De Havilland VAMPIRE User manual

Wingspan

Lenght

Weight

Wing Area

Radio Control

Duct Fan System

ESC

............................

.................................

.................................

...........................

......................

...................

.....................................

1407mm

1134mm

2600~2700g

(Battery excluded)

39.4dm2

6~7 Ch 12 Servos

90mm

80~110A

SPECIFCATIONS

RADIO CONTROLLED 90MM EDF SCALE AIRPLANE

ARF

VAMPIRE

IFYU.133

2

2

3

1

Assemble left and right sides

the same way. Must be purchased separately!

Cut off shaded portion.

Apply epoxy glue. Drill holes with the specified

diameter (here: 2mm).

Pay close attention here!

Apply instant glue (CA glue, super glue).

Ensure smooth non-binding

movement while assembling.

2mm

AB

LR

C.A

LR

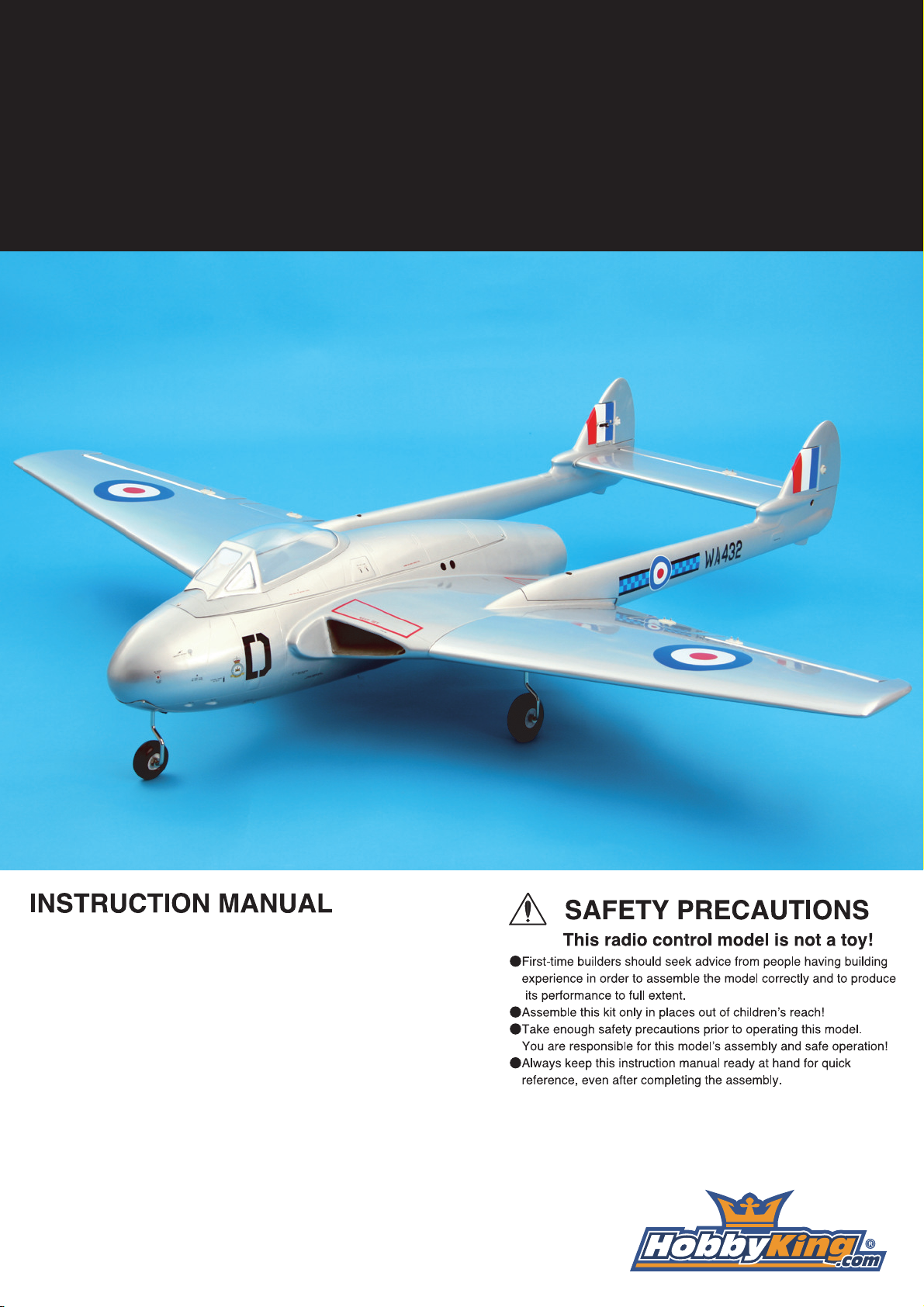

Attach aileron with C/A glue and make sure aileron can

move upward and downward.

