DECKEL SO User manual

-

I

Contents

I

so

Page 2 Nomenclature of Controls

3 Dimensions - Specification

4 Lubrication and Maintenance Schedule - Grinding Spindle

5 Servicing the Index Head Bracket

6 Dressing the Grinding Wheel

7 Cutter Profiles, Tool Angles and Cutting Speeds

B Centering the Cutter Up by Grinding

9 Circular Grinding of Cutters

Grinding the Back Rake Angle of Side Cutting Edges

10 Circular Grinding of Cutters

Grinding the Back Rake Angle of End Cutting EdgL_ (Straight)

11 Circular Grinding of Cutters

Grinding the Bock Rake Angle of End Cutting Edges (Round)

12 Grinding Pointed Cutters

13 Grinding Tapered Cutters

A. Circular Grinding of Side and End Cutting Edges

14 Grinding Tapered Cutters

B. Grinding the Back Rake Angle of Side and End Cutting Edges (Straight)

15 Grinding Tapered Cutters

C. Grinding the Bock Rake Angle of Side and End Cutting Edges (Round)

16 Accessories - Changing the Drive Cord and Grinding Wheel

17 Pedestal - Installing the Machine Lamp

18 Special Index Head - Locating Fixture for Cutter Spindle Assembly

19 Twist Drill Grinding Attachment

20 Nomenclature of Controls

THIS OPERATOR'S MANUAL IS FOR MACHINE NO............

FEINMECHANIK GMBH

Weilheim/Obb

LIZENZ DECKEL

'I

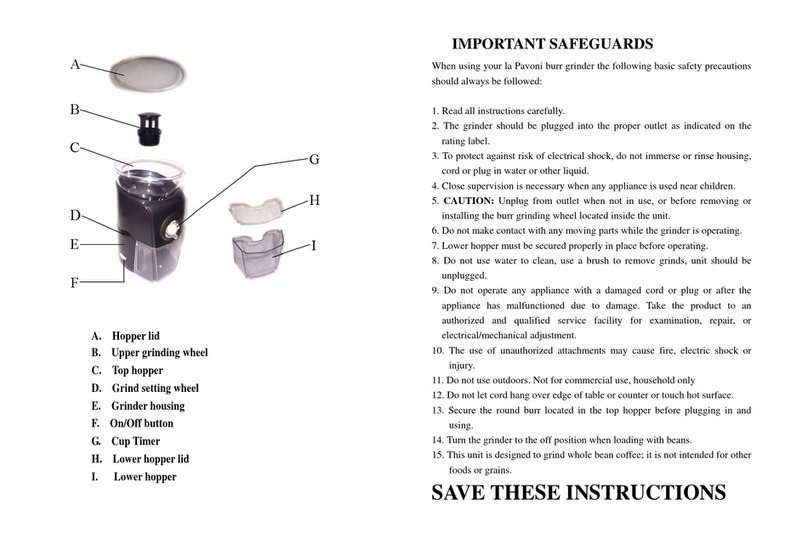

Nomenclature of Controls

U

KI

0

A Wheel dressing attachment

P Spring collet clamping quill

55 Cross slide adjustment screw

KS Cross slide clamping lever

12 Vertical swivel mount setting scale

K2 Vertical swivel mount clamping lever

K3 Horizontal swivel mount clomping lever

K Tubular guide clomping lever

T4 Horizontal swivel mount index drum

Ki Clomping lever for adjustment along tubular guide

F Index head bracket fine adjustment screw

G Adjustable stop screw

E

Cutter lip aligning gouge

K6 Index head slide clamping lever

T5 Cross slide vernier scale for aft-center radii

R

Spring callet index pin

T Index head slide

U Red dot window

06 Index head slide fine adjustment set screw

56 Index head slide fine adjustment screw

Q Crass slide

K4 Index drum 14 clamping lever

For easy reference, a fold-out copy of this sheet

is provided at the end of this manual.

2

FEINMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

20' (510)

-

-

22'14"

(565)

- ------ -

Dimensions - Specification

13/4" (337)

--

r

—

3

1

/s'' (80)

a

C

S

'a

Items in parentheses are mm-values.

12'/7" (316)

Motor capacity

Spindle

Motor speed

Drive

Spindle speed

Max. collet capacity

Taper of adopter sleeves

Max. radius ground

(worn wheel permits greater radius)

Coarse adjustment of index head bracket on

tubular guide

Work

Max. lateral traverse of index head

Capacity

Max. longitudinal traverse of index head

Max. relief angle

Max. Fine adjustment of index head bracket

parallel to spindle axis

Number of index registers

Length

x

width

x

height

imensions

Net weight with/without motor

and

Weight of machine, boxed

Weights

Box dimensions

2800 rpm

4500 rpm

5/8"

17.5 mm

M.T.1, M.T.2 or GA

.4"

10 mm

.4'

100 mm

.4"

10mm

1.6"

40 mm

approx 45°

.6"

15 mm

12

20x22

1

/4x11

1

/2"

510x565x290

mm

71/60 lb

32/27 kg

123 lb

56 kg

5

5

/3x22

5

/Ax I 9

1

h"

650 ;< 550 x 500

mm

FEINMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

Lubrication and Maintenance Schedule -

so

Grinding Spindle

- - see instructions

1

once a week

I

I

Intervals apply

to single-shift

operation.

I

Recommended Lubricants

Specification

Quality

Symbol

4.5° Engler (35 centistokes)

Bearing oil

at 50° C (122° F)

Special

spindle bearing

ISOFLEX SUPER TEL

grease

Grinding spindle

has been serviced

at the factory.

Interval

No.

Item to be lubricated

Quantity of lubricant

Remarks

H

i week

1

Bearing of index head opprax_

li

cu. in. (5 cc.)

Use oil can

1 week

2

bracket adjustment

see below

3

Grinding spindle

M

The grinding wheel spindle is provided with an ample supply of grease for about 3000 hours of operation.

After that time, remove the spindle (see below), disassemble and clean it thoroughly with pure, filtered petrol

(gasoline) or benzene to which a small amount of ISOFLEX SUPER TEL has been added. Then lubricate by

applying a thin coat of the prescribed lubricant (see above) only to the ball cages.

The spindle bearing has been factory-adjusted to exclude ploy while allowing for a free-running spinde. In

the event some play develops in the course of time, such play should be taken up by tightening the two nuts

M. For this purpose, pull spindle from its seat after having loosened screw S and removed the parts as

indicated in the illustration an page 16. When tightening the nuts allow for a free-running spindle. Excessive

tightening would result in bearing failure. After reinserting the spindle assembly, carefully tighten screw S

in the bore, to hold the spindle assembly in position.

