Page 4 (Rev. A - 6/2012)

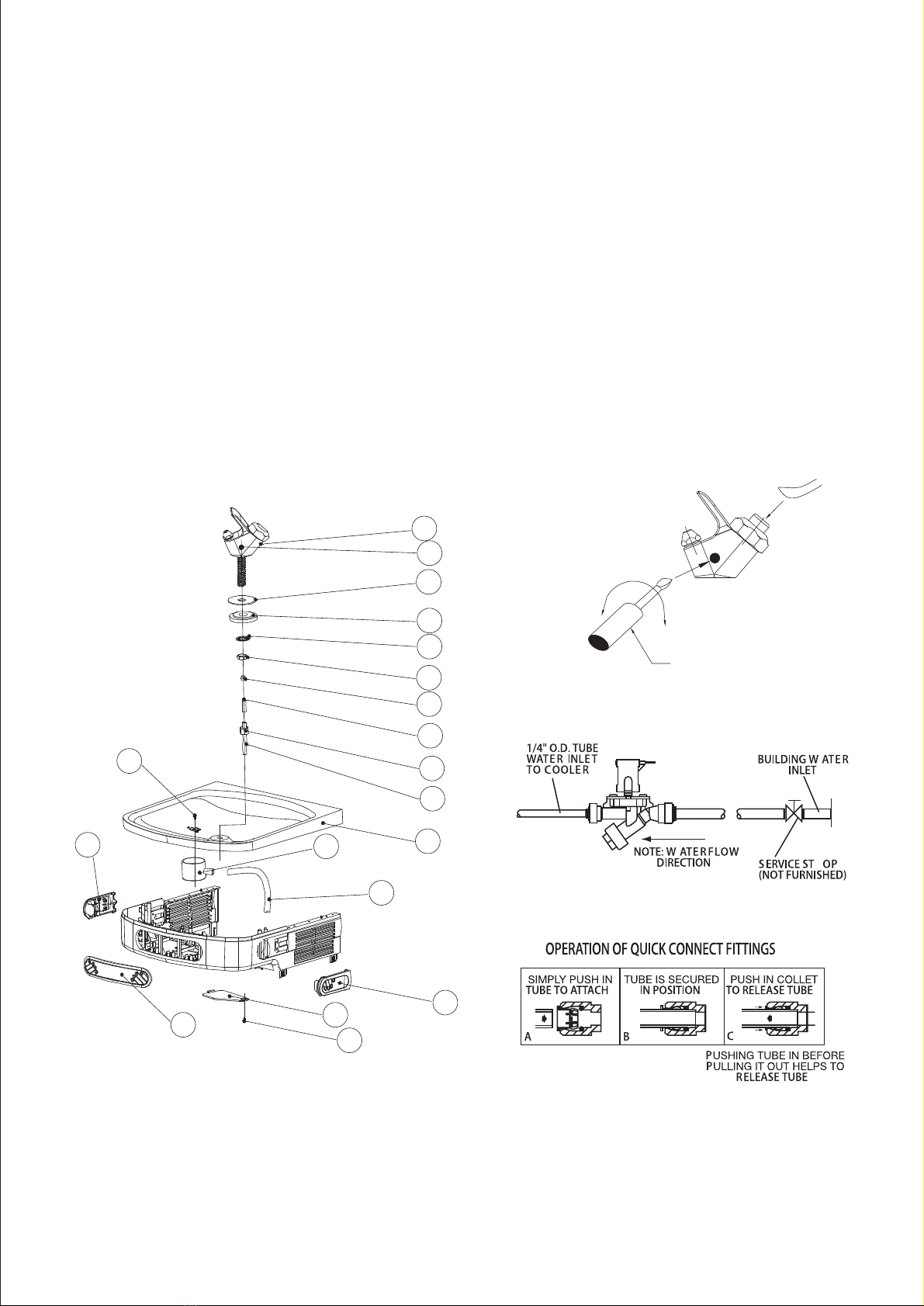

HANGER BRACKETS & TRAP INSTALLATION

1) Remove hanger bracket fastened to back of cooler by removing one (1) screw. SEE FIGURE

3.

2) Mount the hanger bracket to the wall.

NOTE: Hanger Bracket MUST be supported securely. Add fixture support carrier if wall will not

provide adequate support. Anchor hanger securely to wall using all six (6) 1/4 in. dia. mounting

holes.

IMPORTANT:

5-7/8 in. (150mm) dimension from wall to centerline of trap must be maintained for proper fit.

INSTALLATION OF COOLER

3) Hang the cooler on the hanger bracket. Be certain the hanger bracket is engaged properly in

the slots on the cooler back as shown in FIGURE 3.