Attention: Make sure aileron is attached properly.

Main Wing

LR

C.A

C.A

6

Hard wood 12 x 12 x 6mm

24

2 x 8mm TP Screw

6

Hard wood 12 x 12 x 6mm

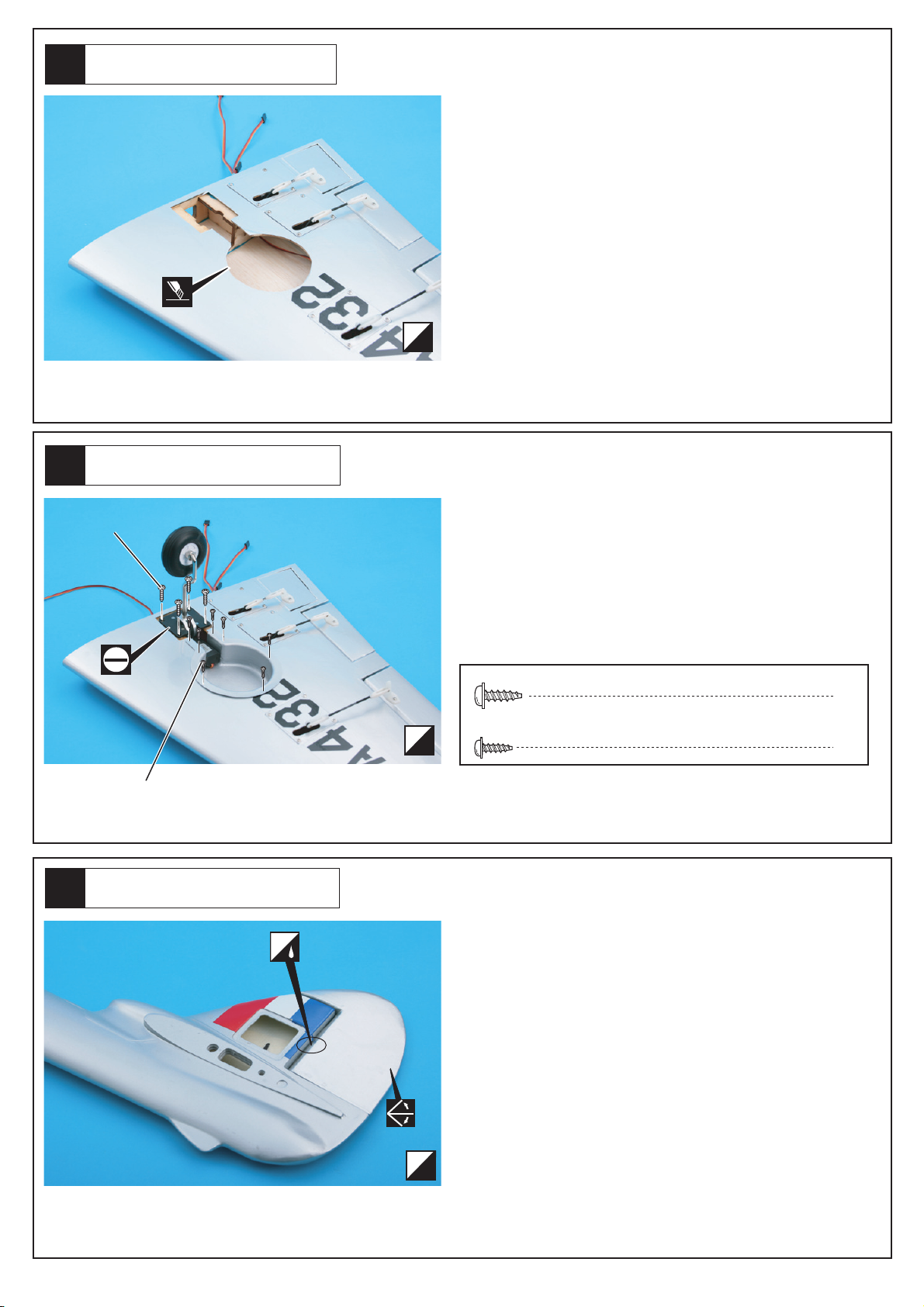

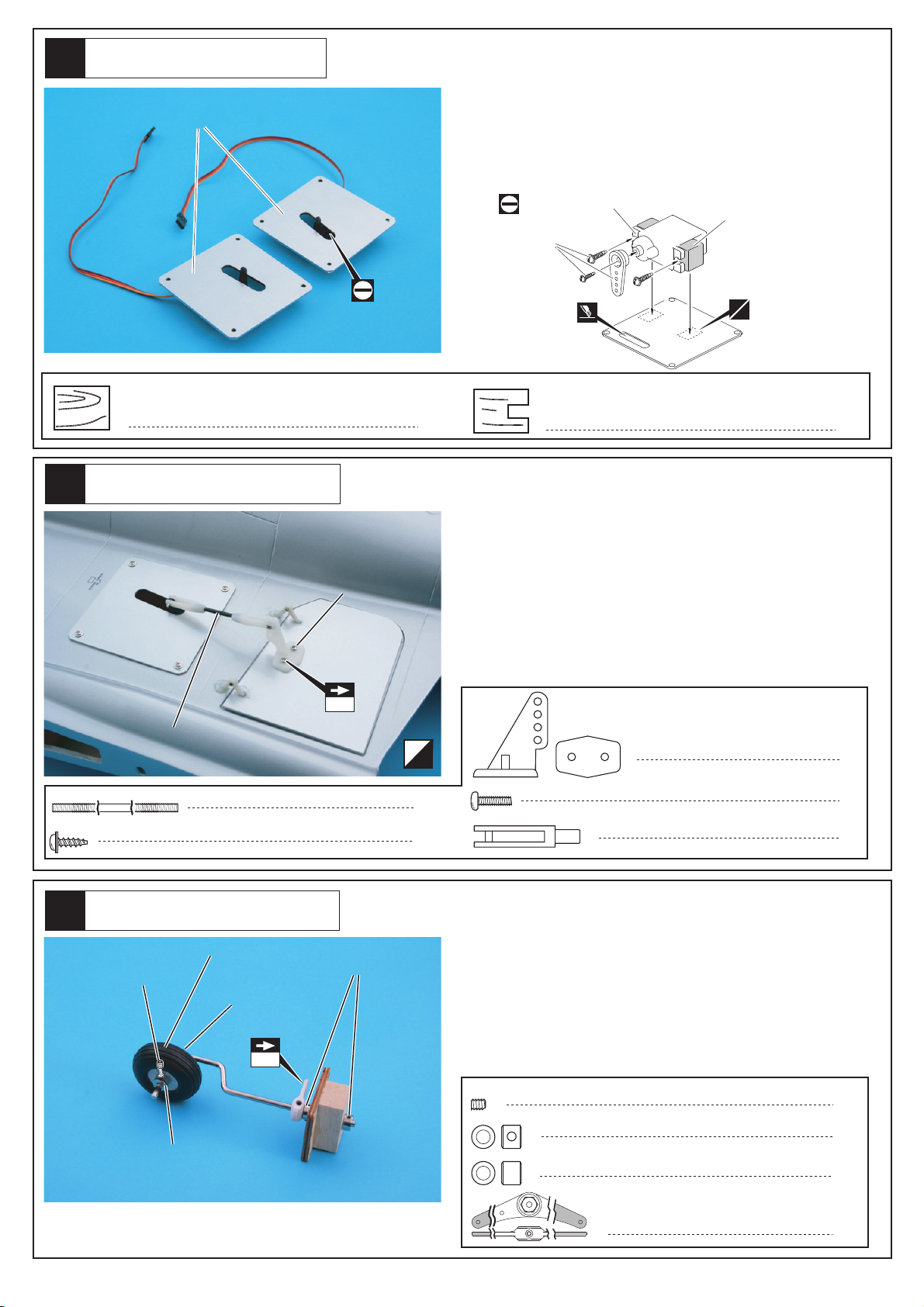

Aileron and Flap Servo

Assembly for (Micro) Servo

Must be purchased

separately!

Hard wood block

mount for servo.

lncluded with

the radio set.

AB

Flap

Aileron

Aileron and Flap Servo

Install aileron servo and flap servo on main wing as

shown in picture. Servo wire should go through from

the side of main wing. Then mount servos in place with

2x8mm TP Screws.

Attach the 12x12x6mm hard wood on servo tray with

A/B glue, then mount servo in place with the screws

supplied with servo.

Note the servo directions for left and right hand,

assemble left & right side the same way.

Note: Servo, servo plate & its parts are NOT included!

5

3

6

4

LR

LR

Drill two 2mm holes on where control horn will be

mounted as shown in picture.

Then put 2x12/16/20mm screws through control horn,

flap and aileron (as shown in picture). Then add the

horn base at the underside of flap and aileron, and

lock it in place. Then connect adjusters to both ends of

the 2mm threaded pushrod. Attach one end to control

horn, adjust to suitable length and then connect to

servo arm. Check the angle between servo arm and

pushrod. Assemble control horns on both sides for the

aileron and flap the same way.

