DEGREE CONTROLS Rooster Monitor100 User manual

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 1 of 33

User Manual

This is proprietary information of Degree Controls Inc., contents are protected under US copyright laws © Degree

Controls, Inc. 2020.

High Performance Airflow Monitor

with Full-Color Touch Screen Display

Version 1.04

Complete Kit includes:

oAlarm Module

oChoice of Sensor Type

oPower Supply

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 2 of 33

Contents

Contents ........................................................................................................................................................................2

Product Overview ..........................................................................................................................................................3

Hard Button Overview ...............................................................................................................................................3

Soft Buttons and Home Screen Layout ......................................................................................................................4

Feature Overview ......................................................................................................................................................4

Rear Panel Layout for Advanced Connections...........................................................................................................7

Technical Specifications.................................................................................................................................................8

Connection and Wiring Information..............................................................................................................................8

Sash Input..................................................................................................................................................................9

Night Setback Input...................................................................................................................................................9

Alarm Outputs .........................................................................................................................................................10

Mechanical Information ..............................................................................................................................................10

Alarm Module..........................................................................................................................................................10

Probe Sensor............................................................................................................................................................11

Sidewall Sensor........................................................................................................................................................11

Inline Sensor ............................................................................................................................................................11

Installation...................................................................................................................................................................12

Back Plate Mounting Options - Alarm Module........................................................................................................12

Installation Procedure .............................................................................................................................................12

Probe Sensor............................................................................................................................................................13

Sidewall Sensor........................................................................................................................................................14

Single Walled Cabinet .........................................................................................................................................14

Dual Walled Cabinet ...........................................................................................................................................16

Inline Sensor ............................................................................................................................................................17

Boot Up Procedure ......................................................................................................................................................18

Access Tier Privileges: USER, EH&S & CERTIFIER ........................................................................................................19

Set/Change Passwords ................................................................................................................................................20

Calibration Procedure..................................................................................................................................................20

Calibration Troubleshooting....................................................................................................................................22

Alarm Threshold Configuration ...................................................................................................................................23

Alarm Troubleshooting............................................................................................................................................23

Alarm Controls.............................................................................................................................................................24

Night SetBack ..........................................................................................................................................................24

Alarm Ringback .......................................................................................................................................................24

Alarm Delay.............................................................................................................................................................25

Startup Delay...........................................................................................................................................................26

Latch Alarm .............................................................................................................................................................26

Alarm Tone Settings ................................................................................................................................................26

Backlight Dimming.......................................................................................................................................................27

Airflow Sensitivity........................................................................................................................................................27

Airflow Resolution .......................................................................................................................................................28

I/O Polarity...................................................................................................................................................................28

Import/Export..............................................................................................................................................................29

EEPROM...................................................................................................................................................................29

Event Log .................................................................................................................................................................29

USB Field Upgrade Procedure .....................................................................................................................................30

Soft Reboot Procedure to Upgrade Rooster TM Monitor100 Operating System .......................................................30

Power Cycle Procedure to Upgrade Rooster TM Monitor100 Operating System ......................................................30

Factory Reset Procedure .............................................................................................................................................31

GUI Map.......................................................................................................................................................................32

Warranty......................................................................................................................................................................33

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 3 of 33

Product Overview

Congratulations on your purchase of the RoosterTM Monitor100. The RoosterTM Monitor100 is a

next-generation airflow monitoring and alarm system for use in a variety of critical containment

applications, where airflow is required to be viewed, monitored, alarmed, and communicated to

building and laboratory systems.

A brief overview of the RoosterTM Monitor100’s many features, including but not limited to:

Glove-friendly touchscreen.

Best in class air velocity sensing.

Sensor for canopies, negative pressure cabinets, and for use in

hospital/laboratory/kitchen.

Quick, 2 step calibration process.

Bright backlit display.

Password protected access tiers limit access to critical functions for authorized users.

Data and event logging for your airflow safety compliance needs.

Import/export configuration file to save setup time and ensure consistency among all

RoosterTM Monitor100s in your facility.

The RoosterTM Monitor100 is the first airflow alarm monitor that allows USB-based plug and play

firmware upgrades, to keep your product current and operating to the latest standards.

