Defy FLAMEMASTER DGS606 User manual

Page 1

FLAMEMASTER DGS606

600 GE 4B MULTIFUNCTION OVEN

Cooking

Instruction manual

Part number: 073307

Page 1

Contents

Dear Customer,

Your new Defy oven was manufactured in a state-of-the-art facility and has passed the strictest quality

control procedures.

Please read this manual carefully before connecting the gas bottle or using your oven for the first time

and then store it within easy reach for future reference.

This manual will provide you with information on how to operate and care for your oven to gain the

maximum benefit from it.

We trust you will enjoy years of trouble free use.

PERMIT NUMBERS

1037-56/1-RSA-12-A

Warning for hot surfaces

Warning for hazardous situations

Warning for risk of fire

Important information or useful hints about usage

EXPLANATION OF SYMBOLS

Throughout this User Manual the following symbols are used:

1. General Information 2

Overview 2

Technical specifications 2

Identification table 2

2. Important safety instructions 3

General safety 3

Safety when working with gas 4

3. Setup 5

Unpacking 5

Connecting the sprague to the oven 5

Connection to the power supply 5

Ventilation 6

Gas installation 6

Important information 6

Connecting the gas hose 6

Gas conversion 7

Routing of the gas hose 8

Anti-tilt mechanism 8

4. Operation Instructions 9

Oven operation 9

Selector switch 9

Cooking times table 9

Gas hobs 10

5. Maintenance and care 11

General cleaning 11

Service Intervals 11

Steam assisted cleaning 11

Caring for gas hobs 11

Replacing the oven light 11

Removing the oven door 12

Gas jet cleaning procedure 12

6. Important Notes 13

Problem solving guide 13

Do’s and don’ts 13

7. Support 14

Customer care line 14

Sub-Saharan Africa Branches 14

8. Warranty 15

PLEASE REGISTER YOUR

PRODUCT AT

www.defy.co.za

DEFY APPLIANCES (PTY) LTD

P.O.BOX 12004

JACOBS

DURBAN

4026

SOUTH AFRICA

Page 2

1. General Information

Overview

Technical specifications

GENERAL

External dimensions

(height / width / depth) 960 mm / 600 mm /

660 mm

Gas type / pressure LPG - G 30/2.8-3.0

kPa

Total gas consumption 8.0 kW

Oven power

consumption 3.4 kW

Grill power

consumption 1.8 kW

Control panel

Oven

thermostat Left front

burner Left rear

burner Right rear

burner Right front

burner

Ringer

timer

Selector

knob

Identification table

Position hob zone 2000 W

Rear left

(RL)

3000 W

Front

left (FL)

1000 W

Front

right (FR)

2000 W

Rear

right

(RR)

Gas type / Gas

pressure

NG - G 20/2.0 kPa 103 R 115 72 103

LPG - G 30/2.8-3.0 kPa 72 87 50 72

Accessories supplied may vary

depending on the model. Not all

accessories in the user manual may

be included with your appliance.

Accessories may be purchased from

Defy spares.

Figures in this manual are

schematic and may not match your

appliance exactly.

Rear left (RL)

2000W

Front left (FL)

3000W

Rear right (RR)

2000W

Front right (FR)

1000W

Page 3

2. Important Safety Instructions

This section contains safety instructions that will help you avoid risk of injury and damage.

All warranties will become void if you do not follow these instructions.

• Be careful when using alcoholic drinks in

your dishes. Alcohol evaporates at high

temperatures and may ignite and cause a

fire.

• Do not heat closed tins and glass jars in

the oven. The pressure that would build

up in the tin/jar may cause it to burst.

• Do not place baking trays, dishes or

aluminium foil directly onto the bottom of

the oven. The heat accumulation might

damage the bottom of the oven.

• Keep all ventilation slots clear of

obstructions.

• The appliance may be hot when it is in

use. Never touch the hot burners, inner

sections of the oven, heaters etc.

• Never touch the metal surfaces of the hob

and control panel during use.

• Always use heat resistant oven gloves

when putting in or removing dishes from

the hot oven.

• Do not use the appliance with the front

door glass removed or cracked.

• Do not trap the mains cable between the

oven door and frame and do not route it

over hot surfaces as the cable insulation

may melt and cause a fire as a result of a

short circuit.

• Make sure that the function knobs are

switched off after every use.

• Always dry food thoroughly before placing

it in hot oil or fat. Frozen food will splatter

if added too quickly.

• Only use the appliance for preparing food.

• Never heat fat or fry with a lid on the pan.

• Do not leave hot fat or oil unattended. If

overheating occurs, these could catch fire.

• Do not store flammable items in the oven.

• Always keep the oven door gasket clean.

General safety

• This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge,

unless they have been given supervision

or instruction concerning the use of the

appliance by a person responsible for

their safety.

• Children should be supervised to ensure

that they do not play with the appliance.

• Connect the appliance to an earthed

outlet/line protected by a fuse of suitable

capacity.

• The earth installation should be

completed by a qualified electrician. Our

company shall not be liable for any

problems arising due to the appliance not

being earthed in accordance with the local

regulations.

• If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent or similar qualified persons in order

to avoid a hazard.

• Do not operate the appliance if it is

defective or has any visible damage.

• Do not carry out any repairs or

modifications on the appliance.

• Never wash down the appliance with

water! There is a risk of electric shock!

• Never use the appliance when your

judgment or coordination is impaired by

alcohol and/or drugs.

• The appliance must be disconnected from

the mains during installation,

maintenance, cleaning and repair

procedures.

• The rear surface of the oven gets hot

when it is in use. Make sure that the gas

or mains connection does not come into

contact with the rear surface as

connections may get damaged.

• Use a deep pan, large enough to cover

the appropriate hob or burner.

Page 4

DANGER. Risk of explosion and

poisoning! Put out all naked

flames and do not smoke, strike

matches or do anything that

could cause ignition. Do not

operate any electric switches

(e.g. light switch, TV, computer,

cooker or door bell). Do not use a

telephone or mobile phone.

• The use of gas cooking appliances results

in the production of heat and moisture in

the room in which it is installed. Ensure

that the kitchen is well ventilated: keep

natural ventilation holes open or install a

mechanical ventilation device (mechanical

extractor hood).

• Gas appliances and systems must be

regularly checked for proper functioning.

The regulator, hose and its clamp must be

checked regularly and replaced within the

periods recommended by its manufacturer

or when necessary.

• Clean the gas burners regularly. The

flames should be blue and burn evenly.

• Good combustion is required in gas

appliances. In case of incomplete

combustion, carbon monoxide (CO) might

develop. Carbon monoxide is a

colourless, odourless and very toxic gas,

which has a lethal effect even in very

small doses.

Safety when working with gas

• Any work carried out on gas equipment

and systems may only be done by

authorised qualified persons who are

registered LPG Gas installers.

• Prior to installation, ensure that the local

distribution conditions (nature of the gas

and gas pressure) and the adjustment of

the appliance are compatible. In the event of a pan fire

• Switch off the Gas supply.

• Smother the flames with a blanket or

damp cloth.

• Burns and injuries are usually caused by

picking up the burning pan and rushing

outside with it.

• Do NOT use water to extinguish an oil or

fat fire.

If you smell gas

• Turn off all valves on gas appliances and

gas meter at the main control valve,

unless it's in a confined space or cellar.

• Extinguish all naked flames.

• Do not operate any electrical appliances.

• Ventilate the area. Open doors and

windows.

• Check for leaks. Check all tubes and

connections for tightness.

• If odour persists contact your nearest

Defy Service Centre for assistance.

• If you still smell gas leave the property.

• Warn the neighbors.

• Call the fire-brigade. Use a telephone

outside the house.

• If you have door or gates that are secured

by an electric lock, or entry phone, please

open these manually.

• Do not re-enter the property until you are

told it is safe to do so.

In the event of a burn back

• In the event of a burn back (where the

flame burns back into the jet ) immediately

turn off the control to the affected burner.

• Wait a few minutes and relight the burner

in the normal manner.

• If the burn back occurs again, turn off the

control knob to the affected burner, and

consult the nearest Defy service

technician, who will advise you.

