De Heus BOXER AGRI PI 135 User manual

ROTARY HARROW

PI 135 ● PI 175 ● PI 200

USER MANUAL

P. de Heus en Zonen Greup B.V.

Stougjesdijk 153

3271 KB Mijnsheerenland

The Netherlands

Tel: +31 (0) 18 66 12 333

E-mail: info@boxeragri.nl

ROTARY HARROW | User manual February 2021

ENG | ENGLISH

TRANSLATION OF THE ORIGINAL MANUAL

CONTENTS

February 2021ROTARY HARROW | User manual

1. USING THE ROTARY HARROW .................................................................................................... 4

2. SAFETY INSTRUCTIONS ............................................................................................................... 5

3. PUTTING INTO OPERATION/OPERATING INSTRUCTIONS ............................................................ 6

4. WORKING METHOD/USE ............................................................................................................ 7

5. STORAGE/MOVING .................................................................................................................... 8

6. MAINTENANCE/REPAIRS ............................................................................................................ 9

7. DISPOSAL AND THE ENVIRONMENT .......................................................................................... 10

8. TECHNICAL FILE ........................................................................................................................ 11

9. FIGURES ................................................................................................................................... 12

Page 4/12

ROTARY HARROW | User manual February 2021

1. USING THE ROTARY HARROW

For tractors

Types: Boxer PI135, PI175 and PI200

The Boxer rotary harrow must be connected to the tractor or a comparable piece of equipment (hereinafter called

the machine) using a three-point mounting frame. The working width is determined by the rotary harrow type.

The rotary harrow can be used on sand and clay to turn and level without waste residue or stones. This may cause

injuries to people or the machine may be damaged.

• Only use and follow the BOXER manual.

• Note the danger symbols, pictograms and recommendations indicated by decals on the machine. Stay at a safe

distance from a rotating machine (at least 10 meters).

• Lubricate all lubrication points of the machine (five times + twice) and power take-off shaft (twice) every

10 hours.

• Inspect the rotary harrow for excessive dirt and damage before you begin to harrow.

• Make sure the open leveling roller on the back is working properly.

• Always drive down slopes in a straight line and not at a slant (only if the tractor is equipped with a ROPS cab).

Model Working width

(cm)

PTO speed

(rpm)

Required power

(HP)

Category Weight

(kg)

Tines

BOXER PI 135 135 540 20 -35 CAT. I 260 12

BOXER PI 175 175 540 30 - 60 CAT. I 320 16

BOXER PI 200 200 540 40 -70 CAT. I 380 18

Page 5/12

February 2021ROTARY HARROW | User manual

2. SAFETY INSTRUCTIONS

The following safety instructions and the ones given in the BOXER manual must be observed:

• The capacity and stability of the machine to which the rotary harrow will be connected must be adjusted to the

rotary harrow on the basis of 540 rpm (PTO).

• The fastening width of the machine must also be the same as the fastening width of the rotary harrow.

• Be aware of the controls and how to stop a tractor quickly.

• Conveying people is strictly forbidden.

• The working speed is between 2 and 7 km/h depending on the depth that is reached by the rotor head tines.

• The machine can be set almost level in the working position by using the lifting device and the open roller.

• Avoid ground that does not provide sufficient support and has too much gravel, stones, etc.

• The warning symbols and pictograms on the machine must continue to be visible and legible.

• Take care that no people or animals come into the operating range while harrowing.

• In particular, do not inspect or clean when the machine is running.

• Wear hearing protection if the sound level is higher than 85 dBA.

• Only use the rotary harrow for harrowing relatively dry soil without stones, gravel, etc.

• Jolting, jerky and swaying movements must be avoided.

• The rotary harrow must be stored on a paved surface.

• All pins and bolted connections must have sound retainers.

• Improper use of the rotary harrow must be avoided at all times.

• Obey traffic regulations.

• If the hydraulics of the tractor’s lifting device are not operating correctly, stop working immediately to prevent

accidents and/or damage.

