DEELAT D1047067 User manual

Digital Weighing Indicator

User Manual

WWW.DEELAT.COM

User ManualUserManual

Digital Weighing IndicatorDigital Weighing Indicator

DIGITAL WEIGHING INDICATOR

- 3 -

DIGITAL WEIGHING INDICATOR

- 2 -

Main Specication

Contents

Main Specication 3

Installation 4

Front and Back View of the Indicator 4

Key Functions 5

Connecting Load Cell to Indicator 6

Operation 7

Power On and Zero Auto 7

Zero Manually 7

Tare 7

Accumulating 7

Counting 8

User Function Setting 8

Connect Scoreboard to Indicator (Function Optional) 10

Serial Communication and Indicator Connection 10

Calibration 12

Error Indication 13

Chargeable Battery 13

Maintenance 14

Notes 15

Model Deelat Floor Scale weighing indicator

Accuracy GradeIII, n=3000

Sample Rate 10 times / second A/D conversion: Δ -∑

Load cell sensitivity 1.5~3mV / V

Scale interval 1/2/5/10/20/50 for selection

Display 6 bits LCD 6 state indicating signals

Scoreboard interface

(optional)

In serial output mode:current loop signal,

transmission distance ≤50m

Communication interface

(optional)

RS232C;

Baud rate 1200/2400/4800/9600 optional

Power supply Battery DC6V/4AH

(display Bat lo when electricity voltage below 5.4V)

Operating temperature/

humidity

0~40°C;

≤85% RH

Transporting temperature -25~55°C

Water proof IP63

DEAR CUSTOMER, PLEASE READ THE USER GUIDE CAREFULLY

BEFORE USING THE INDICATOR!