Gas and electrical connections

must be carried out by qualified

personnel in accordance with

current and local regulations.

Installations carried out by

unauthorized persons will void

the warranty.

IMPORTANT: If the gas type of

the appliance is changed, then

the rating plate that shows the

gas type of the unit must also be

changed. the sticker that is

currently on the rear of the

appliance that reads “Factory

adjusted for LPG gas” must be

replaced by the sticker “Adjusted

for natural gas”. The new sticker

is in the gas jet kit supplied with

the appliance.

Page 5

Unpacking

Please ensure that packaging material is disposed

of in a responsible manner.

Plastic bags should be cut up to prevent children

playing with them and accidentally suffocating.

Remove all packing from the oven cavity and

position the accessories.

If the appliance is damaged in any way, do not

use it. Report the damage to your dealer, who will

take the necessary corrective action.

3. Setup

LPG Gas Only: Do not install this

appliance in a room below ground

level unless it is open to ground level

on at least one side. Failure to install

appliances correctly is dangerous

and could lead to prosecution.

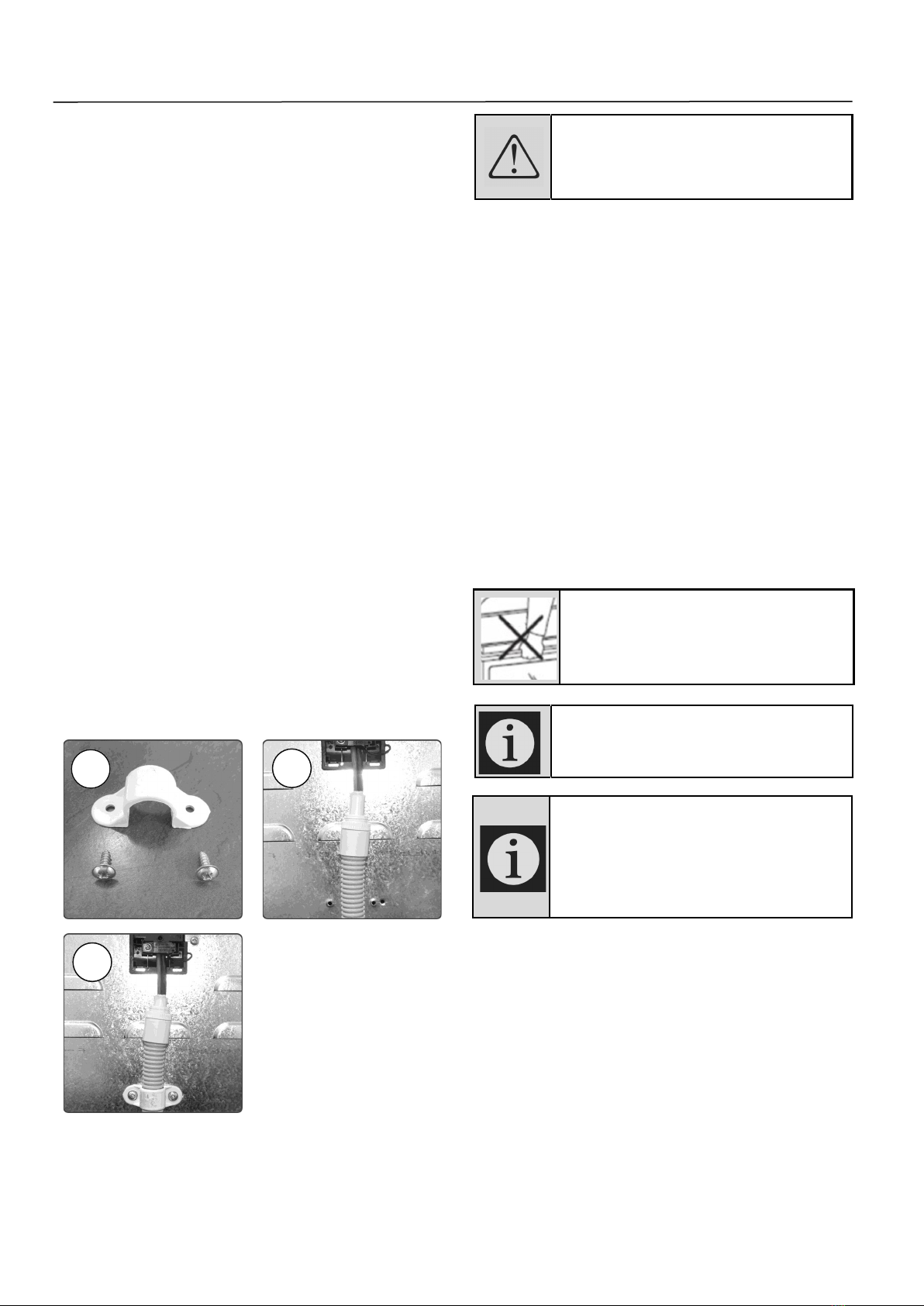

Connecting the sprague to the oven

Purchase a standard plastic/metal saddle type

bracket, capable of going around the 20 mm

diameter sprague and with a hole pitch of 38

mm (Plastic) 45 mm (Metal), and two 4.2mm x

12mm self-tapping screws from your local

hardware store.

Feed the cables through the sprague and

connect to the mains terminal block of the

appliance.

Place the plastic/metal saddle around the

sprague and fasten via the 2 self-tapping

screws onto the factory pre-punched holes

adjacent to the mains terminal block of the

appliance.

WARNING! ELECTRICAL

CONNECTION MUST ONLY BE

DONE BY A QUALIFIED

ELECTRICIAN

Do not carry the product using the

oven door handle, this may damage

your oven door hinges!

You may lift the product with the door

open by holding the inside of the

oven and the back of the hob.

Connection to the power supply

This appliance should not be connected through

an earth leakage system. Refer to S.A.N.S.

10142.

This appliance has a ‘Y’ type supply cord

connection and must be installed by a licensed

electrician, who will ensure that the stove is

correctly connected and safely earthed.

The rated current is printed on the serial number

label attached to the stove upper back panel.

The appliance must be connected to the mains

through an All pole isolating switch which has a

minimum clearance between the contacts of 3

mm in All poles. A means for disconnection must

be provided in the fixed wiring.