• Only work with the rotary harrow in a horizontal position with the roller on the ground. When conveying over

a road, the rotary harrow must be free of the ground and be securely suspended in the lifting chains of the

three-point lifting device so that no obstacles can be hit.

• Follow the safety instructions on the machine carefully and make sure that they are and remain properly legible

and visible. If this is not the case, they must be replaced.

• Stop immediately if a person comes within 10 meters in connection with the danger of flying stones, which

could cause injuries.

• Make sure that the power take-off and its protections are in good condition. Try to maintain a power take-off

rotation of 540 rpm. The power take-off guard is not allowed to rotate! (Use the chain attachment!)

• Never leave the tractor if the tines are still rotating!

• Only work if the machine can be seen (if required, turn on the tractor’s rear lights).

Page 6/12

ROTARY HARROW | User manual February 2021

3. PUTTING INTO OPERATION/OPERATING INSTRUCTIONS

Before connecting the rotary harrow to the machine mechanically, the following must be checked:

• Whether the machine has sufficient capacity in all situations that may arise such as swerving or turning to be

safely fitted with the rotary harrow.

• Whether the connection points to be guaranteed on the rotary harrow match the connection points on the

machine.

• Check that the power take-off shaft does not touch anything with the lifting device in the highest and lowest

position.

• The machine has been provided with sufficiently long tines. Long tines guarantee a good result.

• Check the universal joint for proper connection and sufficient overlap (at least 15 cm).

• Every week, check that all bolted connections have been sufficiently tightened.

After the points above have been checked, the rotary harrow can be connected to the machine mechanically. When

connecting mechanically, the machine must be maneuvered slowly to the attachment system.

Page 7/12

February 2021ROTARY HARROW | User manual

4. WORKING METHOD/USE

Prior to use, the safety instructions given in 2 must be observed.

• Take care that the shaft with universal joint is as level as possible when in the working position.

• Check the safeguards of the top link pins and lifting rod pins.

• Try to work as horizontally as possible.

• If the harrowing depth is set too high, the heads make too much contact with the ground and the machine will

be damaged.

• Work only at a power take-off speed of 540 rpm.

• After every working day, the rotary harrow must be cleaned carefully so that no sand residue remains stuck

anywhere on the system and hardens.

• Park the combination with the machine on a flat surface.

• Do not stand on or in-between the machine if the tines are still rotating.

Page 8/12

ROTARY HARROW | User manual February 2021

5. STORAGE/MOVING

When storing the rotary harrow, make sure that the tines are free of any obstacle and are positioned straight on the

surface.

Do not stand on the machine when moving it.

Page 9/12

February 2021ROTARY HARROW | User manual

6. MAINTENANCE/REPAIRS

• Maintenance and repairs must be done by a competent person.

• When replacing the tines, make sure that the same tine lengths are installed.

• After every working day, the rotary harrow must be cleaned carefully so that no soil residue remains stuck

anywhere on the system and hardens.

• The rotary harrow must be inspected for wear, distortion and cracking every 10 operating hours and after any

unforeseen event.

• No changes may be made to the rotary harrow system without written consent from the manufacturer.

• Check the oil level in the gearbox every week.

• When in doubt, consult the manufacturer.

Every ten operating hours

1. Lubricate the roller with grade II grease

2. Lubricate the power take-off (2x).

3. Check the oil level in the gearbox and, if required, top it up using the hex plug.

4. Check the wear of the tines and, if required, weld them back into their original shape with equal lengths.

Every 50 operating hours

Check the oil level of the gearbox and, if required, top it up.

Every 200 operating hours or annually

Change the oil in the gearbox.

Page 10/12

ROTARY HARROW | User manual February 2021

7. DISPOSAL AND THE ENVIRONMENT

If the rotary harrow is no longer suitable for further use, the oil must be drained.

Each of the sorted materials must be offered separately to the relevant authorities/companies.

Page 11/12

February 2021ROTARY HARROW | User manual

8. TECHNICAL FILE

The technical file, detailed drawings, structural calculations and original CE declaration of conformity are available

for inspection at the office of the manufacturer/supplier.