User ManualUserManual

Digital Weighing IndicatorDigital Weighing Indicator

DIGITAL WEIGHING INDICATOR

- 5 -

DIGITAL WEIGHING INDICATOR

- 4 -

Key Functions

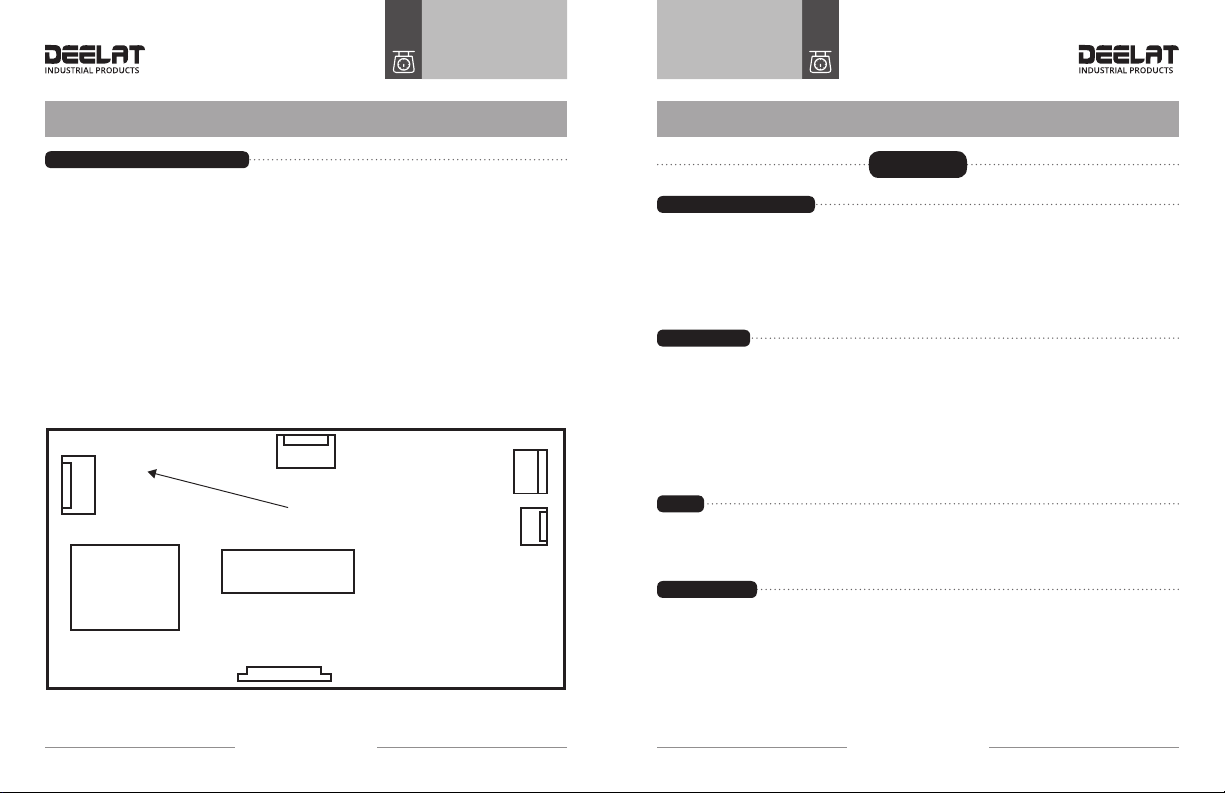

Front and Back View of the Indicator

Installation

Keep pressing this button for 5 seconds more in weighing mode, it will

come into operator setting mode; less than 5 seconds, it will come into

counting mode.

Press this button to accumulating the weight in weighing mode. Press

this button for sample taking in counting mode.

Press this button to tare in weighing mode.

Press this button to zero in weighing mode.

Press this button to turn on/off the scale.

Press this button to stay in weighing mode or Press this button to

save/move in set mode.