This manual will guide you through installation, calibration procedures, firmware upgrades,

alarm control settings, and the full range of features for the RoosterTM Monitor100.

Hard Button Overview

MUTE

Mutes the audible alarm, any time it is sounding. When the alarm has

been muted, a mute icon [ ] will appear in the top center portion

of the home screen. Just like a snooze button, the audible alarm will

re-sound, when the configurable time-out is reached if ringback has

been enabled.

HOME

Returns the user to the home screen when pushed from any menu or

info screen. *Cannot be used to abort the calibration procedure and

some critical system functions.*

LED

A red LED will flash while an airflow alarm is active. The red LED will

also flash if Sash High and Night Setback alarms are active. In all

other cases, this LED will remain off.

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 4 of 33

Soft Buttons and Home Screen Layout

Feature Overview

CUSTOM ASSET TAG

Users logged in as EH&S can change default “Asset Tag” to a custom tag. This is useful

for naming the chemical fume hood, or company asset, or laboratory. A 12-digit numeric

asset tag can be set with the provided on-screen keypad, OR plug in a USB interface

keyboard to enter a 12-character alphanumeric tag. Users can enable or disable display of

the Asset Tag.

Home> Settings>System>Advanced>Configure Asset Tag

CLOCK

Users logged in as EH&S or Certifier can set time, date and change clock to display in 12

or 24-hour format.

Home> Settings>System>Date & Time>Date & Time Settings

KEYPAD AND BUTTON SOUNDS

Users may toggle keypad and button beep sounds on and off.

Home> Settings>System>Alarms/Sound>Key Beep

DEVICE VOLUME

Users can toggle through low, medium or high alarm volumes. If logged in as EH&S or

Certifier, a global minimum volume threshold can be set. This restricts a standard user

from setting an alarm volume too low for particular facility safety requirements.

Home> Settings>System>Alarms/Sound>Device Volume

Startup Delay Indicator

Night Setback/Mute Indicator

Asset Tag

Air Temperature

(touch to toggle units)

Face Velocity

(touch to toggle units)

Settings Menu

USB input for keyboard

and firmware upgrades

Time of Day

Alert Banner

Quick access to current

configuration settings

including: alarm thresholds,

calibration date, and

firmware version

Status Color (Green, Yellow

or Red)

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 5 of 33

ON-SCREEN ALERT BANNERS

A yellow banner will appear beneath on-screen velocity readings to alert users regarding

various scenarios: Low Airflow, Power Failure

Home

TOGGLE VELOCITY UNIT TYPE

Instantly toggle displayed velocity units from m/s to fpm, or vice versa, by pressing on the

displayed velocity reading on the home screen.

Home

TOGGLE TEMPERATURE TYPE

Instantly toggle displayed temperature units from Fahrenheit to Celsius, or vice versa, by

pressing on the displayed temperature reading on the home screen.

Home

PASSWORD-PROTECTED ACCESS TIERS: CERTIFIER & EH&S

Password protected access tiers enable advanced configuration options and features.

Home> Settings>System>Advanced>Change Passwords

USB INTERFACE FOR UPGRADES, DATA EXPORT & SETTINGS IMPORT/EXPORT

Firmware upgrades can be installed on-site via USB flash drive. See the USB Field Upgrade

section of this manual for more information.

Users can export the event log in .csv format to a USB thumb drive.

RoosterTM settings can be saved to a USB thumb drive for future use or for download

onto neighboring RoosterTMs.

CUSTOMIZABLE BOOT SCREEN

Our engineers can configure your unit with a custom image or logo file (240x320) in

portable network graphic (.png) format to display on bootup. Contact our sales team to

get started: sales@degreec.com

NIGHT SETBACK

EH&S or Certifier users can configure 3 convenient modes (Audible, Muted, or Off) of

operation.

The RoosterTM Monitor100 is a normally open device. To trigger audible or muted night

setback, the dry contact relay must be closed. See the Calibration Procedure for

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 6 of 33

instructions on how to setup night setback alarm thresholds.

