de manincor EKB110 User manual

INSTRUCTION MANUAL

THERMO-COOKER EKB110

1. OPERATION AND TECHNICAL CHARACTERISTICS

2. INSTALLATION GUIDE

3. ACTIVATION AND MAINTENANCE

For installation, maintenance and the warranty, see the THERMO-COOKERS and THERMO-

STOVES use and maintenance booklet supplied with thermo-cooker EKB110.

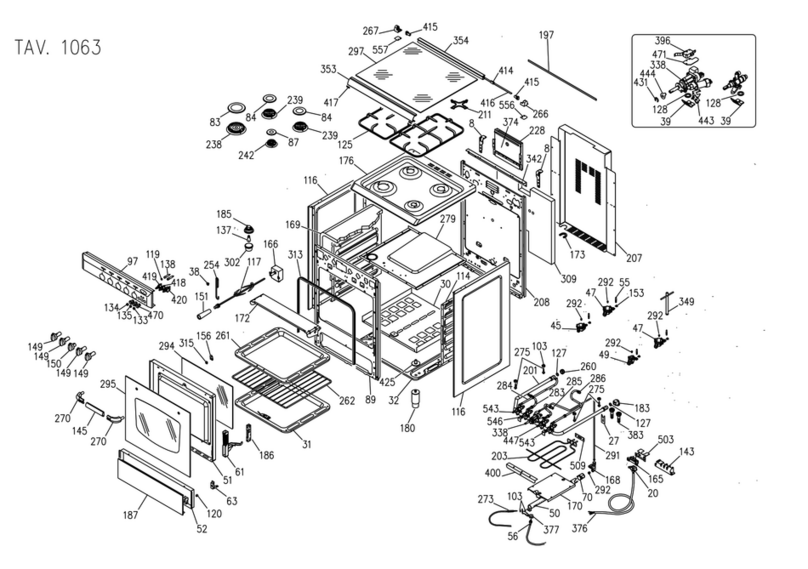

2.3 DESCRIPTION OF THERMO-COOKERS EKB110

a) radiant cast-iron hotplate

b) height-adjustable grill

c) oven with thermometer

d) oven light switch

e) starter for cold ignition of cooker

f) primary air thermostatic regulation

g) smoke path cleaning access

h) wood storage drawer

i) ash pan

j) boiler fittings

SUPPLIED ACCESSORIES

The following accessories are supplied with the

cooker:

k) scraper to clean the flue

l) stoker to move the rings

m) steel brush

n) oven grill and tray

o) oven mitt

p) grill crank

EKB110

1

b

j

i

f

g

h

d

c

e

a

1OPERATION AND TECHNICAL CHARACTERISTICS

The INTEGRATED OPEN TANK allows the separate operation of two circuits, primary (Thermo-

cooker) and secondary (Heating) by a coil heat exchanger with excellent heat transfer. The

thermo-cooker EKB110 can be equipped with a second exchange coil for domestic hot water

production.

1.1 OPERATION AND HYDRAULIC DIAGRAM

OPERATION

By means of the CTC control unit, when the Thermo-cooker reaches the temperature of

30°C (*), the Thermo-cooker pump switches on and then, at the temperature of 70°C

(*), the system pump turns on and the boiler turns off simultaneously. A third

temperature of 40°C (*), which can be set on the control unit, allows the deviation of

DHW production from the boiler to the thermo-cooker when the motorised VD diverter

valve trips.

(*) Preset default temperature value in the supplied control units which can be modified

by the user when installing and operating the system (see Control unit instructions,

pages 5-6).

2

RETURN

DELIVERY

DHW

CIRCUIT

THERMO-COOKER AND HEATING SYSTEM CIRCUITS PUMP 5.5 m wc

speed selector

3

Pumps with one inch fittings, three speeds, centre distance of 130 mm

Power absorbed by each pump: 55 W

3-way motorised diverter valve with fittings: G3/4"- male

Brazed stainless steel instantaneous coil heat exchangers

Galvanised sheet metal support plate 12/10

1.2 TECHNICAL CHARACTERISTICS

The parameters below (which can be modified by the user) indicate the temperature values of

the Thermo-cooker which, when reached, the Electronic control unit activates the various

components of the Hydraulic kit in sequence:

Thermo-cooker pump thermostat: 30°C Thermo-cooker circuit pump actuation (anti-

condensation function)

DHW valve thermostat: 40°C Diverter valve actuation for domestic hot water priority

Heating System pump thermostat: 70°C Heating system pump actuation and simultaneous

boiler switch-off.

