DCCconcepts Zen User manual

Before we go on to talk about installation, Lets discuss

what needs doing to prepare your locomotive for DCC.

Yes, we understand that it might be new!

However as with all products, it’s quite possible that there

may be a need for adjustment, or perhaps assembly is

imperfect or the factory has made a mistake. Its also

quite possible that that something has been damaged but

not noticed when you made your purchase.

So: This is your chance to check that all is well before

you make it truly yours by adding a details, installing a

decoder and tuning it to your satisfaction.

Examine the locomotive.

Does it run well on DC? Are all details good and is the

finish up to scratch? Are there any details to be added?

Are they in the box as they should be?

Take the top off the locomotive.

(if it’s steam loco also remove tender top if it has one)

This usually a simple procedure. There should be some

instructions in the box, if not, check online or ask - there

are many helpful people on forums or E-groups who will

help you with useful information.

If there are details to add, then it might be best to do it

now - this can be much easier to do with the body off.

Examine the wiring and make sure its routed clear of any

tight places so the wires will not get damaged (it is sur-

prising how often manufacturers get wiring caught be-

tween body and chassis, and this can cause damage

over time, leading to frustrating faults later on).

Tidy it up if necessary.

Check and adjust the electrical power pickups..

These are most often springy fingers of phosphor bronze

that are supposed to touch the back or edge of each

wheel. More often than not they are not well adjusted.

Move the any wheels that have pickups left and right and

make sure that no matter where the wheel is, the pickups

never lose contact.

If they do, then they will need adjusting.

Remove anything in the way then gently bend the pickup

outwards a little more. If possible just increase the initial

bend at its root. If you can’t get to that area, bend as far

from the tip as possible as this will give the best contact

with minimum drag.