I

4

FEINMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

I

Servicing the Index Head Bracket

J

SO

17

General

After a major period of use it will be necessary to dismantle the index head bracket and to clean and lubricate

the collet sleeve bearing, the index head slide, and the swivel arm.

Collet Sleeve Bearing

To remove the collet sleeve proceed as follows: Remove ring nut D7, index drum 17, and index ring R7 in that

order. Remove two nuts M3. Pull out index ring bearing sleeve B and collet sleeve BI. The annular grease

chamber in the longitudinal slide L which has thus been made accessible, should then be cleaned with petrol

(gasoline) and refilled with grease.

Slide

Release clamping screw K6 and remove screw D6. Pull out index head slide T. Clean all working surfaces,

smear lightly with oil, wipe dry. Crass slide Q cannot be removed. Release clomping screw KS and turn

screw

35

to move the cross slide to its extreme positions. Clean the bearing surfaces, smear lightly with oil,

wipe dry.

Swivel Arm

To remove the swivel arm and the index head as a unit remove the two nuts M4. Clean the bearing surfaces

and smear them with oil.

Adjusting the Clamping Mechanism of Index Drum 14

If after a major period of use clamping lever (4 should no longer lock swivel arm index drum T4, screw N will

have to be adjusted. For this purpose proceed as follows: Remove swivel arm as described above; remove

screw 31 and stop plate Al; back off nut M2 and screw 32 and pull out clamping lever K4. Lift off index drum

T4 to pull out adjusting nut and screw N. Rotate screw 180

0

relative to nut to reduce the length. - To re-

assemble ports reverse this procedure.

Adjusting the stop pins for the

900

swivel motion

If, due to constant striking of stop plate Al against stop pins A2 and A2, the swivel range should no longer be

exactly 90

0

, correct the adjustment by turning the two eccentric stop pins A2 and A3.

Turning stop pin A2 will change the cylindrical setting of the collet sleeve bearing, while turning stop pin A3

will adjust the

900

swivel motion.

I

FEINMECHANIK GmbH - Weilheim/Obb - LIIZENZ DECKEL

I

so

I

Dressing the Grinding Wheel

Feed screw

I

Fig. 2

flfld" h

-

i nit'

Fig. 4

Fig. 3

Wheel truing and dressing should be performed at regular intervals. Dressing is done by means of o diamond

set in a tip which is held in a swiveling rod. The latter is attached to a swinging arm which is provided with a

feed screw. The diamond tool assembly is supported by the wheel guard (see Figs. 1 and 2). Wheel truing and

dressing is particularly necessary when the wheel has became boded or when the sharp corner has been

worn oft Failure to comply with this rule will result in poor surface finish and overheating of the cutting tools.

Always be sure to use a sharp-painted diamond having the proper clearance angle. The wide range of dia-

mond adjustment ensures economical utilization of diamonds. As will be seen from Fig. 3, the diamond can be

set at any desired position relative to the grinding wheel, since it can be rotated about its axis and set for

endwise position. To reset the diamond, bock off nut D to release the tapered shank of the diamond holder.

After resetting be sure to tighten nut D. Core should be exercised not to allow the wheel to attack the tip in

which the diamond is set. When centering the lip surface of a single-lip cutter it is necessary to relieve the

wheel face exept for a narrow rim portion (see Fig. 4). This will exclude overheating of the tool being ground.

Prior to Finish grinding the cutter be sure to remove the rim portion.

I

6

FEINMECHANIK GmbH - Weilheim/Qbb - LIZENZ DECKEL

Cutter Profiles - Tool Angles - Cutting Speeds

so

Cutter Profiles

As a rule, single-lip milling cutters are given one of the seven basic profiles illustrated below:

cylindrical

cylindrical,

cylindrical,

pointed

tapered,

tapered,

tapered,

w/end relief w/off-center radius rounded off

w/end relief w/off-center radius w/rounded pa

Above are illustrated the seven basic cutter profiles and cross-sectional views of the profiles they will produce.

Tool Angles

As is the case with all metal cutting tools, single-lip milling cutters require the proper amount of cutting edge

relief or bock rake angle for maximum stock removal and high surface Finish. As regards single-lip cutters,

three different tool angles will have to be taken care of, these angles being used in all kinds of cutters (see

illustrations below).

a

ME

i

f

I

To q

Cutter with end relief

Cutter with pointed end

Rounded-off cutter

Angle

P

applies to end relieved cutters only. Cutters having an angle uof less than 20

0

should be relief ground

at between 25° and 30

0

(see special instructions)-

Tool angles and recommended cutting speeds

for single-lip cutters

Recommended cutting speeds for

Material to be cut

Tool Angles

high speed steel single lip cutters -

-,

rouqhinq cut

finishing cut

s.f.p.m.

rn/rain.

s..l.p.rn.

n/rain.

Grey cast iron

Cost steel

195

60

260

i

i

80

Malleable cast iron

Machinery steel,

25 15° 5°

57,000 to 85,000 psi

140

to 60 kg/mm-)

230

70

295

90

85,000 to It 5,000 psi (60 to 00 kg/mrn)

195

60

230

70

over 115.000 psi 80 kg, mm')

130

40

165

50

Tool steel

soft grade

195

60

260

80

hard grade

165

50

230

70

Brass, 5/42

soft grade - - -

655

200

820

250

hard grade

820

250

1150

350

Brass, 63137

soft grade 30 15

5

7

395

120

490

ISO

hard grade

490

ISO

590

180

Bronze

soft grade

525

160

655

200

hard grade

655

200

755

230

Aluminium

soft grade

655

200

985

300

hard grade 35

020

250

1150

350

Wood

-

985

300

1150

350

Plastics Tralon

25 15' Y

L

655

250

985

300

Pertinas, Fiber

200

820

250

Pallapos, Resopal

200

985

300

Astralon, Celluloid Plexi

45 25 20

'555

200

1150

350

Culling Speeds

As regards single-lip mill-

ing cutters, it is recom-

mended to use cutting

speeds three times higher

than those used with

standard type milling cut-

ters. The data tabulated

on the left should be used

as a guide only, as such

factors as drive conditions

and available spindle

speeds will also have to

be taken into

considera-

tion- In end culling edges

the cutting speed will de.

crease towards the cutter

center line. This effect is

particularly noticeable in

rounded-off cutters. As a

consequence, care should

be taken that stock is pref-

erably removed by the

outer portion of the cut.

ling edge. For example,

where inclined surfaces

are concerned, stock

should preferably be re-

moved by milling in on

uaword direction rather

than downward.

When cutting soft alumin-

ium, use kerosene as °

coolant. When cutting

celluloid, the cutter must

always be in feed motion,

in order to avoid nOon'

ma tion.

FEINMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

7

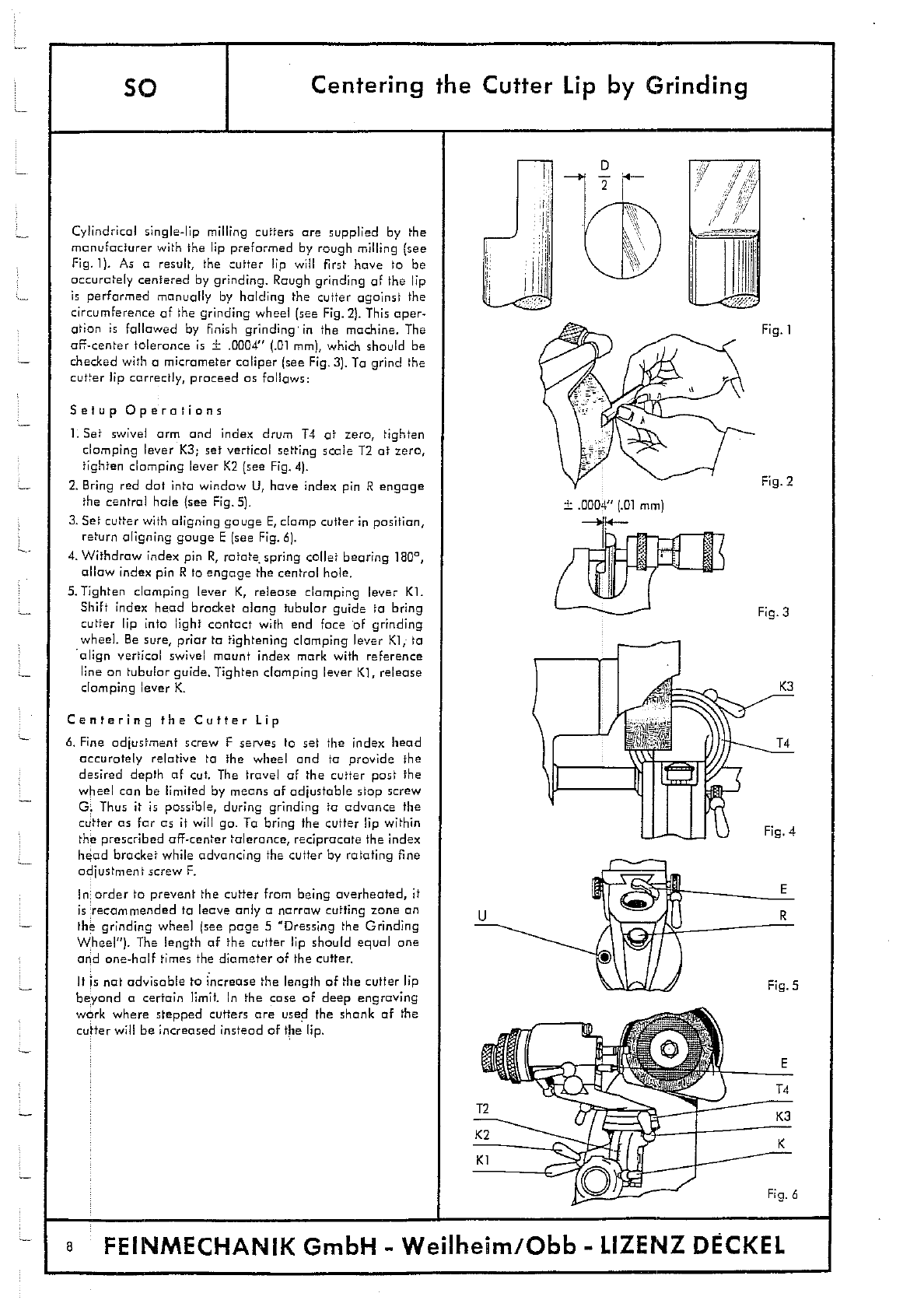

Fig. 1

Fig. 2

Fig. 3

so

Centering the Cutter Lip by Grinding

Cylindrical single-lip milling cutters are supplied by the

manufacturer with the lip preformed by rough milling (see

Fig.]). As o result, the cutter lip will first have to be

accurately centered by grinding. Rough grinding of the lip

is performed manually by holding the cutter against the

circumference of the grinding wheel (see Fig. 2). This oper-

ation is followed by finish grinding in the machine. The

off-center tolerance is ± .0004" (.01 mm), which should be

checked with a micrometer caliper (see Fig. 3). To grind the

cutter lip correctly, proceed as follows:

Setup Operations

I. Set swivel arm and index drum 14 at zero, tighten

clamping lever K3; set vertical setting scale T2 at zero,

tighten clamping lever K2 (see Fig. 4).

2.

Bring red dot into window U, have index pin R engage

the central hale (see Fig. 5).

3.

Set cutter with aligning gauge E, clamp cutter in position,

return aligning gouge E (see Fig. 6).

4.

Withdraw index pin R, rotate spring collet bearing 180,

allow index pin R to engage the central hole.

5.

Tighten clamping lever K, release clamping lever KI.

Shift index head bracket along tubular guide to bring

cutter lip into light contact with end face of grinding

wheel. Be sure, prior to tightening clomping lever Ki,- to

align vertical swivel mount index mark with reference

line on tubular guide. Tighten clamping lever K], release

clamping lever K.

Centering the Cutter Lip

6.

Fine adjustment screw F serves to set the index head

accurately relative to the wheel and to provide the

desired depth of cut. The travel of the cutter past the

wheel can be limited by means of adjustable stop screw

C. Thus it is possible, during grinding to advance the

cutter as far as it will go. To bring the cutter lip within

the prescribed off-center tolerance, reciprocate the index

head bracket while advancing the cutter by rotating fine

adjustment screw F.

In order to prevent the cutter from being overheated, it

is recommended to leave only a narrow cutting zone an

the grinding wheel (see page 5 "Dressing the Grinding

Wheel"). The length of the cutter lip should equal one

and one-half times the diameter of the cutter.

It is not advisable to increase the length of the cutter lip

beyond a certain limit. In the case of deep engraving

work where stepped cutters are used the shank of the

cutter will be increased instead of the lip.

8

FEINMECHANIK

GmbH - Weilheim/Obb

- LIZENZ DECKEL

Circular Grinding of Cutters

-

so

Grinding the Back Rake Angle of Side Cutting Edges

After centering the cutter lip it will be necessary to grind

the back rake angles of both the side cutting edge and

the end cutting edge. The back rake angles of both cutting

edges should be selected to suit the material to be cut (see

To grind the back rake angle of the side cutting edge of

cylindrical cutters (Fig. 1), proceed as follows:

Setup Operations

Fig 1

1.

Rotate swivel arm to set index drum 14 at zero; tighten

R

clamping lever K3.

2.

Bring red dot into window U; engage index pin R into

central hole.

.

no

3.

