Deger MLD Control Energy Converter S1 User manual

A

M

E

n

A

SSE

M

LD

n

ergy

S1

0

MBL

Y

C

o

Con

v

0

0-PF

Y

IN

S

o

ntr

o

v

erter

-SR

S

TRU

C

o

l

S1

C

TION

18.04.2018 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 2

Copyright

All information presented in this technical document and the drawings and technical descriptions made

available by DEGER remain the property of DEGER and may not be reproduced without prior explicit written

permission from DEGER.

We reserve the right to make technical changes.

Version: 2018-03-01

18.04.2018 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 3

List of contents

Abbreviations ................................................................................................................................................. 5

1.1Introduction ........................................................................................................................................ 6

1.2Basic safety information ..................................................................................................................... 6

1.3Exclusion of liability ............................................................................................................................ 6

1.4For your safety ................................................................................................................................... 6

1.4.1Intended purpose of the DEGERtracker ........................................................................................ 6

1.4.2Personal protective equipment ...................................................................................................... 6

1.5Symbols used .................................................................................................................................... 7

1.6Presentation of information ................................................................................................................ 7

1.6.1Lists and instructions ..................................................................................................................... 7

1.6.2Safety information .......................................................................................................................... 7

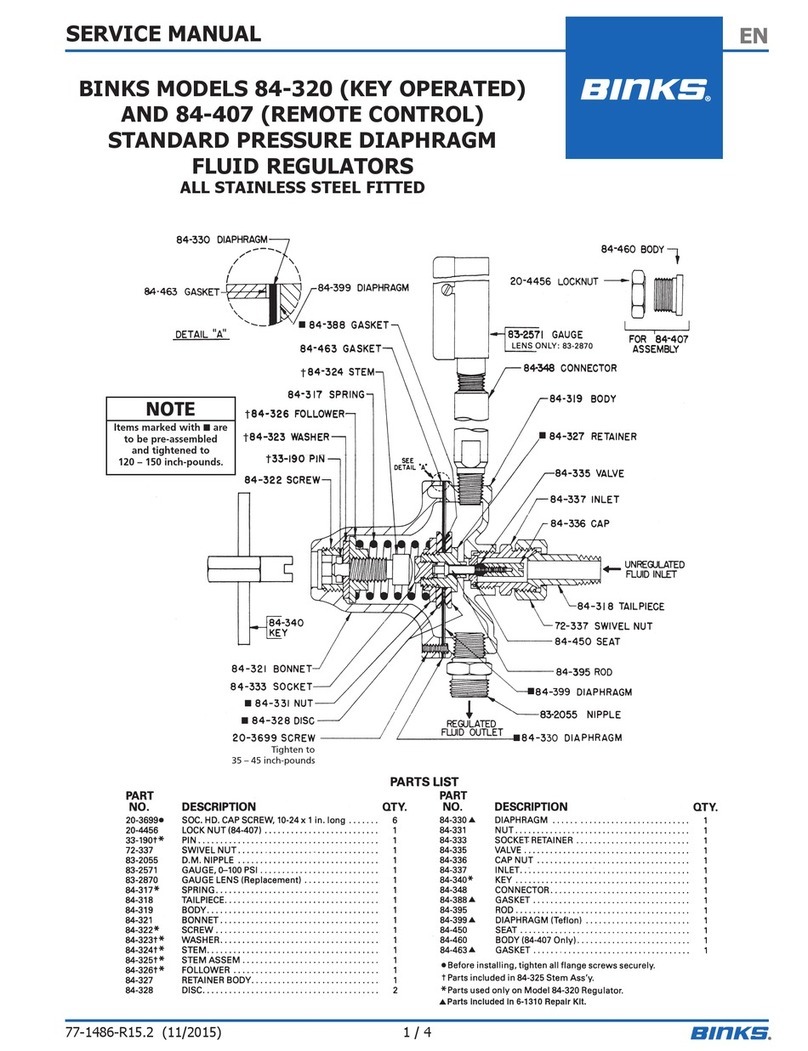

2Energy Converter S1 (EK-S1) .................................................................................................................... 8

2.1EK-S1: Function ................................................................................................................................. 8

2.2EK-S1: Cable connections ................................................................................................................. 8

2.3EK-S1: Pin assignments .................................................................................................................... 9

2.4EK-S1 LED – display ...................................................................................................................... 10

2.4.1LED’s indicating main functions: .................................................................................................. 10

2.4.2LED assignments ......................................................................................................................... 11

3Manual Control ......................................................................................................................................... 12

3.1Joystick Functions ........................................................................................................................... 12

3.1.1Pin assignment ............................................................................................................................ 12

4Wind Guard .............................................................................................................................................. 13

4.1Wind guard....................................................................................................................................... 13

4.2Assembly ......................................................................................................................................... 13

4.3Connection ....................................................................................................................................... 13

5Snow Sensor ............................................................................................................................................ 14

5.1Function ........................................................................................................................................... 14

5.2Positioning ....................................................................................................................................... 14

5.3Assembly ......................................................................................................................................... 15

5.4Connection ....................................................................................................................................... 15

6Connections .............................................................................................................................................. 16

6.1Block diagram .................................................................................................................................. 16

6.2CAN-Bus .......................................................................................................................................... 17

6.2.1CAN-Bus connections EK-S1 ...................................................................................................... 17

6.2.2Connecting CAN-Bus to the management PC ............................................................................ 17

6.3Uninterruptible power supply for a DEGERtracker .......................................................................... 18

7Start-up ..................................................................................................................................................... 19

8Clearance Check ...................................................................................................................................... 19

8.1Start of check ................................................................................................................................... 19

8.2Scope ............................................................................................................................................... 19

9Technical Data .......................................................................................................................................... 20

9.1Electrical ratings .............................................................................................................................. 20

9.2Electrical norms ............................................................................................................................... 20

18.04.2018 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 4

9.3Climatic conditions ........................................................................................................................... 20

