Deger MLD Control Energy Converter S1 User manual

MLD Control

Energy Converter S1

S100-DR S100-SR

ASSEMBLY INSTRUCTION

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 2

Copyright

All information presented in this technical document and the drawings and technical descriptions made

available by DEGER remain the property of DEGER and may not be reproduced without prior explicit written

permission from DEGER.

We reserve the right to make technical changes.

Version: 2019-06-27

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 3

List of contents

Abbreviations ................................................................................................................................................. 5

1Introduction................................................................................................................................................. 6

1.1 Basic safety information..................................................................................................................... 6

1.2 Exclusion of liability............................................................................................................................ 6

1.3 For your safety................................................................................................................................... 6

1.3.1 Intended purpose of the DEGER system ...................................................................................... 6

1.3.2 Personal protective equipment...................................................................................................... 6

1.4 Symbols used .................................................................................................................................... 7

1.5 Presentation of information................................................................................................................ 7

1.5.1 Lists and instructions ..................................................................................................................... 7

1.5.2 Safety information.......................................................................................................................... 7

2Energy Converter S1 (EK-S1).................................................................................................................... 8

2.1 EK-S1 Functions................................................................................................................................ 8

2.2 EK-S1: Cable connections................................................................................................................. 8

2.3 EK-S1: Pin assignments.................................................................................................................... 9

2.4 EK-S1 LED –display...................................................................................................................... 10

2.4.1 LED’s indicating main functions:.................................................................................................. 10

2.4.2 LED assignments......................................................................................................................... 11

3Manual Control......................................................................................................................................... 12

3.1 Joystick Functions ........................................................................................................................... 12

3.2 Pin assignment ................................................................................................................................ 12

4Wind Guard .............................................................................................................................................. 13

4.1 Wind guard....................................................................................................................................... 13

4.2 Assembly ......................................................................................................................................... 13

4.3 Connection....................................................................................................................................... 13

5Snow Sensor............................................................................................................................................ 14

5.1 Function........................................................................................................................................... 14

5.2 Positioning ....................................................................................................................................... 14

5.3 Assembly ......................................................................................................................................... 15

5.4 Connection....................................................................................................................................... 15

6Connections.............................................................................................................................................. 16

6.1 Block diagram.................................................................................................................................. 16

6.2 CAN-Bus.......................................................................................................................................... 17

6.2.1 CAN-Bus connections EK-S1...................................................................................................... 17

6.2.2 Connecting CAN-Bus to the management PC ............................................................................ 17

6.3 Uninterruptible power supply for a DEGER sytem .......................................................................... 18

7Start-up..................................................................................................................................................... 19

8Clearance Check...................................................................................................................................... 20

8.1 CTC manual control......................................................................................................................... 20

8.2 Joystick............................................................................................................................................ 20

8.3 Battery pack..................................................................................................................................... 20

9Technical Data.......................................................................................................................................... 21

9.1 Electrical ratings..................................................................................................................................... 21

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 4

9.2 Electrical norms...................................................................................................................................... 21

9.3 Climatic conditions................................................................................................................................. 21

9.4 General .................................................................................................................................................. 21

10 Troubleshooting................................................................................................................................... 22

10.1 Error Recognition & Removal.......................................................................................................... 22

10.2 Fault Report..................................................................................................................................... 24

11 Maintenance ........................................................................................................................................ 25

12 Cleaning............................................................................................................................................... 25

13 Decommissioning ................................................................................................................................ 26

13.1 Disassembly..................................................................................................................................... 26

13.2 Disposal........................................................................................................................................... 26

14 Conformity Declaration........................................................................................................................ 27

15 Publisher Information........................................................................................................................... 28

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 5

Abbreviations

EL = Elevation (east-west orientation)

CTC = Central Tracker Control (software)

EK-S1 = Energy Converter S1

MLD = Maximum Light Detection

MLD Control = Energy Converter, MLD sensor, wind sensor, snow sensor

PPE = Personal Protective Equipment

UPS = Uninterruptible power supply

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 6

1 Introduction

These assembly instructions were created for the DEGER system. They are a component of the product and

must be saved for the entire lifespan of the DEGER system. The assembly instructions must be included with

the DEGER system should it be transferred to another party.

1.1 Basic safety information

Read these assembly instructions in their entirety before starting assembly work and keep them available

at all times during the assembly process.

Only qualified personnel may perform assembly work.

Keep all objects out of the the DEGER system’s full range of pivoting motion throughout its full range of

motion.

Take necessary actions to protect the installed DEGER system in its full range of motion from unauthorized

access, such as enclosing it within a fence. Near the entry area to the DEGER system there must be a

warning sign stating that it is prohibited to remain within the range of pivoting motion.

Lightning protection and grounding must be installed in all photovoltaic systems according to country-

specific guidelines as stipulated in DIN VDE 0185 and 0100.

Do not operate the DEGER system if the wind guard is not functioning. Always keep the module surface in

the SAFE position (table position) until the wind guard has been tested for function.

If snow has accumulated on the module surface, the module surface must first be cleared. This is

accomplished by manually control via the CTC software or through the snow sensor. If no functioning CTC

remote access and/or snow sensor is available, the module surface must be cleared manually. The snow

sensor availability shall not release the module surface from the obligation to be cleared of snow.

DEGER recommends an Uninterruptible Power Supply (UPS) to ensure the function of the wind monitor.

1.2 Exclusion of liability

As a rule, DEGER’s General Terms and Conditions shall apply. The contents of these documents are

checked continuously and modified as needed. The assembly instructions are available for download in the

dealer section on the website, www.DEGER.biz, and they can also be obtained through the traditional

distribution channels.

Warranty and liability claims will be void if any type of damage occurs that results from one or more of the

following causes:

- Improper or unauthorized use of DEGER system

- Operation of DEGER system in an improper environment

- Operation of DEGER system without taking into account the statutory safety regulations applicable at the

place of installation

- Non-observance of warnings and safety information in all documents relevant to the product

- Operation of DEGER system in the absence of proper safety and protective measures

- Unauthorized modifications to DEGER system

- Drilling holes in any housing, e.g. EK-S1. Use existing free holes for mounting the housings.

