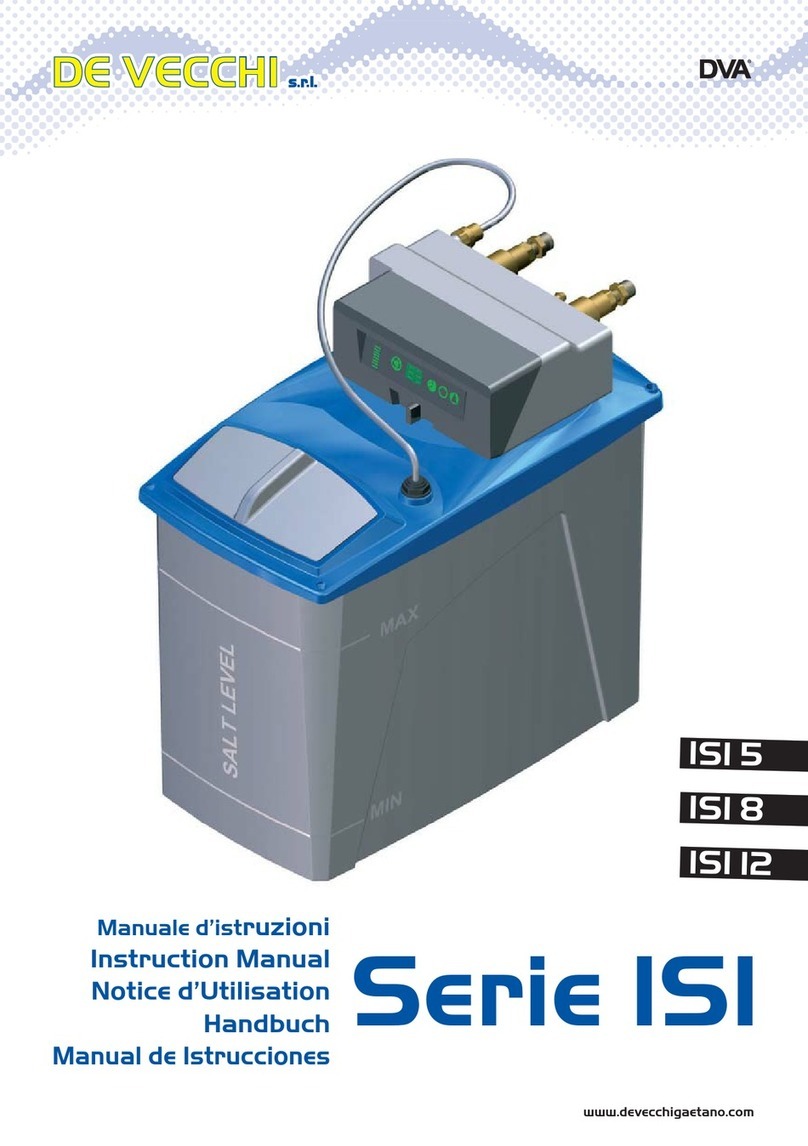

DE VECCHI DVA AL Series Manual

Volumetric automatic water softeners

AL Series with “ALLARM SALT”

Technical information

The AL series softeners feature advanced functions that have specifically been designed

for the catering industry.

“SALT ALARM”

There is a specific function supporting the user in monitoring salt presence in the brine

tank; this prevents the softener from running out of salt.

MULTILINGUAGE DISPLAY

Information can be displayed in English, Italian, French, Spanish and German.

