SAFETY INFORMATION

• ALWAYS place the cable reel roller on a firm, level surface. Be sure the

surface is capable of supporting the full load of the cable reel roller and the

reel of cable.

• ALWAYS remove reel of cable before moving or transporting the cable reel

roller.

• ALWAYS lift the cable reel roller using forklift pockets or by lifting eyes

provided at each corner of the unit.

• NEVER attempt to lift the cable reel roller by the rollers.

• DO NOT operate or store the cable reel roller in wet or damp locations.

DO NOT EXPOSE TO RAIN.

• Only use this unit for its intended purpose as a cable reel roller.

• DO NOT exceed load rating of the cable reel roller.

• ALWAYS inspect the cable reel roller before each use.

• DO NOT operate in explosive atmosphere.

• ALWAYS disconnect the cable reel roller before servicing.

• ALWAYS plug into grounded receptacle that is GFCI protected.

• KEEP all body parts, hair, loose clothing, etc., away from rotating parts and

pinch points.

• DO NOT alter this cable reel roller. Doing so will void the warranty. Guards

and safety features are provided for your protection.

• DO NOT use extension cord longer than 100 ft. Extension cord should be

12 gauge wire with ground.

• When operating, operator should stand to the side of the cable reel roller

and out of the path of the cable.

2

TABLE OF CONTENTS

This manual should be read and understood by all personnel who operate

or service this Cable Reel Roller. Failure to understand how to operate

and service this equipment could result in injury or death. This Cable Reel

Roller should only be operated by qualified personnel.

