DEHN + SÖHNE DEHNrecord DRC SCM XT User manual

Operating Manual

DEHNrecord DRC SCM XT

DEHN + SÖHNE

Issued by : DEHN + SÖHNE GmbH + Co. KG.

BA 1818 / V 1.001 – Update 01/13 / Id.-No. 067335

© 2012 DEHN + SÖHNE / protected by ISO 16016

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 2 of 32 Date: 2013/01/16

Note:

The information provided in the present document may be modified without advance notice. DEHN

+ SÖHNE GmbH + Co.KG. cannot be held liable for any changes made.

Index

1. Terms and Definitions ......................................................................................3

2. Literature / References.....................................................................................3

3. Application .......................................................................................................4

4. LifeCheck® .......................................................................................................4

5. Device Description ...........................................................................................5

6. Design/Configuration .......................................................................................9

7. Wiring.............................................................................................................10

7.1 Power supply..................................................................................................................10

7.2 Remote signalling contact..............................................................................................10

8. Configuration .................................................................................................11

8.1 Number of SPDs to be monitored...................................................................................11

8.2 Device address/Group No...............................................................................................11

9. Programming of SPDs.....................................................................................12

9.1 Direct programming at the DRC SCM XT monitoring device .........................................12

9.2 Offline programming by DRC LC M3+ handheld reader.................................................15

10. Commissioning of DRC SCM XT.....................................................................17

11. Monitoring Status .........................................................................................18

12. Maintenance at Monitoring Status Replace SPD ..........................................19

12.1 On-site determination by pushbutton function at the DRC SCM XT..............................19

12.2 Offline determination by handheld reader DRC LC M3+...............................................20

13. Other Functions of the DRC SCM XT .............................................................22

13.1 Abort during an ongoing test cycle ................................................................................22

13.2 Restore of factory setting / of status when delivered .....................................................22

13.3 Resetting of SPDs...........................................................................................................23

14. Technical Data................................................................................................25

15. Projecting/Instructions for Use......................................................................26

16. Safety Instructions .....................................................................................27

17. Maintenance and Care ..................................................................................28

17.1 Software update.............................................................................................................28

17.2 Cleaning.........................................................................................................................28

17.3 Transport and storage ....................................................................................................28

17.4 Disposal..........................................................................................................................28

18. Problems/Possible solutions..........................................................................29

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 3 of 32 Date: 2013/01/16

1. Terms and Definitions

BLITZDUCTOR®

Surge protection module manufactured by DEHN + SÖHNE

DEHNrecord DRC LC M3+

DEHNrecord DRC LC M3+ is a compact handheld reader with integrated RFID technology for non-

contact testing of surge protection modules (Blitzductors®).

DEHNrecord DRC MCM XT

DEHNrecord DRC MCM XT is a compact monitoring device with integrated RFID technology for sta-

tionary testing of surge protection modules (Blitzductors®) in single and multiple application.

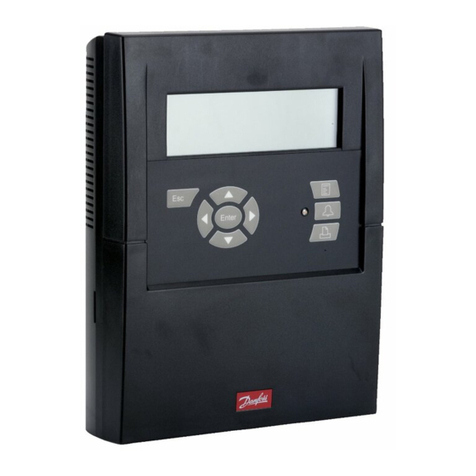

DEHNrecord DRC SCM XT

DEHNrecord DRC SCM XT is a compact monitoring device with integrated RFID technology for sta-

tionary testing of surge protection modules (Blitzductors®) in single device application.

HW

Hardware

SW

Software

LifeCheck®

Test for correct functioning of the surge protection modules during system operation without remo-

ving them.

RFID

Radio Frequency Idendification – Identification procedure per radio technology which allows for

non-contact reading and saving of data.

SPD

Surge Protection Device – surge protection module

FM

Floating remote signalling contact

2. Literature / References

/1/ Operating manual DEHNrecord DRC LC M3+

Issued by : DEHN + SÖHNE

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 4 of 32 Date: 2013/01/16

3. Application

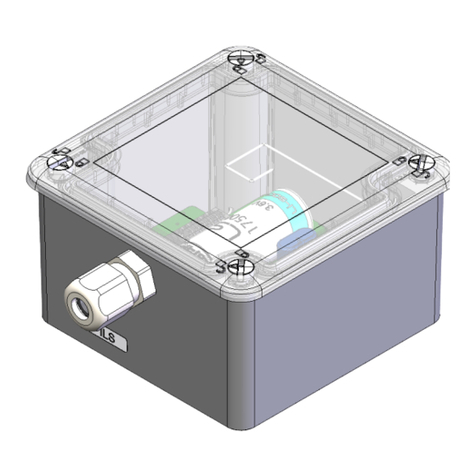

DEHNrecord DRC SCM XT is a compact monitoring device in an XT enclosure with integrated RFID

technology (Radio Frequency Identification) for non-contact stationary monitoring of surge protec-

tion modules (SPDs). SPDs and monitoring device are marked with the LifeCheck®symbol.