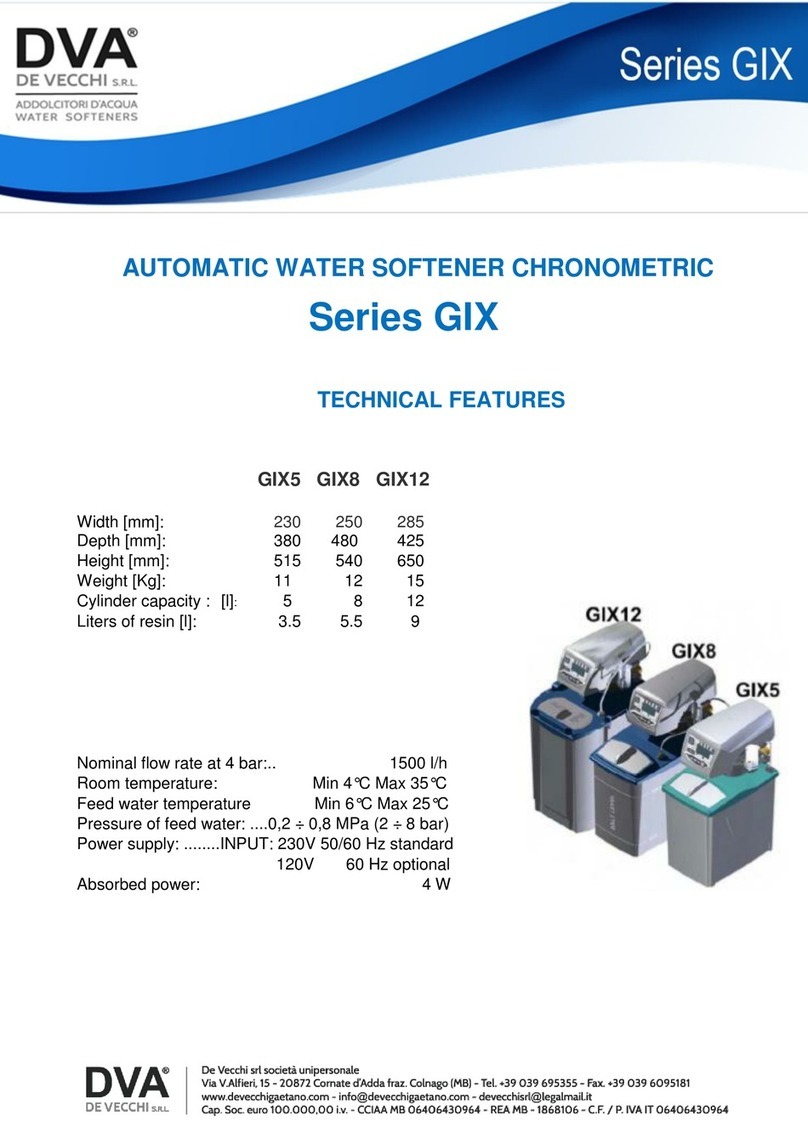

TECHNICAL DATA

MODEL AL5V AL8V AL12V

Width in mm: 230 250 285

Depth in mm: 360 460 405

Height in mm: 460 485 595

Weight in kg: 11 12 15

Cylinder capacity in lt.: 5 8 12

Resin volume in lt.: 3.5 5.5 9

Salt for regeneration (kg) 0.6 1 1.5

TECHNICAL FEATURES

Max flow rate: 1400 l/h

Room temperature: Min 4°C Max 35°C

Infeed water temperature Min 6°C Max 25°C

Water pressure 0.2 Mpa Min 2 bar

0.8 Mpa Max 8 bar

Power supply: Standard 230 V 50/60 Hz

Optional 120 V 60 Hz

Power absorbed: 4 W

“AS” SALT ALARM

This function is useful and ensures correct soft water

supply.

Whenever the resin is regenerated, the softener

checks salt level in the brine tank and, if salt is not

present, an acoustic signal will be triggered, all the

led lights will shift to red and the “ADD SALT”

message will be displayed.

Time and date of such salt alarm will be recorded in

the “Alarm Log” “AS”.

This will allow the maintenance technician to view

the recorded date.

SETTINGS

This device features an easy and user-friendly setting

procedure that is based on the four buttons located

around the display.

The AL softener can be set in Volumetric as well as

Chronometric mode.

Softener settings can be changed at any time so as to

shift from one mode to the other.

Once set, all the data can be displayed. More

specifically:

-Current date and time.

-Salt monitoring function on.

-Softener model.

-Any changes in regeneration cycle duration.

-Day on which the next regenertion will be carried out.

-Whether the softener is in volumetric mode.

VOLUMETRIC SETTINGS

The data used to set the softener in Volumetic mode

are the following:

-softener model;

-hardness of water to be treated;

-the number of days elapsing between regeneration

cycles, irrespective of water consumption.

