Site Requirements

Clearance Site Requirements

Adequate clearance as shown below for servicing and air circulation — room

temperature should be maintained between 40°F and 100°F when the motors

are running.

A flat, level floor that provides stable support.

Protection from the weather and direct sunlight.

A power source within 3 ft. of back-center that provides a dedicated,

breaker-protected circuit.

•

•

•

•

C Series Installation Guide

Compressor Site Requirements

WARNING! Fire Hazard! Running motors generate heat. Do not store flammable

liquids or objects such as clothing, mops, or brooms near or above the unit.

ELECTRICAL REQUIREMENTS

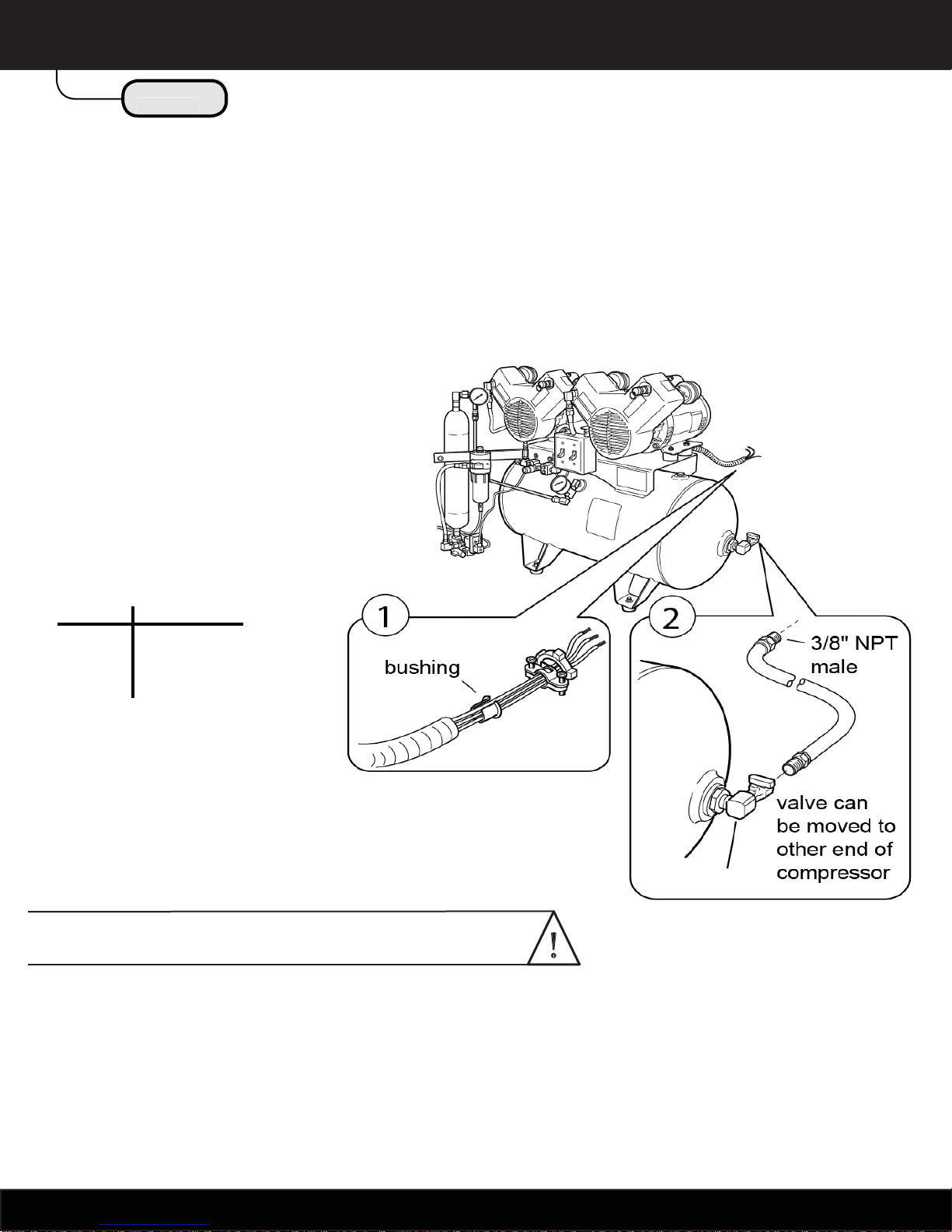

PLUMBING REQUIREMENTS

1. 1/2 in I.D. minimum pipe size.

2. Pipe connection is to be located within 3 ft of

center back of compressor.

3. Install per all Local and State plumbing codes.

1. 3 wire single phase 115 vac or 230 vac. All

voltage ratings ± 5%.

2. Green Wire is to be grounded to a suitable

system ground.

3. Power supply must be on a dedicated circuit.

4. See data tag for appropriate breaker size.

5. Power supply connection is to be located

within 3 ft of center back of compressor.

6. Install per all local and State electrical codes.

1.800.624.2793 3