deconta ME 12 User guide

Original instruction manual

Mobile Deduster

ME 12

Manufacturer: deconta GmbH

Im Geer 20, 46419 Isselburg

Description / Type-No.: Mobile Deduster ME 12 Type 94, 565

Serial-No.: .................

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 2

Table of contents

1.Basic safety advice............................................................................................................3

1.1.Intended use....................................................................................................................................4

1.2.Dangers...........................................................................................................................................4

2.Transport and storage.......................................................................................................5

2.1.Delivery / Transport .........................................................................................................................5

2.1.1.Coupling to towing vehicle.......................................................................................................5

2.1.2.Uncoupling...............................................................................................................................6

2.2.Storage ............................................................................................................................................6

3.Volume of delivery .............................................................................................................6

4.Technical data....................................................................................................................7

4.1.Connections, dimensions and weights............................................................................................7

4.2.Performance data............................................................................................................................7

4.3.Filter data 1. Filter stage (regenerative Filter).................................................................................7

4.4.Filter data 2. Filter stage (HEPA-Filter) ...........................................................................................8

4.5.Requirement for towing vehicle.......................................................................................................8

5.Technical description ........................................................................................................9

5.1.Unit description................................................................................................................................9

5.2.Options.............................................................................................................................................9

5.3.Filter system ....................................................................................................................................9

5.4.Filter cleaning ..................................................................................................................................9

6.Initial operation ................................................................................................................10

6.1.Option automatic control SRE.......................................................................................................11

6.2.Option Dust bunker with filling level control and emptying via suction port ..................................13

7.Maintenance .....................................................................................................................14

7.1.Details on filter change..................................................................................................................14

7.2.Regular maintenance ....................................................................................................................14

8.Possible disturbances and their elimination.................................................................15

9.Declaration of conformity................................................................................................16

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 3

The copyright of this instruction manual remains with deconta. This manual is intended for assembly,

operation and maintenance personnel. It contains instructions and drafts of technical nature which may

neither be distributed nor used in any unauthorised way for competitive purposes or passed on to others.

1.Basic safety advice

The operation of the equipment must only be carried out by trained competent personnel.

The information and instructions contained within this publication are of paramount

importance to the user.

The manual is always to be kept in the immediate proximity, accessible to all personnel.

deconta insists as the equipment user you follow the information and instruction

contained within the handbook and only use it in accordance with the regulations and

never use this Unit in an inappropriate way. In the event of non-observance, deconta

assumes no liability.

To ensure safe operation of the NPU, the following must be strictly observed:

Do not use in potentially explosive atmospheres.

Maintenance work, including removal and replacement of the filters, may only be

carried out by authorized persons wearing suitable protective clothing.

The device must be completely disconnected from the power supply during all

repairs and maintenance work.

The safety and protective systems must be maintained and functioning correctly.

Safety instructions affixed to the unit must be maintained in a legible condition and

must be adhered to.

General, legal and other binding regulations and procedures for accident

prevention and handling of hazardous substances must be observed.

To ensure safety, modifications to the device are not permitted.

To avoid damage, never operate the unit without built-in filters.

ATTENTION!

The Mobile Deduster is not suitable for use in condensing, corrosive, flammable

and explosive atmospheres.

The ambient and medium temperature must not exceed 60 ° C.

We explicitly point out the additional regional and national safety measures and

regulations for the operation of the appliance technology.

The operator must carry out the inspection of the exhaust air at initial acceptance as well

as at a minimum gap of 3 years.

In addition to the instruction manual, general, legal and other binding regulations on

accident prevention and environmental protection must be observed.

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 4

1.1.Intended use

The dust extraction unit is designed for the collection of mineral, metal and other dry fine

and coarse dust in the air.

The unit is not suitable for filtering flammable gases or dusts.

The user must comply with the specified operating parameters of this manual.