- Failure of the DEGER system due to the influence of connected or neighbouring devices outside of the the

permitted limits

- Catastrophes and force majeure

1.3 For your safety

1.3.1 Intended purpose of the DEGER system

The MLD control with EK-S1 is intended only for the purpose of controlling DEGER’s system.

DEGER’s system can be used in the private and commercial sector. They are designed for outdoor

installation and for building integration.

1.3.2 Personal protective equipment

The client must provide enough safety equipment for assembly and maintenance work. Supervisors must

ensure safety equipment is worn.

The following safety equipment is mandatory:

- Protective helmet

- Safety shoes

- Safety gloves

Fall protection equipment and PPE to prevent falling when working more than 1 m above the ground

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 7

1.4 Symbols used

The following symbols appear on the DEGER system and are used in the present document:

No unauthorized access

Read and follow the operating manuals and safety information before start-up

1.5 Presentation of information

1.5.1 Lists and instructions

Lists

Lists have bullet points:

- List

- List

Instructions in a certain order

Instructions that must be followed in a certain order are numbered:

1. Step 1

2. Step 2

Instructions without a certain order

Instructions that do not have to be followed in a certain order are listed with bullet points:

Instruction

Instruction

Results

Results of an action are indicated by a double arrow:

>> Result

1.5.2 Safety information

The following safety information is used in this document:

______________________________________________________________________________________

DANGER!

Imminent danger with a high risk; failure to observe will lead to severe physical injury or death.

______________________________________________________________________________________

WARNING!

Possible danger with a moderate risk; failure to observe can lead to severe physical injury or death.

______________________________________________________________________________________

CAUTION!

Danger with low risk; failure to observe can lead to moderate physical injury.

______________________________________________________________________________________

NOTE!

Failure to observe this information entails the risk of property damage.

_____________________________________________________________________________________

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 8

2 Energy Converter S1 (EK-S1)

2.1 EK-S1 Functions

The EK-S1 is intended to be connected via CAN-Bus to other EK-S1’s and a PC and operated with the

Central Tracker Control (CTC) software from the PC.

For the CTC a separate manual (the CTC User Guide) is available.

Applies in general: 1. External input from CTC (manual control) has priority over MLD sensor.

2. External input from wind sensor has priority over external manual control.

Reverse direction function:

This function ensures the module surface is facing east the next morning to receive the first rays of sunlight.

The motor will switch on for 12 minutes once the EK-S1 has not registered a signal at terminal XG1 for more

than 4 hours. The external inputs, joystick, MLD sensor and wind monitor have priority.

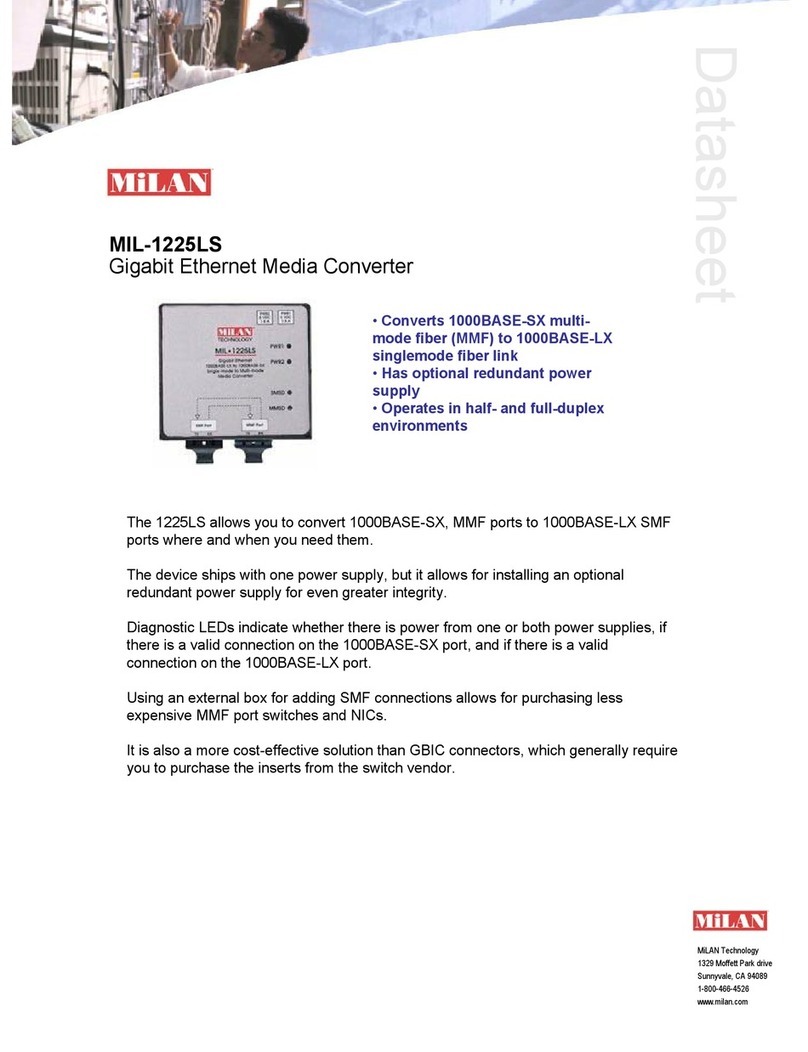

2.2 EK-S1: Cable connections

The EK-S1 is delivered with prewired MLD-sensor, Inclination sensor cabling and motor cabling. PG glands

for the CAN-Bus (M20) and AC power (M16) will be pre-installed.

The PG glands for the wind guard (M20) and the snow sensor (M16) are only needed one time in every

installation and are included as an accessory.

PG glands for the UPS and theft protection (both M16) can be provided on request.

______________________________________________________________________________________

CAUTION!

Please observe the right polarity of the motor cables if disconnecting these during installation.

Reverse polarity can lead to serious damage of the system.

______________________________________________________________________________________

Note!

All PG glands must fit with the installed cables from customer side and must hermetically seal the

housing to avoid moisture inside. Underground slave cables must be laid in a cable conduit.