12

3

Page 6

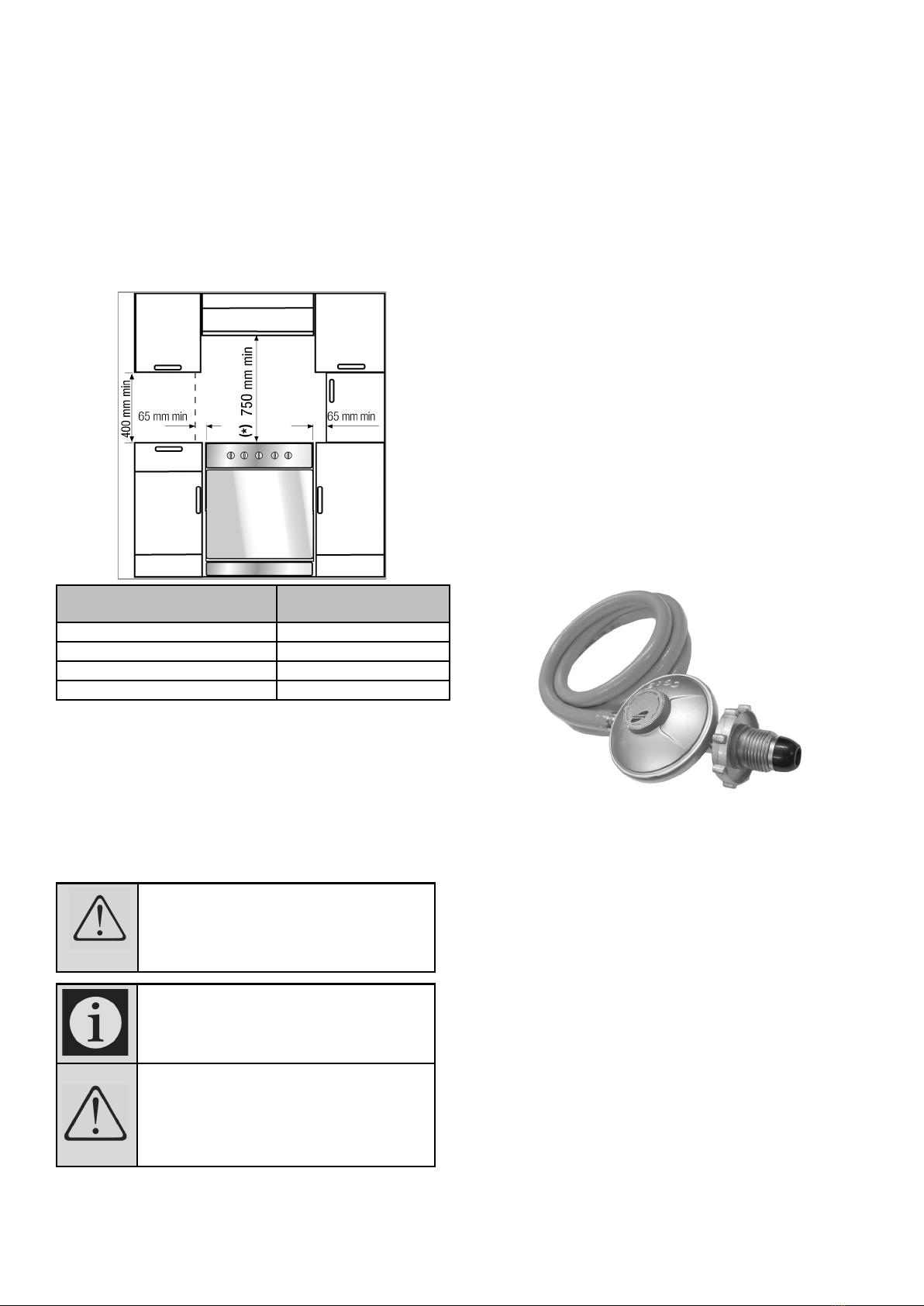

Gas Installation

The manufacturer and the seller do not accept

responsibility for any damage due to incorrect

installation or gas connection.

Gas bottles should be located outdoors in a

suitable ventilated lock-up. The connecting hose

should not exceed 200 cm in length.

Room size Ventilation opening

Smaller than 5 m3min. 100 cm2

5m3 to 10 m3min. 50 cm2

Greater than 10 m3not required

In the cellar or basement min. 65 cm2

Ventilation

Air for combustion is drawn from the room and the

exhaust gases are emitted directly into the room,

therefore good room ventilation is essential for the

safe operation of your appliance. If there is no win-

dow or door available for room ventilation, extra

ventilation must be installed.

The appliance corresponds to device class 1. The

following critical air gaps and ventilation openings

must be maintained:

Important information

Upon completion of the installation ensure that you

are familiar with the following:

a) The position of the isolation or shut-off valve in

the gas supply line to the appliance.

b) The requirements for safe operation of the

appliance

Ensure that pipe clamps are tightened correctly

and are of a good quality.

• Flexible hose

Any hose that is used to connect the stove to

the gas system shall comply with SANS 1156-2

or BS 3212.

• Gas cylinder - Not supplied.

For best results we recommend that gas cylin-

ders with a minimum capacity of 9kg be used.

• Regulator - Not supplied.

A 2.8-3.0 kPa LPG gas regulator which com-

plies with SANS 1237 must be used.

Failure to comply with the above will render the

warranty invalid.

Note: Your invoice is required in the event of

you wishing to make a warranty claim.

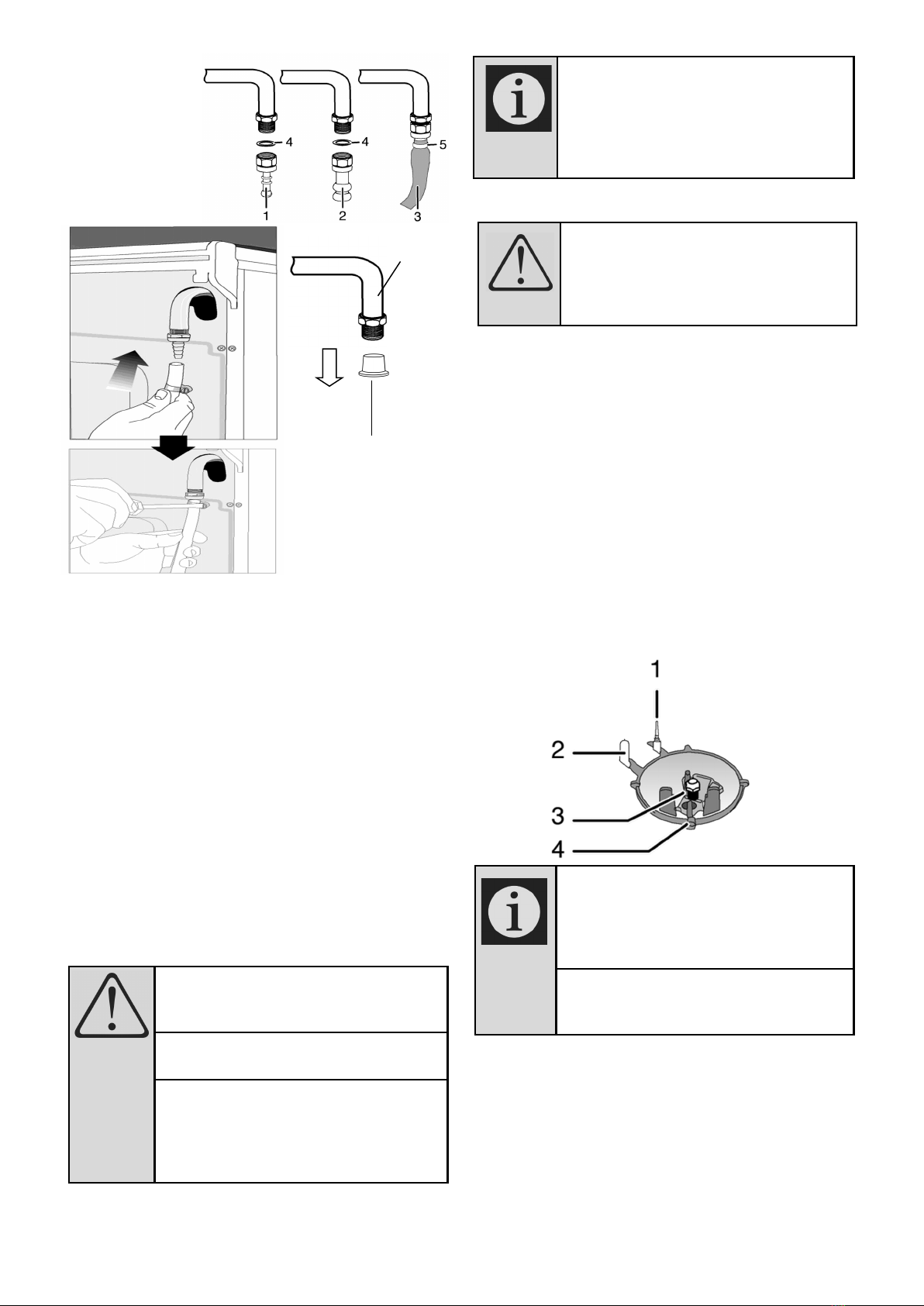

Connecting the gas hose

DANGER Risk of explosion!

Before starting any work on the gas

installation, please shut off the gas

supply.

• Have your appliance connected so that it will be

close to the gas connection. Ensure that there

is no gas leakage.

• Gas bottles should be located outdoors in a

suitable ventilated lock-up.

• The connecting hose to be used must not be

longer than 200 cm in length.

• Fit the clamp to the hose. Soak one end of the

hose (15 mm inner diameter) into hot water for

60 seconds to soften, then slip the softened end

of the hose completely onto the sharp hose tip

of the appliance.

• Secure the hose by tightening the hose clamp.

• Repeat the same procedure for the other end of

the hose by securing it to the regulator on the

gas bottle to complete the gas cylinder

connection.