The device may only be used according to its intended use. Any further use beyond this

is not intended. The user is liable for any damages or injuries of any kind whatsoever.

1.2.Dangers

DANGER

Electric shock due to faulty mains cable.

Touching a defective mains cable may result in death or serious injury.

Do not damage the mains cable (e.g. by vehicle overrun, tearing, squeezing).

Regularly check the mains cable for damage.

Have defective mains cable replaced before use by the deconta service or a qualified

electrician.

CAUTION

Damage due to unsuitable mains voltage.

The device can be damaged if it is connected to an unsuitable mains voltage.

Check whether the voltage indicated on the rating plate matches the local mains

voltage.

WARNING

Hazardous materials.

The following materials may not be filtered:

hot materials (glowing cigarettes, hot ash etc.)

combustible, explosive, aggressive materials and dusts

WARNING

Contaminated Filter.

Filter changes may only be carried out by authorized persons, wearing suitable

protective clothing.

Disposal of filters according to local legal regulations.

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 5

2.Transport and storage

2.1.Delivery / Transport

For transportation and moving of the Mobile Deduster unit, it is coupled to a towing

vehicle with ball head coupling (requirement see technical data) and pulled to its

destination.

Transport damages are to be documented immediately when handed over. Additionally

take down eventual damages on the freight documents.

2.1.1. Coupling to towing vehicle

Put towing vehicle and Deduster in Position (Move coupling of Deduster over the

trailer ball of towing vehicle)

Pull stabilization handle (Pos.1) upwards

Put opened coupling (Pos.2 coupling handle pulled upwards) by winding down of

support wheel on the trailer ball of the towing vehicle

Release coupling handle handle slides back independently into original position

Use our hand to press down handle locking and securing is done automatically

Press stabilisation handle downwards

Pull up support wheel and lock pointing in driving direction

Fasten breakaway cable to eyelet of trailer coupling (towing vehicle)

Plug in light connector of Deduster into socket of towing vehicle

Check lighting of Deduster

Attention: It is only coupled correctly, if the green edge of the safety indicator

(Pos.3) is visible.

1

2

3

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 6

2.1.2. Uncoupling

Wind down support wheel

Release both breakaway cable and light connector

Pull stabilisation handle (Pos.1) upwards

Pull coupling handle (Pos.2) forcibly upwards

Lift coupling off trailer ball of towing vehicle

Safety instructions:

The trailer coupling may only be operated by one person when opened and closed.

2.2.Storage

To avoid any damages the unit may only be parked in areas inaccessible for

unauthorized persons.

3.Volume of delivery

Regardless if the unit is purchased or rented, unless no other agreements have been

made, the volume of delivery of the Mobile Deduster consists of:

Unit ME 12

Instruction manual

Stoppers

Return delivery after ending of rental period

For the protection of our clients and in accordance with the rules for hazmat transport, we

must insist on the following return delivery conditions:

complete as stated above

thoroughly cleaned (ready-to-operate), with emptied dust bunker

free from any adhesive residue

without fibre binding

without damages

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 7

4.Technical data

4.1.Connections, dimensions and weights

Power connection : 400V 32A 3 N PE

Hose connection : 2 x 300 mm

Length (incl. drawbar) : ca. 5200 mm

Width : ca. 2000 mm

Height : ca. 2010 mm

Weight : ca. 1400 Kg

4.2.Performance data

Exhaust air volume : up to 12000 m³/h

Suction speed : up to 25 m/s

Bunkervolumen : ca. 0,5 m³

Shock valve G1 : 12 pcs

Control : electric 12 channels

Dedusting : continuously

Operating pressure : 4,5bar

4.3.Filter data 1. Filter stage (regenerative Filter)

Filter material :Polyester needle, pleated

Filter area :ca. 100m²

Quantity filters :24 pcs

Filter resistance :4300 Pa

Clean air concentration :< 0,15mg/m³

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 8

4.4.Filter data 2. Filter stage (HEPA-Filter)