Power supply: 230 Vac single phase

Maximum absorbed power: 76 W

Maximum operating pressure: 10 bar

Fluid temperature: +2 - 110°C

IN/OUT fittings: 1” GAS

Centre distance: 130 mm

Insulation class: IP 44

Material: Cast iron EN-GJL-150-200

Every year, before the start of the heating season,

unscrew and open the cap at the back of the pump,

being careful of squirting pressurised hot water,

manually turn the rotating part (using a

screwdriver) to unblock the rotor, if necessary

Supply Voltage: 230 Vac

Maximum operating temperature: 90 °C

Maximum operating pressure: 6 bar

Heating hydraulic connection: Ø 3/4"

Domestic Hot Water hydraulic connection: Ø1/2"

Thermo-cooker circuit IN/OUT temperatures: 80/64°C

Heating system IN/OUT temperatures: 55/69°C

HEADS WITH Q1= 1000 I / h

HEADS WITH Q2= 1400 I / h

speed 1

speed 2

speed 3

speed 1

speed 2

speed 3

H = 2.31 m wc

H = 3.62 m wc

H = 4.27 m wc

H = 1.60 m wc

H = 2.90 m wc

H = 3.80 m wc

H = 22.7 kPa

H = 35.5 kPa

H = 41.2 kPa

H = 15.7 kPa

H = 28.4 kPa

H = 37.3 kPa

HYDRAULIC PERFORMANCE CURVES

Head H ( m wc)

Head H ( kPa )

Flow rate Q ( I / h )

INPUTS

PROBE

Thermo-cooker Probe: Temperature Range 0 – 100 °C

FLUX

Flow switch/Boiler - DHW Thermostat ON/OFF Consent

LEV.

ON/OFF level switch

OUTPUTS

PUMP

System pump:

Power supply 230 Vac

Terminals 3(N) - 4(Fon)

VALV

Solenoid valve 2/3 wires:

Power supply 230 Vac

Terminals 5(N) - 6(Foff) - 7(Fon)

AUX

Auxiliary:

Potential-free contacts in exchange

Terminals 8(COM) - 9(N.C.) – 10(N.O.)

FDG ELECTRONIC CONTROL UNIT OPERATION

1. SWITCHING ON/OFF

The Control unit is switched on/off by holding down the button P1 (ON/OFF)

-The OFF status is signalled by the OFF LED lighting up

2. ALARM FUNCTION

If the temperature detected by the PROBE exceeds the alarm Thermostat value A01(90°C):

-the audible and visual warning device switches on

-SILENCE function: the buzzer can be switched off for 5 minutes by pressing any button

-when the 5 minutes have elapsed, if the alarm persists, the audible warning device goes off once again.

3. ANTI-FREEZE FUNCTION

If the temperature detected by the PROBE is below the Anti-freeze

Thermostat value A03 (6°C):

-the thermo-cooker PUMP switches on

-the display reads ICE

4. STANDBY FUNCTION

If the control unit is OFF in ALARM or ANTI-FREEZE condition:

-the control unit automatically switches to the ON status

TEMPERATURE PROBE

This measures and controls the water temperature in the

Thermo-cooker. It consists of a capsule Ø 6 x 30 mm in

Santoprene thermoplastic rubber and a cable diameter Ø 3.2

mm, length 2 m, bipolar (2 x 0.30 mm²).

There is an NTC 10 kΩ ± 1% at 25°C thermoresistive

sensor inside the capsule.

The temperature probe has a temperature range of

-50-120 °C, a response time of approximately 6 seconds,

electric insulation > 20 MΩ at 500 Vac, protection rating

IP68.

5. PUMP ANTI-BLOCK FUNCTION

If the PUMP remains idle for an amount of time longer than the

Anti-block Timer T01 (168 hours, equal to about one week):

-the PUMP switches on for T02 seconds (30 sec)

-the display reads bLP

This function is also activated in STANDBY

6. PUMP TEST FUNCTION

Holding down the button P3

-switches on the PUMP for the whole time the button is pressed

-the display reads tSt

7. LEVEL SWITCH FUNCTION

The level switch detects whether the water in the tank drops below the

minimum level:

-the LED lights up

8. OUTPUTS OPERATION

If the flow switch detects that domestic hot water is being drawn, the PUMP stops:

-the PUMP LED flashes and a flashing dash appears on the display.

It must be used inside a Ø1/2" probe

holder, supplied with control unit,

emerged in the delivery water of the

Thermo-cooker or Boiler. If needed, the

Probe-Hydraulic Kit connection can be

lengthened, to a Max of 15 m, using a

double-wire cable (2 x 0.50 mm²).

This function is not active if the probe temperature exceeds the value of the safety thermostat A02.