9.4General ............................................................................................................................................ 20

10Troubleshooting ................................................................................................................................... 21

10.1Troubleshooting diagram for Energy Converter EK-S1 ................................................................... 21

10.2Fault report....................................................................................................................................... 22

11Maintenance ........................................................................................................................................ 23

12Cleaning ............................................................................................................................................... 23

13Decommissioning ................................................................................................................................ 23

13.1Disassembly .................................................................................................................................... 23

13.2Disposal ........................................................................................................................................... 23

14Conformity Declaration ........................................................................................................................ 24

15Publisher Information ........................................................................................................................... 25

18.04.2018 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 5

Abbreviations

EL = Elevation(east-west orientation)

CTC = Central Tracker Control (software)

EK-S1 = Energy Converter S1

MLD = Maximum Light Detection

MLD Control = Energy Converter, MLD sensor, wind sensor, snow sensor

PPE = Personal Protective Equipment

UPS = Uninterruptible power supply

18.04.2018 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 6

These assembly instructions were created for the DEGERtracker. They are a component of the product and

must be saved for the entire lifespan of the DEGERtracker. The assembly instructions must be included with

the DEGERtracker should it be transferred to another party.

Read these assembly instructions in their entirety before starting assembly work and keep them available

at all times during the assembly process.

Only qualified personnel may perform assembly work.

Keep all objects out of the theDEGERtracker’sfull range of pivoting motion throughout its full range of

motion.

Take necessary actions to protect the installed DEGERtracker in its full range of motion from unauthorized

access, such as enclosing it within a fence. Near the entry area to the DEGERtracker there must be a

warning sign stating that it is prohibited to remain within the range of pivoting motion.

Lightning protection and grounding must be installed in all photovoltaic systems according to country-

specific guidelines as stipulated in DIN VDE 0185 and 0100.

Do not operate the DEGERtracker if the wind guard is not functioning. Always keep the module surface in

the SAFE position (table position) until the wind guard has been tested for function.

If snow has accumulated on the module surface, the module surface must first be cleared. This is

accomplished by manually controlling via the CTC software, the joy stick or through the snow sensor. If no

functioning CTC remote access, joy stick and/or snow sensor is available, the module surface must be

cleared manually. The snow sensor shall not release the module surface from the obligation to be cleared

of snow.

DEGER recommends an Uninterruptible Power Supply (UPS) to ensure the function of the wind monitor.

As a rule, DEGER’s General Terms and Conditions shall apply. The contents of these documents are

checked continuously and modified as needed. The assembly instructions are available for download in the

dealer section on the website, www.DEGER.biz, and they can also be obtained through the traditional

distribution channels.

Warranty and liability claims will be void if any type of damage occurs that results from one or more of the

following causes:

- Improper or unauthorized use of DEGERtracker

- Operation of DEGERtracker in an improper environment

- Operation of DEGERtracker without taking into account the statutory safety regulations applicable at the

place of installation

- Non-observance of warnings and safety information in all documents relevant to the product

- Operation of DEGERtracker in the absence of proper safety and protective measures

- UnauthorizedmodificationstoDEGERtracker

- Drilling holes in any housing, e.g. EK-S1. Use existing free holes for mounting the housings.

- Failure of the DEGERtracker due to the influence of connected or neighbouring devices outside of the the

permitted limits

- Catastrophesandforcemajeure

1.4.1 Intended purpose of theDEGERtracker

The MLD control with EK-S1 is intended only for the purpose of controlling DEGERtrackers.

DEGERtrackers can be used in the private and commercial sector. They are designed for outdoor installation

and for building integration.

1.4.2 Personal protectiveequipment

The client must provide enough safety equipment for assembly and maintenance work. Supervisors must

ensure safety equipment is worn.

The following safety equipment is mandatory:

- Protectivehelmet

- Safetyshoes

- Safetygloves

Fall protection equipment and PPE to prevent falling when working more than 1 m above the ground

18.04.2018

The followi

n

1.6.1 Li

s

Lists

Lists haveb

- List

- List

Instructio

n

Instructions

1. Step 1

2. Step 2

Instructio

n

Instructions

Instructio

n

Instructio

n

Results

Results of

a

>>Result

1.6.2 Sa

f

The followi

n

_________

_

D

A

I

m

_________

_

W

P

o

_________

_

C

A

D

a

_________

_

N

O

F

a

_________

_

n

g symbols

a

No una

u

Read a

n

s

ts andins

t

ulletpoints:

n

s in a certa

s

that must b

e

n

s without a

s

that do not

n

n

a

n action ar

e

f

etyinfor

m

n

g safety inf

o

_

________

_

A

NGER!

m

minent dan

g

_

________

_

W

ARNING!

o

ssible dan

g

_

________

_

A

UTION!

a

nger with l

o

_

________

_

O

TE!

a

ilure to obs

e

_

________

_

a

ppear on th

e

u

thorized ac

c

n

d follow th

e

t

ructions

inorde

r

e

followed i

n

certain ord

have to be f

o

e

indicated b

y

m

ation

o

rmation is u

_

_________

_

g

er with a hi

g

_

_________

_

g

er with a m

o

_

_________

_

o

w risk; failu

r

_

_________

_

e

rve this inf

o

_

_________

_

ASSEMBLY IN

e

DEGERtr

a

c

ess

e

operating

m

a certain or

d

e

r

o

llowed in a

c

y

a double a

r

sed in this d

_

_________

_

g

h risk; failu

r

_

_________

_

o

derate risk;

f

_

_________

_

r

e to observ

e

_

_________

_

o

rmation ent

a

_

_________

_

N

STRUCTIONS

a

cker and ar

e

m

anuals and

r

der are num

certain orde

r

r

row:

ocument:

_

________

_

r

e to observ

e

_

________

_

failure to ob

s

_

________

_

e

can lead t

o

_

________

_

a

ils the risk

o

_

________

_

MLD CONTR

O

e

used in th

e

safety infor

m

bered:

r

are listed

w

_

_________

_

e

will lead to

_

_________

_

s

erve can le

a

_

_________

_

moderate p

_

_________

_

o

f property d

a

_

_________

_

O

L EK-S1

present do

c

m

ation befor

e

w

ith bullet po

i

_

_________

_

severe phy

s

_

_________

_

a

d to severe

_

_________

_

hysical injur

y

_

_________

_

a

mage.