Align cutter by means of gauge E

;

grip cutter in position;

:

return gauge E, see Fig. 2.

14

4.

Release clamping lever K2; set swivel arm at desired

K3

back rake angle, using setting scale 12; tighten clomping

lever K2, see Fig. 3.

T2

5.

Tighten clamping lever K; release clamping lever Ki;

-\

shift work fixture an tubular guide to bring cutter into

C

light contact with grinding wheel-

Fig. 2

Align index mark of vertical swivel mount with reference

line on tubular guide tighten clamping lever K1 ; release

clamping lever K.

4

Back rake

Circular Grinding

angle

& Engage index pin R into right-hand hole; grind desired

-

-

>-- -

a

diameter by rotating spring collet bearing through 360

0

.

During this operation slowly rotate adjustable stop

screw 0, while continuously rotating the spring collet

..

lBOa

bearing, to advance the work fixture past the grinding

V

- --

Fig. 3a

wheel; this will produce uniform stack removal. Fine

adjustment during circular grinding is by screw F. Stop

screw G is used to establish the length of the cylindrical

r

portion which should always be slightly longer than the

-

cutting lip.

-

T2 for a

Setup Operations

K

7. Return red dot into window U; engage index pin R into

left-hand hole to enable the collet bearing to be rotated

180 between the index plate stops.

U

Grinding the Back Rake Angle

B. When grinding the back rake angle, use the fine ad-

justment screw F over the entire range of rotation of

the collet bearing (see Fig. 3a). Grinding of the back

Index mark

Ki

K2

Reference line Fig. 3

rake angle is positively controlled. The angle is required

to extend over the entire length of the cutting lip.

The vertical swivel bearing, which permits the work

0

Land

holding fixture to be swung back, enables relief angles

R

up to

400

to be produced. Relief angles over 40

0

can be

Cutting edge

obtained by additionally rotating the collet bearing in

the index head. (Only for cylindrical or tapered cutters

with straight end cutting edges or for painted cutters.)

Upon completion of grinding operations a very narrow

land must remain at the cutting edge (see Fig. 4)

Fig. 4

F

FEINMECHANIK GmbH - Wejlhejm/Obb - LffZIENZ DECKEL

9

Cg 3

1.4

Circular Grinding of Cutters

--

Grinding the Back Rake Angle of End Cutting Edges (Straight)

so

4:.

/1

'I

Nta 1 Profile

Fig. 1

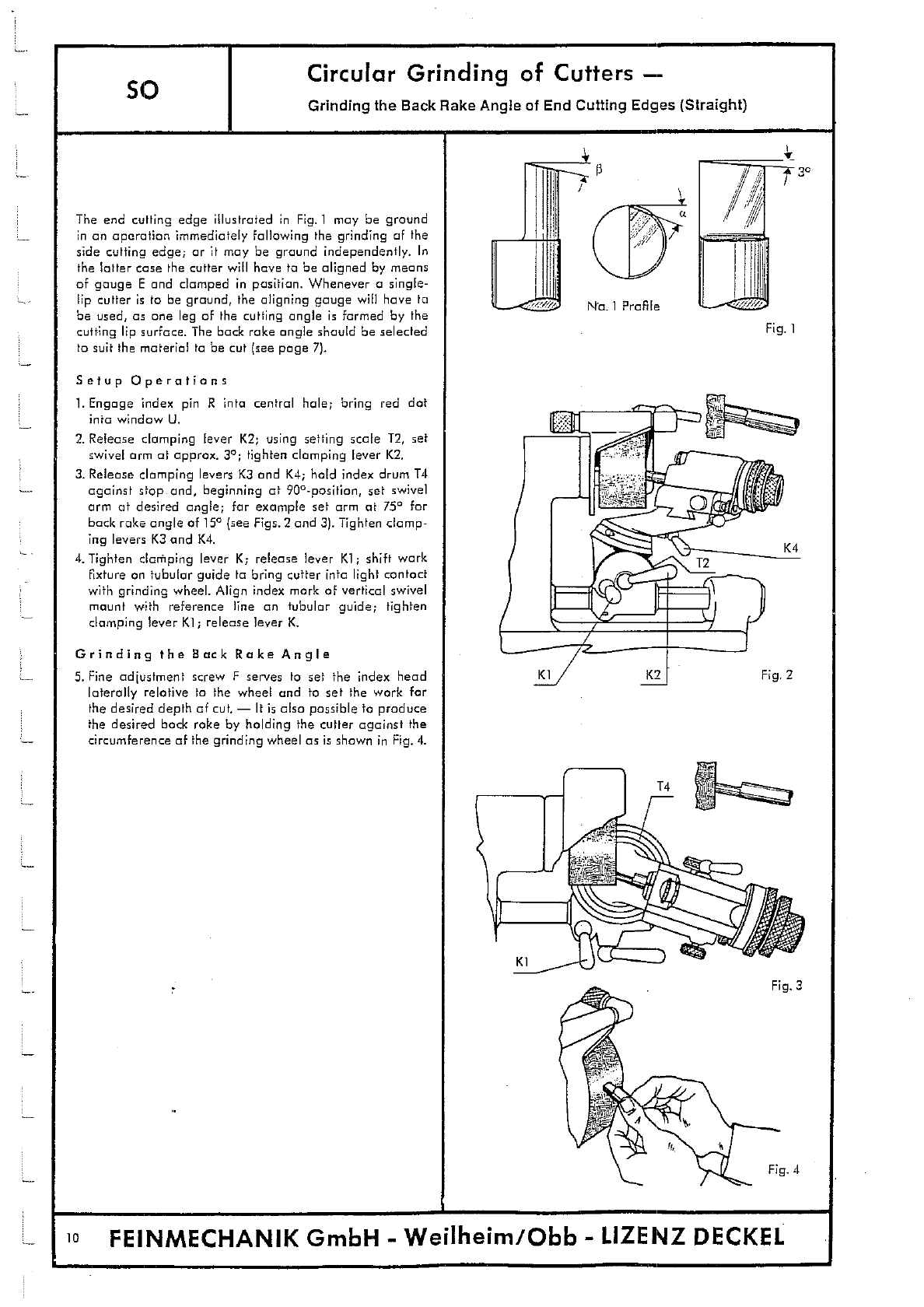

The end cutting edge illustrated in Fig. 1 may be ground

in an operation immediately following the grinding of the

side cutting edge; or it may be ground independently. In

the latter case the cutter will have to be aligned by means

of gouge F and clomped in position. Whenever a single-

lip cutter is to be ground, the aligning gauge will have to

be used, as one leg of the cutting angle is formed by the

cutting lip surface. The back rake angle should be selected

to suit the material to be cut (see page 7).

Setup Operations

1.

Engage index pin R into central hale; bring red dot

into window U.

2.