When the softener is in Volumetric mode, letter “V” is

displayed.

A-Hour

B-Day of the week

C-Extra Rinse

D-Modell

E-Volumetric mode

F-*R* Mean that on this day a regeneration will

take place

G-Acoustic salt alarm off

H-Visual salt alarms off(I)

CHRONOMETRIC SETTINGS

Regeneration cycles can be set in two different ways,

when in Chronometric mode: by setting one or more

days in a week, or by setting the number of days

elapsing between two regeneration cycles.

When the softener is in Chronometric mode, the 4 led

lights are green, but not on the day a regeneration cycle

is scheduled. On that day, only a green led light running

at the bottom of the display is visible.

A-Hour

B-HDay of the week

C-Modell

D-How many day are to elapse before regeneration

E-Regeneration frequency

A-Hour.

B-Day of the week

C-Modell

D-*R* Mean that on this day a regeneration will take

place

E-Regeneration weekly

F-No chime

G-No salt alarm

FIRST INSTALLATION

Once the third automatic regeneration is finished,

the AL softener will report in a log the day on which

it was carried out. That day is processed as the

starting day for the warranty period.

The recorded date is not effaceable.

POSTPONED REGENERATION (R)

Postponed regeneration is a useful function to restore

the salt alarm.

When the salt alarm is triggered, the correct

procedure to be implemented is the following:

silence the audible alarm by simultaneously

pressing the “R” and “-” buttons, add salt in the brine

tank and press the “ R“ button to start a postponed

regeneration cycle.

Letter (R) will be displayed.

Regeneration will be carried out at the same time set

when programming regeneration cycles.

SETTINGS DISPLAY

When running, the softener displays operating data, settings

and any triggered alarms in sequence.

When the AL softener is in Volumetric mode, by pressing the

“+” button, the following data are visible:

-Regeneration start time

-Remaining water

-Water hardness

-Frequency of forced regeneration expressed in days

-Daily water consumption

-Alarm log

-First installation

If the softener regeneration cycles are set on a weekly base,

by pressing the “+” button the following information will be

viewed in sequence:

-Regeneration starting time.

-Day(s) on which regeneration will be executed.

-Alarm log (AS salt alarm).

-First installation date.

If the softener is set so as to carry out regeneration

cycles based on a day interval schedule, by pressing

the “+” button the following data sequence will be

displayed:

Regeneration start time.

Alarm log (AS Salt Alarm).

First installation date.

MULTICOLOUR LED LIGHT READING

Thanks to the four led lights that can display different

coulours, users can easily realize whether the

Volumetric AL softener is correctly running, if it is in a

regeneration cycle or if it is in alarm mode.

Users can understand at a glance the phase the

softener is in.

Each colour expresses a different function:

Green –the softener is correctly running

Red –an alarm is on

White –is for functions in progress

Blinking white –when date, time and language are

being set

Blue –is for the setting phase

When in Volumetric mode, during soft water supply, the

led lights will switch from green to white, and

information on remaning soft water will be displayed.