Safety Alerts ....................................................... 2

Specifications & Features ............................................ 3

Operating Instructions ............................................... 3

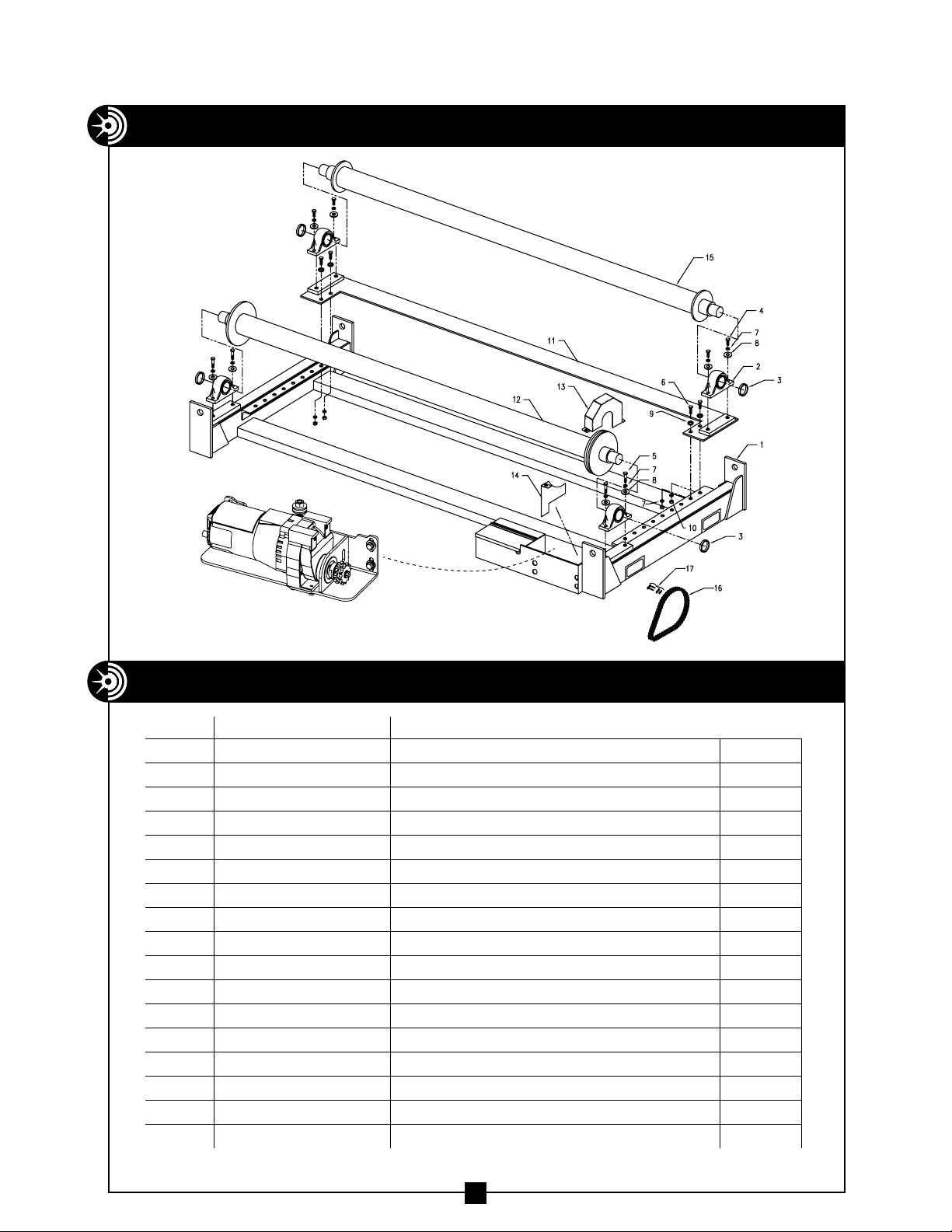

615-255 Motor Assembly Exploded View and Parts List ................... 4

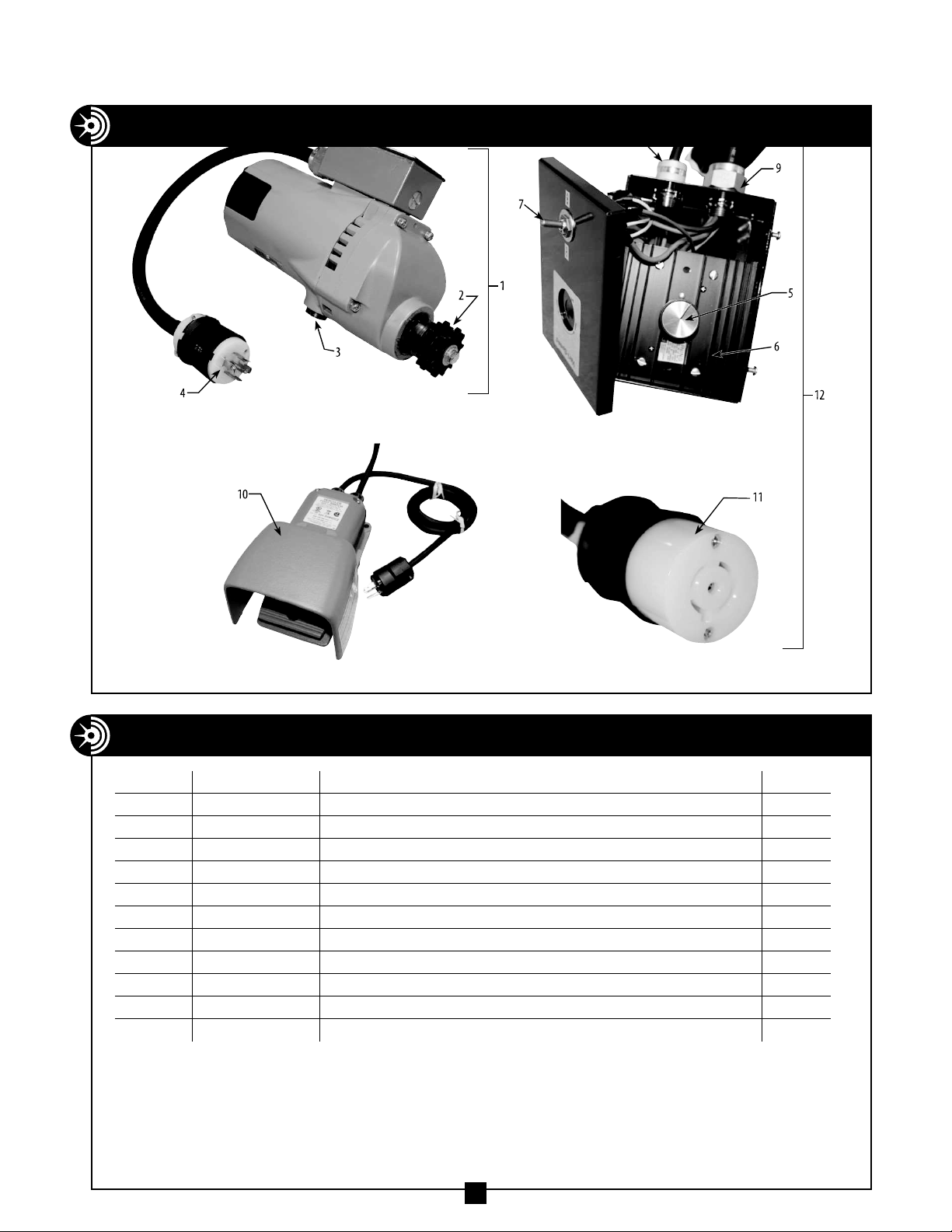

615-255 Motor Assembly Installation..................................5,6