Frame Plastic

Filter medium Micro-Glas fibre paper

Casting compound Polyurethane

Sealing Polyurethane

Filter area per filter 48 m²

Filter class H13 pursuant EN 1822

Degree of separation >99,95% leak-tested in MPPS

(Most Penetrated Particle Size)

Temperature / humidity 110°C/100% RF

(relative humidity)

Filter dimensions (in mm): 610 x 910 x 292

Handle protection Expanded metal, double-sided

4.5.Requirement for towing vehicle

Ball head coupling

Permissible drawbar load 75 kg

Ball head 94/20 EG A 50 with min. diameter 49 mm

Control device not rotatable over 25°

technical changes reserved!

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 9

5.Technical description

5.1.Unit description

The dust extraction unit is designed for the collection of mineral, metal and other dry fine

and coarse dust in the air.

mounted on chassis, complete and ready-to-use

quick relocation possible

galvanized tandem chassis with hit brake, TÜV approved

electronic control unit with various special functions

robust construction, designed for continuous operation

recoverable filter system (automatic cleaning during operation)

dust bunker to collect fine and coarse dust

HEPA-Filter stage

high air flow velocity at the inlet side to prevent deposits in the suction line

differential pressure monitoring for filter control

Manual speed control

5.2.Options

Automatic control SRE

Dust bunker with fill level monitoring and emptying via suction connection

5.3.Filter system

The collected fine dust is deposited on the filter surface and forms the “filter cake” (coat).

An automatically working Jet-cleaning system ensures the cleaning of the filters during

operation. The injection nozzles pull air by a suction effect and jet the coat off the filter,

working from inside to the outside. The blown off dust is collected in the dust bunker and

can be removed from there.

5.4.Filter cleaning

The cleaning operates automatically when the compressor and the cleaning are switched

on. The compressor fills the pressure accumulator, which operates the Jet-cleaning

system.

The Deduster is provided with an integrated compressor for short term uses. In

case of long term uses, it is essential to use the external compressed air supply!

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 10

6.Initial operation

The Mobile Deduster ME12 is supplied ex works and is in a ready-to-use state.

In case of visible damages, do not operate the unit. Please contact deconta GmbH

immediately.

Determine the location of the Deduster. Choose it close to the working area to avoid

unnecessary long hoses and loss of power.

Connect suction line of Deduster to working area.

Establish power supply to Deduster (400V 32A 3N PE)

Switch on Main switch, make sure the Lamp „Mains Ok“ lights up

Switch on „Fan“ („Fan active“ lights up) and wait until the motor is running

Switch on „Cleaning“ („Cleaning active“ lights up). When an external Compressor is

connected the lamp “Compressed air external” lights up.

The unit is operating!

The desired performance can be set, by turning the rotary knob „Fan control“.

Main switch

Mounted plug

Mains OK

Fan active

Fan ON/OFF

Fan control

Filter control

1. Filter stage

(regenerative Filter)

Filter control

2. Filter stage

(HEPA Filter)

Cleaning active

Operating hours

Com

p

resso

r

Cleaning ON/OFF

Operating hours

Fan

Compressed ai

r

external

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 11

6.1.Option automatic control SRE

The main task of the control unit is to measure and to control the required negative

pressure in the working area.

Specify the measuring point in the working area and connect to the connection

negative pressure with PE-hose 8 x 1

Determine the measuring point in the clean area (adjoining rooms) an connect to

the connection atmosphere with PE-hose 8 x 1

Connection external Compressor

Min. 5 bar / max. 10 bar

Connection

negative pressure

Connection

atmosphere

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 12

Manual operation:

In manual operation, the „+“ and „-“ keys are used to set the fan performance. The

display show the performance value in „%“ and the measured negative pressure.