LifeCheck®Symbol:

Up to 10 surge protection modules (Type BLITZDUCTOR®with integrated LifeCheck®) can be assig-

ned to one DRC SCM XT monitoring device.

The following surge protection modules are equipped with LifeCheck®technology:

- BLITZDUCTOR®CT; Type: BCT MLC ...

- BLITZDUCTOR®XT; Type: BXT ML...

- BLITZDUCTOR®XT; Type: BXT ...EX...

- BLITZDUCTOR®XTU; Type: BXTU ML...

The status of this “group” of protection modules is continuously contactless checked via the DEHN-

record DRC SCM XT monitoring device, it is displayed by an integrated LED and signalled by a

potential-free remote signalling switching contact. Both the LED indicator and remote signalling

contact provide general information about the operating state of all protection modules assigned

to the monitoring device:

- All protection modules of the group are okay

- Replacing of at least one protection module necessary

A detailed fault diagnosis either is provided by

- the LED which is integrated in the monitoring device, or

- by manually testing of the individual SPDs with the handheld reader DEHNrecord DRC LC M3+

4. LifeCheck®

Protection modules with LifeCheck®symbol are equipped with a combined RFID based transmission

and monitoring unit. Thermal and electrical overloads of the surge protective device will be reliably

detected.

With the stationary monitoring device DEHNrecord DRC SCM XT, the proper state of these surge

protection modules (Type BLITZDUCTOR®) can be permanently monitored and remotely signalled to

a supervising control centre.

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 5 of 32 Date: 2013/01/16

5. Device Description

The stationary monitoring device DEHNrecord DRC SCM XT consists of

- a special base part for DIN

rail mounting and wiring

- a plug-in module which

includes the condition

monitoring unit

The standard delivery includes a quick guide1) and the labelling system BS BA1.

Current versions of

- Detailed operating manual for DRC SCM XT (Publication No. 1818)

- Operating manual for handheld reader DRC LC M3+ /1/

- Device software for the handheld reader DRC LC M3+ /1/

are available for downloading download under www.dehn.de/download/.

1) Publication No. 1809, see also www.dehn.de

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 6 of 32 Date: 2013/01/16

BA1

Plug-in module DRC SCM XT for inserting/snapping into the base part ; monitoring

device for stationary, permanent LifeCheck®of up to 10 BLITZDUCTOR®XT (or CT).

Button for controlling the DRC SCM XT via the following function:

ctrl controls the detailed status indication via the LED or the

programming of an SPD

Three options are provided: press short (<2 sec.), press long (>5 sec.) and press until chan-

ging of function is recognised.

An ongoing test (LED, orange permanent light) may be interrupted by pressing the button,

see also (“Extended functions for the DRC SCM XT” in chapter 13).

push ctrl

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 7 of 32 Date: 2013/01/16

3-colours-LED for indicating the monitoring and device status. Function is

indicated by the LED flashing.

Device status

Start sequence:

Device status, fault / wrong configuration (DIP switch )

Programming mode

Monitoring status

All SPDs OK

Replace at least one SPD

e.g. SPD No. 3 ⇒ The number of red flashing pulses indicates the SPD No. of the first

SPD to be replaced.

4-fold DIP switch for configurating the monitoring device:

Attention:

Remove the plug-in module before configuration!

Function

Set the quantity (n) of SPDs to

be monitored.

Numbers 1..n then will also

be used as sequence number

for parameterising of the SPDs

monitored.

State when delivered 0

Admissible range 1 ... 10

Setting By setting the corresponding

binary code value: e.g. 10 (=

8+2)

8421

On Off On Off

!

⇒ Follow the quick guide!

Adhesive label: A labelling system which is included in delivery for marking the DRC SCM XT

with the SCM system address (BA1). This device address is necessary for programming the

SPDs for stationary monitoring or for localising damaged SPDs and for providing replacement

devices.

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 8 of 32 Date: 2013/01/16

Special base part for DIN rail mounting, with screw terminals, for insertion of the plug-in

module .

Terminal Function Note

+ / - External d.c. supply,, 18...48 V, max. 100 mA Any polarity

- / +

AFunction not implemented

B

13 Function not implemented Max.: 300 mW at;

d.c. 350 V; 120 mA

a.c. 250 V; 70 mA

Any polarity

14

21 Remote signalling contact 1 break contact, nc

22

!