4

2 x 20mm Screw

Rod adjuster

Horn

612

4

2 x 30mm Rod

2mm

2 x 12mm

Main Wing

2

2 x 60mm Rod

4

2 x 16mm Screw

4

2 x 12mm Screw

2

3 x 4 mm Set Screw

4.2mm Collar 2

75mm 75mm

8

2.6x 12mm TP Screw

Aileron and Flap

2 x 16mm

2 x 20mm

2 x 60mm Rod

2 x 30mm Rod

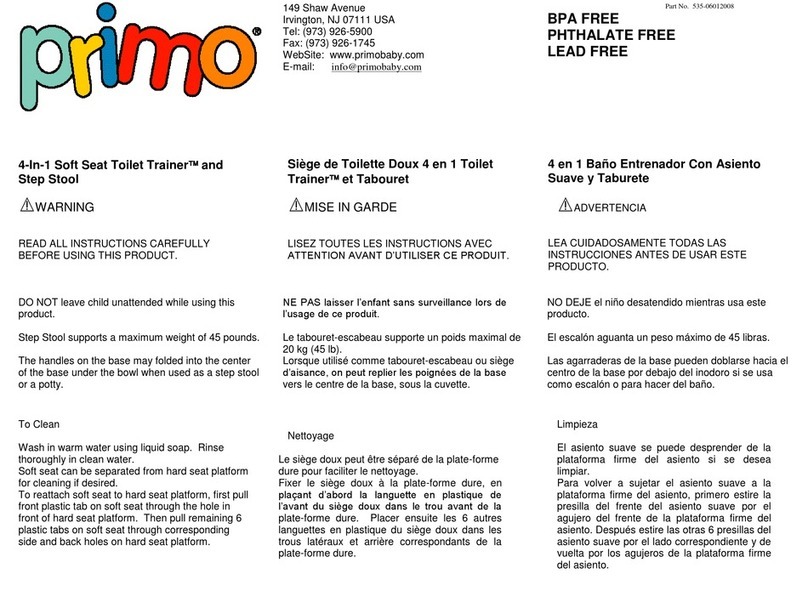

Fixed Landing Gear

2.6 x 12mm Screw

Cut away the covering and mount the fixed landing

gear on main wing with 2.6x12mm screws.

Insert 4mm wire to the wheel, then add the 4.2mm

collar and lock in place with the 3x4mm set screw.

Note: Skip to Step #7 if you are using retractable land-

ing gear.

8

4

9

7

LR

LR

8

2.6x 12mm TP Screw

14

2 x 8mm TP Screw

Mount the retractable landing gear on main wing with

four 2.6x12mm TP screws. Then put the PVC wheel

well in place with lock with 2x8mm TP screw.

Attention: Retractable landing gear and its parts are

NOT included.

Cut away the covering on where the retractable

landing gear will be mounted.

Attention: Not do cut too deep and weaken the balsa-

wood.