Automatic operation:

In automatic mode, the set point in Pascal for the negative pressure is preset with the

keys „+“ and „-„ (display set value in automatic mode). By comparing the entered set

point value with the permanently measured current actual value (measured negative

pressure), the speed of the fan is automatically adapted, that is, the fan moves

automatically „up“ and „down“.

Important:

In the event of power failure, the control saves the last set values, restarts automatically

after damage elimination and restores the saved data.

Set value in automatic operation

Operating mode (AUTO or MANUAL)

Measured negative pressure

Fan performance in %

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 13

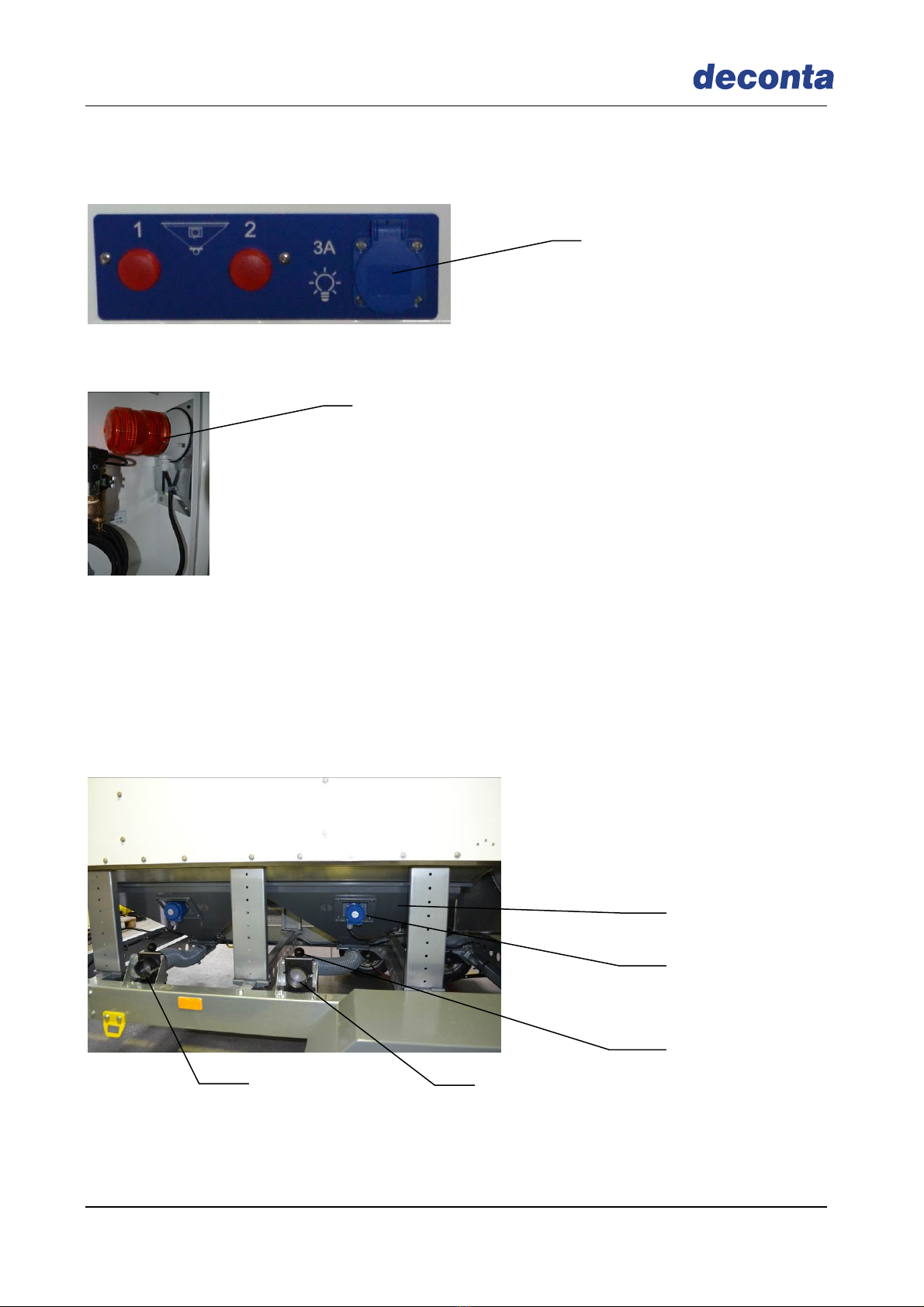

6.2.Option Dust bunker with filling level control and emptying via suction port

A full bunker is indicated by two signal lights on the control unit.

