ARO-

MANUEL DE L’OPERATEUR

I-1998

COMPRENANT : EXPLOlTATION, INSTALLATION & ENTRETIEN

0

F

MEULEUSES DES SERIES GH03A ET GHX03A

Les meuleuses des Series GHOBA et GHX03A sont destinies aux travaux dans des endroits restreints

dans I’industrie des fabrications metalliques, des chantiers navals, des fabrications de tuyauteries, de

matrices et de moules, et pour toutes les applications ou I’espace est limit& En particulier, elks sont

idhales dans les endroits ou les tubes, tuyauteries, gaines, etc. passent ir travers des cloisons ou des

chksis. Ces petites meuleuses sont trks efficaces pour le meulage des cordons de soudure lorsqu’une

bonne finition est requise.

ARO ne peut Qre tenu responsable de la modification des outils par le client pour les adapter h des ap-

plications qui n’ont pas et6 approuvees par ARO.

D’IMPORTANTES INFORMATIONS DE SEClJRITk SONT JOINTES.

LIRE CE MANUEL AVANT D’UTILISER L’OUTIL.

L’EMPLOYEUR EST TENU A COMMUNIQUER LES INFORMATIONS

DE CE MANUEL AUX EMPLOYkS UTILISANT CET OUTIL.

LE NON RESPECT DES AVERTISSEMENTS SUIVANTS PEUT CAUSER DES BLESSURES.

MISE EN SERVICE DE L’OUTIL

Porter toyjours une protection acoustique pendant

l’utilisation de cet outil.

Tolljotus exploiter, inspecter et entretenh- cet outil

conformCment au Code de securite des outils pneuma-

tiques portatifs de 1’American National Standards

Institute (ANSI B186.1).

Couper to4jours l’alhuentation d’air comprhue et

debrancher le flexible d’alhnentation avant d’instal-

ler, deposer ou ajuster tout accessoire sur cet outil, ou

d’entreprendre une operation d’entretien quelconque

sur l’outil.

Ne pas utiliser des flexibles ou des raccords endom-

mages, effiloches ou dit&ior&.