Motor 1

Master

Motor 2

Slave

Inclination sensor

Slave

Inclination sensor

Master

MLD sensor

CAN Bus

In

Snow sensor

Reserve

(option)

AC Power

In

AC Power

Out

Wind guard

(anemometer)

CAN Bus

Out

UPS

(option)

Theft protection

(option)

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 9

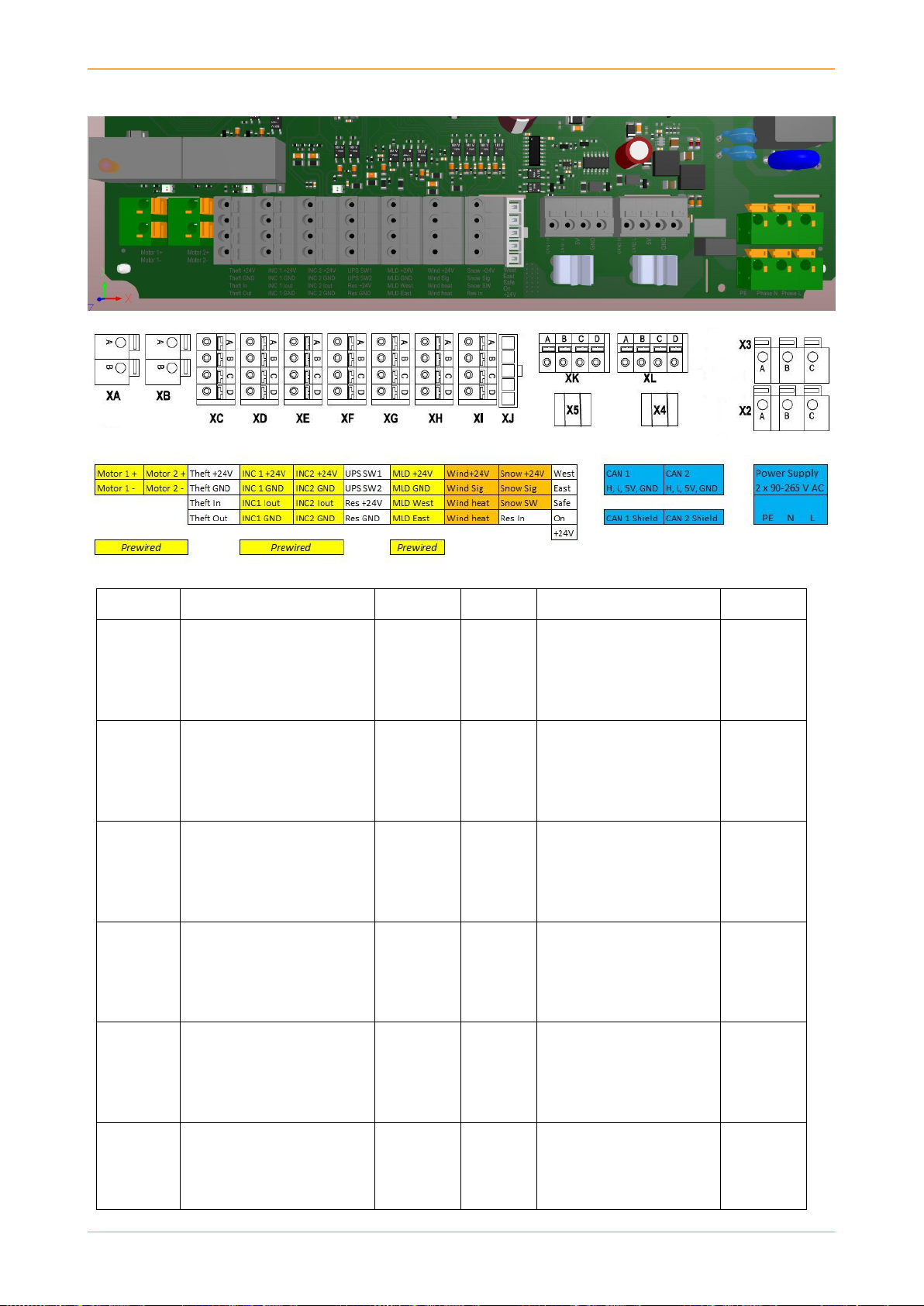

2.3 EK-S1: Pin assignments

Terminal

Function

Wire code

Terminal

Function

Wire code

XA

XB

Drives 24 Vdc

Pin A => Motor 1+ Master

Pin B => Motor 1- Master

Pin A => Motor 2+ Slave

Pin B => Motor 2- Slave

Blue

Red

1 (Blue)

2 (Red)

XH

Wind Sensor

Pin A: => (+24V)

Pin B: => Wind Signal

Pin C: => Wind Heat

Pin D: => Wind Heat

Wire 5

Wire 4

Wire 1

Wire 2

XC

Theft Protection (optional)

Pin A => (+24V)

Pin B => (GND)

Pin C => (IN)

Pin D => (OUT)

User

defined

XI

Snow Sensor

Pin A: => (+24V)

Pin B: => Snow Signal

Pin C: => GND

Reserve IN

Brown

Black

Blue

XD

Inclination Sensor Master

Pin A => Master (+24V)

Pin B => Master (GND)

Pin C => Master Current (Iout)

Pin D => Master (GND)

Brown

White

Green

XJ

Manual Control (Joystick)

Pin 1: => West

Pin 2: => East

Pin 3: => Horizontal Safe

Pin 4: => On

Pin 5: => (+24V)

Plug

XE

Inclination Sensor Slave

Pin A => Slave (+24V)

Pin B => Slave (GND)

Pin C => Slave Current (Iout)

Pin D => Slave (GND)

Brown

White

Green

XK

CAN Bus In

Pin A: => CAN High

Pin B: => CAN Low

Pin C: => (+5V)

Pin D: => GND

User

defined

XF

Uninterruptible Power Supply

(optional)

Pin A => Switch 1,

Pin B => Switch 2

Pin C => Reserve (+24V)

Pin D => Reserve (GND)