Retractable Landing Gear

Retractable Landing Gear

2.6 x 12mm Screw

2 x 8mm TP Screw

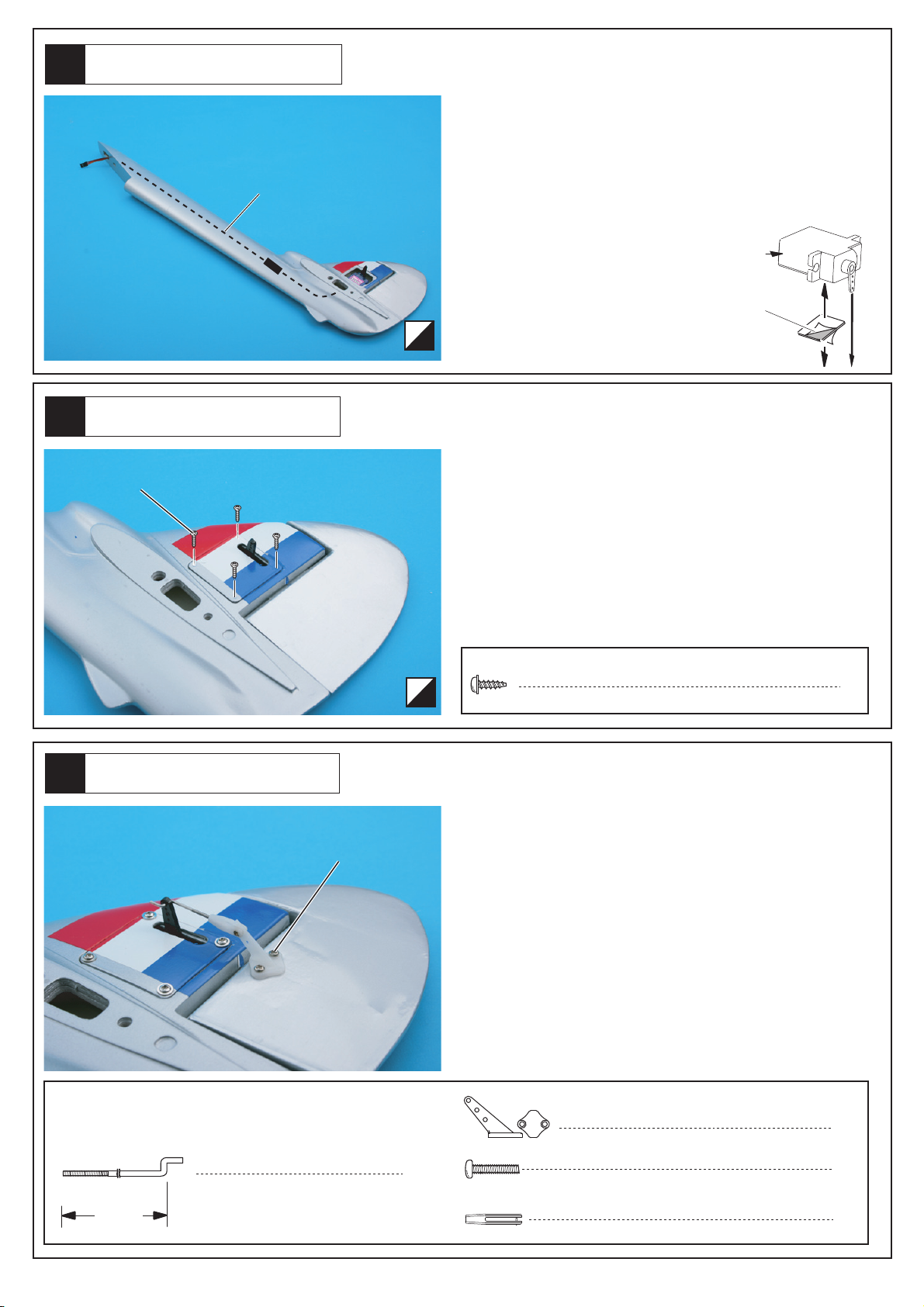

Rudder

Attach rudder with C/A glue and make sure rudder can

move smoothly.

Attention: Make sure rudder is attached properly.

LR

C.A

11

5

12

10

Rudder Servo

8

2 x 8mm Screw

2

NF: 1021 Clevis

4

2 x 16mm Screw

2

NF:1020 Control Horns

2

1.5 x 25mm Rod

25mm

LR

First, use a 400mm extension wire to connect to servo.

Then attach servo to vertical fin with strong double-

sided adhesive tape. Then put the wire through as

shown in picture.

You may also use A/B glue to attach the servo. But

please take into consideration for the quality of servo

and if it can be replaced or repaired easily.

Assemble left and right side the same way.

Attention: Double-sided adhesive tape and extension

wire are NOT included.

Double-Side Tape

Must be purchased

separately!

400mm extension

Place the PVC servo cover and lock with 2x8mm

screws as shown in picture.

Drill two 2mm holes on rudder on where control horn

will be mounted. Then put 2x16mm screw through

control horn and rudder, then add the horn base at the

underside of rudder and lock it in place. Then connect

the “Z” end of the pushrod to servo arm and connect

the other threaded end to clevis, adjust to suitable

length and attach to control horn.

Check the angle between servo arm and pushrod.

Assemble control horns on both sides of rudder the

same way.

Rudder Servo

Rudder Servo

2 x 8mm Screw

LR

2x16mm Screw

14

6

15

13

LR

C.A

C.A

4

2 x 8mm TP Screw

Cut away the covering on where servo will be

mounted. Then attach elevator to tailplane with C/A

glue and make sure elevator can move smoothly.

Attention; Make sure elevator is attached properly.