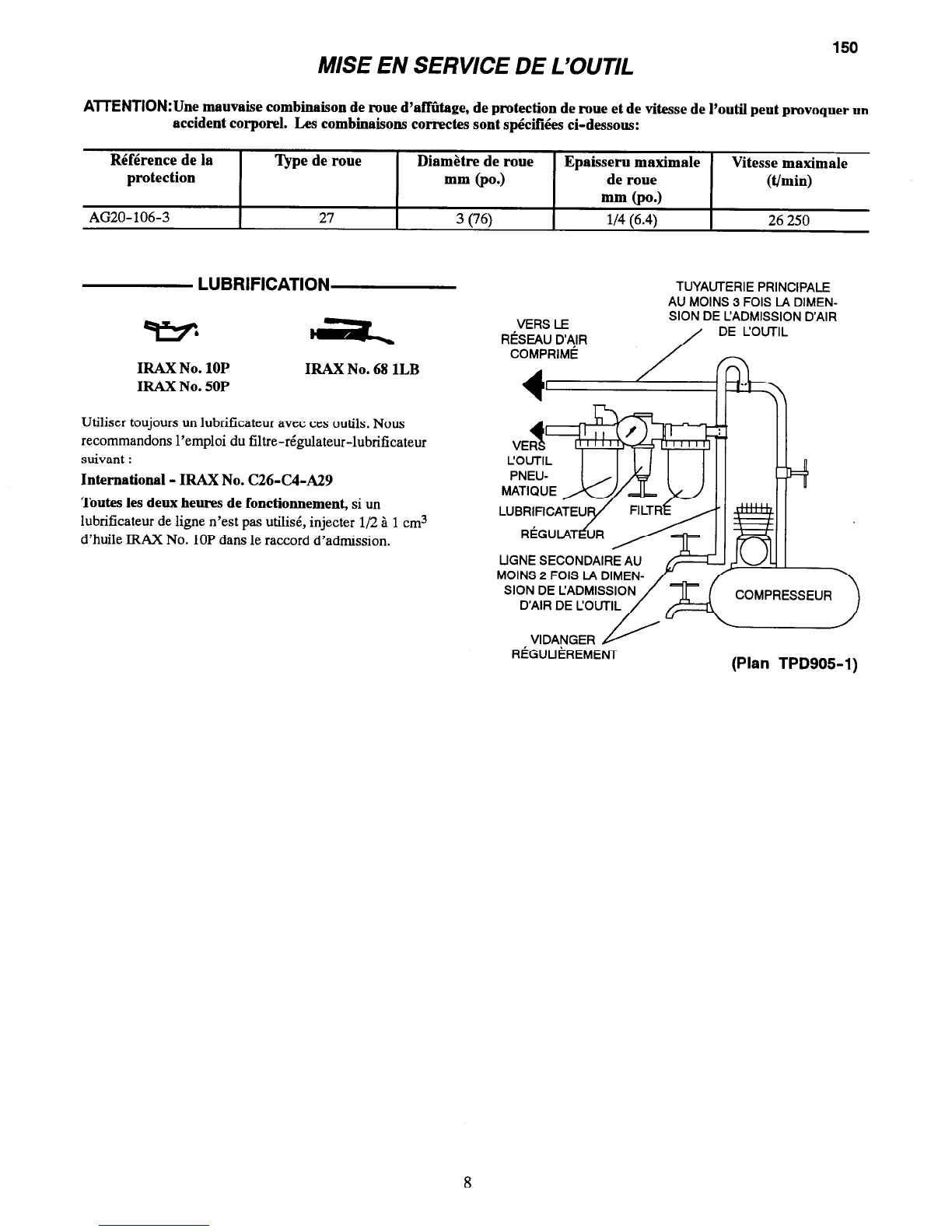

S’assurer que tous les flexibles et les raccords sont

correctement dhuensionnQ et bien set-r&. Voir Plan

TPD905-1 pour un exemple type d’agencement des

tuyauteries.

Utiliser toujours de Pair set et propre P une pression

maxhnum de 6,2 bar. La poussi&e, les fumees corro-

sives et/au une humidit excessive peuvent endom-

mager le moteur d’un outil pneumatique.

Ne jamais lubriller les outils avec des liquides inllam-

mables ou volatiles tels que le k&osene, le gasol ou le

carburant d’aviation.

Ne retirer aucune etiquette. Remplacer toute etiquette

endommagie.

UTILISATION DE L’OUTIL

.

Porter to~ours des lunettes de protection pendant

l’utilisation et l’entretien de cet outll.

Tenir les mains, les v&ements llous et les cheveux

longs, 6loignes de l’extr&ni~ rotative de l’outil.

Pr&oir, et ne pas oublier, que tout 011thmotoris est

susceptible d’8-coups brusques lots de sa mise en

marche et pendant son utilisation.

Carder une position equilibr4e et ferme. Ne pas se

pencher trop en avant pendant l’utilisation de cet out-

il. Des couples de reaction Clevis peuvent se produire

A, ou en dessous, de la pression d’air recommandie.

La rotation des accessoires de l’outil peut continuer

pendant un certain temps aptis le rel&hement de la

gtchette.

Les outils pneumatiques peuvent vibrer pendant l’ex-

ploitation. Les vibrations, les mouvements repetitifs et

les positions hrconfortables peuvent causer des dou-

leurs darts les mains et les bras. N’utiliser plus d’outils

en cas d’inconfort, de picotements ou de douleurs.

Consulter un mCdecht avant de recommencer P utilis-

er l’outil.

Utillser les accessoires recommend& par ARO.

Cet outll n’est pas con9u pour fonctionner darts des

atmospheres explosives,

Cet outil n’est pas is016 contre les chocs ilectriques.

LWilisation de rechanges autres que les pieces d’origineAR0 peut causer des risques d’in&curiti, tiduire les performances de

Poutil et augmenter l’entretien, et peut annuler toutes les garanties.

Les reparations ne doivent &-e effectuees que par des reparateurs qualifies autoris6. Consultez votre Centre de Service ARO

Tool Products le plus proche.

Pour les informations relatives aux pikes et au service, contacter votre distributeur ARO.

ARO Tool Products

Ingersoll-Rand Company

1725 U.S. No. I North, PO Box 8000, Southern Pines, NC 28388-8000

01998 INGERSOLL-RAND COMPANY Imprime aux E.U.

ARO-