• Always check for gas leaks after installation and

whenever a new or refilled gas bottle is used for

the first time.

This appliance is supplied ex-

factory with jets and air settings

for use with LPG gas only

A stove without a flame failure

device may only be used with a free

standing cylinder placed adjacent to

but not closer than 300 mm to the

Page 7

Leakage control at the connection point

• Ensure that the control knobs on the control

panel are in the OFF position.

• Open the valve on the Gas bottle.

• Using a small paint brush, apply some soapy

water to all the connections.

• If there is a leak, bubbles will appear.

• If this occurs, close the gas bottle valve .

• Check and tighten the connections

immediately.

• Repeat the procedure to ensure that there are

no further leaks.

1. Hose tip-LPG

2. Hose tip-NG

3. Safety hose

4. O-ring (gasket)

5. Clamp

DANGER Risk of explosion and

suffocation! LPG bottles must not

be stored in the house.

Caution: Never use a naked flame

to check for gas leaks.

DANGER Risk of explosion by

damage of the safety tube!

The safety tube must not be

clamped, bent or come into contact

with hot parts of the appliance.

Gas conversion

In order to have the appliance's gas type

changed, all the injectors must be changed and

the flame adjustment for all valves must be set

at the reduced flow rate position.

Changing the injectors

1. Take off burner cap and burner body.

2. Unscrew injectors by turning them

counterclockwise.

3. Fit new injectors.

4. Check all connections for secure fitting and

tightness.

The flames should be blue and burn

smoothly. If the flames appear

yellowish, check that the burner cap

is seated correctly or clean the

burner. Switch off the gas and let

burner cool before touching it.

Manifold

protection

plug

Manifold protector plug removal:

The manifold protection plug is inserted into the

manifold at factory level in order to protect the

manifold from being contaminated with debris.

The manifold protection plug must be removed

when the product is installed by the gas installer.

Manifold

1Flame failure device (model dependent)

2Spark plug

3Injector

4Burner

DANGER Risk of explosion or

poisoning by unprofessional

installation. Gas conversion must

only be carried out by a registered

installer.

Unless there is an abnormal

condition, do not attempt to remove

the gas burner taps. You must call

an authorised service agent if it is

necessary to change the taps.

New injectors have their position

marked on their packing or refer to

the Injector table.

Page 8

Reduced gas flow rate setting for taps

1. Ignite the burner that is to be adjusted and

turn the knob to the reduced position.

2. Remove the knob from the gas tap.

3. Use an appropriately sized screwdriver to

adjust the flow rate adjustment screw. For

LPG (Butane - Propane) turn the screw

clockwise. For natural gas, you should turn

the screw counter-clockwise once. The

normal length of a straight flame in the

reduced position should be 6-7 mm

4. If the flame is higher than the desired position,

turn the screw clockwise. If it is smaller turn

anticlockwise.

5. For the last control, bring the burner to both

the high-flame and reduced positions and

check whether the flame is on or off.

Depending on the type of gas tap used in your

appliance the adjustment screw position may

Routing of the gas hose

Before connecting the gas hose, make sure that

the gas hose outlet behind the product is in the

same direction as the hose outlet

X

X

X

• “A” 1 x Stability chain

• “B” 1 x Stability hook with anchor sleeve

• “A” is factory fitted at the rear of the stove in

the centre. (See overleaf for instructions if the

removable splashback is to be fitted)

• Position the stove and move “A” to touch the

wall behind the stove.

• Mark the hole where “A” touches the wall

behind the stove.

• Move the stove away from the wall to allow for

an area to work in.

All stoves can tilt if you or a child sit or lean on an open oven door. Safety regulations

stipulate that the ANTI-TILT mechanism supplied with the stove, must be fitted as shown.

• Using a 8.0 mm concrete bit, drill a hole at

the marked position.

• Using the Stability hook and anchor sleeve

“B”, firmly secure “B” to the wall.

• Slide the stove back in position and engage

the stability chain “A” onto the Stability hook

“B”.

• The stove is then secured and will not

accidentally tilt if downward pressure is

applied to the open oven door.

Anti-tilt mechanism

Page 9

4. Operation Instructions

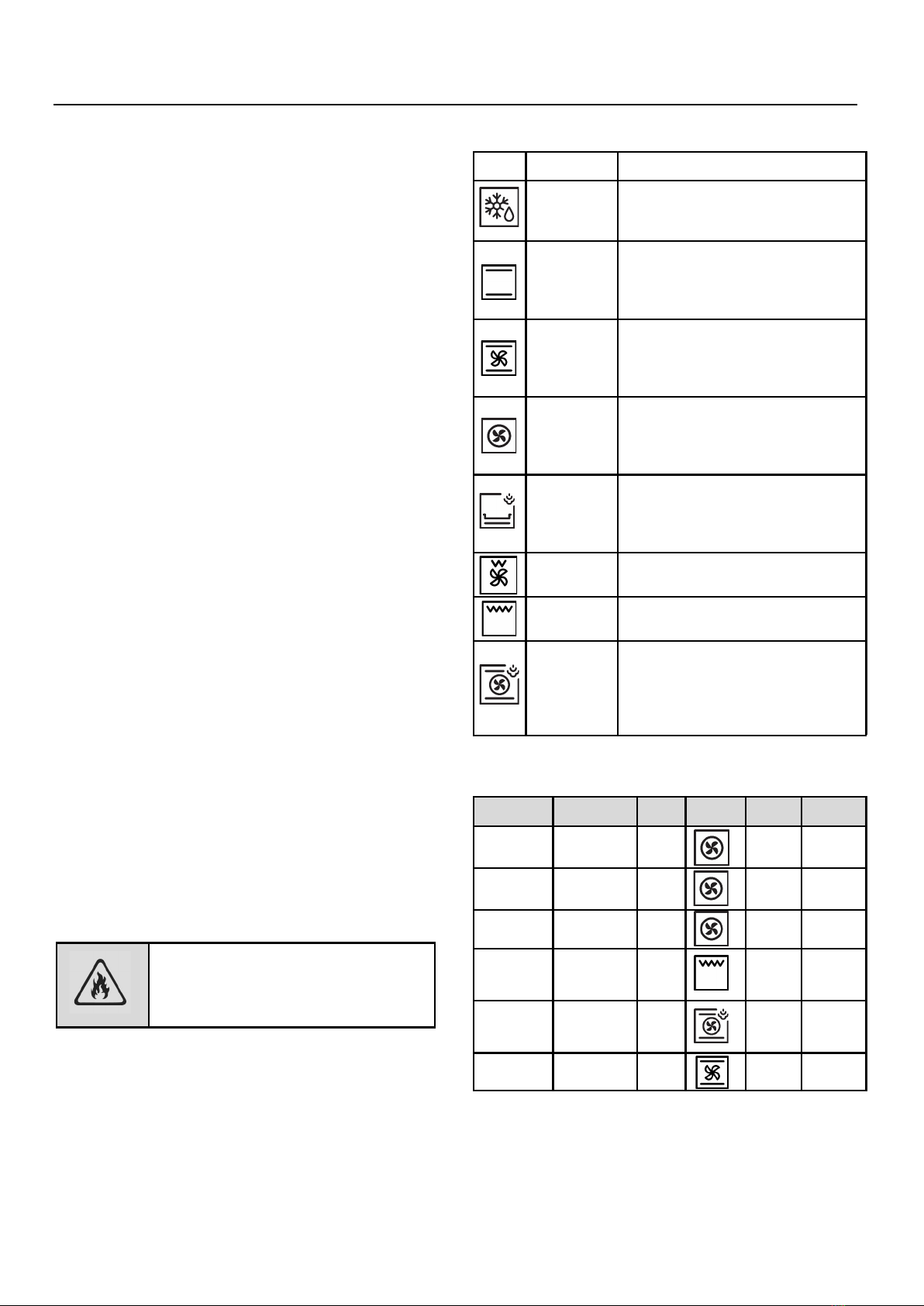

Selector switch

0Off Switches the Oven off

Operating

with fan

(Defrost)

Switches the fan on for thawing

frozen food or cooling cooked food

Convention

al Bake Baking is recommended on one

level only.