Home> Settings>System>Alarms/Sound>Alarm Controls>Night Setback

ALARM LATCHING

EH&S or Certifier users can setup latched alarms to indicate that a low airflow state has

occurred in the “Alarm Controls” menu. User must then enter a EH&S or Certifier

passcode to unlatch an alarm.

Home> Settings>System>Alarms/Sound>Alarm Controls>Latch Alarm

ALARM RINGBACK

EH&S or Certifier users can configure the amount of snooze time before an alarm rings

again after being muted in the “Alarm Controls” menu. Optionally, the audible alarm can

be turned off completely.

Home>Settings>System>Alarms/Sound>Alarm Controls>Alarm Delay Settings>Ringback

BACKLIGHT DIMMING

Users can toggle the brightness setting, as well as the brightness of the screen when set

to “dim”. A “time before dim” option is available that sets the screen to dim after a

predetermined amount of time has expired.

Home> Settings>System>Brightness

AIRFLOW RESOLUTION

EH&S or Certifier users can select the units of measurement displayed for the resolution

of air velocity in either meters per second or feet per minute.

Home>Settings>System>Airflow Settings>Airflow Resolution

TWO POINT CALIBRATION

For greater accuracy and performance, the RoosterTM Monitor100 uses a two-point

calibration procedure to collect both a high velocity and low velocity reference point. The

low velocity reference point is collected by leaving the sensor cover in place while

performing this calibration step (note: for probe sensor calibration only). See the

Calibration Procedure section of this manual.

Home>Settings>Calibration>Calibrate

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 7 of 33

Rear Panel Layout for Advanced Connections

Figure 1 Connections

Connection

Description

Connector Type

Mating Connector

Power Entry

2-Pin, polarized, Phoenix

Contact

Included and attached to AC/DC power supply

Sensor Connection

RJ-11

Included as part of sensor assembly

Output Connection

8-pin, polarized, Phoenix

Contact

*2-position connectors will fit

Not included

8-position orderable Part Number: Phoenix Contact 1803633

2-position orderable Part Number: Phoenix Contact 1803578

Input Connection

10-pin, polarized, Phoenix

Contact

*2-position connectors will fit

Not included

10-position orderable Part Number: Phoenix Contact 1803659

2-position orderable Part Number: Phoenix Contact 1803578

Table 1 Connections - Rear Panel of Display Module

Optional Sash Switch kit, Degree Controls P/N: 62310AS004 includes 10-postion Phoenix

Contact connector.

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 8 of 33

Technical Specifications

Connection and Wiring Information

Degree Controls recommends 18-24 AWG wire be used for all wiring connections to the input

and output connectors. The Sensor and Power Entry connections have been prepared for you,

and merely need to be pulled through the openings and connected to the display module. If the

Sash Switch option is purchased, this is pre-connectorized for you as well.

The RoosterTM Monitor100 has additional input and output capabilities for night setback and

customers using their own sash switch. These cable harnesses should be prepared by the client,

using the orderable mating connectors listed above.

The I/O connectors present on the RoosterTM Monitor100 have some pins deactivated as these

are reserved for future Rooster TM models designed for more advanced control functionality:

oOutput Connector, Pins 5-8

oInput Connector, Pins 7-10

Leave these pins non-connected.

Alarm Module Size

82mm x 135mm x 19mm (3.2” x 5.3” x 0.7”)

(without back plate)

LCD Display Area

57mm x 70mm (2.3” x 2.7”)

Airflow Velocity Range

30-2,000 fpm (0.15- 10.0 m/s)

Response Time

< 1 second

Supply Voltage

24VAC/VDC & Wall Adapter

Night-Set Back Input

Dry Contact Closure (0V)

Pins 5-6

Sash Switch Input

Pin 1= +15V Power (For Proximity SW)

Pin 2= SASH (Contact or Proximity)

Pin 3= GND (Contact or Proximity)

Relay Outputs

Qty. (2), 1A, 24VDC

Pins 1-2 Air Alarm

Pins 3-4 Sash Alarm

Power Adapter

90-250V

Red LED indicator

160° viewing angle

Alarm Volume

0 - 85dB (adjustable)

Relative Humidity

(non-condensing) 5 - 95%

Operating temperature

5°C - 60°C (40°F - 140°F)

Storage temperature

-40°C - 85°C (-40°F - 185°F)

Weight

<170g (<6oz)

Compliance Standards

CE, RoHS

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 9 of 33

Sash Input

This sash position input is a digital input, and the default I/O polarity of this input is normally

open. The design intent is as follows:

When the sash is in a safe position, the proximity sensor should not detect metallic

object/strip.