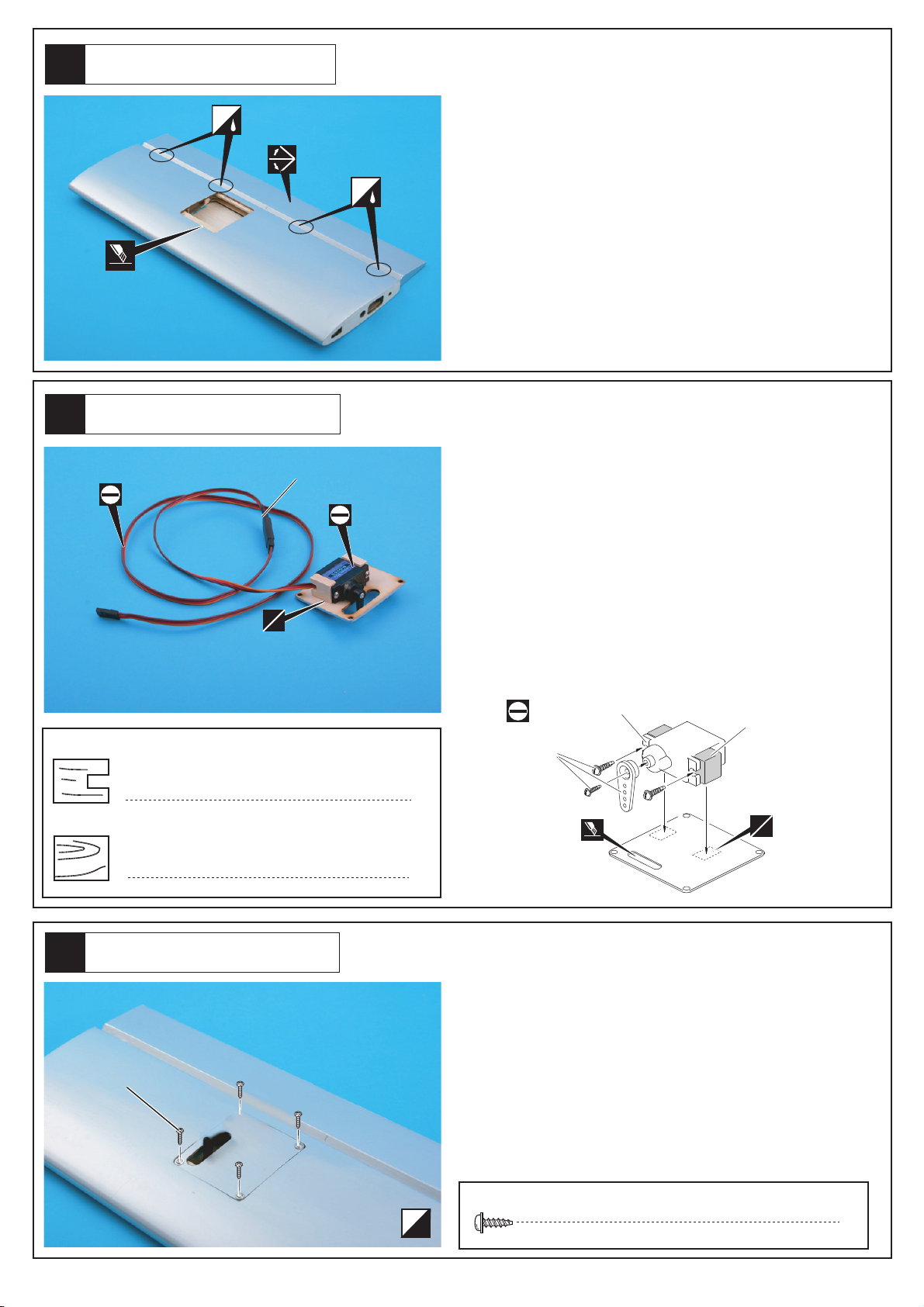

Tailplane

Elevator Servo

6

Hard wood 12 x 12 x 6mm

6

Hard wood 12 x 12 x 6mm

Must be purchased

separately! Hard wood block

mount for servo.

lncluded with

the radio set.

AB

approx. 600mm

AB

Elevator Servo

Put servo in place as shown in picture. The servo wire

will go through from the side of tailplane, and then lock

in place with 2x8mm screws.

2 x 8mm Screw

Assembly for (Micro) Servo

Connect extension wire (approx. 600mm) to servo.

Attach the 12x12x6mm hard wood on servo tray with

A/B glue, then mount servo in place with the screws

supplied with servo.

Note the servo directions for left and right hand.

Attention: Extension wire, servo, servo plate & its parts

are NOT included!

17

7

18

16

Tailplane

Tailplane

Flap

2

2 x 20mm Screw

Rod adjuster

Horn

12

1

2 x 30mm Rod

3 x 20mm Screw

3mm Washer

4

4

4

3mm No:1022

Drill two 2mm holes on where control horn will be

mounted as shown in picture. Then put 2x20mm screw

through control horn and elevator, then add the horn

base at the underside of elevator and lock it in place.

Then connect adjusters to both ends of the 2mm

threaded pushrod. Attach one end to control horn,

adjust to suitable length and attach the other end to

servo arm. Check the angle between servo arm and

pushrod.