This mode is recommended for

cakes, pastries and casseroles

Fan

assisted

cooking

Heat from the top and bottom

elements is rapidly and evenly

distributed by the fan. For cooking

two meals on different shelf levels

Thermofan

heating Heat from the top rear element is

rapidly and evenly distributed by

the fan. For cooking two meals on

different shelf levels

Static Bake

& Steam

Assisted

Clean

Recommended for dishes that

require further cooking at the

center or the base

Turbo grill Suitable for grilling small amounts

of food quickly

Full grill Suitable for grilling large amounts

of food

3D

Function &

steam

assisted

cooking

Top heating, bottom heating and

Thermofan heating are in

operation. Food is cooked evenly

and quickly all around. Cook with

one shelf only

Oven operation

Set the function knob to the desired operating

mode. See page 5 for functions.

Set the temperature knob to the desired

temperature. The thermostat indicator light will

glow and remain on until the oven has reached

the selected temperature.

The indicator light will then switch between off

and on as the thermostat maintains the selected

temperature.

Note:

The oven thermostat is marked to 70°C. When

set to this position, the oven may be used as a

warmer.

Baking / Roasting

Set the selector knob to the desired mode.

Set the oven thermostat to the desired

temperature.

Once the thermostat indicator light turns off,

preheating is complete.

Thereafter place the food in the oven on the

middle shelf where possible.

Grilling

Both the wire shelf and roast pan may be used

for grilling. If you are grilling on the wire shelf,

use the baking tray on the lower rack as a drip

tray.

Position the shelf in the desired position below

the grill element. Set the selector switch and

oven thermostat to their respective grill positions.

Preheat the grill element for about 5 minutes.

Place the food in the center of the shelf and

monitor the grilling to avoid burning the food.

Foods that are not suitable for

grilling create a fire risk. Only grill

food which is suitable for intensive

grilling heat.

Ringer timer

The ringer timer can time a period of up to 60

minutes. First wind the timer by turning the knob

fully clockwise. Return the knob to the desired

time period. Note: If the timer is not first fully

wound the bell may not ring.

Dish Acc. pos. P°C Time

Sponge

cake Cake

Tin** 1&4 170°C 20 Min

Cup-

cakes Muffin

Tin** 1&4 170°C 22 Min

Biscuits Bake

Tray* 1&4 170°C 22 Min

Chicken

breasts

(150 g)

Roast

Pan* 4Max 20 Min

Roast

chicken

(1.3 kg)

Roast

Pan* 1180°C 70 Min

Pizza Wire

Shelf* 2190°C 8 Min

Cooking times table

Timings in this table are meant as a guide.

*These accessories may not be included with your

product

**These accessories are not included with your

product. They are commercially available.

Page 10

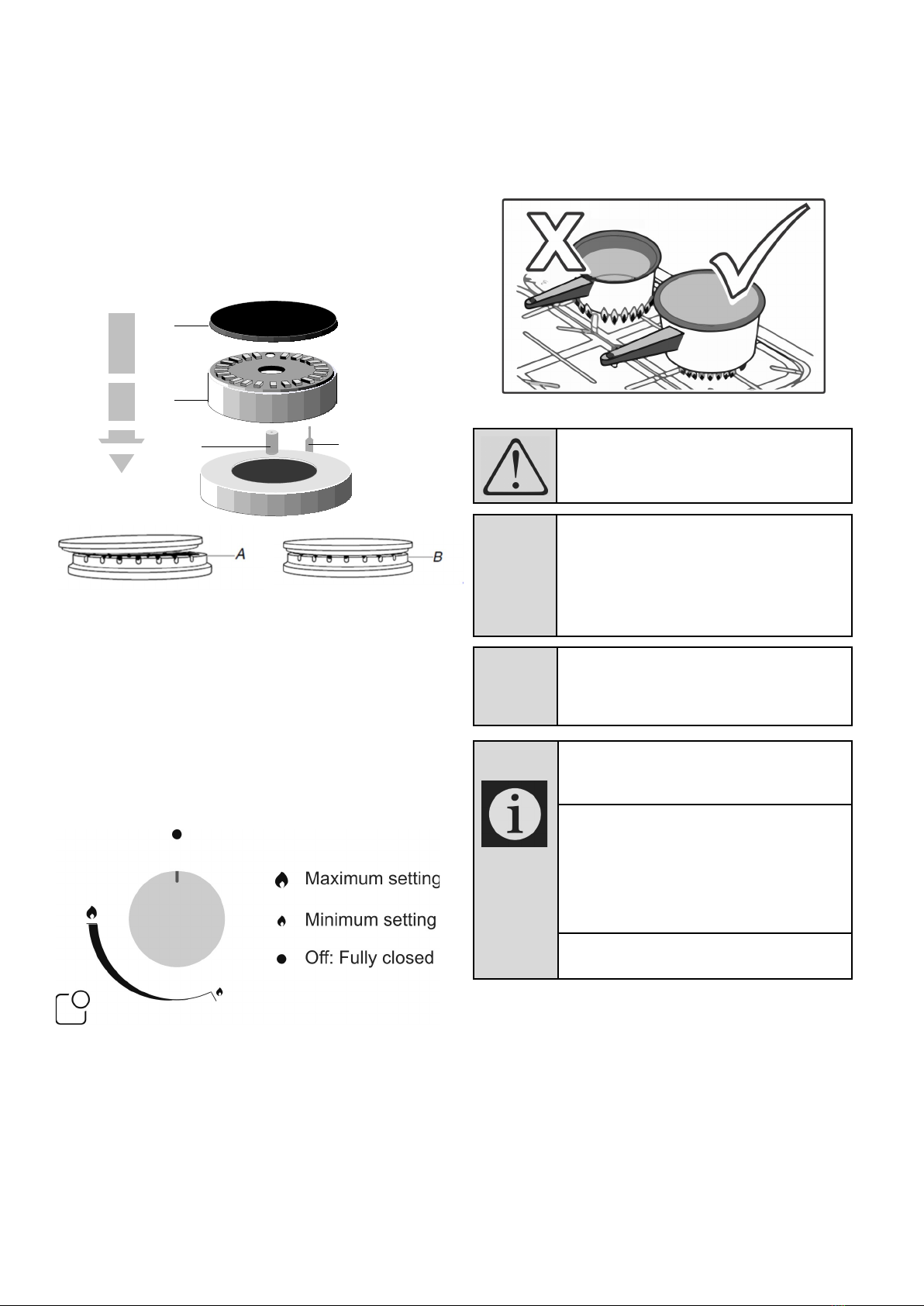

The size of the cooking vessel and the flame must be

suited to each other. Adjust the gas flames so that they

do not extend past the bottom of the cooking vessel

and ensure that the cooking vessel is centered on the

saucepan carrier.

Igniting the gas burners

Burner is equipped with automatic ignition.

• Keep the burner knob pressed in.

• Turn it counter clockwise to the large flame

symbol.

• Ignite the hob by pressing the automatic

ignition.

• Adjust it to the desired cooking power.

Gas hobs

Turning off the gas burners

Turn the knob to off (upper) position.

BURNER BODY

BURNER CAP

FLAME FAILURE SENSOR IGNITION

ELECTRODE

IGNITION ELECTRODE

FLAME

FAILURE

SENSOR

Incorrect Correct

Fitting the burner caps

• Carefully align the hole in the burner body

with the flame failure sensor.

• Gently lower the burner body into position.

• Centralise and level the burner cap onto the

burner body. (The burner cap must be

positioned so that it rests centrally on the

burner body). Ensure that it is correctly

seated. Refit the pot stands.

Wrong centralizing of the burner caps

may result in a flash back and cause

burners to melt and deform.

Wrong control of the gas valves: Gas

valves must be controlled from 90° to

210° (or 160° according to the gas valve

model) If flame is set from 0° to 90° the

burner will be below the minimum output

and may result in a flash back and cause

burners to melt and deform.

The above user faults are not covered by

the warranty.

WARNING: Unattended cooking on

a hob with fat or oil can be

dangerous and may result in a fire.

Danger of fire: Do not store items on

the cooking surface.