Sash position input logic may be reversed using the I/O polarity menu on the Rooster™

Monitor100 to achieve a different result, and any proximity sensor may be implemented.

Degree Controls can provide you with an optional Sash Position Sensor comprised of (1)

inductive proximity sensor and (1) 10-position connector which mates to the input connection

of the display module. This inductive proximity sensor switches state when it contacts metal

surfaces. This sash sensor is a normally open device, meaning it closes upon sensing metallic

objects.

The DegreeC Sash Position Sensor (Part# 62310AS004), comes with three stripped and tinned

wire leads:

Brown = +15V

Black = Sash

Blue = Ground

Wire these in their respective positions 1, 2, and 3 on the input connection block.

Note: For implementation support, or for users preferring to use a micro-switch for sash alarm

activation, please contact Degree Controls.

Night Setback Input

The RoosterTM Monitor100 allows the user to connect to a digital input, dry contact, on positions

5 & 6 of the Input Connector, for Night Setback. The purpose of the Night Setback input is to

provide the user with the ability to send a remote signal to all RoosterTM Monitor100s

simultaneously, to change their behavior during low flow conditions. This signal is normally

initiated by a Laboratory or Building Management System (BMS).

Once the wiring connections are made, the user can assert, and also remove, the Night Setback

signal via the BMS. Three Monitor100 night setback states can be selected.

Audible: In this state, when a Night setback signal is asserted, the Monitor100 will still

audibly alarm when airflow drops below the NSB trip threshold. Note: NSB threshold is

independently set.

Muted: In this state, when the Night Setback signal is asserted, the Monitor100 will

alarm (screen will display a red background, and the LED will flash) when airflow drops

below the NSB trip threshold, but the alarm will be muted.

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 10 of 33

Off (default): In this state, when the Night Setback signal is asserted, the Monitor100

will ignore it.

Alarm Outputs

The RoosterTM Monitor100 alarms for airflow and sash position. The Alarm outputs are relay

outputs available on the output connection of the display module. I/O polarity logic of outputs

may be reversed as well. See the I/O Polarity menu of the Rooster™ Monitor100.

Mechanical Information

Alarm Module

Figure 2 Alarm Module with Wall-Mount Back Plate

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 11 of 33

Probe Sensor

Figure 3 Probe Sensor

Sidewall Sensor

Figure 4 Sidewall Sensor

Inline Sensor

Figure 5 Inline Sensor

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 12 of 33

Installation

Installation of the RoosterTM Monitor100 involves selecting and preparing appropriate locations

for the alarm module and sensor, wiring and connecting the unit, and then mounting both the

alarm module and sensor securely.

Back Plate Mounting Options - Alarm Module

The RoosterTM Monitor100 is mountable to a cabinet or wall panel by first securing the back plate.

Once this is complete, the RoosterTM is easily aligned to the back plate and secured with bottom

captive screw. Two back plate versions are available:

1. Wall Mount: This back plate sits directly on the wall or cabinet surface, and is secured by

self-tapping screws, or industrial Velcro. Sensor and control wiring access is at the back,

while access for power in from the wall mount power supply is at the bottom of the back

plate.

2. Semi-Flush: This back plate sits partially inside a standard electrical gang box, allowing the

RoosterTM to be recessed and sit approximately 15mm [0.6”] proud of the mounting surface.

Self-tapping screws secure it, and there is open back access to accept building power.

Figure 6 Wall Mount (left), Semi-Flush Mount (right) - for Alarm Module

Installation Procedure

1. Determine mounting locations for the RoosterTM Monitor100 alarm module and sensor.

2. Choose alarm module mounting method: Wall Mount or Semi-Flush.

3. Mark the surface where the RoosterTM Monitor100 alarm module will be located, and

make the necessary drills/cutout.