_

_________

_

c

ument:

e

start-up

ints:

_

________

_

s

ical injury o

r

_

________

_

physical inj

u

_

________

_

y

.

_

________

_

_

________

_

Page

7

_

_________

r

death.

_

_________

u

ry or death.

_

_________

_

_________

_

________

7

Mot

o

Mas

t

Mot

o

Slav

e

In

c

M

a

18.04.2018

2 Ene

Applies in

Reverse di

This functio

The motor

w

than 4 hour

2.2 EK-

S

The EK-S1

for the CA

N

The PG gla

installation

a

PG glands

f

No

t

A

ll

P

ho

u

o

r 1

t

er

o

r 2

e

c

linationsen

s

a

ster

Theft

p

(opti

o

rgy Co

n

general:

rection fun

c

o

n ensures t

h

w

ill switch o

n

s. The exter

n

S

1: Cable

c

is delivered

N

-Bus (M20)

nds for the

w

a

nd are incl

u

f

or the UPS

a

t

e!

P

G glands

m

u

sing to avoi

d

In

c

Sl

a

s

or

p

rotection

o

n)

n

verte

r

S

1. External

i

2. External

i

c

tion:

h

e module s

u

n

for 12 min

u

n

al inputs, j

o

c

onnectio

n

with prewire

and AC po

w

w

ind guard (

M

u

ded as an

a

a

nd theft pr

o

m

ust fit with t

h

d

moisture i

n

c

linationsen

s

a

ve

UPS

(optio

n

ASSEMBLY IN

S

1 (EK-

S

nput has pri

o

nput from w

i

u

rface is faci

n

u

tes once th

e

o

ystick, MLD

n

s

d MLD-sens

w

er (M16) wil

l

M

20) and th

e

a

ccessory.

o

tection (bot

h

h

e installed

c

n

side. Under

g

s

or M

L

W

(a

n

)

N

STRUCTIONS

S

1)

o

rity over M

L

ind sensor h

ng east the

n

e

EK-S1 has

sensor and

s

or, Inclinati

o

l

be pre-inst

a

e

snow sens

o

h

M16) can

b

c

ables from

c

g

round slav

e

L

D sensor

W

ind guard

nemometer)

MLD CONTR

O

L

D sensor.

as priority o

v

n

ext mornin

g

not register

e

wind monito

o

n sensor ca

b

a

lled.

o

r (M16) are

b

e provided

o

c

ustomer si

d

e

cables mu

s

CAN

B

In

Snow s

e

O

L EK-S1

v

er external

m

g

to receive t

h

e

d a signal a

r have priori

t

b

ling and m

o

only neede

d

o

n request.

d

e and must

s

t be laid in

a

B

us

e

nsor R

e

(

o

C

A

O

manual con

t

he first rays

a

t terminal X

F

t

y.

o

tor cabling.

d

one time i

n

hermeticall

y

a

cable cond

eserve

o

ption)

A

N Bus

ut

Page

8

t

rol.

of sunlight.

F

1 for more

PG glands

n

every

y

seal the

uit.

A

C Power

In

A

C Power

Out

8

18.04.2018

Terminal

XA

XB

XC

XD

XE

XF

XG

Function

Drives 24

V

Pin A => M

Pin B =>

M

Pin A => M

Pin B =>

M

Theft Prot

e

Pin A => (

+

Pin B => (

G

Pin C => (

I

Pin D => (

O

Inclination

Pin A =>M

Pin B => M

Pin C =>M

Pin D => M

Inclination

Pin A =>Sl

a

Pin B => Sl

Pin C =>

S

Pin D => S

l

Uninterru

p

(optional)

Pin A =>

S

Pin B =>

S

Pin C =>

R

Pin D =>

R

MLD Sens

o

Pin A: =>

M

Pin B: =>

M

Pin C: =>

M

Pin D: =>

M

V

dc

otor 1+ Master

M

otor 1- Master

otor 2+ Slave

M

otor 2- Slave

e

ction (optiona

l

+

24V)

G

ND)

I

N)

O

UT)

Sensor Mast

e

aster (+24V)

aste

r

(GND)

aster Current (I

aster (GND)

Sensor Slave

a

ve (+24V)

ave (GND)

S

lave Current (I

o

l

ave (GND)

p

tible Power S

u

S

witch 1,

S

witch 2

R

eserve (+24V)

R

eserve (GND)

o

r

M

LD (+24V)

M

LD GND

M

LD West

M

LD East

ASSEMBLY IN

Wire

c

Blue

Red

1 (Blu

e

2 (Re

d

l

)

User

define

e

r

out)

Brow

n

White

Green

o

ut)

Brow

n

White

Green

u

pply

User

define

Brow

n

White

Yello

w

Green

N

STRUCTIONS

c

ode Ter

m

e

)

d

)

XH

d

XI

n

n

XJ

n

n

XK

d

XL

n

w

n

X2

X3

MLD CONTR

O

m

inal Funct

Wind

S

Pin A:

Pin B:

Pin C:

Pin D:

Snow

S

Pin A:

Pin B:

Pin C:

Reser

v

Manu

a

Pin 1:

=

Pin 2:

Pin 3:

Pin 4:

Pin 5:

CAN

B

Pin A:

=

Pin B:

=

Pin C:

=

Pin D:

=

CAN

B

Pin A:

=

Pin B:

=

Pin C:

=

Pin D:

=

Power

Pin A:

=

Pin B:

=

Pin C:

=

O

L EK-S1

i

on

S

ensor

=> (+24V)

=> Wind Signa

l

=> Wind Heat

=> Wind Heat

S

ensor

=> (+24V)