2mm

2 x 20mm

2 x 30mm Rod

LR

First, put the servo wire through from the back of verti-

cal fin to the front, as shown in picture. Then insert

3x20mm screws at the side of fin, add 3mm washer

and lock tailplane in place.

3 x 20mm Screw

extension

AB

Attach 3mm hinge (#1022) in place with A/B glue, and

make sure flap can move smoothly

AB

20

8

21

19

Flap Servo

4

2 x 12mm Screw

Rod adjuster

Horn

2

4

2

2 x 60mm Rod

8

2 x 8mm TP Screw

NO:1006 (M4)

6

Hard wood 12 x 12 x 6mm

6

Hard wood 12 x 12 x 6mm

Must be purchased

separately! Hard wood block

mount for servo.

lncluded with

the radio set.

AB

Flap

Flap Servo

LR

Drill two 2mm holes on where control horn will be

mounted as shown in picture.

Then insert 2x12mm screws through control horn and

flap. Then add the horn base at the underside of flap,

and lock it in place. Then connect adjusters to both

ends of the 2mm threaded pushrod. Attach one end to

control horn, adjust to suitable length and then

connect to servo arm. Check the angle between servo

arm and pushrod. Assemble control horns on both

sides the same way.

2mm

2 x 12mm

2 x 60mm Rod

4

3 x 4 mm Set Screw

1

3

4.1mm Collar

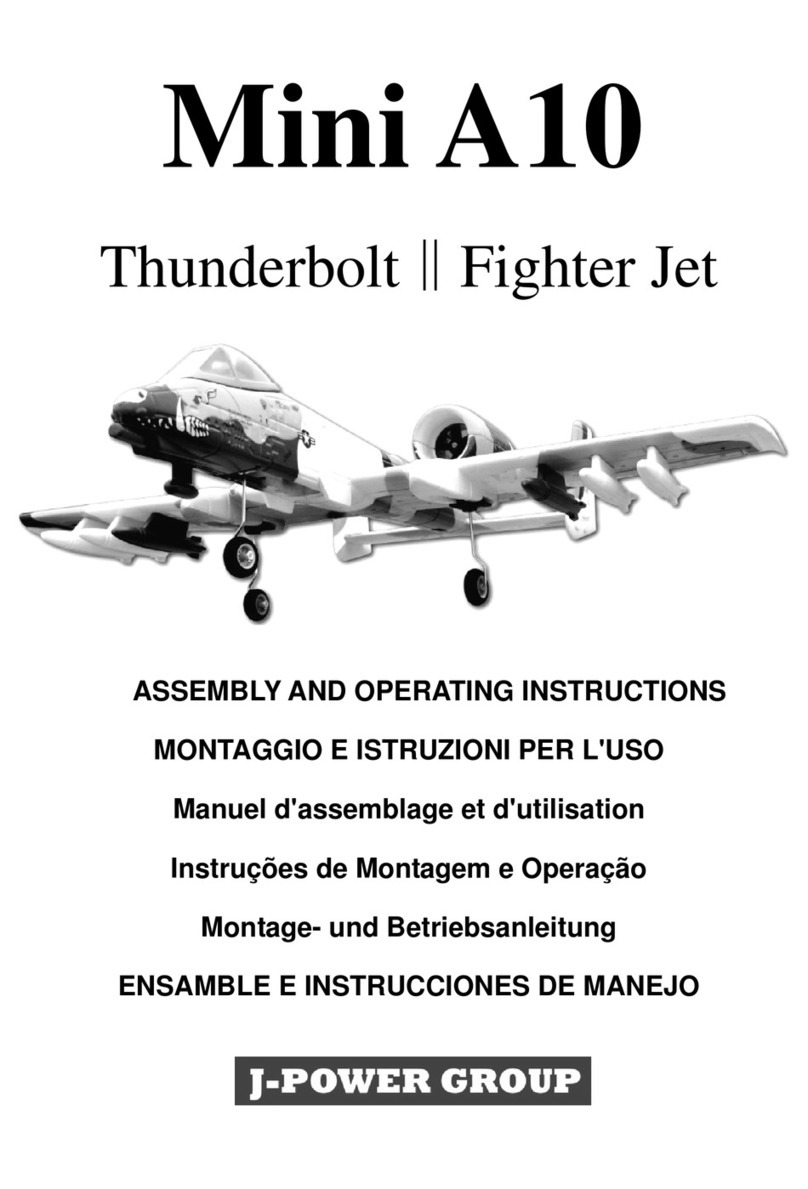

Fixed Landing Gear

Insert M4 collar to the 4mm landing gear and insert to

the hard wood mount, adjust to suitable length and

lock in place with 3x4mm set screw.

Then attach the steering arm and lock it at suitable

direction with the 3x4mm set screw. Then drill a 2mm

hole on the steering arm.