Base part only for plug-in module DRC SCM XT ⇒ Follow quick guide!

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 9 of 32 Date: 2013/01/16

6. Design/Configuration

DRC SCM XT monitoring device allows for permanent LifeCheck®monitoring of up to 10 BLITZDUC-

TOR®XT or CT.

For monitoring of BXT...EX...modules, TW DRC MCM EX partitions are mandatory in order to ensure

the separation distance between intrinsically safe and not intrinsically safe current circuits! A space

requirement of at least 14 cm for a partition must be observed (e.g. distance from cable ducts at

least 14 cm, DIN rail arranged in the centre).

SPDs shall be equally assigned to the monitoring devices.

DRC SCM XT, however, must be arranged preferably in the centre of the assigned SPDs. Reserve

plug-in places are to be arranged on the outside. In case of a mixed monitoring of BLITZDUCTOR®

XT and CT they shall be arranged according to type each at one side.

Potential sources of interference, e.g. switching system components, providing an RFID similar fre-

quency, also shall be inserted in the minimum distance.

Single device application

DRC SCM XT is only for single device application, i.e. a minimum distance of 50 cm (all direc-

tions) must be kept between the individual DRC SCM XT, in order to exclude mutual influencing and

wrong measurements.

1.1

BA 1

1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 1.10

BA 1 1.1 1.2 1.3 1.51.4

BA 1

BA 1

1.1 1.2 1.3 1.4 1.1 1.2 1.41.3

BA 1

50 cm 50 cm

50 cm 50 cm

50 cm

min. 14 cm

The specified device address 1 (BA1) is applicable for each DRC SCM XT.The assigned SPDs have to

be programmed according to the number of SPDs to be monitored.

In addition to the connection of the remote signalling contact the DRC SCM XT only needs a d.c.

voltage supply.

partition TW DRC MCM EX

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 10 of 32 Date: 2013/01/16

7. Wiring

Remove the plug-in module for the wiring to be carried out at the base part.

Shown remote signalling contact: Function principle! Contact is integrated in the monitoring

module!

Optional remote signalling contact (FM)

Galvanically isolated switch contact

integrated in the DRC SCM XT monitoring

module. Voltage supply

UN18...48 V d.c.; max. 100 mA

max. 350 V d.c. / 120 mA PIN: +/-; -/+

250 V a.c. / 70 mA

300 mW

Pin: 21-22 break contact (nc)

*) Switch contact shown in its normal state (all monitored SPDs are OK), that is supply voltage is applied and the

DRC SCM XT module is plugged in.

Note:

Single-core, non-sheathed cables of intrinsically and non-intrinsically safe circuits routed together in

conductor bundles or cable ducts must be separated by an intermediate layer of insulating material

or an earthed metal intermediate layer in accordance with EN 60079-14. Separation is not required

if sheathed cables or cable shields are used in intrinsically and non-intrinsically safe circuits.

7.1 Power supply

Connect the device to d.c. supply at the terminals +/- and -/+ .

Polaritity: any

Nominal voltage (range): 24 (18...48) Vd.c.

Max. power consumption: 80 (100...60) mA

Smoothing and residual ripple of the power supply used, have to comply with the nominal voltage

range!

7.2 Remote signalling contact

Remote signalling of the monitoring state of each group is possible via the galvanically isolated

break contact which is integrated in the DRC SCM XT.

Without power supply the status of the FM contacts is at “Replace SPD”.

*)

22

21

+/- d.c.

-/+ d.c.

*)

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 11 of 32 Date: 2013/01/16

8. Configuration

The plug-in module must be removed for settings/changes of the device configuration.

When delivered all DIP switches are set to OFF. When starting operation therefore error is indicat-

ed (inadmissible configuration).

8.1 Number of SPDs to be monitored

The maximum number of 10 SPDs to be monitored is set laterally by 4 DIP switches . On starting

operation, the LED indicates error when setting 0 or >10.

DIP switch

State when delivered 0

Admissible range 1...10

Configuration Binary by setting of the

corresponding number,

e.g. 10 (=8+2)

8421

On

Off

On

Off

8.2 Device address/Group No.

The device address is also used as group no. of the assigned SPDs.

It is internally set to 1 and can not be changed.

The code for the SPDs to be programmed consists of the group no. and the consecutive position no.

within the monitoring group: Group number. Position number. As the group number is preset to 1,

only the position number varies. The code of an SPD at position five within the monitoring group

thus is: 1.5 (see also 9. Programming of SPDs).

On

Off

DEHN + SÖHNE Bedienungsanleitung DEHNrecord DRC SCM XT

protected by ISO 16016 12 von 32 Bearbeitungsdatum: 16.01.2013

9. Programming of SPDs

When delivered, the Blitzductors®XT and CT can not be used with a DRC SCM XT monitoring device.