=> GND

=> Snow Sign

a

v

e IN

l Control (Joy

s

=

> West

=> East

=> Horizontal

S

=> On

=> (+24V)

us In

=

> CAN High

=

> CAN Low

=

> (+5V)

=

> GND

us Out

=

> CAN High

=

> CAN Low

=

> (+5V)

=

> GND

(100 – 265 VA

C

=

>PE -Potentia

l

=

>N - Phase N

e

=

>L - Phase Li

v

Wi

r

l

Wi

r

Wi

r

Wi

r

Wi

r

a

l

Br

o

Blu

Bla

s

tick)

S

afe

Plu

g

Us

e

defi

n

Us

e

defi

n

C

)

l Earth

e

utral

v

e

Co

u

Sp

e

Page

9

r

ecode

r

e 5

r

e 4

r

e 1

r

e 2

o

wn

e

ck

g

e

r

n

ed

e

r

n

ed

u

ntry

e

cific

9

18.04.2018

2.4 EK-

S

2.4.1 LE

D

DA 1 - Mo

t

Green LED

Re

d

LE

D

S

1 LED–

d

D

’s indica

t

t

or 1 active

movin

g

d

LED

D

of

f

d

isplay

t

ing main

f

DG

1

Gre

Re

d

LE

D

DB

g

to face wes

t

moving to

f

motor is o

f

ASSEMBLY IN

f

unctions:

1

- Wind sen

en LED

d

LED

D

off

1 - Motor 2

a

t

f

ace east

ff

N

STRUCTIONS

n

sor

wind ok

wind alar

m

no senso

r

a

ctive

Gre

e

MLD CONTR

O

m

r

present

DC 1 -

M

e

n LED

Red LE

D

LED off

O

L EK-S1

DD1

Gre

e

Red

LE

D

M

LD sensor

a

moving to f

a

D

m

o

no signal fr

o

– Snow se

n

e

n LED

d

LED

D

of

f

a

ctive

a

ce wes

t

o

ving to face

e

o

m sensor

Page 1

0

n

sor

snow ok

snow alar

m

no senso

r

e

as

t

0

m

r

18.04.2018 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 11

2.4.2 LED assignments

Part Code Assignment Function

Multi-Color-

LED

DA1 Motor 1 active

Green: Moving to face west

Red: Moving to face east

LED off: motor is off

X

DB1 Motor 2 active

Green: Moving to face west

Red: Moving to face east

LED off: motor is off

X

DC1 MLD sensor

Green: Irradiation west predominant

Red: Irradiation east predominant

X

DD1 Snow sensor

Off: No sensor registered

Green: Sensor connected and OK

Red: Snow alarm activated

Red Slow Flash: Moving to unload position

Red Fast Flash: Sensor fault

X

DE1 Joystick manualcontrol

Red: Joystick plugged in and active

Red Fast Flash: Joystick error

X

DF1 CTC manualcontrol

Green: CTC move to face west

Red: CTC move to face east

Off: No command from CTC

X

DG1 Wind sensor

Off: No sensor registered

Green: Sensor connected and OK

Red: Wind alarm activated

Red Slow Flash: Waiting for wind alarm

end Red Fast Flash: Sensor fault

X

D29 Inclinationsensor 2

On: Sensor ok

Flashing: Sensor error

D31 Inclinationsensor 1

On: Sensor ok

Flashing: Sensor error

D35 Motor 2 status

Off: Motor ok

On: Motor error, defective

Flashing: Motor waits until next attempt

D41 Motor 1 status

Off: Motor ok

On: Motor error, defective

Flashing: Motor waits until next attempt

D43 System status

Off: System status ok

On: Excessive heat, Motor stopped

Flashing: System waits for ok

D64 Controller power

On: Microcontroller voltage ok

Fast Flash: Power error

D65 MLD sensor power

On: MLD sensor voltage ok

Fast Flash: Power error

D66 Motor power

On: Motor voltage ok

Fast Flash: Power error

D67 Bus power

On: Bus voltage ok

Slow Flash: Data transfer

Fast Flash: Power error

18.04.2018

3 Ma

n

3.1 Joy

s

The extern

a

of the hous

i

Only the sy

s

For exampl

e

manual sn

o

_________

_

W

H

i

_________

_

3.1.1 Pi

n

Terminal

designatio

n

XJ1 Pin 1

XJ1 Pin 2

XJ1 Pin 3

XJ1 Pin 4

XJ1 Pin 5

West

n

ual Co

n

s

tic

k

Func

t

a

l Joystick c

a

i

ng. Automa

t

s

tem where

e

, the modul

o

w removal.

T

_

________

_

W

ARNING!

i

gh voltage

p

_

________

_

n

assignm

e

n

Functi

o

Moving

t

Moving

t

Moving

t

“ON” si

g

(+24V)

Table

p

Nofu

n

n

trol

t

ions

a

n be plugg

e

t

ic mode an

d

the joystick

i

es can all b

e

T

he system

w

_

_________

_

p

resent! Onl

y

_

_________

_

e

nt

o

n

t

o face west

t

o face east

t

o table “SA

F

g

nal to CTC

(

p

osition

n

ction

ASSEMBLY IN

e

d into sock

e

d

manual mo

s plugged in

e

set flat, for

w

ill switch b

a

_

_________

_

y

qualified p

e

_

_________

_

F

E” position

(

+24 V)

East

+

Sno

w

remo

v

N

STRUCTIONS

e

t XJ1 durin

g

o

de from CT

C

n

will move i

n

maintenanc

e

a

ck to autom

a

_

________

_

e

rsonnel ma

y

_

________

_

+

w

v

al

Terminal

XJ1

MLD CONTR

O

operation o

f

C

is deactiva

n

the directio

e

work (mo

w

a

tic mode o

n

_

_________

_

y

open the h

o

_

_________

_

O

L EK-S1

f

the EK-S1

a

t

ed once th

e

n

indicated

b

w

ing grass),

o

n

ce the joyst

i

_

_________

_

o

using and

c

_

_________

_

after removi

n

e

joystick is

p

b

y the joysti

c

o

r at a steep

ick is remov

e

_

________

_

connect the

_

________

_

Page 1

2

n

g the cove

r

p

lugged in.

c

k.

incline, for

e

d.