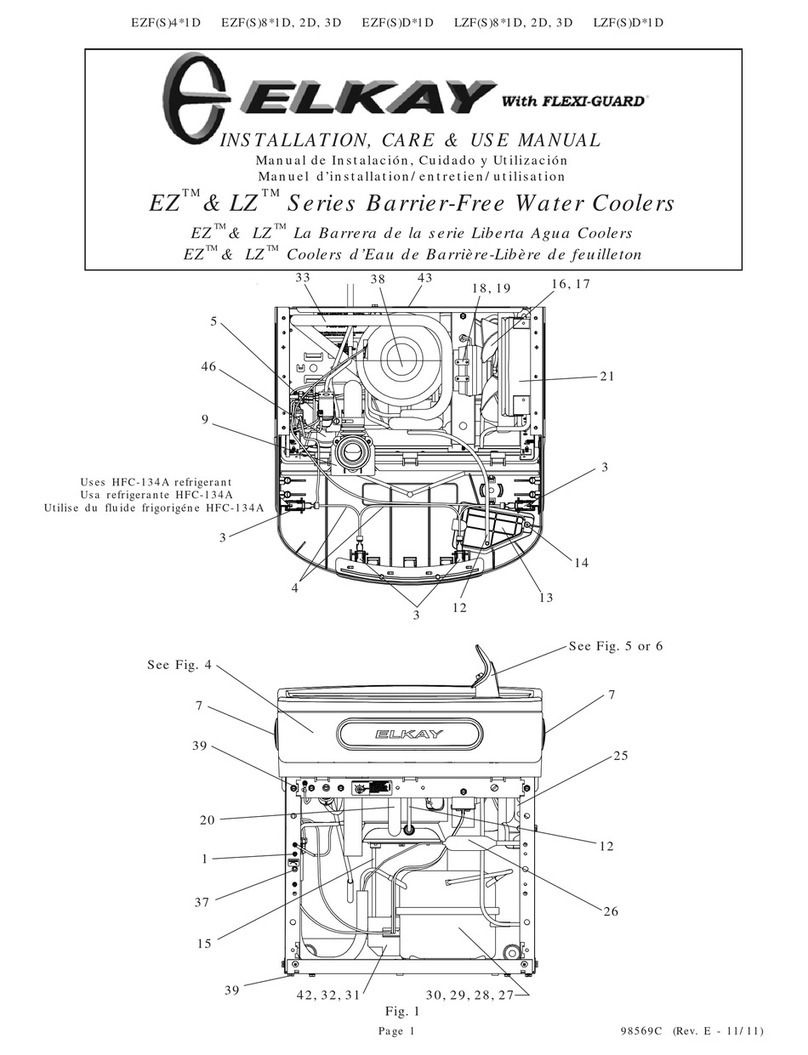

ANTI-FLOODING OPTIONAL DEVICE

This is an optional device that improves reliability of the AL series softeners by

preventing water from overflowing from the brine tank, in case of over filling.

It can be requested and installed on all models.

Softener settings, controls and functions will not change.

ANTI-FLOODING OPERATION

Water level control in the brine tank is based

on a safety mechanism. The float detects any

water flowing in the brine and, if needed, it

triggers a mechanism to stop water from

flowing in it.

In case it is triggered, checking the cause and

the correct softener operation is

recommended.

The anti-flooding device only acts on the

connection between the valve and the

brine; it does not replace the float used for

the overflow function, which will have to be

installed anyway.