When the bunker is full, the alarm socket is supplied with power. An external signal light

or signal horn can be connected to this alarm socket.

For emptying the bunker, there are 2 suction connections on the unit.

Switch off Fan and Cleaning function of the mobile dust extractor!

Connect the suitable vacuum cleaner to the suction connection

Open shut-off valve

The Bunker can now be vacuumed

Please note!

After emptying, the shut-off valve must be closed again.

Dust bunker

Fill level monitoring

Suction connection 1

Suction connection 2

Shut-off valve

Alarm socket

Signal lamp in

transport mechanism

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 14

7.Maintenance

Maintenance work, including changing/removing filters, may only be carried out by

authorised persons wearing suitable protective clothing.

The appliance must be completely disconnected from the power supply during all repairs

and maintenance work.

We expressly refer to possible additional regional and national regulations in the

maintenance of the appliance technology.

The air-conditioning systems (dust extraction unit, industrial vacuum cleaners and

devices used for venting or negative pressurisation) must be serviced as required, at

least once a year, and checked by a qualified technician. The test result shall be

presented on request.

7.1.Details on filter change

The frequency of the filter change depends on the degree of contamination of the filters.

As the filter occupancy is increased (contamination of the filters), the air performance

decreases.

For filter monitoring during operation, there are two manometers installed on the device.

We recommend a filter change when the “max” mark has been reached.

Important: Only use approved, flawless filters!

7.2.Regular maintenance

Check for air tightness

Check solenoid valves function properly

Check oil level of compressor

Regularly emty dust bunker

After the end of work, release overpressure in pressure accumulator by moving the hand

gear.

Filter control

1. Filter stage

(regenerative Filter)

Filter control

2. Filter stage

(HEPA Filter)

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 15

8.Possible disturbances and their elimination

Disturbance Possible reason Elimination

Unit does not work Power source out of order Have power source repaired by expert

Unit does not work Defective compononents Have unit repaired by deconta or a

workshop authorized by deconta

Cleaning of filter does

not work Plug of solenoid valve

may be loose Insert plug one more time

Compressor does not

run Compressor is not

switched on Remove right front panel und switch

on compressor

Compressor does not

run Plug of compressor came

off Remove right front panel and insert

plug again

Caution!

Work on the unit may only be carried out in a voltage-free state.

Instruction manual

Mobile Deduster ME 12

Version 1 Seite 16

9.Declaration of conformity

EC Declaration of Conformity acc. to Machinery Directive 2006/42 / EC Annex II 1.A

The manufacturer

deconta GmbH

Im Geer 20

46419 Isselburg

hereby confirms that the following product

Product description: mobile dust extraction unit

Type designation: ME 12

Type number: 94, 565

complies with all applicable regulations of the above-mentioned directive and the other applicable

directives (hereafter), including the amendments applicable at the time of the declaration.

The following other EU directives were applied:

EMC directive 2004/108 / EC

The following harmonized standards were applied:

EN 60204-1:2006/AC:2010

EN 60335-2-69:2012

The following national or international standards (or parts / clauses thereof) and specifications were

applied:

DIN VDE 0701-0702 (VDE 0701-0702):2008-06

Place: Isselburg

Date: 14.11.2016

(Wilhelm Weßling)

Director

Table of contents

Other deconta Vacuum Cleaner manuals