User

defined

XL

CAN Bus Out

Pin A: => CAN High

Pin B: => CAN Low

Pin C: => (+5V)

Pin D: => GND

User

defined

XG

MLD Sensor

Pin A: => MLD (+24V)

Pin B: => MLD GND

Pin C: => MLD West

Pin D: => MLD East

Brown

White

Yellow

Green

X2

X3

Power (100 –265 VAC)

Pin A: => PE -Potential Earth

Pin B: => N - Phase Neutral

Pin C: => L - Phase Live

Country

Specific

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 10

2.4 EK-S1 LED –display

2.4.1 LED’s indicating main functions:

DG1 - Wind sensor DD1 –Snow sensor

Green LED

wind ok Green LED

snow ok

Red LED

wind alarm Red LED

snow alarm

LED off

no sensor present LED off

no sensor present

DA 1 –Master motor active DB 1 –Slave motor active DC 1 - MLD sensor active

Green LED

moving to face west Green LED

Irradiation west predominant

Red LED

moving to face east Red LED

Irradiation east predominant

LED off

motor is off LED off

no signal from sensor

D29 –Inclination sensor Slave

LED on: sensor ok

Flashing: sensor error

D31 –Inclination sensor Master

LED on: sensor ok

Flashing: sensor error

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 11

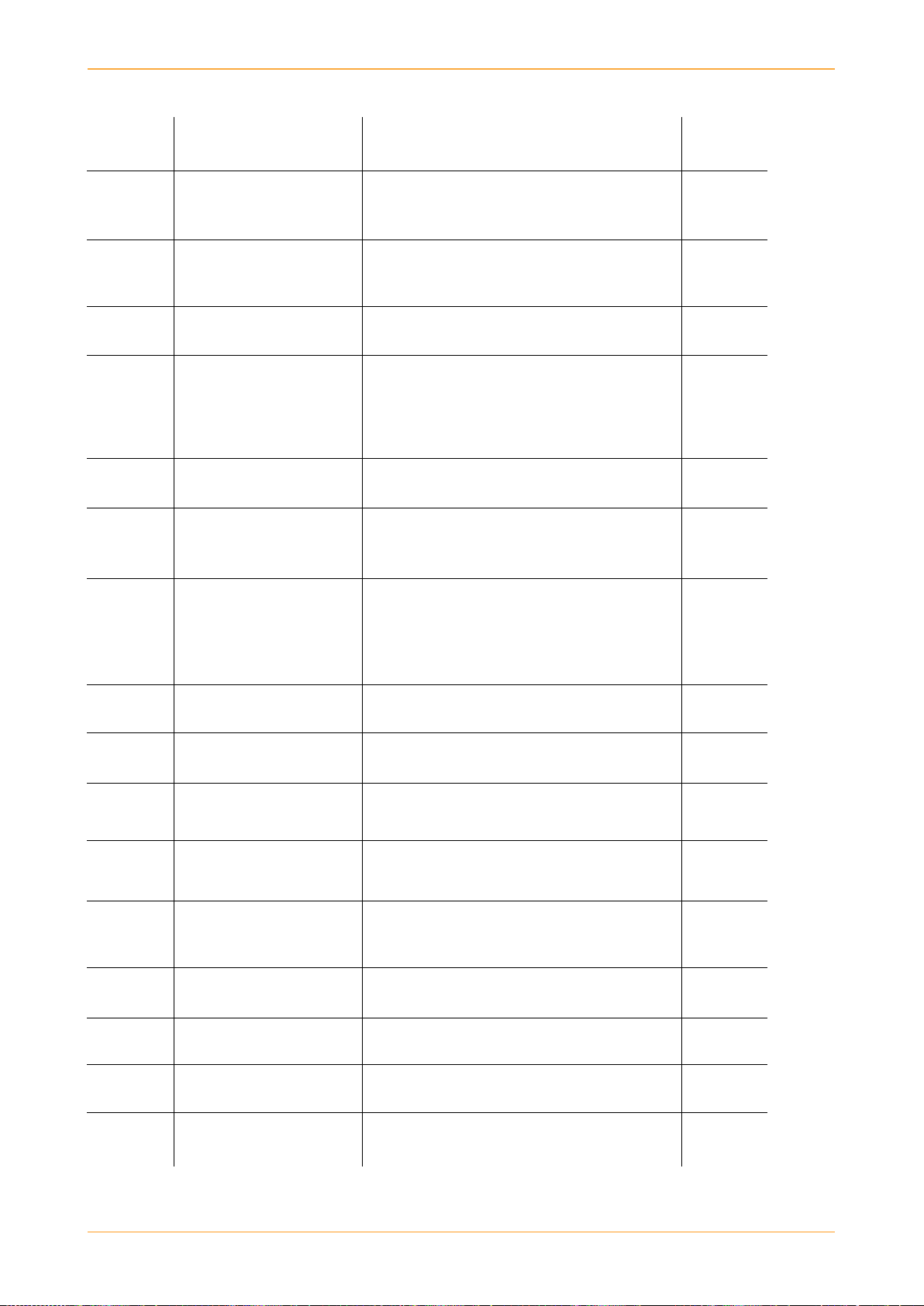

2.4.2 LED assignments

Part Code

Assignment

Function

Multi-

Color-

LED

DA1

Motor 1 (Master) active

Green: Moving to face west

Red: Moving to face east

LED off: motor is off

X

DB1

Motor 2 (Slave) active

Green: Moving to face west

Red: Moving to face east

LED off: motor is off

X

DC1

MLD sensor

Green: Irradiation west predominant

Red: Irradiation east predominant

X

DD1

Snow sensor

Off: No sensor registered on EK-S1

Green: Sensor connected and OK

Red: Snow alarm activated

Red Slow Flash: Moving to unload position

Red Fast Flash: Sensor fault

X

DE1

Joystick manual control

Red: Joystick plugged in and active

Red Fast Flash: Joystick error

X

DF1

CTC manual control

Green: CTC move to face west

Red: CTC move to face east

Off: No command from CTC

X

DG1

Wind sensor

Off: No sensor registered on EK-S1

Green: Sensor connected and OK

Red: Wind alarm activated

Red Slow Flash: Waiting for wind alarm end

Red Fast Flash: Sensor fault

X

D29

Inclination sensor Slave

On: Sensor ok

Flashing: Sensor error

D31

Inclination sensor Master

On: Sensor ok

Flashing: Sensor error

D35

Motor 2 (Slave)