Maintenance ....................................................... 7

Wiring Schematic ................................................... 7

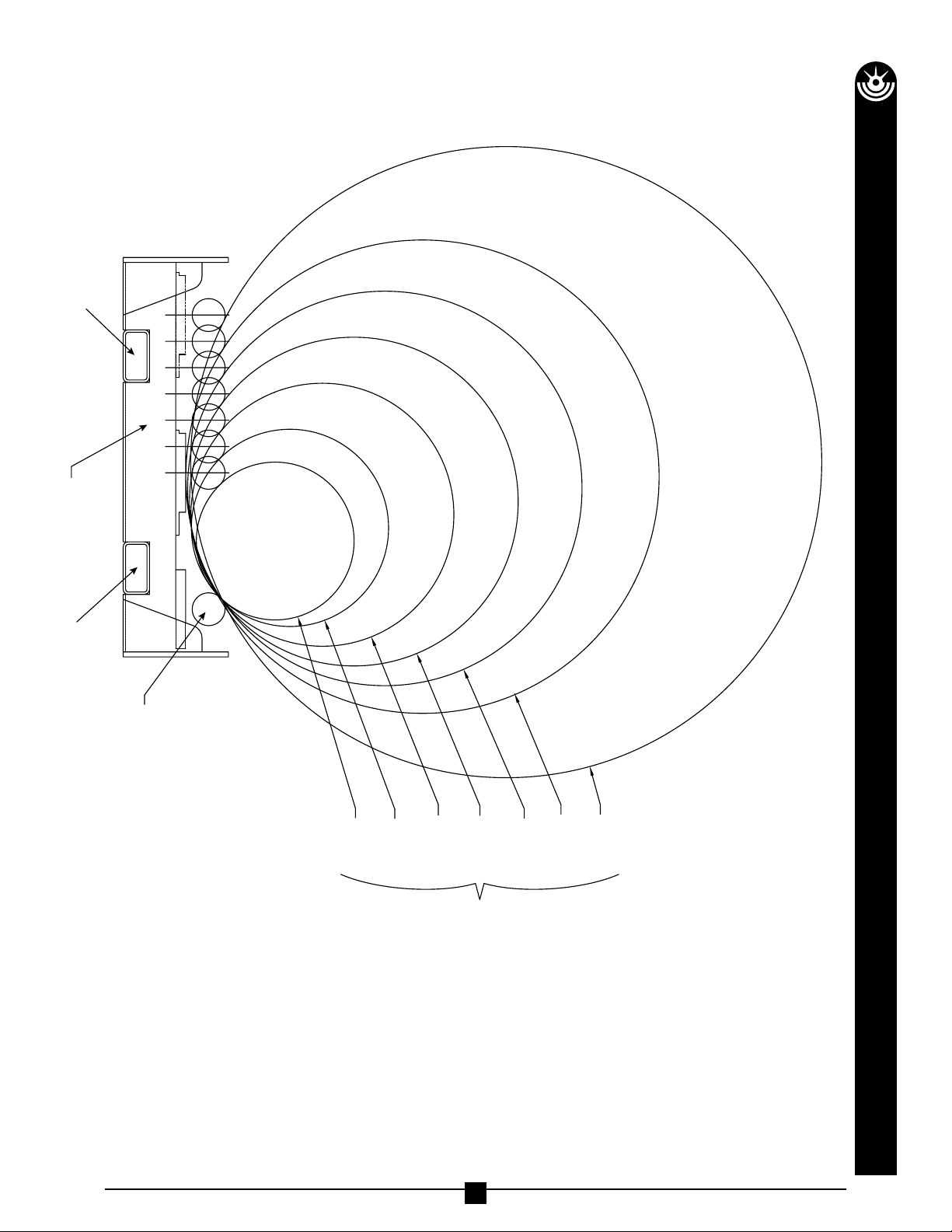

Roller Position Chart ................................................ 8

Exploded View and Parts List — Frame and Rollers....................... 9

Major Components and Parts List .................................... 10