Then insert 4mm nylon ring to the landing gear and

insert the 45mm wheel. Then add the M4 collar and

lock in place with set screw.

45mm

4mm Nylon Ring

1

4.1mm Collar

3 x 4 mm

2mm

4mm Nylon Ring

4.1mm Collar

Attention: Skip to Step#26 if you are using

retractable landing gear.

Assembly for (Micro) Servo

Attach the 12x12x6mm hard wood on servo tray with

A/B glue, then mount servo in place with the screws

supplied with servo.

Note the servo directions for left and right hand,

assemble left & right side the same way.

Note: Servo, servo plate & its parts are NOT included!

23

9

24

22

1

2 x 200mm Rod

1

3 x 4 mm Set Screw

Linkage Stopper

2mm Nut 1

1

4

2.6x 12mm TP Screw

Rod adjuster 1

2.6x 12mm TP Screw

Fixed Landing Gear

Mount the assembled nose steering landing gear on

fuselage with 2.6x12mm TP screws.

Nose Steering Servo

Must be purchased separately!

3 x 4mm

Linkage Stopper

Mount the linkage stopper on servo plate as shown in

below picture. Then mount servo on wood plate with

the screws supplied with servo.

Attach rod adjuster to the threaded end of the 200mm

rod, and connect to steering. Insert the other end with

the linkage stopper.

Attention: Servo, servo plate and its parts are NOT

included.

Nose Steering

Lock the 3x4mm set screw on linkage stopper in place

until the nose wheel is set at a suitable angle.

26

10

27

25

3 x 10mm

Aluminum tube

Collar

4

2 x 8mm TP Screw

4

2.6x 12mm TP Screw

4

0.4 x 500mm Wire

3 x 10mm Round brass tube

Rod adjuster 4

4

2 mm Rigging Couplers

1

2 x 8mm TP Screw

Nose Gear Cover

Drill a 5mm hole on nose gear cover and mount it in

place with 2x8mm TP screws.

5mm

Nose Retract

Mount nose retract in place with 2.6x12mm TP screws

as shown in picture.

Attention: Nose retract and it parts are NOT included.

2 x 8mm TP Screw

lncluded with

the radio set.

Steering Servo

Mount the nose steering servo in place with the screws

supplied with servo.

Insert the wire into the 3x10mm aluminum tube, add

the 2mm coupler and insert it back to the tube. Then

compress the tube so that the wire is tightened. Then

attach rod adjuster to coupler, adjust to suitable posi-

tion and connect to steering servo plate.

You may use shrinking rudder to wrap the wires for

better appearance.

Attention: Shrinking rubber, servo, servo plate and its

parts ARE NOT included.

29

11

30

28

3 x 10mm

Aluminum tube

Collar

Nose Steering

Nose Cover

4

2 x 8mm Screw

Aluminum tube

Insert the other end of the wire into 3x10mm aluminum

tube, then through the steering arm on front leg and

compress the tube so that the wire is tightened.

You may use shrinking rudder to wrap the wires for

better appearance.

Attention: Shrinking rubber is NOT included.

2 x 8mm TP Screw

Make cut-out on the cover for the nose steering, then

you can mount it on fuselage with 2x8mm TP screws.

Ducted Fan

Cut the exhaust pipe as shown in picture and mount

ESC in place with stripe

Attention: ESC and stripes are NOT included.

35

13

36

34

4 x 20mm Screw

4mm Washer

2

2

4

2 x 8mm TP Screw

AB

Tail Booms

Mount tail booms in place with two 4x20mm screws

and 4mm washers.

4 x 20mm Screw

4mm Washer

Canopy Cover

Place canopy cover on fuselage, then drill 1.2mm hole

on canopy and lock it in place with 2x8mm screws, as

shown in picture.

1.2mm

Attach canopy with canopy cover with A/B glue.

Canopy

1.2mm

14

37

12-18mm

12-18mm

0mm

64mm

65mm

C.G

AILERON

FLAP

RUDDER

ELEVATOR

15-25mm

15-25mm

0mm

12-18mm

12-18mm

0mm

15-40mm

0mm

Never fly before checking the C.G’s required position.

Control Surface Movement

This manual suits for next models

2

Popular Toy manuals by other brands

Primo Water

Primo Water 4-in-1 Potty instructions

Maxford USA

Maxford USA Albatros D.Va instruction manual

Reely Sky

Reely Sky EXTRA 300 operating instructions

Fisher-Price

Fisher-Price W9859 instruction sheet

Smoby

Smoby 330104 quick start guide

J-Power

J-Power Thunderbolt Mini A10 Assembly and operating instructions