Page 12/12

ROTARY HARROW | User manual February 2021

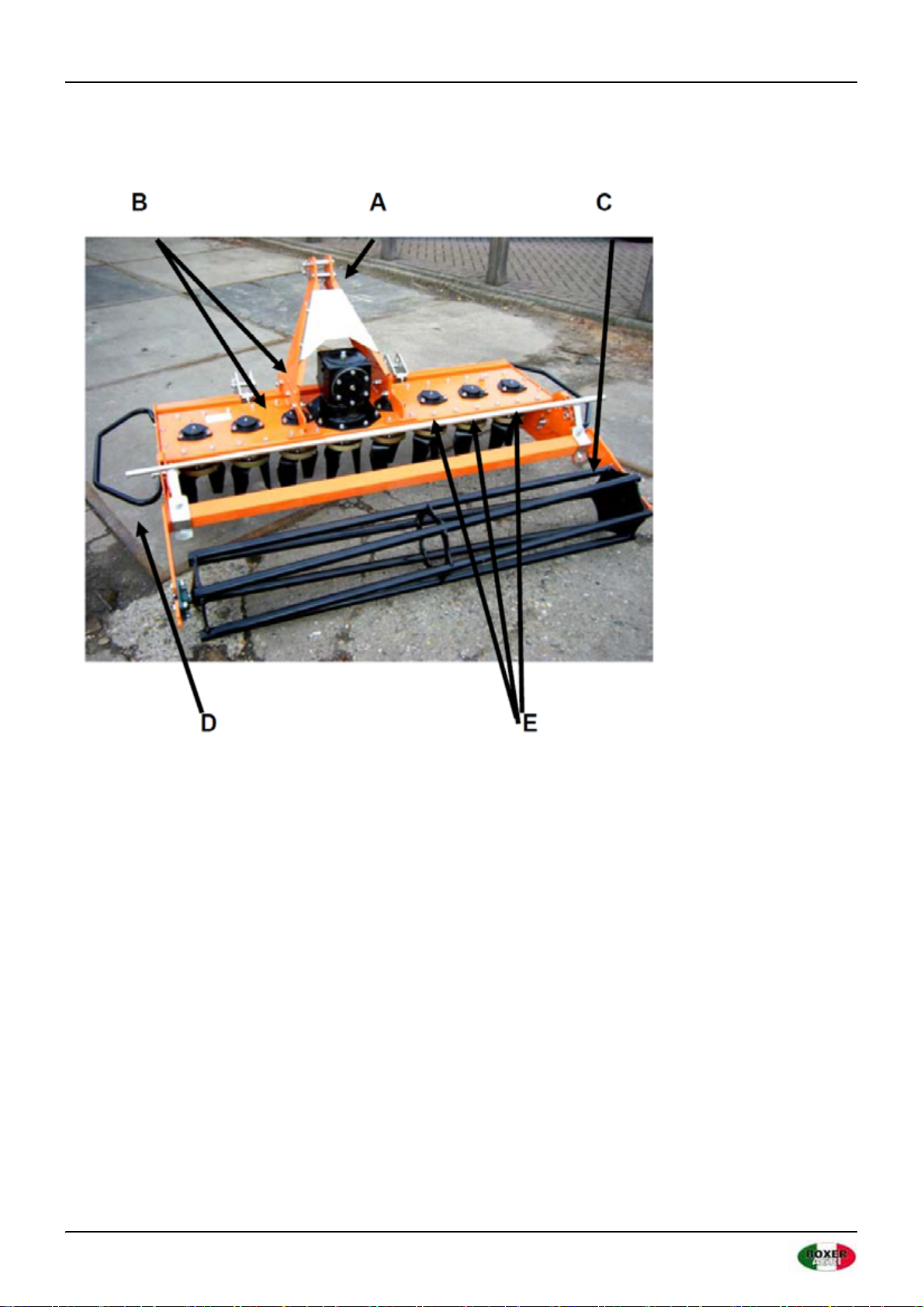

9. FIGURES

A - Third fastening point

B - Sideway openings

C - Leveling roller

D - Side guard

E - Rotor with blade

This manual suits for next models

2

Table of contents