Release clomping lever K2; using setting scale T2, set

swivel arm at approx. 3

0

; tighten clamping lever K2.

3.

Release clamping levers K3 and K4; hold index drum T4

against stop and, beginning at

90a.positian,

set swivel

arm at desired angle; for example set arm at 75

0

for

back rake angle of 15

0

(see Figs. 2 and 3). Tighten clomp-

ing levers K3 and K4.

4.

Tighten clamping lever K; release lever K1; shift work

Fixture an tubular guide to bring cutter into light contact

with grinding wheel. Align index mark of vertical swivel

mount with reference line an tubular guide; tighten

clamping lever K1 ; release lever K.

Grinding the Back Rake Angle

5.

Fine adjustment screw F serves to set the index head

laterally relative to the wheel and to set the work for

the desired depth of cut. - It is also possible to produce

the desired bock rake by holding the cutter against the

circumference of the grinding wheel as is shown in Fig. 4.

110

FEINMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

No. 2 Profile

No. 3 Profile

Fig. 1

15

Fig. S

Circular Grinding of Cutters -

so

Grinding the Back Rake Angle of End Cutting Edges (Round)

Cutter profiles having either on-center or off-center radii

are derived from cylindrical single-lip cutters having a

straight end cutting edge by rounding off the corner as

shown in Fig. 1 (No.2 and 3 profiles).

In rounded cutters of this type the bock rake angle of the

side cutting edge is the some as that of the end cutting

edge. For this reason it is necessary, during grinding the

end rake angle, that the work fixture is set at the side rake

angle by means of setting scale 12. If the end cutting edge

is ground immediately after grinding the side cutting edge,

it will not be necessary to re-set the work fixture and to

re-align the cutting lip by means of gauge E -

Setup Operations

1.

Engage index pin R into left-hand hale; bring red dot

into window U.

2.

a)No. 2 profile: Release clamping lever KS; rotate

knurled knob 55 to set crass slide by means of vernier

scale T5 for desired radius (to the right); tighten

clamping lever K5, see Fig. 2. As the radiused corner

is required to be tangent to the cutter diameter, the

amount of offset "a is:a =

Example:

Given r = .06" (1.5 mm); D = .30" (8 mm)

o = .15" (4 mm) —.06" (1.5 mm) = .09" (2.5 mm)

2. b)No. 3 profile: The vernier scale 15 of the crass slide

must be set at zero (see Fig. 3).

3.

Rotate fine adjustment screw F to bring the side cutting

edge of the cutter into light contact with the face of

the grinding wheel. Caution: Do not injure the land of

the hide cuffing edge. Now screw F must no longer be

rotated.

Grinding the Back Rake Angle

4.

Swivel index head through

90

(see Fig. 4). Depth of

cut adjustment now is by index head slide T. Fine

adjustment is by micrometer screw S6 of the index

head slide with adjustment screw D6 tightened. The

end of the cutter is rounded by slowly swivelling the

index head back to its original position, while the

collet bearing is continuously rotated bock and forth

between the stops, the rotation being through

1800

(see

Figs. 5 and 6). Friar to grinding, be sure to withdraw

the index head a slight amount by rotating screw 56

in order to prevent overheating of the cutter by exces-

sive stock removal. After each pass of the grinding

wheel the cutter is then fed towards the wheel by

means of screw 56.

In order to obtain a satisfactory cutting edge it is advis-

able, as a final operation, to swivel the index head through

90

0

with the cutter lip pointing vertically upward.

In cases where cutters given a No.3 profile are intended

for the machining of hard steel which requires a small bath

rake angle, it is good practice to flatten the curvature of

the cutter by a manual grinding operation as shown in

Fig. 7.