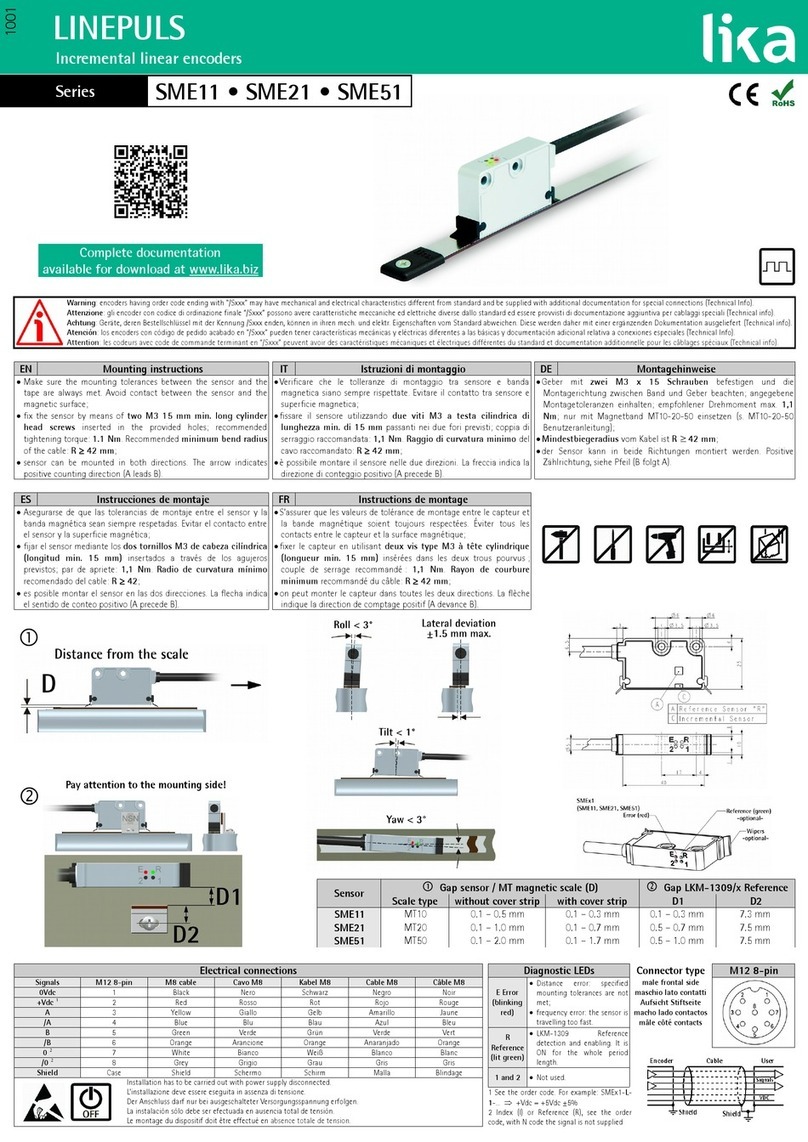

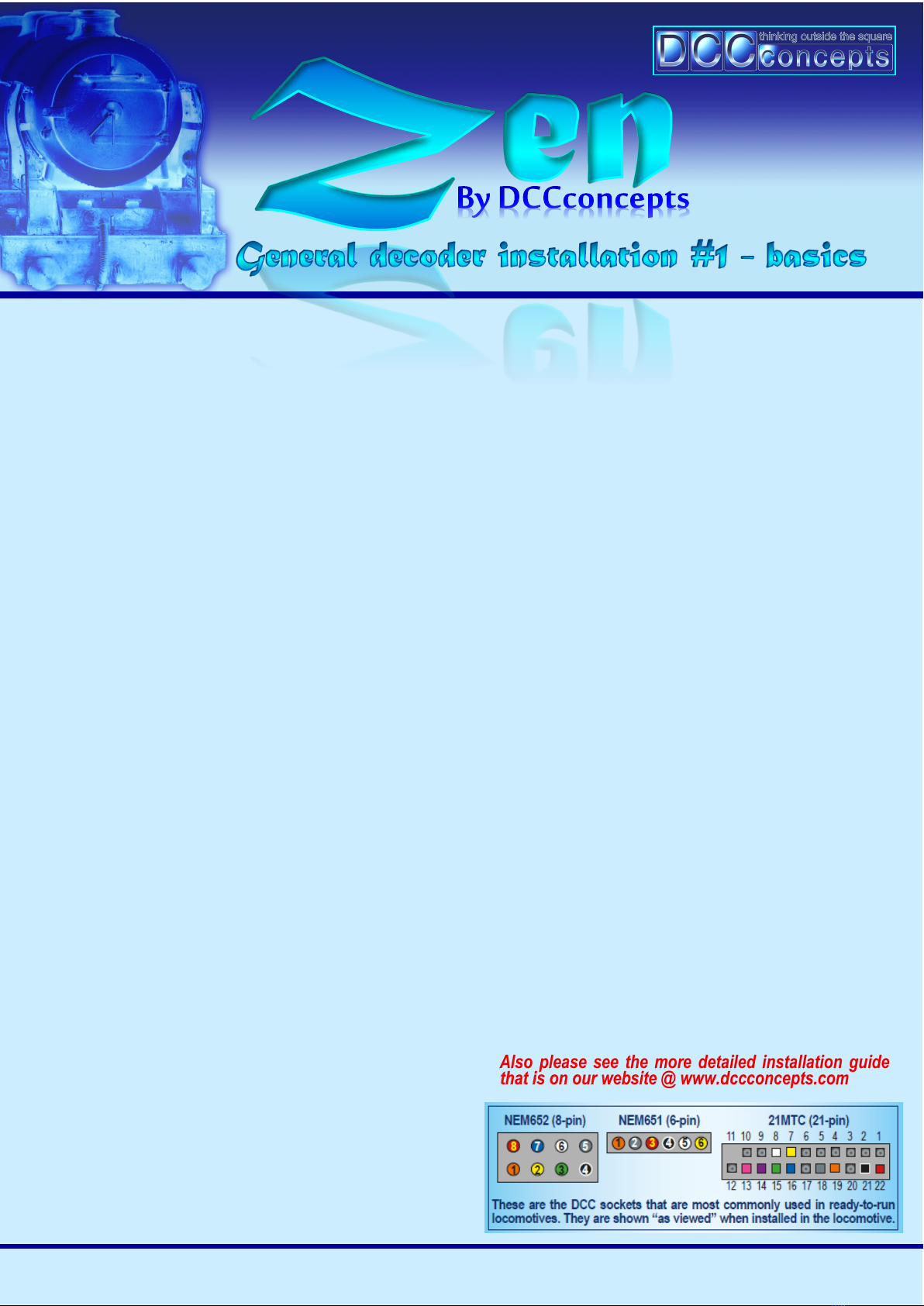

If it is DCC ready, remove theblanking plugfrom the DCC socket

Examine the socket The drawing to the right shows the

terminal numbers. Check for solder bridging any two of

the terminals. Terminals that must NOT be bridged are:

For an 8-pin, check most carefully between 1 & 8, 4 & 5.