CAUTION: The cooking process

has to be supervised. A short term

cooking process has to be

supervised continuously.

Use only pots with a solid level

base. An uneven base can prolong

cooking times and waste energy.

Page 11

5. Maintenance and Care

Service intervals

• Every twelve months the appliance should be

serviced by a Defy Service agent to ensure

continued efficient and safe operation.

• If required, the cleaning of the valves should

only be carried out by a qualified Defy

technician. i.e. Burner not functioning correctly.

• Wash removable burner parts weekly with hot

water and detergent.

• Remove any encrustations and ensure that the

burner holes are clear.

• The condition of the gas hose and valve must

be inspected for leaks when the gas bottle is re-

filled.

Steam assisted cleaning

• Pour 100 ml of water into the emboss on the

oven floor.

• Select the steam assisted cleaning function.

• Turn the oven on to run this cycle for 5 minutes.

• At the end of the cycle, wait 5 minutes before

opening the door.

• Open the door and wipe the inner surfaces of

the oven with a damp sponge or cloth.

• Use warm water with washing liquid, a soft cloth

or sponge to clean persistent dirt and wipe it

with a dry cloth.

General cleaning

• Wipe down glass panels, cabinet, door, control

knobs, trims and handles with a hot soapy

cloth. Do not use a steam cleaner.

• Use only liquid household cleaners and avoid

abrasive powders or scouring pads.

Caring for gas hobs

• Remove the burner caps and wipe them with

a thin damp cloth or non-abrasive sponge.

• Remove and clean the saucepan carriers and

the hob.

• Dry burners afterward and blow away any

residual water in the gas outlet holes.

• Install the burner caps and make sure that

they are seated correctly.

Replacing the oven light

The oven light is switched on by the oven

thermostat and switches off when the thermostat

knob is returned to 0.

To replace a faulty light bulb:

• Switch off the power at the wall isolator to

avoid the possibility of electric shock.

• Unscrew the light cover.

• Unscrew the faulty bulb and fit a new 25-watt

bulb rated for 300’C

• Refit the light cover.

DANGER Risk of electric shock!

Switch off the electricity before

cleaning the appliance.

Important! Any food residue must be

removed from the bottom of the

cavity before you start steam assisted

cleaning. Remove all oven

accessories.

The surface of the appliance may be

damaged by some detergents or

cleaning materials. Do not use

aggressive detergents, cleaning

powder, cream or any sharp objects.

Page 12

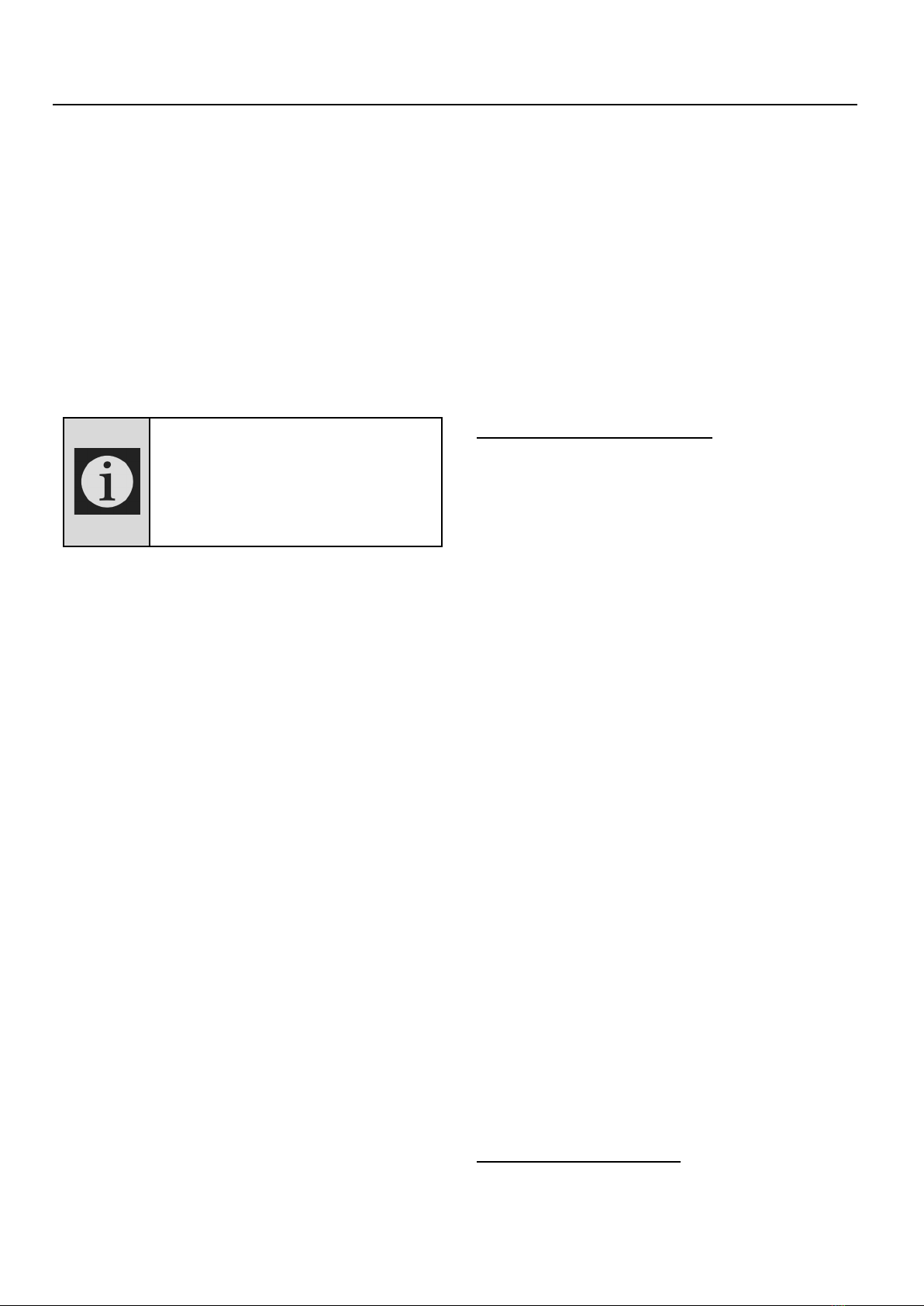

Gas Jet Cleaning Procedure

• The gas jets on your hob should be cleaned

every 6 months.

• This may be done using a Gas Jet Cleaning

Kit which may be purchased from your

nearest Defy Service Centre.

• The kit comprises of a sliding T-bar (A) a

socket (B) and a ‘Classic pin’ (C).

• Fit the T-bar to the socket and remove the

pot stands, burner caps and burner

bodies.

1. Insert the socket into the central tube of the

burner so that it locates over the brass gas jet

at the bottom of the tube.

2. Gently loosen the brass gas jet by turning the

socket in an anti-clockwise direction.

3. Carefully lift the socket and loosened brass

gas jet from the central burner tube.

4. Insert the Classic pin into central hole of the

jet and slide it up and down until the jet is free

of accumulated dirt.