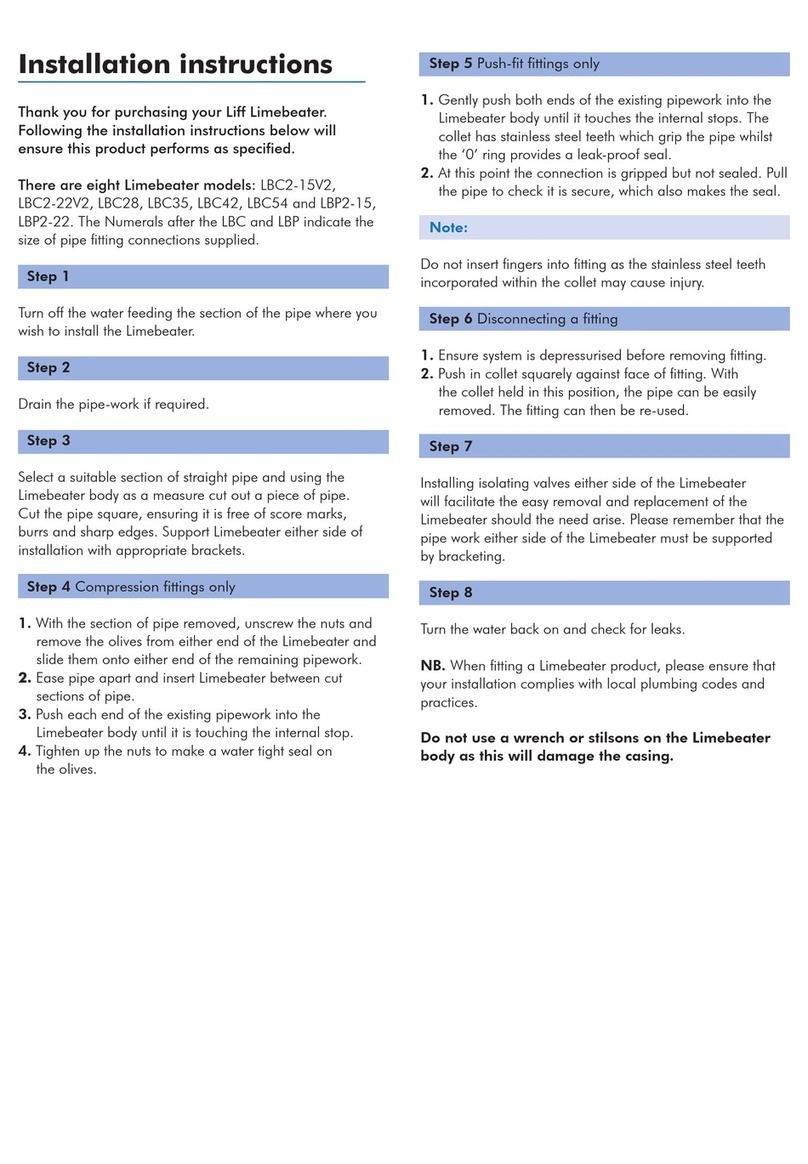

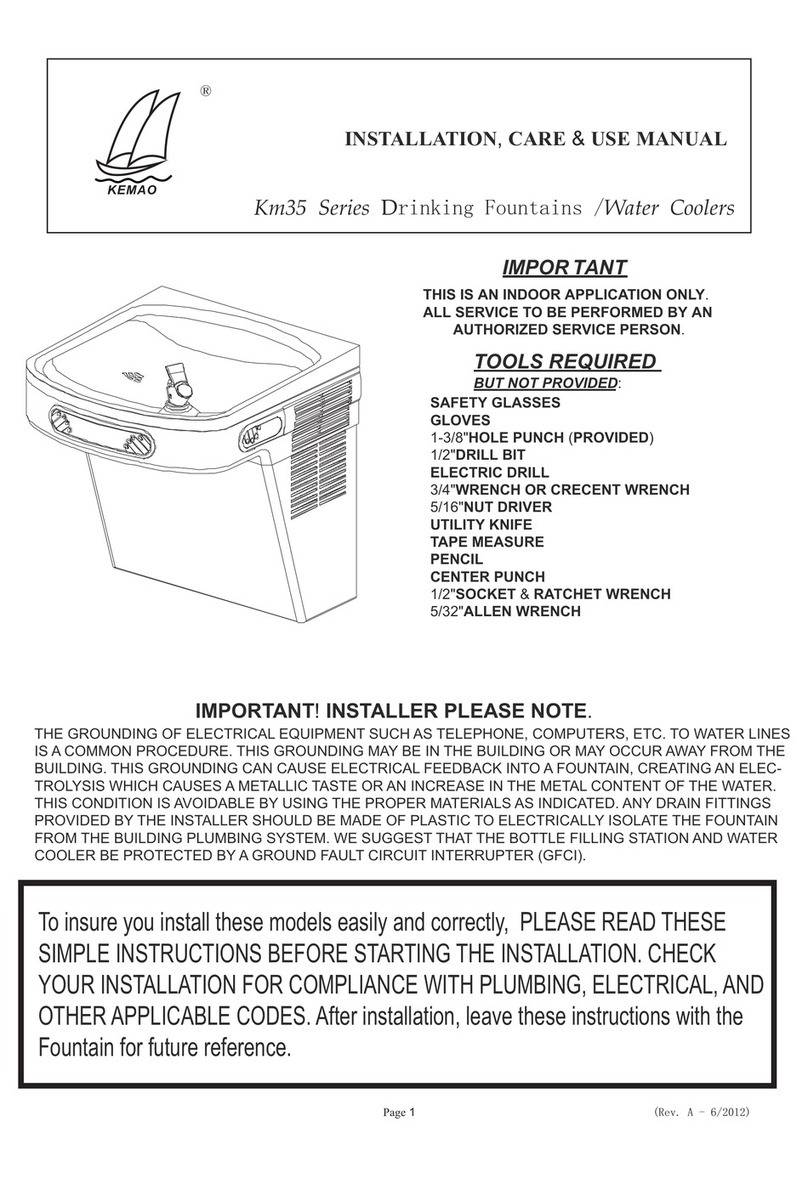

INSTALLATION SUGGESTIONS

The installation illustrated in the figure on the side

is suggested.