For a 6-pin, check most carefully between 1,2,3,4

DCCconcepts Pty Ltd, 3/13 Lionel St., Naval Base WA 6165 Australia. * www.dccconcepts.com * +61 8 9437 2470 * sales@dccconcepts.com

Check for suppression capacitors.

Locomotives sold for DC running in UK and Europe will

usually have some suppression on the DC motor. This

usually includes capacitors and resistor-like items called

inductors. When running on DCC they are not needed.

You could of course leave them there, but quite often,

they will cause poor running, especially at slow speeds,

because the capacitor interferes with the very important

communication between the motor and the decoder.

The best answer is to remove it all and simply take wires

directly between (for an 8-pin socket) pin 1 (orange) and

one motor brush, pin 5 (grey) and the other motor brush.

However if you are careful, you can also just remove the

capacitor (it usually looks like a tiny biscuit coloured disc)

by just cutting its leads close to its body and making sure

no bare wire ends touch where they should not. Please

note that some loco brands like Bachmann, may have 2

or 3 of them attached to the motor. Remove them all.

Installing a decoder in a DCC-ready locomotive.

Now all of the pre-checks are done, the unnecessary

suppression parts are gone and all is well, it is time to

install the decoder. This is the simplest step of all!

For an NEM652 8-pin plug/socket or DP decoder.

Pin 1 is also the orange wire. It will be marked on the de-

coder and the locomotive socket with a 1, a star or a dot.

Orient the plug/socket correctly and gently but firmly

press it into place.

For a 6-pin NEM651 plug/socket or DP decoder.

Pin 1 is also the orange wire. It will be marked as per the

8 pin but if not, you would normally orient the decoder

with the component side outwards. Orient the plug/socket

correctly and gently but firmly press it into place.

For a 21-pin 21MTC Direct-Plug decoder.

Observe the drawing below - this is the socket as you see

it when looking at the locomotive.

Orient the decoder with the connector on top of the pcb

and facing you, so that the locomotive pins will enter the

PCB before entering the socket.. Align it very carefully

(the pins are fine and can bend if you do not). Press

evenly and firmly until the two PCBs are close together.

Also please see the more detailed installation guide

that is on our website @ www.dccconcepts.com

DCCconcepts Pty Ltd, 3/13 Lionel St., Naval Base WA 6165 Australia. * www.dccconcepts.com * +61 8 9437 2470 * sales@dccconcepts.com

Installing a decoder into non-DCC ready locomotives.

This can be much easier than you might imagine. You will

need only a few simple tools and it is a job that every

modeller can manage quite easily if you just take your

time and follow a few simple rules. Here’s how.

Do the same checking as on page 1.

As with a new DCC ready locomotive, give the locomotive

a good test run, adjust as needed, lubricate/clean and

check pickups. Make sure it runs well… before you take

the next steps.

Remove the wires from the motor brushes and check.

We need to have 100% separation between track power

and the motor brushes. After removing those wires from

the motor brushes, place the locomotive and its tender (if

it has one) onto a length of newly cleaned track.

Set your meter to Ω “ohms”.

Place one probe on the left rail and then touch the other

probe to each of the motor brushes in turn. There should

be NO reaction. Now move the probe from the left to the

right rail and touch each of the motor brushes again. As

previously, there should be NO reaction.

If you had no reaction, move to the next step. If not,

then we will need to do a wee bit more work first!

If there WAS a reaction, we really DO need to isolate that

motor brush before continuing or the decoder will be

damaged.

Again you will find the Web helpful. Ask us, Search with

google or ask on a forum. There WILL be someone who

can help you with good advice and maybe even photo’s!