Off: Motor ok

On: Motor error, defective

Flashing: Motor waits until next attempt

D41

Motor 1 (Master)

Off: Motor ok

On: Motor error, defective

Flashing: Motor waits until next attempt

D43

System status (Overload)

Off: System status ok

On: Excessive heat, Motor stopped

Flashing: System waits for ok

D64

Controller power

On: Microcontroller voltage ok

Fast Flash: Power error

D65

MLD sensor power

On: MLD sensor voltage ok

Fast Flash: Power error

D66

Motor power

On: Motor voltage ok

Fast Flash: Power error

D67

CAN-Bus power

On: Bus voltage ok

Slow Flash: Data transfer

Fast Flash: Power error

For interpretation of LED states and resulting actions in case of faults see Section 10 Troubleshooting

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 12

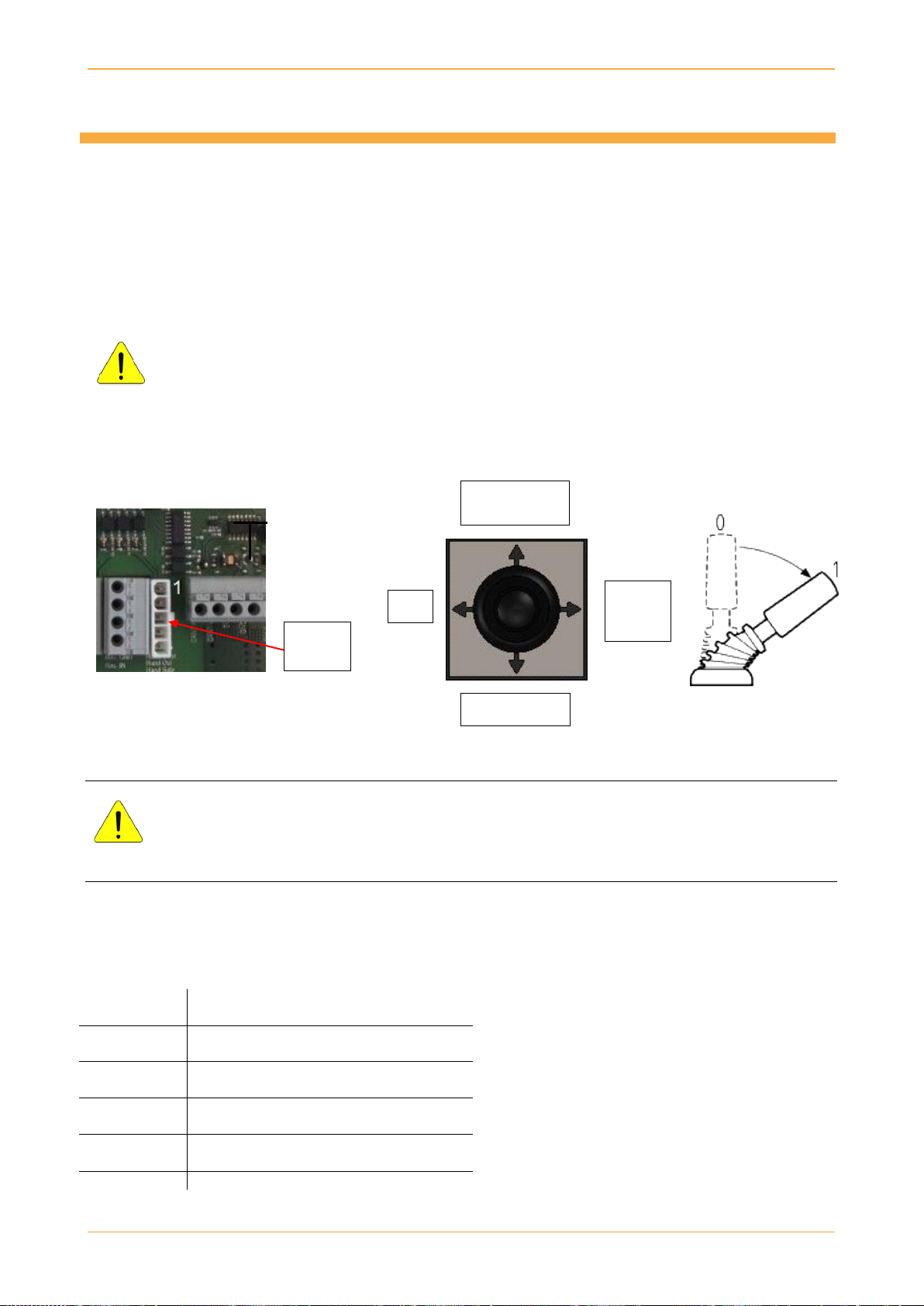

3 Manual Control

3.1 Joystick Functions

The external Joystick can be plugged into socket XJ1 during operation of the EK-S1 after removing the cover

of the housing. Automatic mode and manual mode from CTC is deactivated once the joystick is plugged in.

Only the system where the joystick is plugged in will move in the direction indicated by the joystick.

For example, the modules can all be set flat, for maintenance work (mowing grass), or at a steep incline, for

manual snow removal. The system will switch back to automatic mode once the joystick is removed.

______________________________________________________________________________________

WARNING!

High voltage present! Only qualified personnel may open the housing and connect the joystick.

______________________________________________________________________________________

CAUTION!

Serious damage to the tracker will happen when exceeding the maximum angle values.

Use an angle meter to not exceed the maximum physical angles of 700East and 500West.

3.2 Pin assignment

Terminal

designation

Function

XJ1 Pin 1

Moving to face west

XJ1 Pin 2

Moving to face east

XJ1 Pin 3

Moving to table “SAFE” position

XJ1 Pin 4

“ON” signal to CTC (+24 V)

XJ1 Pin 5

(+24V)

Horizontal

position

No function

East +

Snow

removal

West

Terminal

XJ1

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 13

4 Wind Guard

4.1 Wind guard

The wind alarm becomes activated when the wind speed continuously exceeds the default setting of 12 m/s.