_

_________

joystick.

_

_________

2

r

18.04.2018

4 Win

d

The wind al

The alarm

w

duration of

a

will start ov

e

Speed [m/s]

12 m/ s

10 m/ s

4.2 As

s

_________

_

T

T

T

e

_________

_

NO

T

Th

e

4.3 Co

n

The wind g

u

described i

n

_________

_

NO

T

A

w

ha

s

Terminal

designati

o

XG1Pin C

XG1 Pin

D

XG1 Pin

B

XG1 Pin

A

d

Guar

d

arm becom

e

w

ill stop whe

a

pproximat

e

e

r for anoth

e

1s

Relay is

Wind al

a

s

embly

_

________

_

CAUTION!

T

he anemo

m

T

he anemo

m

T

he minimu

m

e

ast or west

_

________

_

T

E!

e

assembly

n

nection

u

ard is equi

p

n

chapters 2

.

_

________

_

T

E!

w

ind guard d

s

several sys

o

n

Fun

c

-

D

-

B

Sign

a

-

A

-

d

e

s activated

w

n the wind s

e

ly 10 minut

e

e

r 10 minute

s

deactivate

d

a

r

m

_

_________

_

m

eter must b

m

eter should

m

height mu

s

end positio

n

_

_________

_

directly on

t

p

ped with a

2

.

3 and 6.

_

_________

_

oes not hav

e

tems. One

w

c

tion

DC 24 V

DC 0 V

a

linput

0 to 20 m

DC 24 V

ASSEMBLY IN

w

hen the wi

n

peed is cont

e

s. If the win

d

s

.The alarm

c

10 m i n

R

e

Wi

_

_________

_

e installed i

n

not be insta

s

t be the top

n

!

_

_________

_

t

he tracker

2

0 m connec

t

_

_________

_

e

to be insta

l

w

ind guard

c

A

N

STRUCTIONS

n

d speed co

n

inuously slo

w

d

speed exc

e

can be canc

Zeit [

e

lay is ac tiveted

i

nd alarm stop

_

________

_

n

a higher lo

c

a

lled in the w

edge of the

_

________

_

is not allo

w

tion cable.

T

_

________

_

l

led on ever

y

c

an be used

f

MLD CONTR

O

n

tinuously e

x

w

er than the

e

eds 10 m/s

elled earlier

]

_

_________

_

c

ation wher

e

ind shadow

o

module sur

f

_

_________

_

w

ed!!!

T

he cable ha

s

_

_________

_

y

DEGERtra

c

f

or up to 10

0

O

L EK-S1

x

ceeds the

d

default setti

n

within these

by unlockin

g

_

_________

_

it is expose

d

o

f objects.

f

ace when th

_

_________

_

s

to be conn

e

_

_________

_

c

ker in a sol

a

0

EK-S1.

Wire

Wire

Wire

Wire

d

efault settin

g

ng of 10 m/

s

e

10 minutes

,

g

the power

r

_

________

_

d to wind.

e tracker is

i

_

________

_

e

cted to the

_

________

_

a

r energy pl

a

1 ofanemo

m

2 ofanemo

m

4 ofanemo

m

5 ofanemo

m

Cable

Page 1

3

g

of 12 m/s.

s

for a

,

the time

r

eset.

_

________

n complete

_

_________

EK-S1 as

_

_______

a

nt that

m

eter

m

eter

m

eter

m

eter

length 20 m

3

18.04.2018

5 Sno

w

5.1 Fun

c

The snows

e

accumulati

o

on theDEG

E

When a ce

r

or ice accu

m

sensor, a si

CTC, whic

h

modules in

t

inclined po

s

_________

_

N

O

D

c

_________

_

5.2 Po

s

The snow s

positioned

n

It is suitabl

e

w

Sens

o

c

tion

e

nsordetect

s

o

ns of snow

a

E

Rtracker.

r

tain amount

m

ulates on t

h

gnal is sent

h

moves the

s

t

o the greate

s

ition to facili

_

________

_

O

TE!

D

o not chan

g

c

laims.

_

________

_

s

itioning

s

ensor has t

o

n

ext to the

m

e

for module

or

s

a

nd ice

of snow

h

e

to the

s

olar

st

tate the sno

w

_

_________

_

g

e the defa

u

_

_________

_

o

be mounte

d

m

iddle of the

t

heights up t

o

ASSEMBLY IN

w

to slide of

f

_

_________

_

lt switching

t

_

_________

_

d

to the east

e

t

racker.

o

65 mm.

N

STRUCTIONS

f

.

_

________

_

t

hreshold. C

h

_

________

_

e

rn side of t

h

MLD CONTR

O

_

_________

_

h

anging the

_

_________

_

h

e modules

O

L EK-S1

_

_________

_

default setti

n

_

_________

_

_

________

_

n

g will void

a

_

________

_

Page 1

4

_

_________

a

ny warranty

_

_________

4

18.04.2018

5.3 As

s

1.The 20 c

m

mounted to

surfaceusin

plates and

t

Torque: 8

N

_________

_

2.Loosen b

o

thealuminiu

against the

Torque: 38

_________

_

3.Position t

h

edge of the

To do so, l

o

and place t

h

The snow s

the module

Torque: 19

5.4 Co

n

The snow s

described i

n

_________

_

NO

T

A

s

n

ha

s

s

embly

m

aluminum

the east sid

e

g two bolts

M

t

wo sliding n

N

m

_

________

_

o

lts M10x20

m profile fro

solar modul

e

Nm

_

________

_

h

e snow se

n

module sur

f

o

osen the tw

o

h

e snow sen

s

ensor housi

n

surface.