Possibility #1: If it’s an open frame motor with a V

shaped spring holding brushes mounted into an insulated

strip on the motor (like the Triang/Hornby XO4 motor),

then you will just need to isolate the brushes from the

spring by adding heat-shrink or a tube of insulation

stripped from some wire.

Possibility #2: It is fortunately quite rare, but if it is an

open frame motor and one brush is set in to/not insulated

from the metal body of the motor itself, then you will have

to isolate the WHOLE MOTOR from the loco frame.

(examples, US Pittman type motors or some of the earlier

designs of Hornby-Dublo and Wrenn locomotives which

use the chassis as part of the motor frame).

Possibility #3: Motors that have one motor brush

grounded to the frame by a metal clip or a screw that

penetrates into the frame. You will need to remove or cut

the clip. If it’s a screw, either use a shorter screw OR drill

out the screw hole and insert a plug of plastic, then drive

the screw into the plastic plug. (examples are Many Horn-

by tender or motor bogie drives, Lima, Rivarossi, some

Mehano, some earlier low end US diesels).

Possibility #4: Pancake motors with a metal or PCB type

faceplate such as Fleischmann. If it’s a metal plate, then

the plate needs isolating from the motor frame. If it’s a

PCB plate, then the tracks need cutting to isolate the mo-

tor brush from the frame. Fleischmann also do make

some replacement “DCC motor plates” for this kind of

pancake motor if you aren’t confident doing modifications.

Possibility #5: Motors that are semi-embedded into a

cast chassis - this is very common with earlier US loco

brands such as Athearn. The top brush has a long metal

clip that joins the motor top to a metal bracket on top of

each truck tower, the lower brush contacts the chassis

via a clip. Throw away the top clip. Remove the motor,

remove the bottom clip and insulate the area below the

motor with thin plastic OR (a top tip) a couple of coats of

clear finger-nail varnish. Solder one wire directly to the

bottom brush clip, the other to the top brush retaining clip.

Keep the lower wire really flat relative to the motor.

Possibility #6: The split chassis: Commonly used by

Mainline, earlier Bachmann. The motor is encapsulated

between the two chassis halves. The halves are insulated

from each other and the brushes of the motor make con-

tact with each chassis half via a spring clip on the brush.

Disassemble the chassis parts and carefully remove

these clips as cleanly as possible. Grind out the area

where they made contact with a Dremel or similar. Coat

the area with some clear nail polish, leaving it lots of time

to dry. Solder pre-tinned wires to each brush, keeping the

join tidy and flat (minimum solder). Reassemble but be

careful about where the wires run—be sure you do not

get them caught between the chassis and motor etc. or

the insulation may be damaged, causing a short.

There are many things on the DCCconcepts website

that make installation easier...

DCCconcepts Pty Ltd, 3/13 Lionel St., Naval Base WA 6165 Australia. * www.dccconcepts.com * +61 8 9437 2470 * sales@dccconcepts.com

OK… The loco is pre-checked and the brushes are both

confirmed as being isolated, the most important part of

the pre-install work is done.

We can move on! Its time to begin the wiring...

We will take our time explaining this procedure - and we

may well rabble on a bit and spread it over a couple of

pages because its important to get it done both correctly

and tidily, and that needs both thought and planning.

Do the first couple “one step at a time” and it will become

an easy and relaxed process very quickly. Rush and you

will damage decoders and just become frustrated.

Size matters.

Before you get out the wire strippers, plan the installation.

Decide where the decoder will go. Position it there, hold

in place with thin tape & check the body will go back on.

Tidiness matters - so now we plan the wire lengths.

If you need wire, DCCconcepts have an excellent range

including all of the DCC-wiring standards colours. We

even offer pre-twinned wires for key wiring areas such as:

Red + Black (track power wire colours)

Orange + Grey (decoder-to-motor colours)

Blue + White (front lighting colours)

Blue + Yellow (rear lighting colours)

Assess wire lengths needed and cut them, leaving a little

excess to allow wires to be routed tidily without strain.

Keep wire off-cuts as they will always find a use later on.

How you strip & tin the wire matters too.

Don’t just strip by pulling, don’t use blades or teeth either!