The alarm will stop when the wind speed is continuously slower than the default setting of 10 m/s for a

duration of approximately 10 minutes. If the wind speed exceeds 10 m/s within these 10 minutes, the timer

will start over for another 10 minutes. The alarm can be cancelled earlier by clicking System Reset button in

CTC software Manual Control. Please see a detailed description in CTC software manual.

Speed [m/s]

12m/s

10m/s

1s 10 min

Zeit [ ]

Relay is deactivated

Relay is activeted

Wind alarm

Wind alarmstop

4.2 Assembly

_____________________________________________________________________________________

CAUTION!

The anemometer must be installed in a higher location where it is exposed to wind at all times.

The anemometer cannot be installed in the wind shadow of objects.

The minimum height must be at least the height of the top edge of the module surface when the

tracker is in complete east end position!

______________________________________________________________________________________

NOTE!

Anemometer assembly directly on the tracker is not allowed!!!

4.3 Connection

The anemometer is equipped with a 20 m connection cable. The cable has to be connected to the EK-S1 as

described in chapters 2.3 and 6.

____________________________________________________________________________________

NOTE!

An anemometer does not have to be installed on every DEGER system in a solar energy plant that

has several systems. One anemometer can be used for up to 100 EK-S1.

Terminal

designation

Function

XH1 Pin C

- DC 24 V

Wire 1 of anemometer

XH1 Pin D

- DC 0 V

Wire 2 of anemometer

XH1 Pin B

Signal input

- 0 to 20 mA

Wire 4 of anemometer

XH1 Pin A

- DC 24 V

Wire 5 of anemometer

Cable length 20 m

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 14

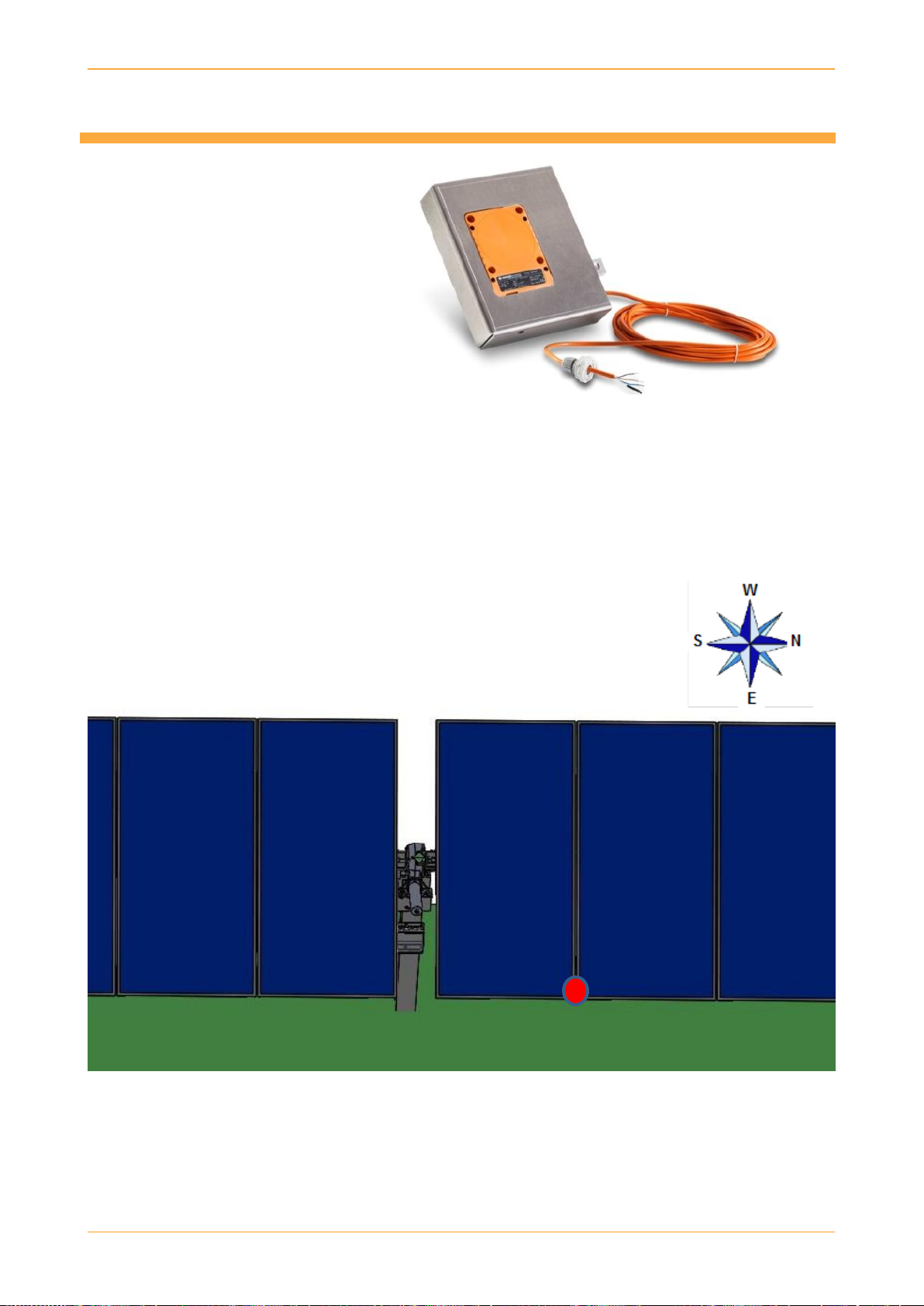

5 Snow Sensor

5.1 Function

The snow sensor detects

accumulations of snow and ice

on the DEGER system.

When a certain amount of snow

or ice accumulates on the

sensor, a signal is sent to the

CTC, which moves the solar

modules into the greatest

inclined position to facilitate the snow to slide off.

______________________________________________________________________________________

NOTE!