5. Re-assemble in reverse order.

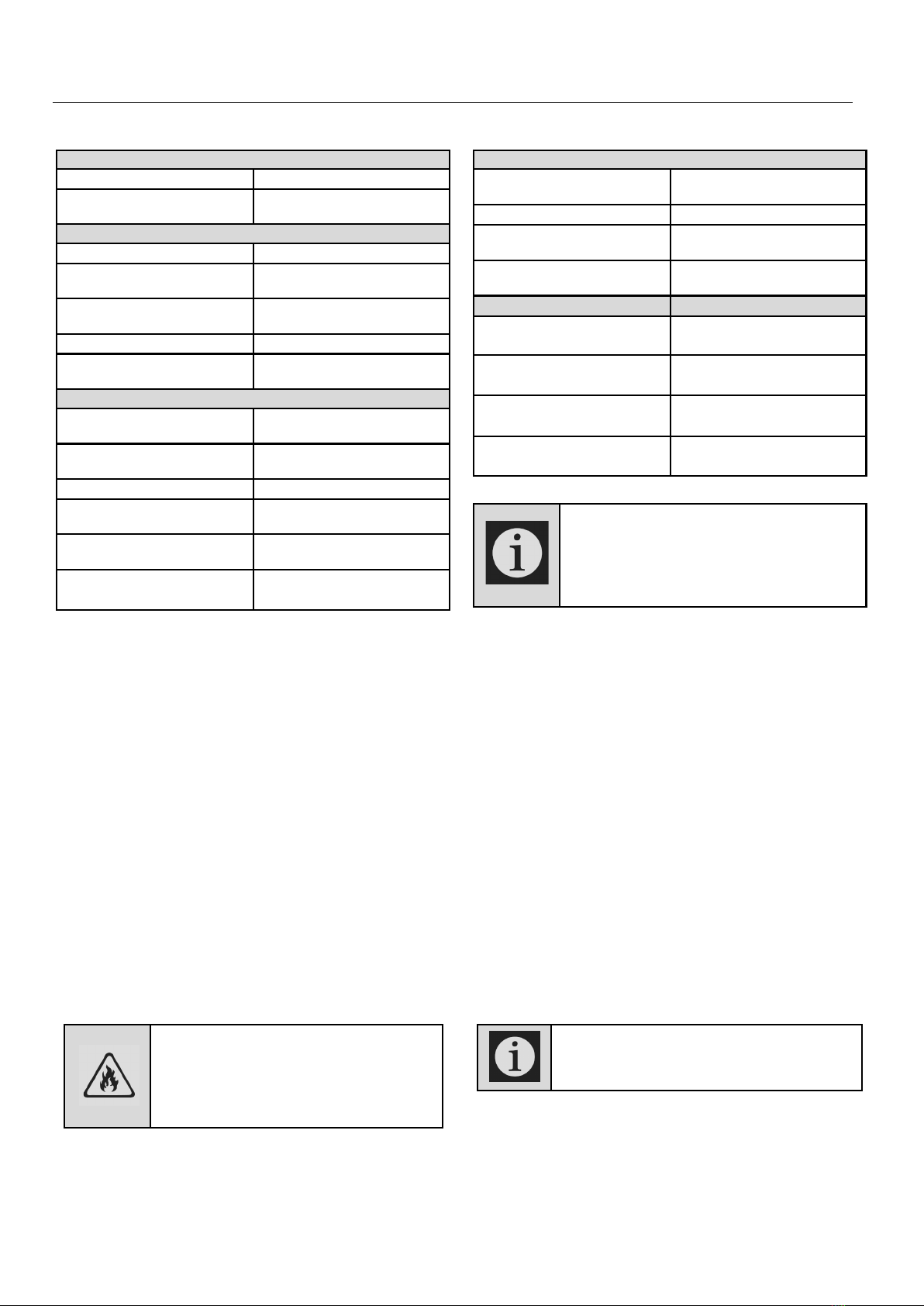

Removing the Oven Door Glass

A. Press clips on both ends of the top décor.

B. Lift the top décor & remove from door.

C. Lift the glass to a 45 degree position and pull

towards yourself.

The front door inner glass is coated

with an easy clean material. Do not

use any harsh abrasive cleaners,

hard metal scrapers, scouring pads or

bleach to clean the front door inner

glass as they may scratch the surface

and destroy the coating material.

These steps should be carried out in

reverse order to install the door. Do

not forget to close the clips at the

hinge housing when reinstalling.

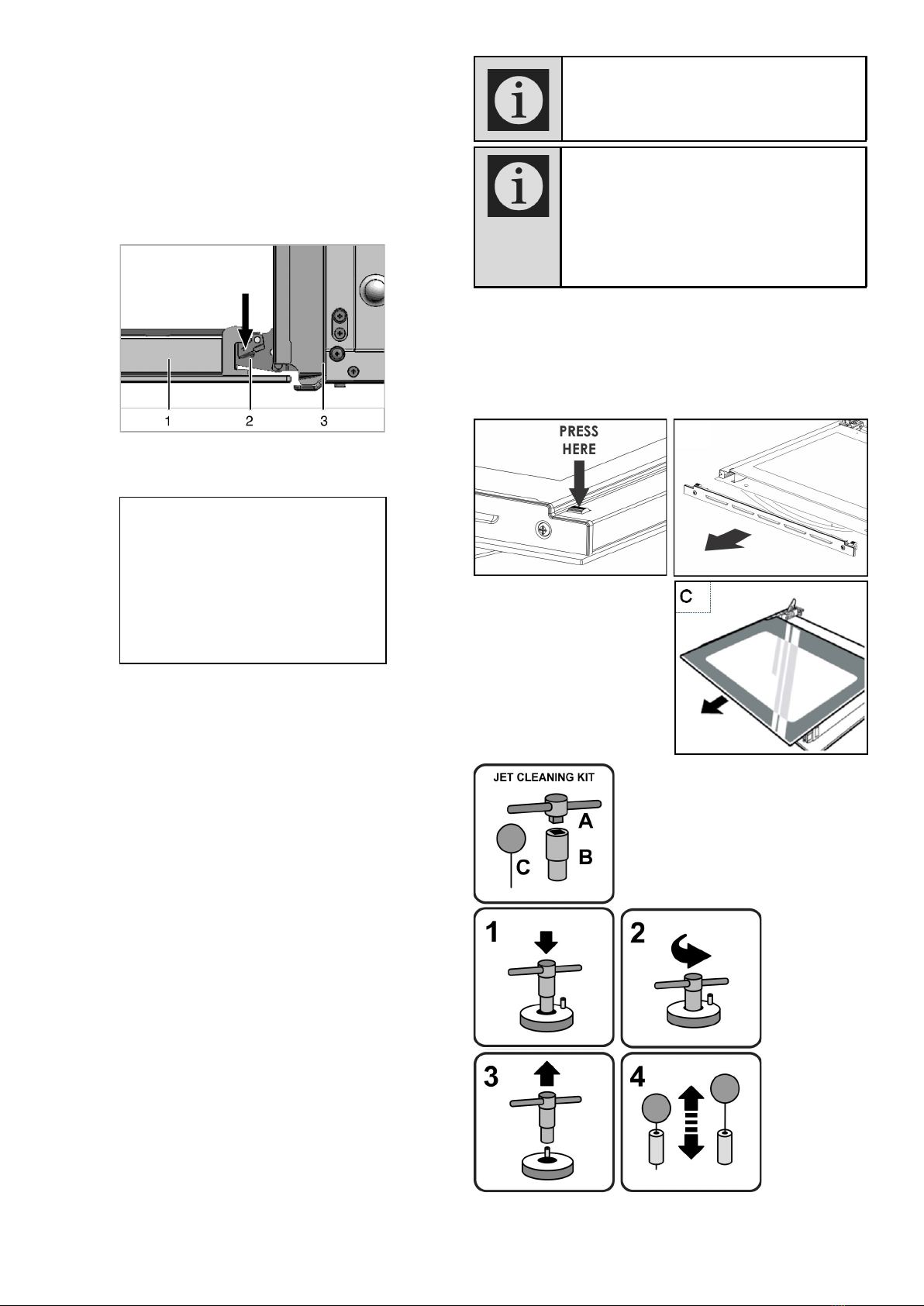

Removing the oven door

The oven door may be removed to improve oven

access during cleaning.

Open the front door (1).

Push down the clips at the hinge housing (2)

on the left and right hand sides of the front

door by pressing them down as illustrated in

the figure.

AB

3. Open the door to halfway.

4. Remove the door by pulling it upwards to

release it from the hinges.

Page 13

6. Important Notes

Problem solving guide—before calling for technical support

There is no gas:

Main gas valve is closed. Open the gas valve.

Gas pipe is bent. Ensure the gas pipe has

been properly fitted.

Burners are not burning properly or at all:

Burners are dirty. Clean burner components.

Burners are wet. Dry the burner

components.

Burner cap is not mounted

safely. Mount the burner cap

properly.

Gas valve is closed. Open gas valve.

Gas cylinder is empty

(when using LPG). Replace the gas cylinder.

The burners will not light:

The gas pipe is twisted,

bent or kinked. Ensure the gas pipe has

been properly fitted.