Use good quality wire strippers such as the DCCconcepts

FWS Fine wire strippers to ring-cut insulation about 5mm

from the end.

The DCT-FWS wire strippers are without doubt the BEST

small wire strippers available anywhere. They have sharp

cutters between the stripping grooves, and they can be

pre-set and locked for consistent perfect results.

Once the wire is ring-cut (close the strippers and twist),

we can put the strippers down.

Now, instead of just pulling, pull gently at the cut-end of

the insulation and as you do, twist it so that the fine cop-

per strands are all perfectly twisted at the same time.

This guarantees a perfectly tidy wire end to work with.

All that remains is to tin and trim it.

Using a generous helping of No-Clean flux and a tiny bit

of 179 solder, tin the end of the wires, then cut off leaving

about 2~3mm with a perfectly tidy end ready to connect.

Now the basics are covered, We are ready to discuss

how to attach wires, to each other, to the decoder, the

motor and to the chassis or pickups of the locomotive.

While we are checking things… lets look at any lighting

you may need to change or add during an installation.

Key point: We are mainly talking here about older

non-DCC-ready locomotives. Many DCC ready loco’s

will already be wired for basic lighting, and later DC

locomotives will usually have LEDs already fitted.

However… Earlier DC locomotives equipped with

lights will usually be fitted with incandescent bulbs.

These can be OK, but they will also run very hot

when used with DCC, as they will always be on all of

the time and of course, the DCC track voltage will

usually be at a level above the average voltage used

when you were running that locomotive on DC.

So...It is a good idea to replace them with LEDs while

you already have the top off for the DCC installation.

LEDs are not expensive but please - do not use the

“white” LEDs sold in the local electronics shop as these

will almost always be an unrealistic blue-tinted white.

For all but the most modern of locomotives by far the

most realistic colour for these LEDs will be what we call

“Prototype White”. Common sizes for model use are the

3mm, the 2mm tower and 1.8mm size. For small lighting

in larger scales (such as marker lights) or most lighting in

N scale, DCCconcepts prewired “NANOlights will be best.

How are the lights connected and how do I wire them

so that I can control them with my DCC system?

In DC-days, lighting was generally installed quite simply.

It was either “one wire to chassis and one to the power

pickup” or with more sophisticated loco’s, they added a

diode to make it directional. In more expensive loco’s

there may have also been a diode bridge with a low volt-

age bulb across it… but none of this matters really, be-

cause basically, if you want to have lights that can be

properly configured/controllable, it’ll have to be changed.

Yes, you could modify the wiring, but lots of experienced

gained from many hundreds of installations says that it

really is easier to re-wire. The next tutorial covers this.

To prepare you a little for rewiring of your loco’s, the

next page will focus on the connections you may

need to make within a locomotive during installation.

Red (track power,usually

thought of as “right rail)

Black (track power, usually

thought of as “left rail)

Orange (Motor, usually top or

right brush holder)

Grey (Motor, usually lower or

left brush holder)

Blue (common positive wire for

all lights/active functions)

White (function 1, FL or front

light). Def=F0 “on forward only”

Yellow (function 2, FL or front

light). Def= F0“on reverse only”

Green (function 3 or Aux 1)

Def= F1, on forward + reverse

Purple (function 4or Aux 2)

Def= F2, on forward + reverse

Brown (function 5 or Aux 3)

Def= F3, on forward + reverse

Brown is also quite often used

for sound/speaker connections.

Pink (function 6 or Aux 4)

Def= F4, on forward + reverse

DCCconcepts Pty Ltd, 3/13 Lionel St., Naval Base WA 6165 Australia. * www.dccconcepts.com * +61 8 9437 2470 * sales@dccconcepts.com

Joining wires to each other… to the motor, the chassis.

and tips for reliably connecting them in other places,

(some of which hate solder) but that will still need them!

Basically the procedure for all stripping and tinning

is as we have already described. Stripping slightly

long, twisting, tinning then cutting is the best way to

guarantee a nice clean wire ends and safe joints.

Joining two wires:

If two wires are to be joined, then hold one steady on the

bench and add flux to it again. Before joining two wires,

we need to think about proper insulation of the joint, so

add about 7mm of fine heat-shrink to the second wire

before you solder them together.