FUNC

TARE

ZERO

#

*

Unit Kg Charge

A12

COUNT FUNC TARE STABLE ZERO

FUNC#

ZEROTARE

*

*

6V

Rechargable

Battery

Calibration

Span

Power

Swithc

Power

Wire

Rs 232

Interface

Load Cell

Wire

User ManualUserManual

Digital Weighing IndicatorDigital Weighing Indicator

DIGITAL WEIGHING INDICATOR

- 7 -

DIGITAL WEIGHING INDICATOR

- 6 -

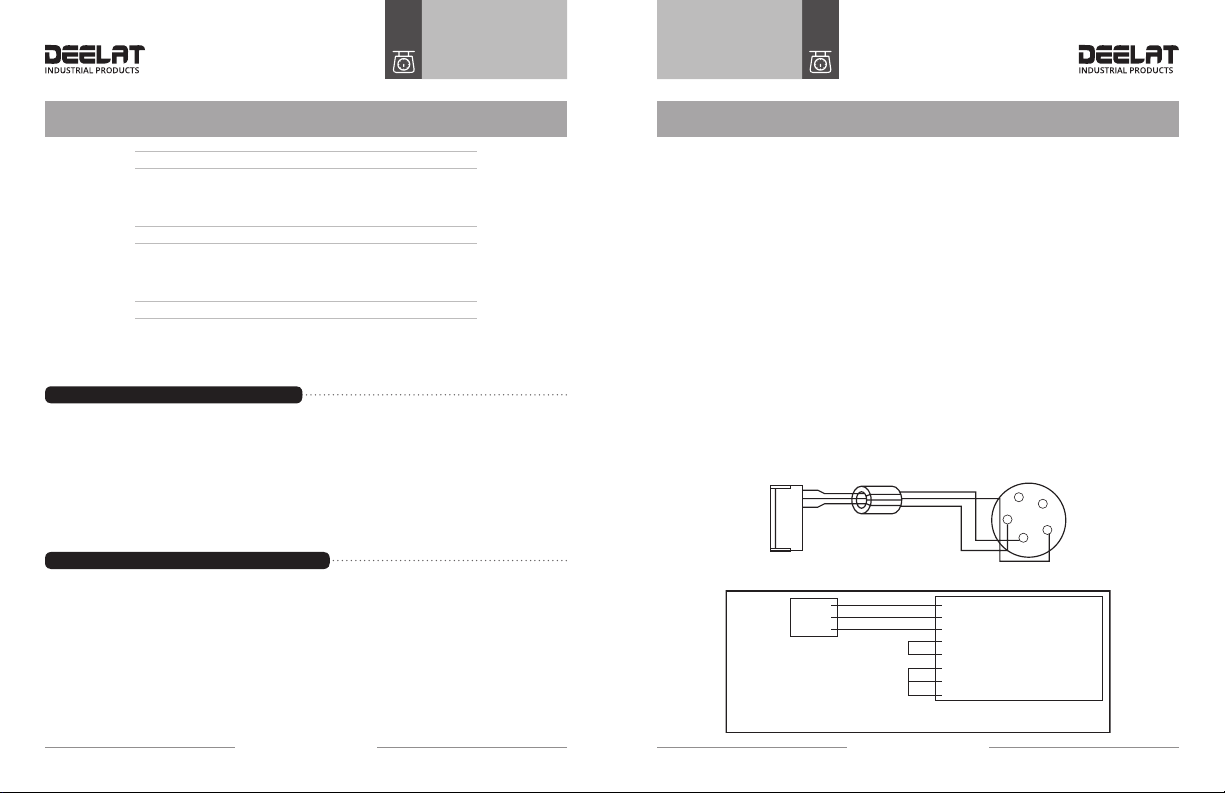

Connecting Load Cell to Indicator

Power On and Zero Auto

Manual Zero

Tare

1. The 5-pin (2.54MM) socket is used to connect to the load cell, as indicated in the graph below.

Please Note: Pin 1 EX+; Pin 2 EX-; Pin 3 SHIELD; Pin 4 IN+; Pin 5: In-

2. When the 4-pin shielded cable is connected, the indicator has a long distance function.

3. The indicator must be connected to the load cell and the shield cable of the load cell

Must be grounded.

4. The sensor and indicator are static sensitive devices. Do not operate under high voltage.

Operation

1. The indicator will perform “999999-000000” to self-check when turning on. Then it will enter

weighing mode.

2. When powered on, if loading weight on the scale deviates from the zero point, but still within auto

zero setting range, the indicator will set to zero automatically; if it is out of auto zero setting

range, it is necessary to adjust the zero point or recalibrate or reset.

1. In weighing mode, when there is a degree of tolerance after removing weight, press [ZERO] to set

the indicator to zero.

2. If the displayed value deviates from the zero point, but it is still within the manual zero-range, the

[ZERO] key will return the indictor to zero. If not within the manual zero-range, then the [ZERO]

key will not function. *If this is the case, please recalibrate or reset zero parameters.

3. Only when a stable indication is displayed can the zero operation function.

1. When the indicator is in weighing mode, and the displaying positive weight is stable, pressing the

[Tare] key will deduct the displayed weight value as tare weight. The indicator will then display

net weight as “0” and the Tare indicator is on.

Accumulation

1. In weighing mode, when the displayed value is positive and stable, press the [*] key to accumulate

the present weight and display the accumulated weight. The accumulate indicator “(*)” will be

on. Press this key again and it will go back to weighing mode and the accumulate indication “(*)”

will not be displayed. The next accumulation operation must be performed after the weight

is returned to zero. When the accumulated weight is displayed, press the [Func] key to clean

the accumulated weight in Memory and press [*] to return to weighing mode. If the accumulated

weight needs to be checked, please keep the load of the platform at zero, then press [*] to display

the accumulated weight.

Connect to Load Cell

CPUA/D

CONVERSION

CN1

CN3

CN4

CN2

EX+

EX-

SHELD

IN+

IN-

User ManualUserManual

Digital Weighing IndicatorDigital Weighing Indicator

DIGITAL WEIGHING INDICATOR

- 9 -

DIGITAL WEIGHING INDICATOR

- 8 -

Counting

User Function Setting

1. In weighing mode, press [Func] to enter into the counting state. It will display “count”, and pressing the

[*] key will display “C00000”. Then press [Tare] to move the digit directed by the small triangle, and the

number corresponding with the small triangle will be increased one each time after pressing the [Zero]

key (it will enter into counting function mode after the sample quantity is input and [*] is pressed).

“0” will be displayed and the counting indication will be activated. Press [Func] key to return to

weighing mode. After entering counting mode, “count” will be displayed. Press [*] two times to enter

counting mode directly and the indicator will display the previous result. (During this process, if ERR4

is displayed, then sampling has failed, and the indicator will keep the result from the last sampling.