Nm

n

nection

s

ensor is eq

u

n

chapters2.

3

_

________

_

T

E!

n

ow sensor

d

s

several sys

profile has t

o

e

of the mo

d

M

6, two cla

m

uts M6.

_

_________

_

and slide th

e

m undernea

t

e

.

_

_________

_

n

sor so that i

t

f

ace.

o

bolts, M8x

2

sor at the h

e

n

g should n

o

u

ipped with

a

3

and 6.

_

_________

_

d

oes not ha

v

tems. One s

ASSEMBLY IN

o

be

d

ule

m

p

_

_________

_

e

snow sen

s

t

h until it is fl

_

_________

_

t

is flush wit

h

2

0, on the a

n

e

ight of the

m

o

t stick out a

b

a

5m connec

t

_

_________

_

v

e to be inst

a

now sensor

Modul

Sliding

N

STRUCTIONS

_

________

_

s

or into

ush

_

________

_

h

the upper

n

gle holder

m

odules.

b

ove

t

ion cable. T

_

________

_

a

lled on eve

r

can be use

d

e

nu

t

Cla

m

MLD CONTR

O

_

_________

_

_

_________

_

he cable ha

s

_

_________

_

r

y DEGERtr

a

d

for up to 1

0

A

lumin

u

m

p plate

O

L EK-S1

_

_________

_

_

_________

_

s

to be conn

e

_

_________

_

a

cker in a so

0 EK-S1.

u

m profile

Mod

u

_

________

_

_

________

_

e

cted to the

_

________

_

o

lar energy p

u

le

Page 1

5

_

______

_

_________

EK-S1 as

_

_______

l

ant that

5

18.04.2018

6 Con

6.1 Blo

c

_________

_

D

A

O

_________

_

D

A

T

h

m

b

r

_________

_

nection

s

c

k diagra

m

_

________

_

A

NGER!

nly trained a

_

________

_

A

NGER!

h

e external

v

andatorydis

c

r

eaker must

b

_

________

_

s

m

_

_________

_

nd qualified

_

_________

_

v

oltage supp

c

onnection

a

b

e fully acc

e

_

_________

_

ASSEMBLY IN

_

_________

_

personnel

m

_

_________

_

l

y must mee

t

a

bility from t

h

e

ssible.

_

_________

_

N

STRUCTIONS

_

________

_

m

ay connect

t

_

________

_

t

the region

a

h

e supply vol

_

________

_

MLD CONTR

O

_

_________

_

t

he EK-S1 t

o

_

_________

_

a

l regulation

s

tage by a 6

A

_

_________

_

O

L EK-S1

_

_________

_

o

external de

_

_________

_

s

. The EK-S1

A

-B circuit br

e

_

_________

_

_

________

_

e

vices.

_

________

_

1

musthave

eaker. The

c

_

________

_

Page 1

6

_

_________

_

_________

c

ircuit

_

_________

6

18.04.2018

6.2 CA

N

6.2.1 C

A

The EK-S1

The shieldi

n

The first E

K

software.

The last E

K

6.2.2 Co

n

For connec

t

sources ca

n

The CAN-b

u

CAN-Low, i

the adapter

The termin

a

chain.

For more i

n

N

-Bus

A

N-Bus co

n

offers two c

o

n

g of the CA

K

-S1 in the

C

K

-S1 in the C

n

necting

C

t

ing the PC

r

n

be found o

u

s cable mu

s

.e. pin 2 an

d

.

a

tion at the

E

n

formation

a

n

nections

E

o

nnections:

C

N-Bus cable

C

an-Bus chai

an-Bus chai

n

C

AN-Bus t

o

r

unning the

C

n the websit

e

s

t be termin

a

d

pin 7 of the

E

K-S1’s is m

a

a

bout CTC

f

ASSEMBLY IN

EK

-S1

C

AN Bus In

s must be p

r

n (ID1) is co

n

(IDn) is on

o

the man

a

C

TC you ne

e

e

www.canu

s

a

ted with a 1

D-Sub 9 fe

m

a

de onboar

d

f

unctionalit

y

N

STRUCTIONS

(terminal X

K

r

operly strip

p

nnected to t

h

ly connecte

d

a

gement

P

e

d a CAN-U

S

sb.com.

20 ohm resi

s

m

ale plug, w

h

d

, so you do

n

y

and featu

r

MLD CONTR

O

K

) and Can

B

p

ed and fixe

d

h

e PC runni

n

d

to the term

i

P

C

S

B adapter f

r

s

tor at the a

d

h

ich is need

e

n

’t need a re

s

r

es refer to

t

O

L EK-S1

us Out (ter

m

d

into the m

e

n

g the CTC

(

i

nal XK (CA

N

r

om Lawicel.

d

apter end b

e

d to conne

c

s

istor at the

l

t

he “CTC U

s

m

inal XL).

e

tal clips X4

a

(

Central Tra

c

N

Bus In).

.

More infor

m

b

etween CA

N

c

t the CAN-

B

last unit in t

h

s

er Guide”.

Page 1

7

a

nd X5.

c

ker Control

)

m

ation and

N

-High and

B

us cable to

h

e CAN-bus

7

)

18.04.2018

6.3 Uni

n

It is possibl

e

move the D

The UPS h

a

Furthermor

e

The UPS h

a

connected

o

The syste

m

UPS with p

o

UPS witho

u

n

terruptibl

e

to provide

EGERtrack

e

a

s to be dim

e

e

the UPS h

a

a

s to be wir

e

o

nly to one

E

m

moves im

m

o

tential free

u

t potential f

r

e power s

an Uninterr

u

e

r in case of

e

nsioned to

d

a

s to be des

e

d as shown

E

K-S1, the p

o

m

ediately aft

e

contact:

r

ee contact:

ASSEMBLY IN

upply for

a

u

ptible Powe

r

a power fail

u

d

eliver a po

w

igned to be i

in the follow

o

wer failure

e

r the failure

N

STRUCTIONS

a

DEGERtr

a

r Supply (U

P

u

re into safe

t

w

er of 180

W

n accordan

c

ing connecti

o

information

w

of the suppl

y

MLD CONTR

O

a

cker

P

S) for a DE

G

t

y position.