Please note: Less is more when it comes to solder. If you

are using our S179 it will flow really easily and you should

need little or no added solder. If your soldering Iron tip is

bright and clean, and the Iron hot, the entire joint should

be able to be made in less than two seconds.

There is NO need to twist wires together.. .and two pre-

stripped/tinned wires need almost NO additional solder!

Just add flux, hold together and with a clean and shiny

soldering Iron tip, apply heat... The whole process should

ideally take one second, and always take less than two.

Always use fine heat-shrink on any joint. It is the ONLY

way to guarantee zero short circuits in wire joints. Note:

These wires are small and old or young, you will find add-

ed light and some magnification really will help.

Adding wires to the motor brushes:

The motor wires will be Orange and Grey. If you have

not already done it, plan their ideal length and cut them.

Strip & tin them using the techniques already mentioned.

Most of the time, the motor brushes will be mounted into

the motor using a hard thermoplastic but that does not

mean you can use lots of heat. If there is a usable tag on

it, use it. Linger too long and the brush holder will melt or

soften and throw the brush alignment out of line.

(1) Clean the brush holder with a fibreglass brush or simi-

lar if it is not already tinned. If it is tinned, add a tiny bit

of flux and remove old solder. Use a “solder mop” if

you have one to absorb the excess.

(2) Add flux (a cotton bud is best). Hold the wire onto the

brush holder as flat as possible. Make sure the solder-

ing Iron tip is clean, pick up a TINY bit of solder on the

tip and apply heat to the already fluxed joint area.

(3) The solder should flow immediately. Remove the tip of

the soldering Iron as soon as it does, hold the wire still

for a second or so and the joint will harden.

(4) Using the correct solder and a quality flux and of

course also using a clean soldering Iron tip, this whole

process should take less than TWO seconds.

Time to talk about soldering wires to power pickups and

heat sensitive parts…. and to “Un-Solderable bits” too.

Power pickups are usually Phosphor Bronze.

Phosphor bronze is used because its springier than brass

and has good wearing characteristics, but it’s springiness

will be lost if you heat it too much… so be careful.

Its often attached to some heat sensitive plastic that’s

within the chassis. so what’s the best way to handle it?

Pre-tin any wire you will want to connect to it.

Before you start, clean it with a fibreglass brush or similar

to expose bright, bare fresh metal (even clean-looking

phosphor bronze has an oxide layer). Add no-clean flux

and tin with a tiny amount of our 179 solder. Be quick.

Add more flux, hold the wire to it and just touch with the

Iron - solder will flow and the wire will be neatly attached.

Attaching wires to the chassis for power collection is

often required - but how can you manage it, because

Chassis metal is an alloy that just can’t be soldered!

The metal used in chassis’ is a “low temp” casting alloy.

In an ideal world it would be Pewter but much lower cost

alloys have almost always been used, and now that

health and safety rules have excluded elements like

Lead, what we now have is usually a combination of Zinc,

Antimony, magnesium, Aluminium and Cadmium.

As a result is will NOT take solder, no matter how you try!

However you’ll often need to attach wires to it for

power pickup / other purposes, so how do you do it?

(1) Drill and tap. Also not quite so easy as the alloy has a

tendency to “grab” at taps and snap them. If you want

to tap it use a lubricant like kerosene and keep it wet.

(2) Drill and screw or drill and plug. Much more practical

for most of us. Again, lubricate when drilling. Find a

drill for a hole a bit smaller than an offcut of brass rod.

Taper the end of the rod a wee bit. Pre-tin the end of

the brass rod with flux and 179 solder ready for later.

To further prepare the hole, countersink it.

When the hole is ready, drive in the brass rod and cut

it off only a little bit above the chassis surface.

When all that is done, Hold the pre-tinned wire in the

hole, add flux and a bit more solder with a hot Iron.

The solder will fill the countersink and the wire will be

really tidily attached to the brass rod.

(3) Add a Screw to solder to. Brass is best but steel is

fine. Do as for 2, but countersink to match the screw.

File any plating off the screw head. Drive it the screw

and solder your wire to the screw head.

For detailed light function wiring and more advanced wiring ideas visit our website @ www.dccconcepts.com

Other DCCconcepts Media Converter manuals