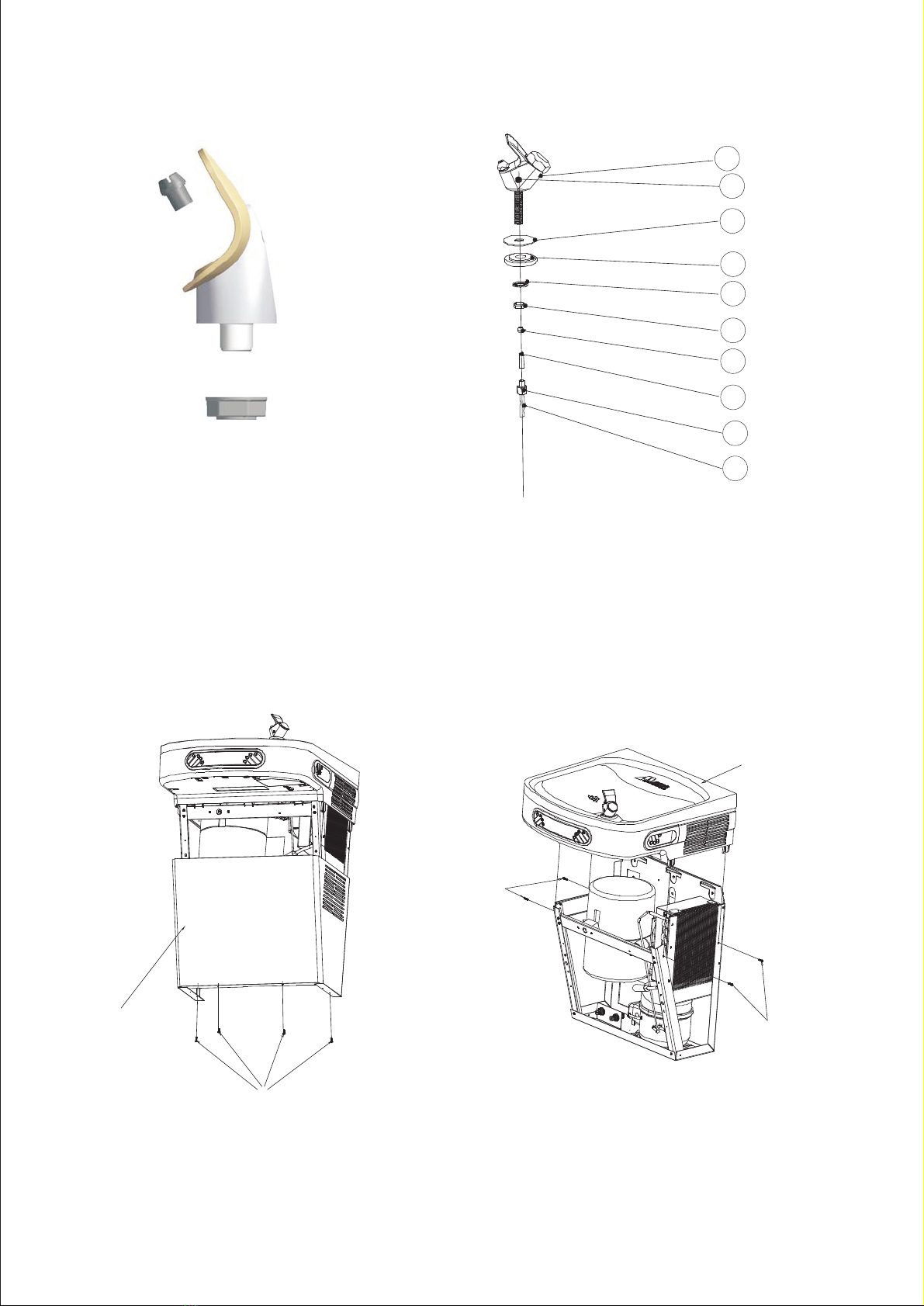

4) Remove the four (4) screws holding the lower front panel at the bottom of cooler. Remove the

front panel by pulling straight down and set aside, SEE FIG. 4, FIG.5.

WATER CONNECTION TO THE MAIN

5) Before making the water connection, make sure the mains water pressure is between 20 and

60 psi.

6) If the mains water pressure exceeds 60 psi, predispose a pressure reducer capable of reducing

the latter to the 20~60 psi.

7)Connection to the mains water supply is carried out with the aid of 1/4in PE tube

provided(dia 1/4").

8)The tube terminals (1/2”×1/4”fitting) must be connected to the mains supply by means of a

“water supply valve” G (not provided). SEE FIGURE 3.

FILLING INTERNAL ICE BANK

9) Remove the white plugs marked" Fill Ice Bank".

10) Connect water supply tube into the connector "Fill Ice Bank".

11)Open the "water supply valve" G, let the water enter the ice bank slowly and fill the ice bank;

once reach the right level, the exceeding water will run over the outlet of Overflow pipe, then close

"water supply valve" G. After that, connect water pipe into coupling-- "water in" with proper

pressure. SEE FIGURE 3.

Note: The connection of tank charge--"Fill Ice Bank" has to be disconnected.

12) Insert the white plug back to its original position(overflow).

DRAIN CONNECTION

The drain water is clean and it comes from the tray(basin) that collects any dripping during

dispensing.

Connect the drain pipe (O.D. 20mm) to drain with a drain-trap. If necessary, cut the pipe so as to

avoid narrowing or rising or backflow problems.

CLEANING

Warm, soapy water or mild household cleaning products can be used to clean the exterior panels

of the TB35 water coolers. Extra caution should be used to clean the mirror finished stainless steel

panels. They can be easily scratched and should only be cleaned with mild soap and water or

Windex glass cleaner and a clean, soft cloth. Use of harsh chemicals or petroleum based or abrasive

cleaners will void the Warranty.