F8NMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

11

Fig. 1

g. 2

ex

F!. 40

mark

K1

Fig. 3

.0004" (.01 mm) c

r

f3

/

Reference

K2

line

3C

so

Grinding Pointed Cutters

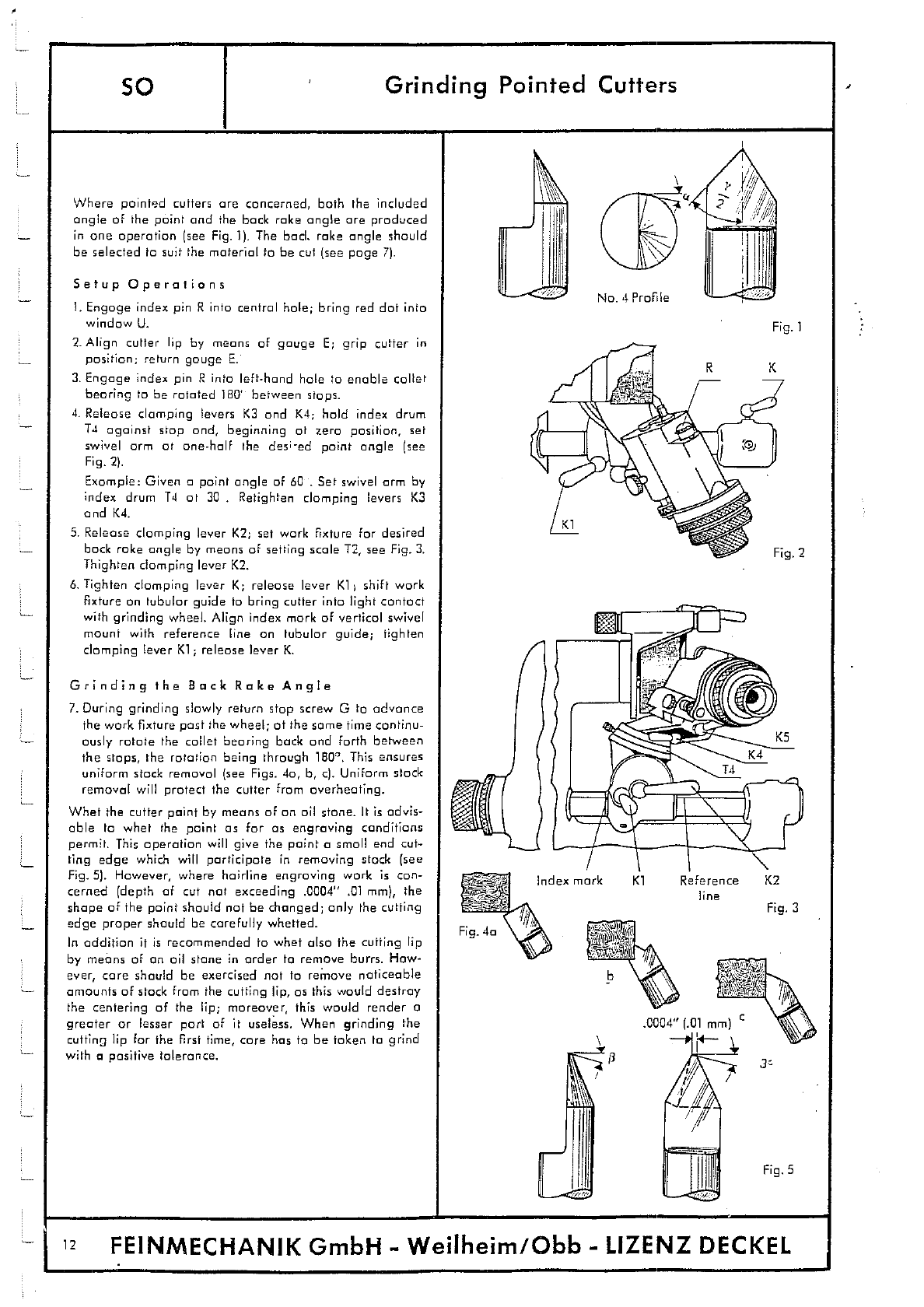

Where pointed cutters are concerned, both the included

angle of the point and the bock rake angle are produced

in one operation (see Fig. 1). The bad, rake angle should

be selected to suit the material to be cut (see page 7).

Setup Operations

I. Engage index pin R into central hole; bring red dot into

window U.

2.

Align cutler lip by means of gouge F; grip cutter in

position

;

return gouge E.

3.

Engage index pin R into left-hand hole to enable collet

bearing to be rotated 180 between stops.

4.

Release clomping levers K3 and K4

;

hold index drum

T4 against stop and, beginning at zero position, set

swivel arm at one-half the desHed point angle (see

Fig. 2).

Example: Given o point angle of 60 . Set swivel arm by

index drum 14 at 30 . Retighten clomping levers K3

and K4.

5.

Release clomping lever K2; set work fixture for desired

bock rake angle by means of setting scale T2, see Fig. 3.

Thighten clomping lever <2.

6.

Tighten clomping lever K; release lever K1; shift work

Fixture on tubular guide to bring cutter into light contact

with grinding wheel. Align index mark of vertical swivel

mount with reference line on tubular guide; tighten

clomping lever K1

;

release lever K.

Grinding the Back Rake Angle

7.

During grinding slowly return stop screw G to advance

the work fixture post the wheel; at the some time continu-

ously rotate the collet bearing bock and forth between

the stops, the rotation being through 180'. This ensures

uniform stock removal (see Figs. 4o, b, c). Uniform stock

removal will protect the cutter from overheating.

Whet the cutter point by means of on oil stone. It is advis-

able to whet the paint as for as engraving conditions

permit. This operation will give the point a small end cut-

ting edge which will participate in removing stock (see

Fig. 5). However, where hairline engraving work is con-

cerned (depth of cut not exceeding .0004" .01 mm), the

shape of the point should not be changed; only the cutting

edge proper should be carefully whetted.

In addition it is recommended to whet also the cutting lip

by means of on oil stone in order to remove burrs. How-

ever, core should be exercised not to remove noticeable

amounts of stock from the cutting lip, as this would destroy

the centering of the lip; moreover, this would render o

greater or lesser port of it useless. When grinding the

cutting lip for the first time, core has to be token to grind

with a positive tolerance.

A

Fig. 5

FEINMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

L1

LI__

nfl

IF

1yi\

lit

fl/A

F

7

I

frfl

/1

2

2

No.5 Profile

Na. 6 Profile

Fig.]

Na. 7 Profile

Fig.2

Fig.3

FP

Fig. 4

I. S

10

41

Fic.

I-

Grinding Tapered Cutters -

so

A. Circular Grinding of Side and End Cutting Edges

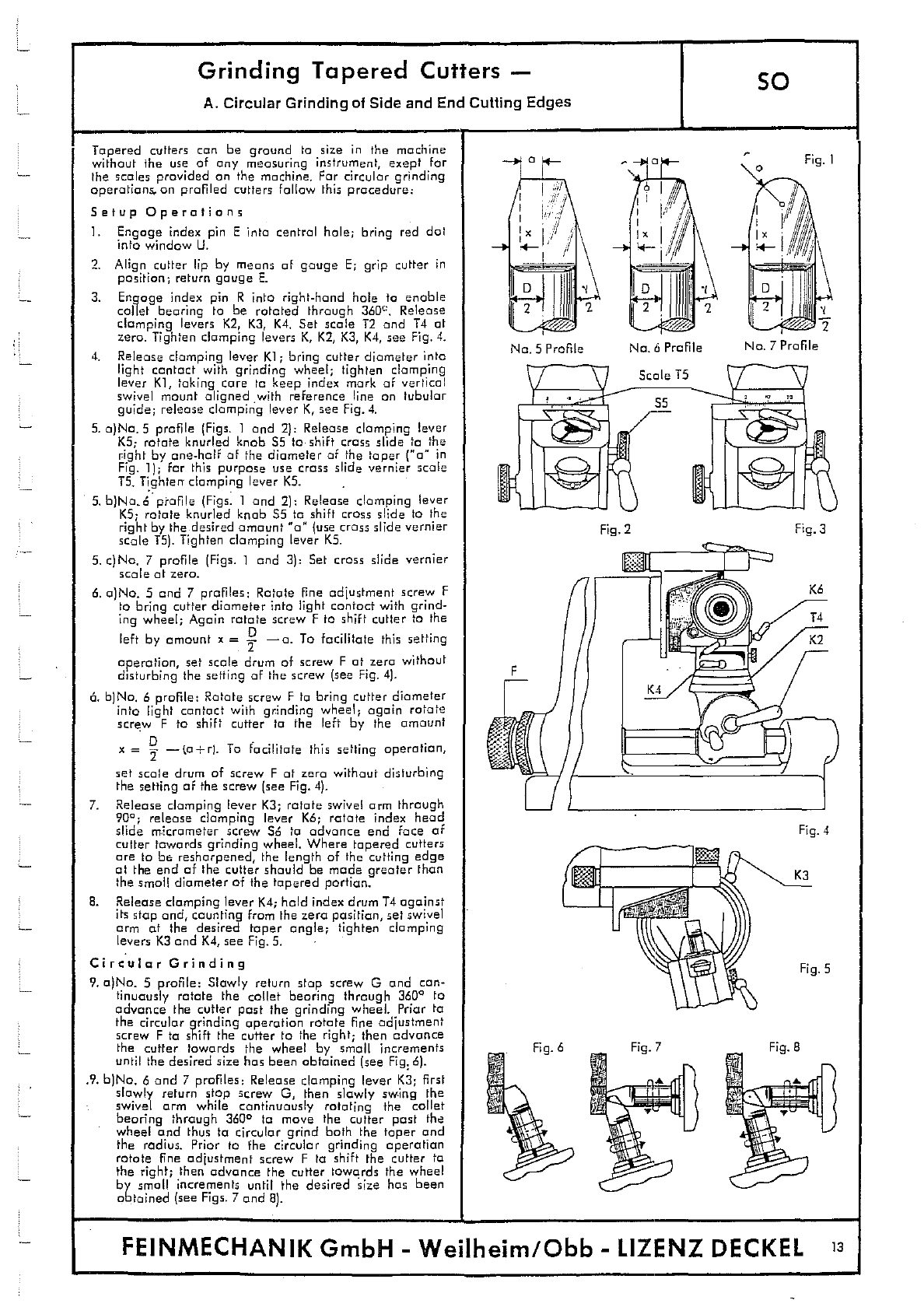

Tapered cutters can be ground to size in the machine

without the use of any measuring instrument, exept for

the scales provided on the machine. For circular grinding

operations, on profiled cutters follow this procedure:

Setup Operations

1. Engage index pin E into central hole; bring red dot

into window U.