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 13 of 33

4. Secure back plate.

5. Mount the sensor. See below for sensor installation descriptions with different sensor

styles.

6. Feed power and sensor wire harnesses through the opening(s) and make connections to

the RoosterTM Monitor100 alarm module. Make any other optional connections to the

alarm module.

7. Align top of alarm module with tabs on back plate, and secure in place with captive

screw at bottom of alarm module.

Figure 7 Wall Mount Back Plate Mounting

Figure 8 Semi-Flush Back Plate Mounting

Probe Sensor

The Probe sensor should be located in the duct system in the

best laminar (stable) flow possible. The sensor should be

placed at least two duct diameters away from duct elbows and

constrictions, and follow ASHRAE best practices.

Probe sensor installation steps:

1. Drill 16mm [5/8”] hole.

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 14 of 33

2. Adjust insertion depth and tighten (A) gland nut onto sensor probe.

3. Insert into duct hole, with wider flange first, and then rotate into position.

4. Tighten mounting nut (B) in left-hand direction.

5. Make sure the sensor head faces airflow by positioning the probe elbow in the flow

direction.

A gland fitting is included with the Probe sensor. (Gland Fitting, Degree Controls P/N: HA1203)

Sidewall Sensor

When determining the face velocity of a negatively pressurized

cabinet, the Sidewall sensor is often the best choice, as it measures

clean, temperature-controlled, laboratory air. This is preferable to

measuring potentially heated, dirty air in the exhaust duct. The

Sidewall sensor has a removable air screen, which is washable and

provides the sensor with a level of protection against tampering.

Single Walled Cabinet

When an airflow channel only needs to pass through a single sheet metal panel, the “single wall”

installation method is required. This is most typical when the Sidewall sensor is mounted on the

side of a cabinet, and airflow simply travels through the sensor body with no need for additional

ducting. In this case, the user will not need to use the PVC flex tubing, nor the end cap, which is

included in the RoosterTM Monitor100 assembly.

A

B

Figure 9 Probe Sensor Installation

Single hole drilled

16.1mm (5/8”) Dia

Figure 10 Align Sensor Head Into Direction of

Airflow

Curve in sensor

probe aligns wire

and sensor head

into direction of

airflow

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 15 of 33

Figure 11 Sidewall Sensor on Single Walled Cabinet

Figure 12 Sidewall Sensor Mounting –Single Walled Cabinet

Figure 13 Sidewall Sensor Mounting Dimensions

Self-tapping

mounting screw

Extends through wall,

no ducting needed

RJ11 connection to

RoosterTM Monitor100

10-16 x 1”

self-drill screw

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 16 of 33

Dual Walled Cabinet

For those installations where the Sidewall sensor will be on the front face of the fume hood, and

a duct is needed to create an airflow path from the front face to the inside face of the cabinet,

the “dual walled” installation method is required. This method is also required for installations

where the Sidewall sensor is mounted on the side, but there are two sheet metal walls for the air

flow to travel through. In both of these scenarios, the Sidewall sensor will need to be installed

according to the “dual walled” method depicted in the diagram below. The dual walled solution

simply involves the use of the supplied PVC tubing and end cap.

Figure 14 Sidewall Sensor on Dual Walled Cabinet

Figure 15 Sidewall Sensor Mounting –Double Walled Cabinet

10-16 x 1”

self-drill screw

Flow-through

tube

Exterior cabinet

surface

Interior cabinet

surface

RJ11 connection to

RoosterTM Monitor100

10-16 x 1”

self-drill screw

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 17 of 33

Figure 16 Mounting Dimensions –Wall 1 (Front) Figure 17 Mounting Dimensions –Wall 2 (Rear)

Inline Sensor

We recognize that certain airflow monitors, already installed in cabinets,

may have failed in the field or do not meet the level of safety required in

recent years. In addition, in some installations, the equipment manager

may require a sensor installation where tampering is prevented, by

moving the sensor assembly out of sight and away from any tool access.

