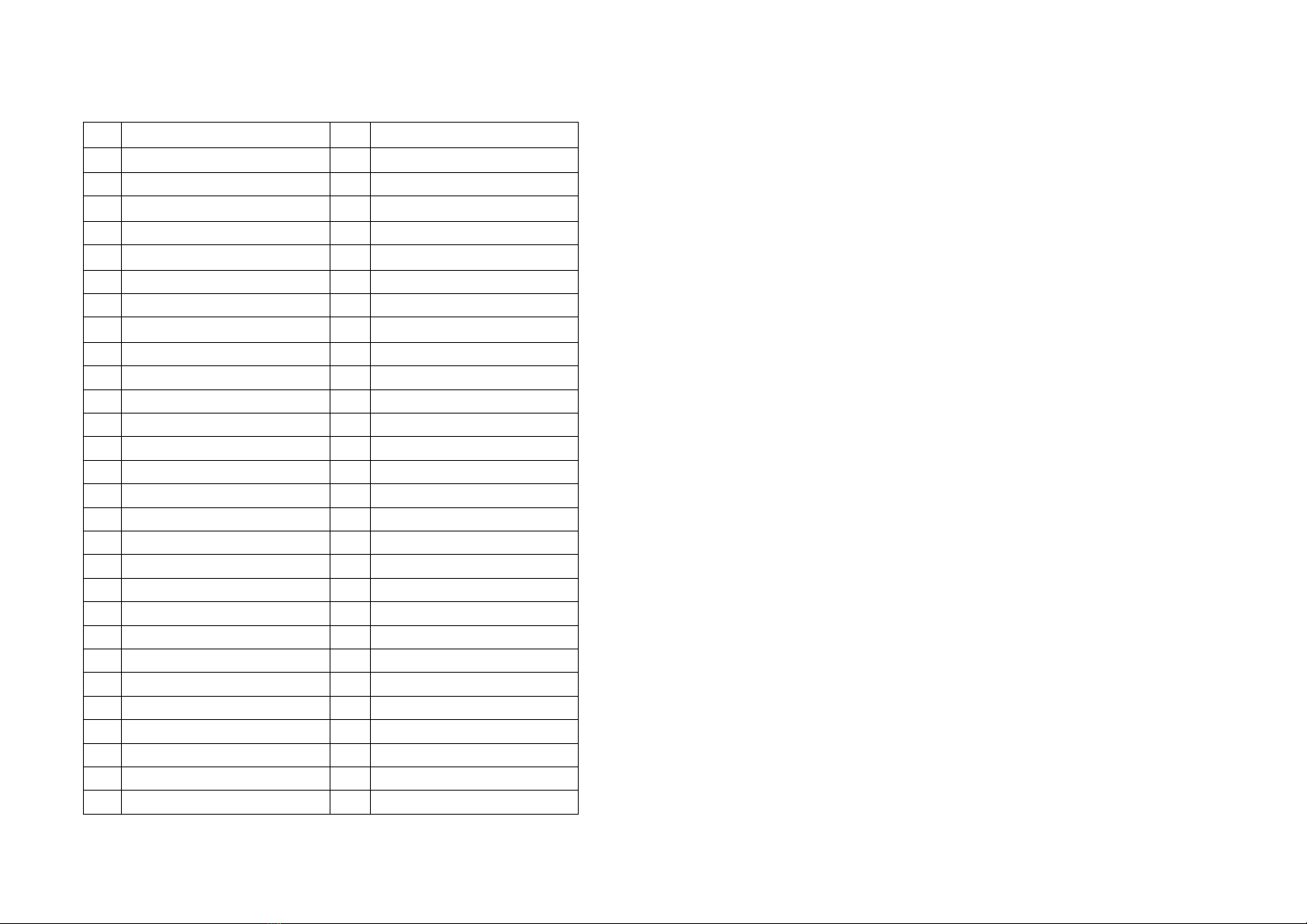

EXPLAINATION OF GENERAL VIEW

1 Baffle Plate 26 Cover Seal

2 Armature Assembly 27 Pan Head Screw M4×10

3 Pan Head Tapping Screw ST4.8×63

28 Oil Cap

4 Screw Cover 29 Rubber Seal

5 Stator Assembly 30 Pan Head Tapping Screw

6 Flat Washer 31 Trigger Switch

7 Ball Bearing 32 Oil Felt

8 Wave Washer 33 Hex Socket Head Screw M5×12

9 Handle Set 34 Rear Cover

10 Screw Cover 35 Insulation Washer

11 Hex Socket Head Screw 36 Hex Socket Screw with Flat Point

M5×8

12 Screw Cover 37 Lock Pin

13 Screw Cover 38 Ball Bearing

14 Hex Socket Head Screw M6×25 39 2

#

Gear

15 Lubricant Oiler 40 Ball Bearing

16 Switch Cover 41 Ball Bearing

17 Cord 42 Bearing Retainer

17A

Cord Guard 43 Hex Socket Head Screw M5×12

18 Strain Relief 44 Spring Lock Washer

19 PanHeadTappingScrewST4×16

45 Hex Socket Head Screw M6×45

20 Wrench 46 Nameplate

21 Hex Wrench 47 Gear Housing Cover

22 Oil Gauge 48 Ball Bearing

23 Oil Seal 49 3

#

Gear

24 Cover Plate 50 Guide Washer

25 Pan Head Tapping Screw ST4.2×20

51 Hexagon Seal

-9- -10-

EXPLAINATION OF GENERAL VIEW

52

Guide Pin 81

Gear Housing

53

Hex Socket Head Screw M8×20

82

Carbon Brush Holder

54

Metal Plate 83

Carbon Brush

55

Connecting Rod 84

Brush Holder Cap

56

Needle Bearing 85

Rubber Washer

57

Crank Shaft 86

Brush Holder Cap Cover

58

Woodruff Key 87

Pan Head Screw M4×10

59

Hex Socket Head Screw M5×16 88

Fiber Washer

60

Bearing Retainer 89

Nylon Seal

61

Ball Bearing 90

Washer

62

Steel Case 91

Rubber Sleeve

63

Flat Washer 92

Snap Washer

64

Compression Spring 93

Shank Sleeve

65

Spring Retainer 94

O Ring

66

Flat Washer 95

Nylon Seal

67

Hex Socket Head Screw M8×40 96

Cylinder Case

68

Six-Hole Rubber Pad 97

Hex Socket Head Screw M8×35

69

Rear Cover 98

Spring Washer

70

Roll Pin 99

Washer

71

Stopper Lever 100

O Ring

72

Cap 101

Auxiliary Handle

73

Iron Sleeve 102

Hex Socket Head Screw M5×12

74

Six-Hole Shim 103

Grip

75

O Ring 104

Hex Socket Head Screw M8×16

76

Cylinder 105

Split Pin

77

Piston Pin 106

Auxiliary Handle Shaft

78

Seal 107

Auxiliary Handle Holder

79

Piston 108

Hex Nut M8

80

Motor Housing 109

Capacitor

-11-

Table of contents

Popular Tools manuals by other brands

Tsubaki

Tsubaki BS-F Series Installation and maintenance manual

Parkside

Parkside 73785 Operation and safety notes translation of original operation manual

Current Tools

Current Tools 615 Operating, Maintenance, Safety and Parts Manual

MSW

MSW MSW-OPG-12.2 user manual

Hilti

Hilti DD 30-W manual

Macnaught

Macnaught MAN1915-01 manual