W

att for at le

a

c

e with local

e

o

n diagram

s

w

ill be forwa

y

voltage in

s

O

L EK-S1

G

ERtracker.

a

st 10 minut

e

e

nvironmen

t

. The potent

r

ded to othe

r

s

torm positi

o

The power

p

e

s per EK-S

1

t

and the leg

a

t

ial free cont

a

r EK-S1 via

C

o

n/safety po

s

Page 1

8

p

rovided will

1

.

a

l regulation

a

ct has to b

e

C

AN-Bus.

s

ition.

8

.

e

18.04.2018

7 Sta

r

D

A

E

l

C

o

T

T

T

C

A

D

a

M

D

R

Close all h

o

8 Cle

a

The rotary

d

move freel

y

off the mot

o

N

O

W

e

v

l

o

C

L

T

T

1. The easi

e

chapter 3.1

2.

A

lternati

v

change dir

e

Change th

e

r

t-up

A

NGER!

l

ectrical cu

r

o

ntact with li

T

he externa

l

T

he EK-S1

m

T

he circuit b

A

UTION!

a

nger from

oving parts

d

D

o not rema

R

emove obj

e

o

using cover

s

a

rance

C

d

rive must b

e

y

, that all ca

b

o

rs.

O

TE!

W

hen severa

v

ery syste

m

o

calised bef

o

C

ables mus

t

L

imit switch

e

T

he full rota

t

T

here shoul

d

e

st way to p

e

..

v

ely, the mot

e

ction of mot

o

e

direction a

c

r

rent can b

e

ve compon

e

l

voltage su

p

m

ust be able

reaker must

unintentio

n

d

uring DEG

E

in within the

e

cts from th

e

s

. Torque 1

.

C

heck

e

moved alo

n

b

les are long

l DEGERtra

m

individuall

y

o

re damag

e

t

not be subj

e

e

s should s

w

t

ion spectru

m

d

not be any

e

rform the cl

or drive can

o

r.

c

cording to t

h

ASSEMBLY IN

fatal!

e

nts can be f

a

p

ply must m

e

to be disco

n

be fully acc

e

n

al moveme

n

E

Rtracker st

a

DEGERtra

c

e

DEGERtra

c

2 Nm (han

d

n

g the entir

e

enough for

t

cke

r

s are i

n

y

. This ens

u

e

occurs.

e

ct to mech

a

w

itch offat th

e

m

should be

a

unusual noi

s

earance ch

e

be connect

e

h

e note in ch

N

STRUCTIONS

a

tal due to e

e

et the regio

n

n

nected fro

m

e

ssible.

n

t of the m

a

a

r

t

-up can c

a

c

ker’s range

o

c

ker’s range

d

-tight)

e

path to ens

t

he entire ra

n

n

stalled, th

e

u

res that a

n

a

nical stress

.

e

right time.

a

chieved.

s

e.

e

ck is by usi

n

e

d to a batte

r

apter 2.4.1..

MLD CONTR

O

lectric shoc

k

n

al regulatio

n

m

the power

s

a

chine!

a

use injury.

o

f rotational

of rotationa

l

ure that the

D

n

ge of motio

clearance

c

n

y possible

i

.

n

g the EK-S

1

r

y pack (12

V

O

L EK-S1

k

.

n

s.

s

upply by a

6

motion.

motion.

D

EGERtrac

k

n

, and that t

h

c

heck must

i

nstallation

1

joystick lik

e

V

to 26 V).

A

6A

-B circuit

b

k

er mechani

s

h

e limit swit

c

be perfor

m

errors can

b

e

described i

change in

p

Page 1

9

b

reaker.

s

m can

c

hes switch

m

ed for

b

e

n

p

olarity will

9

18.04.2018 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 20

9 Technical Data

9.1 Electrical ratings

Nominal input voltage 100 to 240VAC/ 110-250VDC

Line frequency 50 to 60 Hz

Inrush current 30 A @ Tu 250C

Input power 179W @ Uin= 230 VAC

Nominal current 0,78 A

Output voltage motors 24 VDC

Nominal output current 3A (in Manual Control mode)

Peak output current 3,1 A for 25 min / 5 A for 10 min / 14 A for 100 ms

Output voltage sensors 24 VDC

Peak output current 1,2 A (200 mA sensors, 1,0 A for wind guard heating)

Output voltage CAN-Bus 5 VDC (galvanicallyisolated)