Do not change the default switching threshold on the snow sensor. Changing the default setting

will void any warranty claims.

______________________________________________________________________________________

5.2 Positioning

The snow sensor has to be mounted to the eastern side of the modules

positioned next to the middle of the tracker.

It is suitable for module heights up to 65 mm.

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 15

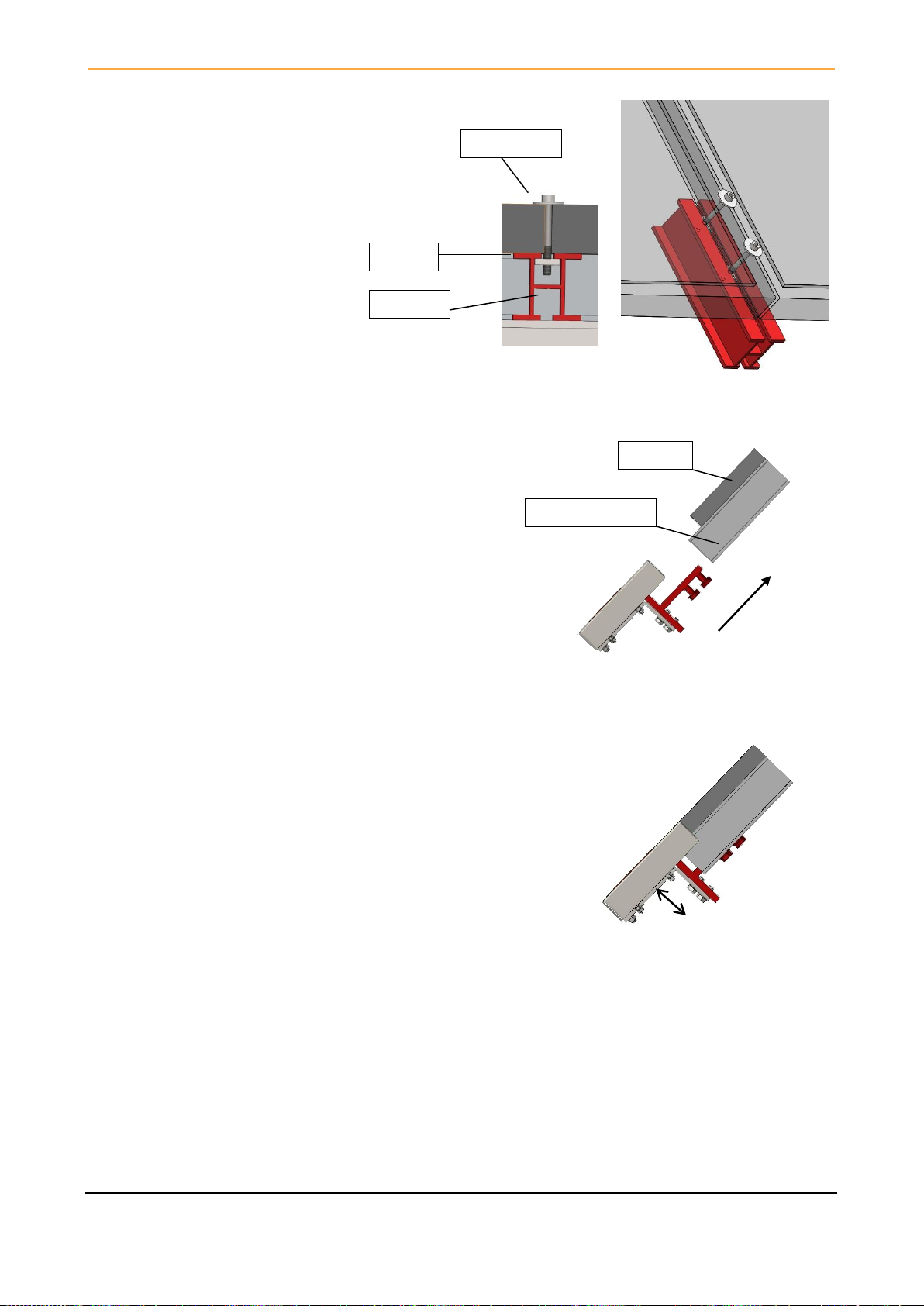

5.3 Assembly

1. The 20 cm aluminum profile has to be

mounted to the east side of the module

surface using two bolts M6, two clamp

plates and two sliding nuts M6.

Torque: 8 Nm

___________________________________________________________________________________

2. Loosen bolts M10x20 and slide the snow sensor into

the aluminium profile from underneath until it is flush

against the solar module.

Torque: 38 Nm

______________________________________________________________________________________

3. Position the snow sensor so that it is flush with the upper

edge of the module surface.

To do so, loosen the two bolts, M8x20, on the angle holder

and place the snow sensor at the height of the modules.

The snow sensor housing should not stick out above or sit below

the module surface.

Torque: 19 Nm

5.4 Connection

The snow sensor is equipped with a 5 m connection cable. The cable has to be connected to the EK-S1 as

described in chapters 2.3 and 6.

____________________________________________________________________________________

NOTE!

A snow sensor does not have to be installed on every DEGER system in a solar energy plant that

has several systems. One snow sensor can be used for up to 100 EK-S1.

Aluminum profile

Module

Module

Sliding nut

Clamp plate

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 16

6 Connections

6.1 Block diagram

______________________________________________________________________________________

DANGER!

Only trained and qualified personnel may connect the EK-S1 to external devices.

______________________________________________________________________________________

DANGER!

The external voltage supply must meet the regional regulations. The EK-S1 must have mandatory

disconnection ability from the supply voltage by a 6A-B circuit breaker. The circuit breaker must be

fully accessible.

______________________________________________________________________________________

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 17

6.2 CAN-Bus

6.2.1 CAN-Bus connections EK-S1

The EK-S1 offers two connections: CAN Bus In (terminal XK) and Can Bus Out (terminal XL).

The shielding of the CAN-Bus cables must be properly stripped and fixed into the metal clips X4 and X5.

The first EK-S1 in the Can-Bus chain (ID1) is connected to the PC running the CTC (Central Tracker Control)

software.