The burners are dirty or

wet. Clean / dry the burner

components.

The gas cylinder is empty. Replace the gas cylinder.

The burner caps are not

fitted correctly. Fit the burner caps

correctly.

The gas pressure

regulator is closed. Check to see if the

regulator is open.

Lighting procedure not

been correctly followed. Follow the correct lighting

procedure.

The flame is yellow, pots and pans are stained:

The burners are dirty or

wet. Clean / dry the burner

components.

The gas is running out. Replace the gas cylinder.

The burner caps are not

fitted properly. Fit the burner caps

properly.

The gas pipe is twisted,

bent or kinked. Ensure the gas pipe has

been properly fitted.

Smell of leaking gas: Smell of leaking gas:

Are all the control knobs in

the off position? Check to see the knobs

are in the off position.

The gas pipe is fitted

incorrectly. Ensure the gas pipe has

been properly fitted.

The hose clamps require

tightening or replacing. Have hose clamps

tightened or replaced.

The regulator is faulty and

needs to be replaced. Have regulator checked

and replaced.

Do

• Clean your appliance regularly.

• Use flat-bottomed pots and pans when

cooking on the hotplates. This will maximize

efficiency and reduce electricity costs.

• Leave about a 40 mm. air gap between

baking tins and the oven walls. Adequate air

circulation is important for good baking

results.

• Get into the habit of wearing oven gloves

when handling utensils in a hot oven. This will

help to avoid accidental burns.

• Partly slide out the oven shelf before

removing hot dishes. This prevents accidental

contact with the hot oven sides.

Don’t

• Use pots which are smaller than the hotplate

diameter. This wastes electricity and allows

the pot handles to overheat.

• Place anything on the open oven door. The

glass is not a work surface and could get

scratched.

• Use the appliance to heat the home. Neither

the hotplates nor the oven was designed for

this purpose and damage could occur.

• Allow pot handles to overhang the front of the

appliance. Children might be tempted to grab

them with harmful consequences.

OVER THE YEARS, DEFY'S SERVICE CENTRES HAVE IDENTIFIED THIS LIST OF DO'S AND

DON'TS AS BEING IMPORTANT FOR CUSTOMER SATISFACTION AND SAFETY. PLEASE READ IT

AND FAMILIARISE YOURSELF WITH ITS CONTENTS.

The oven may emit steam during use.

This is normal and is not a fault.

When metal parts are heated, they

may expand and cause noise. This is

not a fault.

Never try to extinguish a fire with

water! When oil has caught fire,

immediately cover the pot or pan

with a lid. Switch off the hob if safe

to do so and phone the fire service.

Do NOT engage ringer timer control

knob in anti-clockwise direction from

the "0" position.

Page 14

Customer care line

If you still have a problem after following all the

instructions, contact the customer care line on

086 100 3339. They will be able to advise you on

any aspect of the appliance.

7. Support

Sub-Saharan Africa Branches

ZAMBIA: SOUTHGATE INVESTMENTS LTD

Plot 1606, Sheki Sheki Road

P.O. Box 33681

Lusaka, 10101, Zambia

Tel: +260 0211 242332/3

Fax: +260 0211 242933

sgiservicecentre@microlink.zm

NAMIBIA: ATLANTIC DISTRIBUTORS

C/O Edison and Einstein Street

Southern Industrial

Windhoek

Namibia

Tel: +264 61 216 162

Fax: +264 61 216 134

Email: atlantic@mweb.com.na

ZIMBABWE: TRADECOMAFRICA

Trade Com Africa, 183 Loreley Crescent

Msasa, Harare, Zimbabwe

Tel: +263 4 486165/6

Cell: +263 772 469010

Cell: +263 772 469011

BOTSWANA: RAY MORGAN AGENCIES

Plot 48, East Gate

Gabarone International Commerce Park

Kgale View

Gaborone

Botswana

Tel: +267 390 6476

Fax: +267 395 9705

Email: service@rma.co.bw

SWAZILAND: LYNDS DISTRIBUTORS

Lot 581 King Sobhuza the 2nd Avenue

Unit 4 & 5 SIDC factory Shells

Matsapha

Eswatini

Tel: +268 2518 4310

Fax: +268 251 4318

MOZAMBIQUE: COOL WORLD. LDA

Rua da Resistencia No. 97B R/C

Cell: +258 84 44 61 234

coolw[email protected]

Nosso Show Room

Do not attempt any repairs yourself. Before calling a service technician, please check:

• The mains distribution board for tripped circuit breakers.

• The wall switch is on.

• Gas fittings are connected properly.

Remember that you may be charged for a service call even during the warranty period if the fault is due to

or caused by any of the above.

If the problem cannot be remedied after

following the troubleshooting problem

solving guide, please consult with an

authorised service agent or the dealer

where you purchased the appliance.

Never attempt to repair a defective

appliance yourself.

Page 15

8. Warranty

This certificate is issued by DEFY APPLIANCES (PTY) LTD manufacturers of Defy and Ocean

products, hereinafter the Company, to the original purchaser only, of the appliance described on the

certificate and shall constitute the only warranty given in respect of this appliance.

The Company warrants to the original purchaser that for a period of THREE YEARS from date of

purchase the appliance is free from defect under normal domestic use, both in workmanship and

material, subject to the following conditions.

1. Repair or replacement of any part of this appliance, found by the Company to be defective, shall

be at the election of the Company. The Company reserves the right to effect such service through

any of its Service Divisions or Authorised Service Dealers. The cost of such service shall be borne

by the Company in full, provided that the appliance is located no further than 50 km from a

Company Service Centre or an Authorised Service Dealer. Where the appliance is located beyond

the 50 km radius, the purchaser shall be liable for the standard travelling charges, as determined by

the Company.

CARRY IN SERVICE Microwave ovens, Compact cookers and small appliances are repaired in our

service centres and are not collected from the customers home. Faulty units must be delivered to

the purchasing dealer or to the nearest Company Service Centre for warranty repairs.

2. Rusted or corroded plates, vitreous enamelware, fuses and lamps are specifically excluded from

these warranties. It is an express condition of these warranties that the purchaser takes due care

and attention in the use and maintenance of the appliance. Abuse, misuse in conflict with operating

instructions, connection to incorrect voltages and subjection to commercial use shall release the

Company from its obligations.

3. This warranty shall become void and cease to operate if the appliance is dismantled by, or any

repairs to the appliance are effected by any persons not duly authorised by the Company, or if

substitute parts not approved by the Company are used in the appliance, or if the serial number of

the appliance is removed.

4. The Company shall not be responsible for damages resulting from fire, flood, civil disturbances or

any Act of God. The Company shall not, in terms of these warranties be responsible nor held liable

for any consequential loss or damage of any kind caused by or due to the failure or malfunction of

the appliance. The Company shall not be responsible for damages caused by insect and/or animal

infestation.

5. The Company shall not be responsible for transportation or other costs other than those incurred

within the provisions of Point 1 of this Certificate.

6. For warranties in the Republic of South Africa and Sub-Saharan Africa, please contact the

customer care line. Please refer to the previous page for respective South African branches

and Sub-Saharan Africa branches.

7. Where service is requested under warranty and no fault or defect can be found by the Company,

all costs incurred will be for the purchaser's account.

8. This Certificate as well as your invoice will serve as proof of purchase. For the purpose of

warranty, it will be essential to produce this Certificate and invoice. Failure to do so, will render the

purchaser liable for service costs.

KEEP THIS CERTIFICATE AND SALES INVOICE AS PROOF OF PURCHASE FOR WARRANTY

PURPOSES.

Table of contents

Other Defy Oven manuals

Defy

Defy DBO 435 Black User manual

Defy

Defy 600STE User manual

Defy

Defy DBO478 User manual

Defy

Defy Slimline Series User manual

Defy

Defy GEMINI PETIT CHEF MULTIFUNCTION THERMOFAN User manual

Defy

Defy 600STE User manual

Defy

Defy 600STS User manual

Defy

Defy Slimline 600MTE DBO464 User manual

Defy

Defy 600 EMBW User manual

Defy

Defy 600 MGSE User manual