Peak output current 0,3 A

Max. voltage for UPS potential-free contact 24 VDC

Max. current for UPS potential-free contact 0,1 A

IP protection class IP 66 according to EN 60529, UL50 / UL746C, UL 94

Safety EN 60950-1

Electromagnetic Interference (EMI) EN 55032, EN 61000

Climatic conditions

Installation above sea level max. 2000m

Operating ambient temperature -20 °C to +50 °C

with wind guard heating -20 °C to +20 °C

Relative humidity 5% - 95%, non-condensing

Expanded air humidity range wind guard 0% to 100%

Dimensions 245 mm x 180 mm x 111 mm

Total weight including MLD sensor Approx. 3 kg

Other manuals for MLD Control Energy Converter S1

1

This manual suits for next models

1

Table of contents

Other Deger Controllers manuals

Popular Controllers manuals by other brands

TVILIGHT

TVILIGHT OPENSKY Zhaga IoT installation manual

Madas

Madas RG/2MBLZ DN 80 Technical manual

Novus

Novus N3000 instruction manual

EnvironmentalLights.com

EnvironmentalLights.com rgb-mini-BT user manual

PRECISION DIGITAL

PRECISION DIGITAL PD6210-6R2 instruction manual

Hunter

Hunter i-core IC-600PL quick start guide

Blankom

Blankom 965x.01 series operating instructions

Spacesaver

Spacesaver POWER PRO Operation instructions

Aube Technologies

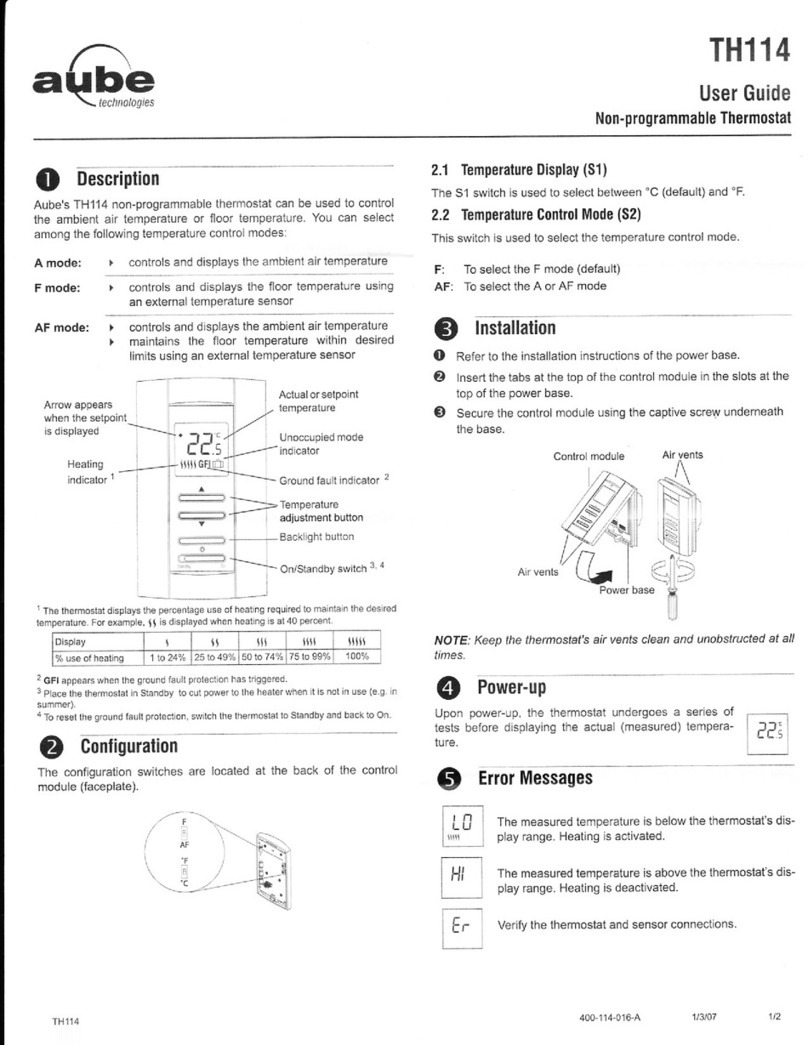

Aube Technologies TH114 user guide

ABB

ABB Relion 670 series Commissioning manual

Binks

Binks 84-320 Service manual

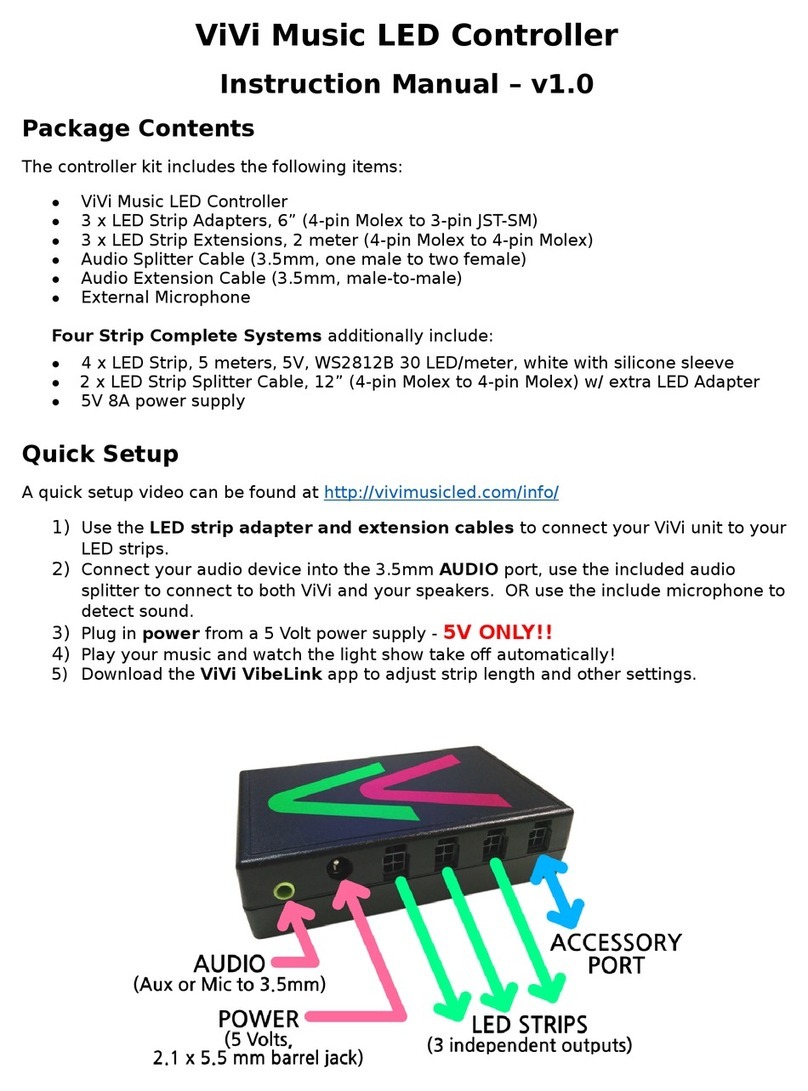

Visual Vibes

Visual Vibes ViVi Music LED Controller instruction manual