If the temperature of the probe exceeds the AUX thermostat value, the AUX output is activated.

If the temperature of the probe exceeds the VALV thermostat value, the VALV output is activated.

9. MAIN MENU

Setting of operating thermostats of controlled outputs:

-PUMP thermostat to control the operation of the system pump

4

FDG ADJUSTABLE 3-THERMOSTAT ELECTRONIC CONTROL UNIT

2 3 4 5 6 7 9 10 12

11

SENSITIVE

ELEMENT

LINE

PUMP

VALVE

AUX

LEV.

COM

N.C.

N.O.

PROBE

FLUX

-AUX thermostat for gas boiler integration, solenoid valve control or other application

-VALV thermostat to control diverter valve for domestic hot water

Simply clicking the button P1 (MENU) you may scroll the set Thermostat values, signalled by the flashing

associated PUMP / VALV / AUX LED

To change it, go to the thermostat value that needs to be modified:

-pressing button P2 increases the value

-pressing button P3 reduces the value

To save it, wait about 10 seconds or scroll all the parameters by pressing the (MENU) button

MAIN MENU PARAMETERS

MIN

DEFAULT

MAX

TYPICAL

VALUES

SET VALUES

Thermo-cooker PUMP thermostat

20

40

85

40

DHW VALVE thermostat

20

40

85

45

AUX thermostat

20

45

85

65

10. INSTALLER MENU (this menu must only be accessed by expert personnel, as changing these

parameters could make the product unsuitable for the application in use) To access the MENU

simultaneously hold down buttons P1 (MENU) and P4 ON/OFF for approximately 5 seconds

Press buttons P3 and P2 to scroll the labels of the parameters

Press P1 (MENU) to view the value of the parameter

To edit the value, press P3 and P2 while pressing P1(MENU)

To view the parameter list again and to store the value, press P1 (MENU)

Wait about 10 seconds to exit and save

MAIN MENU PARAMETERS

SYMBOL

MIN

DEFAULT

MAX

INSTALLED

VALUES

ALARM FUNCTION activation thermostat (°C)

A01

85

90

99

SAFETY thermostat (°C)

A02

20

85

90

“ICE" ANTI-FREEZE activation thermostat (°C)

A03

4

6

8

PUMP Thermostat Hysteresis (°C)

A04

1

4

10

Valve Thermostat Hysteresis (°C)

A05

1

2

10

AUX Thermostat Hysteresis (°C)

A06

1

2

10

ANTI-BLOCK Timer (h)

t 01

1

168

255

ANTI-BLOCK pump activation time (sec)

t 02

0

20

99

11. PROBE FAILURE ALERT

Flashing message LO (indicates out of scale towards low temperature below 0°C) = PROBE INTERRUPTED

Flashing message HI (indicates out of scale towards high temperature above 100°C) = PROBE SHORT-CIRCUITED

TECHNICAL CHARACTERISTICS

POWER SUPPLY: 230 Vac ± 10% ~ 50 Hz (protective fuse T3,15 A)

ABSORBED POWER: 2 Va ~

TEMPERATURE PROBE: In silicon/pvc cable

Operating temperature: -50 °C/ 130 °C

Measuring limits: 0-99 °C Precision: ± 1 °C

OUTPUTS: PUMP output powered 230 Vac max capacity 5 A 250 Vac

AUX output potential free contact max capacity 5 A 250 Vac

SERV output powered 230 Vac max capacity 5 A 250 Vac

MECHANICAL DIMENSIONS: Recessed temperature controller: 120x80x50 mm

Applied standards EN 60730-1 50081-1 EN 60730-1 A1 50081-2

5

The figure to the side shows the connections inside the

control unit, indicating the colours of the cables. You

can see that the terminals marked as FLUX are

jumpered: check for the presence of the above-

mentioned jumper, as without it the valve for DHW

production would be excluded.

These wiring diagrams must only be used by

qualified technical personnel.

2 INSTALLATION GUIDE

The appliance must be installed according to professional standard, following the instructions in this manual

and in compliance with the laws and regulations of each country, by QUALIFIED PERSONNEL acting

on behalf of Companies fit to assume full responsibility for the whole system.

Before putting the thermo-cooker into service, it is mandatory to set up the connections of the heating

system. Using the thermo-cooker with the boiler empty or not connected to the system would irreversibly

damage the boiler. In any case, the delivery connector, the return connector and the drain connector (to

empty the boiler in case of maintenance) must be connected to the system.

The tank of the thermo-cooker’s boiler must be filled manually, and topped up when notified by the specific

signal on the control unit.