2. Align cutter lip by means of gouge E; grip cutter in

position; return gouge E.

3. Engage index pin R into right-hand hole to enable

collet bearing to be rotated through

3600.

Release

clomping levers K2, K3, K4. Set scale T2 and T4 at

zero Tighten clamping levers K, K2, K3, K4, see Fig. 4.

4.

Release clamping lever Ki; bring cutter diameter into

light contact with grinding wheel; tighten clomping

lever KI, taking care to keep index mark of vertical

swivel mount aligned with reference line on tubular

guide; release clomping lever K, see Fig. 4.

5. o)Na. 5 profile (Figs. I and 2): Release clomping lever

KS

;

rotate knurled knob 55 to shift cross slide to the

right by one-half of the diameter of the taper ('o in

Fig. 1); for this purpose use cross slide vernier scale

T5. Tighten clamping lever KS. -

5. b)Na,6 ptauile (Figs. I and 2): Release clamping lever

KS; rotate knurled knob 55 to shift cross slide to the

right by the desired amount 'a" (use crass slide vernier

scale T5). Tighten clomping lever K5.

5. c)Na. 7 profile (Figs. 1 and 3): Set cross slide vernier

scale at zero.

6. a)No. 5 and 7 profiles: Rotate fine adjustment screw F

to bring cutter diameter into light contact with grind-

ing wheel; Again rotate screw F to shift cutter to the

left by amount x =

—a. To facilitate this setting

operation, set scale drum of screw F at zero without

disturbing the setting of the screw (see Fig. 4).

6.

b)Na. 6 profile: Rotate screw F to bring cutter diameter

into light contact with grinding wheel

;

again rotate

screw F to shift cutter to the left by the amount

x =

—to—

,

0. To facilitate this setting operation,

set scale drum of screw F at zero without disturbing

the setting of the screw (see Fig. 4).

7.

Release clamping lever K3; rotate swivel arm through

900; release clomping lever Ko; rotate index head

slide rnicrameter screw 56 to advance end face of

cutter towards grinding wheel. Where tapered cutters

are Ia be resharpened, the length of the cutting edge

at the end of the cutter should be made greater than

the small diameter of the tapered portion.

8.

Release clamping lever K4; hold index drum 14 against

its stop and, counting from the zero position, set swivel

arm at the desired taper angle; tighten clamping

levers K3 and K4, see Fig. 5.

Circular Grinding

9.

a)Na. S profile: Slowly return stop screw 0 and con-

tinuously rotate the collet bearing through 360° to

advance the cutter past the grinding wheel. Prior to

the circular grinding operation rotate fine ad1ustment

screw F to shift the cutter to the right

;

then advance

the cutter towards the wheel by small increments

until the desired size has been obtained (see Fig. 6).

.9. b)Na. 6 and 7 profiles: Release clamping lever K3; first

slowly return stop screw 0, then slowly swing the

swivel arm while continuously rotating the collet

bearing through 360

0

to move the cutter past the

wheel and thus to circular grind bath the taper and

the radius. Prior to the circular grinding operation

rotate fine adjustment screw F to shift the cutter to

the right; then advance the cutter towards the wheel

by small increments until the desired size has been

obtained (see Figs. 7 and 8).

FEINMECHANIK GmbH - Weilheim/Obb - 1.IZENZ DECKEL

13

Fig. 3

Pi- 1

Fig. 5

so

Grinding Tapered Cutters -

(B) Grinding the Back Rake Angie of Side and End Cutting Edges (Straight)

The bock rake angles of the side and end cutting edges

may be ground immediately after circular grinding the

desired cutter profile; or in cases where only the taper

angle (not, however, the small diameter of the tapered

portion) is of importance, grinding may be performed in

an independent operation. Where the small taper diameter

must be held within close tolerances, only the end cutting

face will be ground

;

in this case the cutter will have to be

aligned by means of gauge E and clamped in position. The

back rake angles of the side and end cutting edges should

be selected to suit the material to be cut (see page 7). For

tool angles refer to Fig. 1.

Grinding the Side Cutting Edge

Setup Operations

1.

Engage index pin R into left-hand hale; bring red dot

into window U.

2.

Release clamping lever K2; using scale T2, set cutter at

desired back rake angle

;

tighten clomping lever K2, see

Fig. 2.

3.

Tighten clamping lever K; "release lever Ki

;

shift work

fixture on tubular guide to bring cutter into light contact

with grinding wheel; tightenclomping lever Ki, taking

care to keep index mark of vertical swivel mount aligned

with reference line on tubular guide; release clamping

lever K.

Grinding the Bock Rake Angie

4.

While continuously rotating the collet bearing through

1600 (bock and forth between the stops), advance the

cutter towards the grinding wheel by means of fine

adjustment screw F. This will produce the desired bock

rake angle in a positively controlled operation (see

Fig. 2).

Upon completion of the grinding operations on the side

cutting edge, a very narrow land must remain at the

edge.

Grinding the End Cutting Edge

Setup Operations

1.

Engage index pin R into central hale

;

bring red dot into

window U.

2.

Release clomping lever K2; using scale T2, set swivel

arm at an angle of approx. 30; tighten clamping lever

K2, see Fig. 3.

3.

Release clomping levers K3 and K4; hold scale T4 against

its stop and, beginning

of

the 90

0

-positian, set swivel

arm at the desired angle; for example, where an angle

of

100

is desired, the swivel arm will have to be set at

80

0

. Tighten clamping levers K3 and K4, see Fig. 4.

4.

Tighten clamping lever K; release lever KI; shift work

fixture along tubular guide to bring end face of cutter

into light contact with grinding wheel; tighten clamping

lever K1, taking care to keep index mark of vertical

swivel mount aligned with reference line on tubular

guide; release clamping lever K.

Grinding the Back Rake Angle

5.