The last EK-S1 in the Can-Bus chain (IDn) is only connected to the terminal XK (CAN Bus In).

6.2.2 Connecting CAN-Bus to the management PC

For connecting the PC running the CTC you need a CAN-USB adapter from Lawicel. More information and

sources can be found on the website www.canusb.com.

The CAN-bus cable must be terminated with a 120 ohm resistor at the adapter end between CAN-High and

CAN-Low, i.e. pin 2 and pin 7 of the D-Sub 9 female plug, which is needed to connect the CAN-Bus cable to

the adapter.

The termination at the EK-S1’s is made onboard, so you don’t need a resistor at the last unit in the CAN-bus

chain.

For more information about CTC functionality and features refer to the “CTC User Guide”.

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 18

6.3 Uninterruptible power supply for a DEGER system

It is possible to provide an Uninterruptible Power Supply (UPS) for a DEGER system. The power provided will

move the DEGER system in case of a power failure into safety position.

The UPS must be dimensioned to deliver a power of 180 Watt for at least 10 minutes per EK-S1.

Furthermore the UPS has to be designed to be in accordance with local environment and the legal regulations.

The UPS must be wired as shown in the following connection diagrams. The potential free contact has to be

connected only to one EK-S1, the power failure information will be forwarded to other EK-S1 via CAN-Bus.

The system moves immediately after the failure of the supply voltage to storm position/safety position.

UPS with potential free contact:

UPS without potential free contact:

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 19

7 Start-up

DANGER!

Electrical current can be fatal!

Contact with live components can be fatal due to electric shock.

The external voltage supply must meet the regional regulations.

The EK-S1 must be able to be disconnected from the power supply by a 6A-B circuit breaker.

The circuit breaker must be fully accessible.

CAUTION!

Danger from unintentional movement of the machine!

Moving parts during DEGER system start-up can cause injury.

Do not remain within the DEGER’s system range of rotational motion.

Remove objects from the DEGER’s system’s range of rotational motion.

The EK-S1 is delivered with prewired MLD-sensor, Inclination sensor cabling and motor cabling.

PG glands for the CAN-Bus (M20) and AC power (M16) will be pre-installed.

Open the cover and connect the CAN-Bus cables as described in section 6.2.1.

If the respectice EK-S1 is determined for connecting the Wind sensor and/or the Snow sensor install the PG

glands and connect the cables to the designated terminals as described in section 2.2. and 2.3.

Connect the AC power IN- and OUT cables to the respective terminals described in section 2.3.

Close all housing covers. Torque 1.2 Nm (hand-tight)

Supply power to the EK-S1 and perform the Initial start-up check as described in chapter 10, check main

LED’s as described in section 2.4.1.

27.06.2019 ASSEMBLY INSTRUCTIONS MLD CONTROL EK-S1 Page 20

8 Clearance Check

CAUTION!

Serious damage to the tracker will happen when exceeding the maximum angle values or

when connecting the motor with wrong polarity to the EK-S1.

The rotary drive must be moved along the entire path to ensure that the DEGER system mechanism can

move freely and that all cables are long enough for the entire range of motion.

Cables must not be subject to mechanical stress.

The full rotation spectrum should be achieved.

There should not be any unusual noise.

8.1 CTC manual control

The easiest way to perform the clearance check is to use the MANUAL CONTROL function of the CTC

(central tracker control) management software. See CTC User Guide.

8.2 Joystick

The EK-S1 joystick, as described in chapter 3.1, can also be used.

8.3 Battery pack

Alternatively, the drive motor can be connected to a battery pack (12 V to 26 V). A change in polarity will

change the direction of the motor. Use an angle meter to not exceed the maximum physical angles of 700

East and 500West (equal to the CTC software values of 200and 1400 generated by the inclination sensors).

______________________________________________________________________________________

NOTE!

When several DEGER systems are installed, the clearance check must be performed for every

system individually. This ensures that any possible installation errors can be localised before

damage occurs.

Other manuals for MLD Control Energy Converter S1

1

This manual suits for next models

2

Table of contents

Popular Media Converter manuals by other brands

Avitech

Avitech Pacific C-SHS user manual

Danfoss

Danfoss FC 100 operating instructions

Omnitron Systems Technology

Omnitron Systems Technology iConverter 2GXM quick start guide

SoundTraxx

SoundTraxx Tsunami TSU-AT1000 Application note

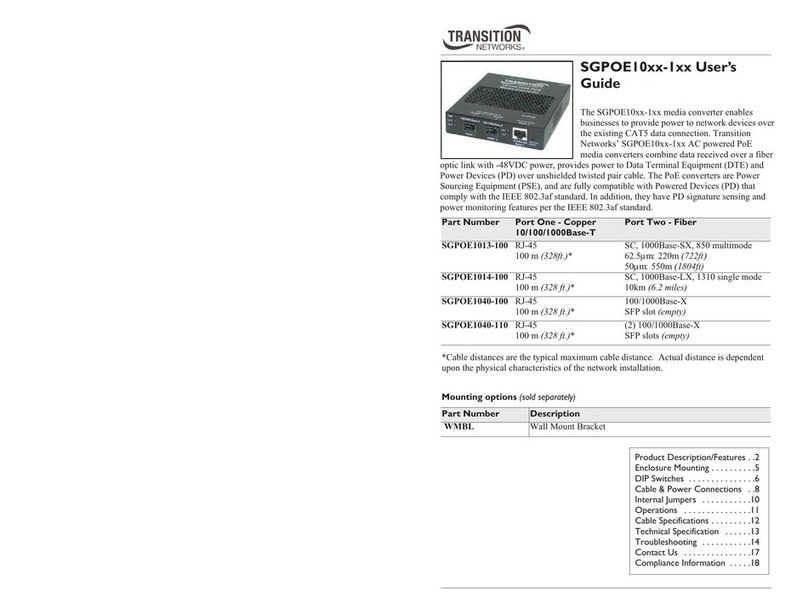

Transition Networks

Transition Networks SGPOE10 1 Series user guide

ClearClick

ClearClick Video2Digital user manual