For this reason, the RoosterTM can be ordered with an inline sensor which

is quickly connected by splicing into the existing ½” flow tube being

used by another monitor. The suggested installation procedure is

depicted below. *Inline sensor includes sensor and tubing only. Call

Degree Controls for pricing on additional installation components.

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 18 of 33

Figure 19 Suggested Inline Sensor Installation

Boot Up Procedure

The RoosterTM does not have a power-on switch and will become energized as

soon as it is plugged in. The RoosterTM boots to the screen depicted on the

right, with a slot for a custom logo. The boot screen is designed to support a

custom image or logo file in portable network graphic (.png) format with

(240x320) dimensions. This feature must be requested and is not setup for

manual configuration. Once the start procedure has completed, the Home

screen will appear with two system buttons and an “Uncalibrated” message on

the yellow status banner across the screen. Before performing a first-time

calibration of your unit, you will need to setup password-protected access

tiers for advanced system functions (Calibration requires a Certifier passcode). This is explained

in the “Access Tier Privileges” section below.

The RoosterTM Monitor can be rebooted at any time by pushing the hard “Home”and “Mute”

Buttons simultaneously until the boot screen reappears.

10-16 x 1”

self-drill screw

Flow-through tube

for ½” tubing

connections

Exterior cabinet

surface

Interior cabinet

surface

RJ11 connection to

RoosterTM Monitor100

Figure 18 Inline Sensor Includes

Sensor with Cable and Tubing Only

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 19 of 33

Access Tier Privileges: USER, EH&S & CERTIFIER

Users have the ability to customize their containment

cabinets within a defined set of options for each

authorization level. There are three levels of access to the

RoosterTM: User, EH&S/Facility Manager and Certifier.

These are managed by logging in with a 4-digit

numerical passcode. The User access level does not

require a passcode.

Access Privileges Defined

Function

Passcode Required

Adjust Alarm Volume

None

Set Minimum Alarm Volume Threshold (superceded by Alarm Tones

Settings)

EH&S, Certifier

Alarm Ringback Setting

EH&S, Certifier

Alarm Delay Setting

EH&S, Certifier

Startup Delay Setting

EH&S, Certifier

Alarm Latching Setting

EH&S, Certifier

Alarm Tones Settings

EH&S, Certifier

Mute Live Alarm

None

Perform Calibration

Certifier

Set Asset Tag

EH&S

Set Time / Clock Format

EH&S, Certifier

Import / Export

EH&S, Certifier

Toggle between Fahrenheit or Centigrade Temperature Units on Home

Screen

None

Toggle between Metric or Imperial Air Velocity Units on Home Screen

None

Toggle ON/OFF Keypad Sounds

None

Unlatch Alarm (if Alarm Latching is set to Password)

EH&S

Manufacturer default passcodes:

EH&S = 8377

Certifier = 6425

Rooster™ Monitor100 USER MANUAL

Rooster™ Monitor100 USER MANUAL 62310MN000-A04 20 of 33

Set/Change Passwords

To change or set a password, follow this GUI path to trigger the password change sequence:

Home> Settings>System>Advanced>Change Passwords

You will have to enter an EH&S or Certifier passcode to get access to the “Advanced” menu. To

change either the EH&S or Certifier passcode, you must first re-enter the old passcode. Please

note that if you have authorization to perform both EH&S and Certifier functions, you may set

an identical passcode for both access tiers to make logging in and accessing key functions

easier.

Calibration Procedure

Once you have installed and booted up your RoosterTM Monitor100, you must perform a first-

time calibration to set the alarm threshold and establish both low velocity and normal

operational velocity set points. Follow this procedure to get your unit calibrated:

1. Before calibrating your unit, you must first make sure that the system clock and date are

accurate, because the RoosterTM saves the date and time of calibration for quick

referencing. Follow the path below, and set an accurate date and time (you may choose

to set the clock in 12 or 24-hour format).