Lateralfine adjustment of the work Fixture relative to

the grinding wheel and adjustment for depth of cut is

obtained by means of screw i

-

. iris aisa passible to grind

the back rake angle manually; care should, however, be

taken to produce the correct tool angles (see Fig. 5).

In cases where close tolerances an the small taper diam-

eter after grinding the end cuffing edge are prescribed,

the corner of the side cuffing edge will have to be main-

tained; this will make it possible to check whether or not

the small taper diameter was changed during grinding

operations (see Fig. 6).

c

I

1

14

FEINMECHANIK GmbH — Weilheim/Qbb — LIZENZ DECKEL

Grinding Tapered Cutters -

so

C. Grinding the Back Rake Angle of Side and End Cutting Edges (Round)

Tapered cutters having either an off-center or an on-center

radius can be given a back rake angle only in connection

with the circular grinding operation (see Fig. 1). The back

rake angle of the side cutting edge equals that of the

straight or rounded end cutting edge: the proper angle to

be used will be found in page 7. After tapered cutters

with rounded end cutting edges have become dull, first

proceed with the circular grinding operation described an

page 13; then fallow the procedure indicated below.

Setup Operations

1.

Engage index pin R into left-hand hole; bring red dot

into window U.

2.

Release clamping lever K2; use scale T2 to set work

Fixture at desired bock rake angle

;

tighten clamping

lever 1(2.

3.

Tighten clomping lever K; release lever K1 ; shift work

Fixture along tubular guide to bring cutter into light

contact with grinding wheel; tighten clomping lever K1

taking core to keep index mark of vertical swivel mount

aligned with reference line on tubular guide; release

clamping lever K, see Fig. 2.

Grinding the Back Rake Angle

4.

While continuously rotating the collet bearing through

180 (bock and forth between the stops), advance the

cutter towards the grinding wheel by means of Fine

adjustment screw F. This will produce the desired bock

rake angle on both the side and the end cutting edges

in o positively controlled operation (see Figs. 3, 4, 5).

Upon completion of grinding operations, o very narrow

land must remain at the cutting edge.

5.

In cases where the cutter is intended for the machining

of hard steel which requires a small bock rake angle, it

is advisable to grind off port of the curvature in o

manual operation (see Fig. 6).

In addition it is recommended, with regard to all single-lip

cutters, to whet also the cutting lip by means of on oil

stone in order to remove burrs. However, core should be

exercised not to remove noticeable amounts of stock from

the cutting lip, as this would destroy the centering of the

lip; moreover, this would render a greater or lesser port

of it useless.

No.6 Profile

No.7 Profile

F;,-, I

- I

F8NMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

15

Accessories

so

Changing the Drive Cord and Grinding Wheel

4

3

2

1

To change the drive cord, proceed as follows:

1.

Bock off and remove hexagon nut;

2.

pull

off

grinding wheel;

3.

loosen hexagon socket screws and take off wheel guard;

4.

replpce drive cord.

To re-assemble the parts, reverse the above procedure.

For tensioning the cord, adjust the motor bracket (bock off hexagon socket screws).

The grinding wheel is attached to the grinding spindle by means

of

a wheel mount. The entire assembly, i.e.,

wheel and mount, is puThed on the spindle and secured by hexagon nut 1.

5light out-of-round of the grinding wheel may be adjusted by backing off the nut on the wheel mount.

16

FEINMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

Pedestal

Installing the Machine Lamp

so

The welded all-steel pedestal, designed to eliminate vibra-

tion, permits the grinder to be placed at any point of the

workshop. All controls are at a level most convenient for

the operator, and the machine is independent of work

benches or wall brackets. The diagram an the right shows

the position in which the grinder should be secured to the

pedestal by means of two bolts inserted from above.

The pedestal comprises a bandy tray for tools and the

like and has a hinged accessory box.

Overall height of pedestal:

3872

in

(980

mm)

Dimensions of pedestal base: 17'14:< 1 1 Vt in.

(450x300

mm)

Approx. weight:

79

lb

(35

kg)

.6 (15 mm)

Installing the Machine Lamp

Slide the tubular lamp holder into the vertical bore provided in the upper portion of the machine and push

down until the retaining screw engages the slot in the tubular holder. Then insert the thrust plate and compres-

sion spring and tighten the clomping screw (Fig. 2). Thread the cable through the hole in the machine base

and connect to lighting circuit (Fig. 1).

fl

Clomping scre

Compression sj

Thrust plate

Retaining scre

2

FEINMECHANIK GmbH - Weilheim/Qbb - LIZENZ DECKEL

17

Special Index Head

Locating Fixture for Cutter Spindle Assembly

A special index head is available for receiving cylindrical-shank cutters of " or 1" diameter or M.T. 1, ML 2,

or M.T. 3 taper shankcutters.

Except for cylindrical-shank cutters of I" diameter, which are mounted direct in the index head, a clamping

sleeve or taper sleeve (5), respectively, is interposed for locating the cutters. The head is provided with 2

hexagon socket screws at the front and 2 at the rear (i) for clamping the cutters as required.

The locating fixture for the spindle assembly permits

regrinding of single-lip cutters while held in the

Locatinp

cutter spindle of the milling machine. For this pur-

fixture

pose, remove the index head slide from its bracket

assembly

after loosening screw Do and clamp Ko and insert

the locating fixture into the V-guide of the index

Do head bracket. For grinding operations insert the

spindle assembly with cutter into the locating fixture

and clamp firmly. The index pin engages the notches

provided on the card pulley of the spindle assembly.

Exchanging the index heads may cause on eccentricity which should be determined as follows: -

Set the scale of the cross slide at zero, mount an qrbor"o on the standard index head and bring the arbor

into light contact with the grinding wheel.

-

Now exchange index heads and, depending on the type of sleeve used, mount on arbor "A" on the special

index head. (The some procedure applies if the locating fixture for the cutter spindle assembly ii mounted

instead of the standard index head.)

Again adjust the cross slide until arbor "A" is in light contact with the grinding wheel.

The value which is read above or below dimension "X (see formula below) on the scale of the cross slide is

the desired amount of eccentricity. It must be taken into account for all settings mod"e with the special index

head or the locating fixture.

A-a

Dimension X =

.

18

FEINMECHANIK GmbH Weilheirn/Obb - LIZENZ DECKEL

I

'V

Table of contents

Popular Grinder manuals by other brands

DeWalt

DeWalt DCG413 instruction manual

Parkside

Parkside PFBS 9.6 A1 Operation and safety notes

Bosch

Bosch GWS Professional 7-100 GWS Professional Original instructions

La Pavoni

La Pavoni PA-8801B user manual

Extol Industrial

Extol Industrial SHARE 8791840 Translation of the original user manual

Hilti

Hilti AG 6D-22-125 manual