A non-return valve shall be installed in the outlet

water pipe (A). This protects the softener from hot

water flowing back and damaging the softener.

A-NON-RETURN VALVE

B-OUTLET WATER TAP

C-BY-PASS TAP

D-INLET WATER TAP

E-OVERFLOW PIPE

F-DRAIN PIPE

G-INLET WATER PIPE

H- OUTLET WATER PIPE

I-OVERFLOW COUPLING

L- ID LABEL

M- MIXING PIECE

LOCATION SUGGESTIONS

The distance between the softener and the drain

system shall be as short as possible.

If the drain pipe is located at a higher level than the

softener, maximum height shall be 1.8 meters,

provided that the pipe is no longer than 5 meters and

that water pipe pressure is at least 3 bars.

If the softener is close to a boiler, water pipes and the

softener shall not be impacted by excessive heating.

Whenever possible, it is advisable to keep at least a

3-metre distance between the softener's outlet water

pipe and the boiler's inlet water pipe.

Do not install the softener close to acid and/or

corrosive substances and/or fumes.

FLOWMETER TURBINE

This softener must feature a flowmeter turbine so as to run in

Volumetric mode.

If such turbine is not present, the softener will only run in

Chronometric mode.

DRAIN PIPE SUGGESTIONS (A)

When installing the pipe lines, the drain pipe shall not

be crashed or too tightly bent so as to avoid water

clogs.

OVERFLOW DRAIN PIPE (B)

The overflow drain pipe shall be installed below its

coupling. The water that might overflow is caused by

a water system failure and will be drained thanks to

gravity.

INSTALLATION PROGRAM

Once the installation is over, by pressing the “OK” and “-“

buttons, the AL softener will carry out the auto-installation

program. The device will be ready to run and supply soft

water upon completion of such procedure.

The auto-installation program will rinse the resin and fill

the brine tank with the right amount of water in a few

minutes and in fully-automated mode.

RESIN RINSING PROGRAMME

It can sometimes happen that the softener supplies

salt water.

This problem is caused by lack of pressure in the

water pipes during the last regeneration cycle

preventing an adequate rinsing procedure.

Thanks to the resin rinsing program, all the salt water

in the softener can be drained in a matter of minutes.

Press the “+” and the “ok” buttons so as to read the

following message in the display to start this program:

“ RESIN RINSING”

INSTALLER MAINTENANCE

It is advisable to have the installer clean the electrodes

(A), the ejector (B), the filter (C) and the caps (D) at

least once a year, and check all the connections.

Poor or lack of maintenance can cause softener

failure.

Filling up of brine tank (clogged ejector) and non

aspiration of brine (air infiltration in quick pipe

couplings) are the types of problem that might arise

due to lack of maintenance by an installation

technician.

USER SUGGESTIONS

Users shall ensure that salt is present in the brine also

making sure to top it up if close to depletion.

QUANTITY OF SALT REQUIRED ACCORDING TO THE MODEL

VOLUME OF WATER DELIVERED ACCORDING TO THE MODEL

ICIM

HYGIENIC SAFETY NORMS AND ICIM TESTING

This equipment has been tested by the ICIM Institute of Italian

Certificated for the Mechanic, licensed credited labora-tory,

certificated to the compliance with:

• Reg. n.1935/2004/CE products and componence contact with

elements according to the dispositions MOCA.

• D.M. n.174/2004 products and componence utilised in contact

with feed water.

It is NECESSARY to use original replacements for repairs and

maintenance, to guarantee hygienic safety.