Home> Settings>System>Date & Time>Date & Time Settings

2. Navigate to the Calibration screen by following this path:

Home> Settings>Calibration

3. Push the grey “Calibrate” button to enter the Calibration menu screen.

Home> Settings>Calibration>Calibrate

4. In order to proceed, you will need to enter your “Certify”password. If

you have not set a custom password, the factory default is “6425”

Home> Settings>Calibration>Calibrate

5. For your initial calibration, keeping the default "Normal" value for

"Allowed Turbulence" is recommended. Setting the “Allowed

Turbulence” to “High” will help you overcome cabinet-level airflow

instability issues. In most cases, changing this setting to “High” is not

necessary. It should be reserved for rare circumstances where there is difficulty achieving

stable, laminar airflow.

Home> Settings>Calibration>Calibrate>Allowed Turbulence

Table of contents

Popular Security System manuals by other brands

Velleman

Velleman DWH G955 Installation and operation instruction manual

ADEMCO

ADEMCO VISTA-48D Installation and setup guide

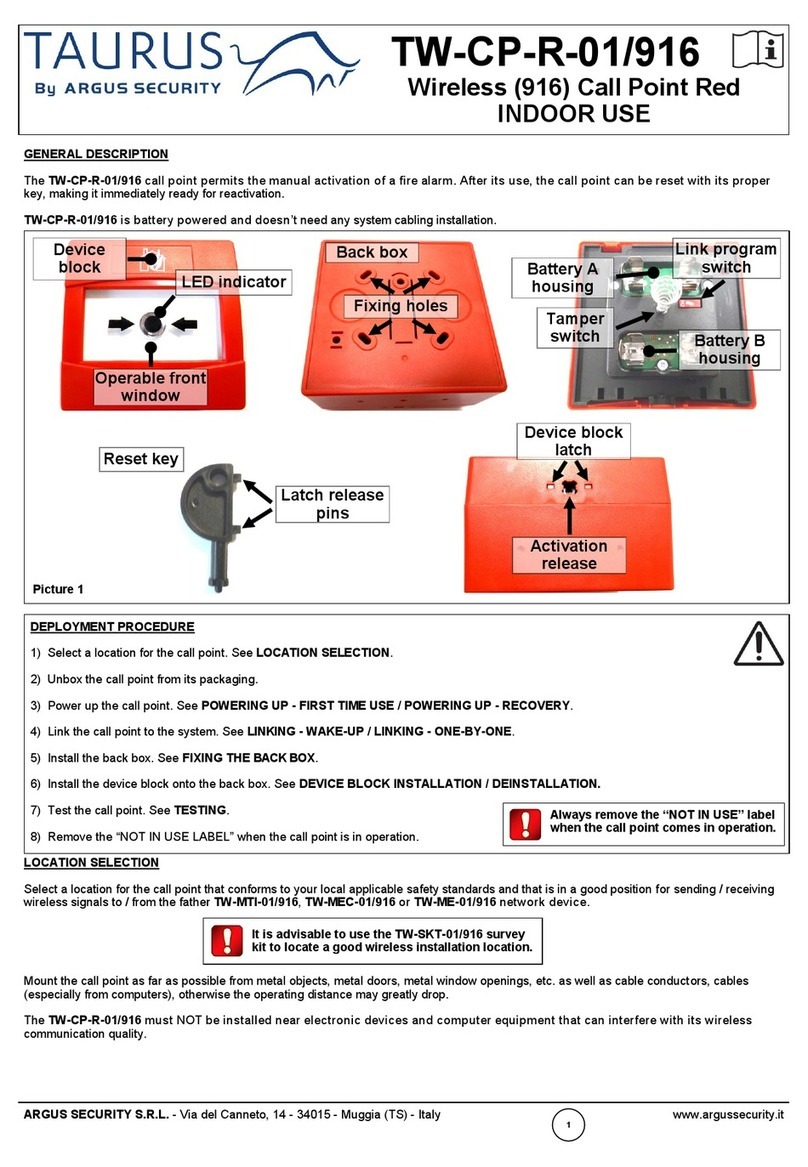

Argus

Argus TAURUS TW-CP-R-01/916 quick start guide

E2S

E2S SPECTRA H110 T instructions

Hella

Hella 3SL 996 139-101 installation instructions

Haake

Haake HST-TZ2 Installation and operating manual