2.1 HYDRAULIC CONNECTION

Pay special attention when setting up the hydraulic connection, not to force or twist the copper connections.

To counter the tightening torque exerted on the connection pipe flanged with the hydraulic system, use a

spanner or other tool on the nut of the pipe to be connected.

HYDRAULIC TESTING

When assembly operations are over, each Thermo-cooker is tested hydraulically with air at 6 bar, to make

sure that the different connections are perfectly airtight when pressurised.

After having transported/handled the thermo-cooker, tighten all the ring nuts of the copper pipes. They have

a diameter of Ø20 when used for heating and Ø14 for domestic hot water production. It is recommended to

install manual outlet shut-off valves, to facilitate maintenance: valves with GAS 3/4" male-female couplings

for heating and GAS 1/2" for domestic hot water production.

HYDRAULIC CONNECTION

Set up the hydraulic connection according to the diagram on page 2 of this manual. It is recommended to

install shut-off valves.

2.2 ELECTRICAL CONNECTION

Before setting up the electrical connection, make sure

the mains power is disconnected.

Connect the power line to a two-pole switch complete with

fuses (power supply 230 Vac: 50Hz), including the

essential and correct connection to the earthing system.

The Thermo-cooker must be powered by a line with a

residual current device upstream, as set forth by current

standards. Correct operation of the control relays is only

guaranteed for pump and valve motors with load up to

100W. The manufacturer will not be held liable for

improper use.

ELECTRICAL TESTING

Each HYDRAULIC KIT is tested electrically by connecting the

control unit to a control board, where the different possible

temperatures in the thermo-cooker are simulated in sequence,

from the anti-freeze function to the maximum temperature safety

function A02 at 99°C.

6

3 ACTIVATION AND MAINTENANCE

Before installing the thermo-cooker, you must wash the pipes of the system it is connected to. The thermo-cooker

could malfunction if the pipes are dirty inside.

When the hydraulic installation and electric wiring have been set up, fill the system of the Thermo-cooker and of the

Heating system with water.

ATTENTION. Running the pump without first completely eliminating any air inside would burn the motor due

to overheating. Heat the probe with a lighter or hairdryer to start the pump. Make sure there are no water leaks when

the system is pressurised.

We remind you that the circulation pump has 3 rotation speeds, to be adjusted manually depending on the features of

the system and on the flow rate/head technical data expected by the design engineer.

The speed is set at 2 when the appliance leaves the factory.

Maintenance must be assigned to qualified personnel working in compliance with standards in force and according to

the instructions in this booklet. Before starting any maintenance operation, make sure that the mains power is

disconnected. Before performing any extraordinary maintenance which entails disassembly, make sure to have

closed the shut-off valves on the Thermo-cooker’s external piping.

PROBLEM

CAUSE

SOLUTION

The thermo-cooker quickly reaches

operating temperature (70 - 80 °C) while

the heating system (radiators) stays cold

Air pockets in the secondary

heating circuit

Carefully vent the entire heating system and

bring the pressure of the closed tank part to a

value suitable for the height of the system.

The thermo-cooker quickly reaches

operating temperature (70 - 80 °C) while

the heating system (radiators) stays cold

The circulation pumps do not work

Check that the electrical connections of the

pumps and of the control unit are intact and

efficient

The control unit indicates LO

Probe defect.

Ambient temperature lower

than zero.

Risk of freezing

Check that the probe is well-connected to the relative

terminals of the control unit. If LO is still displayed,

make sure the probe is not interrupted or blown

The control unit indicates Hl

Probe short-circuited.

Temperature of the thermo-

cooker

>100°C

The Thermo-cooker is in overtemperature,

immediately reduce the fire, open the door to cool

the combustion chamber and make sure the

system is vented. If the Thermo-cooker is not on,

use a Tester to check whether the resistance of

the probe is at zero

Domestic hot water is not produced

Malfunction of the motorised

diverter valve

Check that the valve temperature set on the

control unit is not too high; check the position of

the 3-way valve control rod.

As per the figure on page 4

The control unit does not switch on

Power failure

Check that there is a voltage of 230 Vac in the

power line and at the relative terminals of the

control unit. Check the fuse inside the control unit

.

7

Table of contents

Other de manincor Cooker manuals

Popular Cooker manuals by other brands

Garwoods

Garwoods EC-2072 Installation & operating instructions

Zanussi

Zanussi ZCV667MWC user manual

Electrolux

Electrolux ETG729GKT installation instructions

VOX electronics

VOX electronics GHT631 operating instructions

Tricity Bendix

Tricity Bendix SI360 OPERATING AND INSTALLATION Manual

Bosch

Bosch HSB738257 M instruction manual