1. In weighing mode, hold and press [Func] for 5 seconds and it will enter user function setting

mode (mode P). There are 12 modes from P1 to P12. Press [*] to choose the mode and press [Tare]

to choose the parameter. The description of parameters is as follows:

P1 kg — Lb change

X=1: kg display

X=2: Lb display

P2 automatically power off

X=1: N/A

X=2: Power off in 10 minutes

X=3: Power off in 20 minutes

X=4: Power off in 30 minutes

P3 Baud rate setting

X=1: 9600

X=2: 4800

X=3: 2400

X=4: 1200

P4 RS232 Net/Gross weight output option

X=1: Net weight output

X=2: Gross weight output

P5 RS232 output mode option

X=1: No transmission (RS232 stop)

X=2: Continuous transmission

X=3: Continuous transmission when stable

X=4: Command mode

(Z:zero; T:tare;R:transmit weight data once time)

X=5: Current loop output

X=6: Keep for Printing

P6 Backlight setting

X=1: No backlight

X=2: Automatic backlight

X=3: Backlight On

P7 Zero-tracking range

X=1: 0.5e

X=2: 1.0e

X=3: 1.5e

X=4: 2.0e

X=5: 2.5e

X=6: 3.0e

X=7: 5.0e

P8 Manual zero range

X=1: 2%FS

X=2: 4%FS

X=3: 10%FS

X=4: 20%FS

P9 Auto zero range

X=1: 2%FS

X=2: 4%FS

X=3: 10%FS

X=4: 20%FS

User ManualUserManual

Digital Weighing IndicatorDigital Weighing Indicator

DIGITAL WEIGHING INDICATOR

- 11 -

DIGITAL WEIGHING INDICATOR

- 10 -

P10 Digital ltering intensity

X=1: high

X=2: medium

X=3: low

P11 Stable time

X=1: high

X=2: medium

X=3: low

P12 Stable scope

X=1: low

X=2: medium

X=3: high

Connect Scoreboard to Indicator (Optional)

Serial Communication and Indicator Connection

1. Current loop or RS232 signal is used for scoreboard connection, which is transmitted in serial

binary code style. The baud rate is adjustable.

• Make sure that scoreboard and signal output is connected correctly. If there is something wrong

with the connection, damage will happen to the output port of the instrument and input port of

the scoreboard.

• Only use the provided connecting cable

1. Make sure that communication interface output and computer are connected correctly. Iif there

is something wrong with the connection, damage will happen to the output port of the instrument

and the input port of computer. Data format for the RS232 output is the following: the 1st is

starting the bit, the 10th is the stop bit, and the middle are 8 data bits.

Communication mode as follows:

1. In continuous mode:

The data transmitted is weight (Gross weight or net weight)

The format of G.W.: ww000.000kg or ww000.000lb

The format of N.W: wn000.000kg or wn000.000lb

Note:The position of above decimal is decided by the decimal set on the indicator.

2. In command mode:

The indicator performs the corresponding operation according to the command transmitted

from the pc.

Command R The indicator sends weight data once in receipt of command R from pc

(the format is the same as the continuous mode)

Command T The indicator tares in receipt of command T from pc (the same as tare key).

If no command is received the indicator displays CR LF

Command Z The indicator zero in receipt of command T from Z (the same as zero key If no

command is received the indicator displays CR LF

1

2

3

4

5

B port

RS 232 C 5 pin (Male)

A port

CH2.54-8P

Orange 1

Red 2

Black 3

B 4

L 5

A 6

N 7

K 8

Orange TXD

Black GND

3 Transmit Data

2 Receive Data

5 Chassis Ground

1 Carrier Detect

4 Data Terminal Ready

6 Data Set Ready

7 Request To Send

8 Clear To Send

9 Pin Port (Female)

Computer

5 Pin Port (Male)

RXD 2

TXD 3

GND 5

Red RXD

User ManualUserManual

Digital Weighing IndicatorDigital Weighing Indicator

DIGITAL WEIGHING INDICATOR

- 13 -

DIGITAL WEIGHING INDICATOR

- 12 -

Calibration

Error Indication

Chargeable Battery

1. Connect the load cell properly and then turn on the indicator and press the [#] key during initial-

ization. It will enter into the calibration mode and calibrate as following:

STEP OPERATION DISPLAY NOTES

1Press [TARE] for selection of

division [d X]

Select optional division (1/2/5/10/20/50),

press [#] to conrm

Example: 20

2Press [TARE] for selection of

DECIMAL POINT selection [P X ]