MODEL

Quantity of salt for

regeneration kg)

Quantity of salt in the brine

tank di sale (kg)

AL5V

0,6

10

AL8V

1

20

AL12V

1,5

25

SOFT WATER LITRES BASED ON WATER HARDNESS

°f

°d

ppm CaCO3

20

11

200

30

16

300

40

22

400

50

28

500

60

33

600

Cyclic

capacity

m 3.°f

AL5V

1050

700

525

420

350

21.0

AL8V

1680

1120

840

672

560

33.6

AL12V

2520

1680

1260

1008

840

50.4

CODE ORDER:

Automatic water softener AL CHRONOMETRIC ALIA valve

With “ALLARM SALT”

ACL077 = AUTOMATIC SOFTENER AL5V 3/4”G

AAL077 = AUTOMATIC SOFTENER AL8V 3/4"G

ABL077 = AUTOMATIC SOFTENER AL12V 3/4"G

With “ALLARM SALT” and ANTI-OVERFLOW

ACL077G = AUTOMATIC SOFTENER AL5V 3/4”G NG

AAL077G = AUTOMATIC SOFTENER AL8V 3/4"G NG

ABL077G = AUTOMATIC SOFTENER AL12V 3/4"G NG

This manual suits for next models

3

Table of contents

Other DE VECCHI Water Dispenser manuals

Popular Water Dispenser manuals by other brands

Soleus Air

Soleus Air WA2-02-50A user manual

Elkay

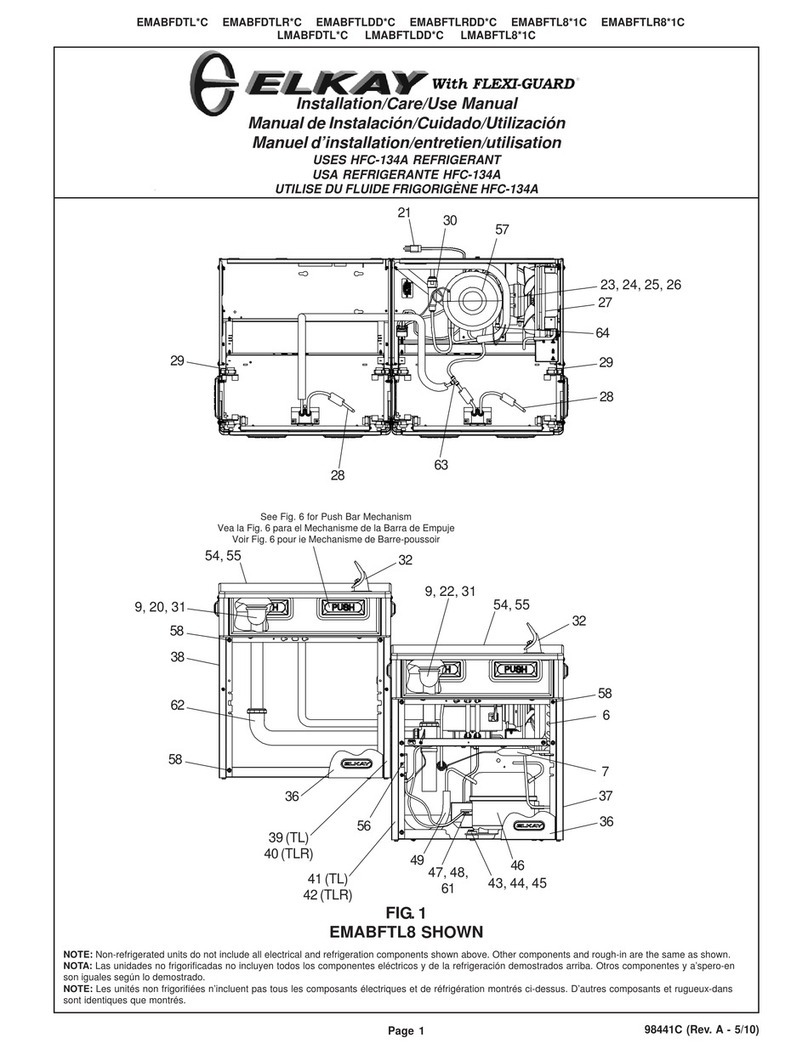

Elkay Space-ette FD700-3 1J Series Installation, care & use manual

Elkay

Elkay EMABFDTL C Series Installation, care & use manual

Excalibur

Excalibur EWS SD15 Series Installation and user guide

Sage

Sage SAGECRDM instruction manual

Aqua Cooler

Aqua Cooler Allure Series Usage and care guide