Select optional decimal point: 0~3, press [#]

to conrm

Example: 3

3 Set the full range [FULL]

Press [TARE] for selection of the digit bit; Press

[ZERO] for selection of the digit; Press [#] to

conrm the input of the full range

4Zero point calibration: Press [#]

when the stable signal is on [nOLOAD] Conrm there is no load

5

Full range point calibration:

Press [#] when the value input

is the same as the loaded weight

and the stable signal is on

[AdLOAD]

While inputting the loaded weight,

Press [TARE] for selection of the digit bit; Press

[ZERO] for selection of the digit; when the

input value is the same as the loaded weight

and the digit bit is at the highest bit, press [#]

when the stable signal is on

6[End]

7

Press the calibration span under

the lead sealing board at the

back of the indicator

It saves the calibration parameter and returns

to the weighing status.

Attention: If you do not press the calibration

switch the parameters will not be saved

2. FAST CALIBRATION FOR ZERO POINT AND FULL RANGE POINT

Press [#] while it is initializing and it will enter into the calibration mode.

3. Fast calibration for zero point:

At any point before it displays [nOLOAD], press [FUNC] and it will keep the original division,

decimal point, full range and enter into the zero point calibration mode. Press [ZERO] when the

stable signal is on and it will display [End] and keep the original full range point calibration. Press

the calibration switch under the lead sealing board at the back of the indicator and it will save the

setting and return to the weighing status.

4. Fast calibration for full range point:

Fast calibration for full range point: At any point before it shows [AdLOAD], press [ACCU] and it will

keep the original division, decimal point, full range, zero point calibration and enter into the full range

point calibration mode. When it is nished, press the calibration switch under the lead sealing board

at the back of the indicator and it will save the setting and return to the weighing status.

EER 1 The AD value is too small when calibrated at full range point.

EER 2 The zero point is out of range when calibrated at zero point.

EER 3 The zero point is out or auto zero range upon starting

EER 4 The input sample quantity is zero when sampling in counting mode.

EER 5 The input weight is zero when full scale calibrated in calibrating mode.

EER 6 The unit weight is less than 0.25e when sampling in counting mode

bAt-lo Low power

1. Turn on the AC power and the indicator will charge the battery automatically. If you don’t use the

battery frequently, you should take the battery out.

• Note: red end is +, and the black end is -. Incorrect connection will ruin the indicator.

• Note: The built-in battery should be fully charged before it is used for the rst time.

2. When you turn off the AC power, and push start key the battery will work. When [LouoL] is

displayed it means there is insufcient voltage and it needs to charge.

3. When you use the battery for the rst time, you should charge the battery for 20 hours in order

to ensure maximum battery life.

4. If you don’t use battery for a long time, you should charge the battery for 10-12 hours every

2 month period to prolong battery life.

User ManualUserManual

Digital Weighing IndicatorDigital Weighing Indicator

DIGITAL WEIGHING INDICATOR

- 15 -

DIGITAL WEIGHING INDICATOR

- 14 -

Maintenance Notes

1. To ensure proper function of the indicator, it should not be placed directly under sunshine and

should be placed in a well ventilated space.

2. The indicator should not be installed in a place with severe dust or where vibrations are present

3. The Load cell requires a solid connection with the indicator, and the system should always be

grounded. The indicator must avoid coming into contact with electric and magnetic elds.

• Avoid using the indicator in a place that has ammable gas or ammable steam:

• In order to protect the operator, indicator and relevant device, you should mount a lightning rod

in thunderstorm prone geographic areas.

• Load cell and indicator are static sensitive device, you must adopt anti static measures.

4. Do not clean the case of indicator with intensive solvents (for example: benzene and nitro oils)

5. Liquid and conductive substances should not come into contact with the indicator, otherwise the

electronic components can be damaged and the user could get shocked.

6. Make sure to cut off the power supply to the indicator and relevant devices before connecting

and disconnecting any external devices.

7. During operation, if major problems occur, operator must pull off the power supply plug immediately,

and user should return this indicator for repair. Unauthorized manufacturers, repair centers, or users

should NOT repair the scale on their own, otherwise further damage may occur.

8. In order to prolong product life, please charge the cell fully before using it. If you don’t use the

indicator for a long time, you must charge the cell every two months and for eight hours per

charging time.

9. Moving or installation must be performed carefully and avoid sudden movements, vibration,

and bumps in order to protect the storage cell from being damaged.

WWW.DEELAT.COM

Table of contents