The SPDs will be assigned to the respective DRC SCM XT only by a corresponding programming of

the RFID transponders in the SPDs.

When programming the SPDs, a definite code which includes the device address/group number of

the assigned monitoring device (fixed 1) as well as the consecutive number of corresponding Blitz-

ductor within the group is generated for every transponder and deposited there.

In operation the SPD then only responds to questions which include the code.

There are two possibilities of programming:

Direct programming at the DRC SCM XT monitoring device

Offline programming via handheld DRC LC M3+ reader

9.1 Direct programming at the DRC SCM XT monitoring device

SPDs are programmed via the SHOW mode of the DRC SCM XT. The mode is automatically started

if non-existent SPDs or SPDs to be replaced are detected during a LifeCheck test. This function also

allows for programming of SPDs with LifeCheck which are in the state as delivered, directly in the

installation without further auxiliaries.

Faulty SPDs can be easily replaced in case of maintenance or be programmed and inserted on site

at the initial commissioning of a system. At initial commissioning, the first LifeCheck test should be

aborted after the boot up by pressing button (see also 13.1 Abort of an ongoing test), the SHOW

mode then is immediately implemented (when delivered the monitoring status is set to “Replace all

SPDs”).

The SPDs are programmed via the button at the DRC SCM XT monitoring device and the LED status

indication. In the SHOW mode, the number of the first SPD to be programmed or replaced is indica-

ted by the number of red flashing pulses of the LED.

The following flowchart describes the programming of SPDs via the DRC SCM XT monitoring device.

Observe that only one unprogrammed SPD is in the base part for programming and all other unpro-

grammed SPDs are located at least 50 cm away from the monitoring device. Only this ensures that

always just one SPD is programmed with the corresponding code.

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 13 of 32 Date: 2013/01/16

Flowchart of SPD programming

!

Note: An ongoing LifeCheck test can be manually aborted by pressing the ctrl button

(see also 13.1 Abort of an ongoing test).

push ctrl

2

3

1a1b

> 5 sec.

Initial state when commissioning Remove faulty SPD during maintenance work

SHOW mode

Number of red flashing pulses corresponds to the SPD No. to be programmed/replaced

e.g. SPD No. 2

Programming mode activated

LED flashes orange

Press button

Press the ctrl button when the LED flashes orange and release it after the LED goes out.

Note: If the button is not pressed within one minute, the SHOW mode is terminated and

the monitoring cycle is restarted.

4

Keep button pressed for about 1 to 2 seconds for

programming

Press button

1-2 Sek.

3a

Press button for more than 5 seconds to jump to

the next SPD

⇒ Next SPD is shown

3b

Press button

⇒ Programming mode activated

Press short Press long

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 14 of 32 Date: 2013/01/16

!

push ctrl

3

click

5

6

8

7a7b

9

10

Always insert only one

unprogrammed SPD for

programming! Do not snap it

in completely (see pictures)!

Commissioning Maintenance work

Start programming

Press the ctrl button to start programming until the LED is continuously

illuminated orange.

Programming in progress … Wait for result!

Insert an unprogrammed SPD

Programming successful Programming failed 2)

3 sec. ⇒ SPD No. is indicated again (for new

programming attempt)

Attach label for programmed SPD address (SCM

address•position No.)!

Eindrücken

Eindrücken

3 sec.

Snap SPD into base part

Any other SPDs to be programmed? Next SPD No. is

automatically shown

Yes

No

End of programming

The SHOW mode is automatically terminated, a new test cycle is started.

Label SPD

2) see 18. Problems / Possible solutions

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 15 of 32 Date: 2013/01/16

9.2 Offline programming by DRC LC M3+ handheld reader

Description Offline programming via DRC LC M3+ - Part 1 Handheld reader display

Programming of SPDs for stationary monitoring without DRC SCM XT is

possible via the handheld reader DRC LC M3+. Minimum requirement is

a 1.1.02 version of DRC LC M3.

For updating of the device software use the PC software DRC SW Up-

date. Device software is available for downloading under www.dehn.

de/download/. For closer details on the device update please see the

operating manual for the handheld reader. /2/

Programming of the SPDs and all other functions for the SPDs in relation

to the DRC SCM XT and DRC MCM XT are collected at the DRC LC M3+

under the DRC MCM mode:

Selection of the submenu for programming of SPDs

Mode < - >

DRC MCM

Menu selection

Use the submenu item “SPD programme” for programming. After

confirmation enter at first the device address “01” of the SCM and the

consecutive number of the Blitzductor to be programmed.

Use the blue arrow keys to change between entering the device

address and the SPD number.

DRC MCM:

SPD programme

ADR=01 SPD=01

SPD prog. -> OK

The modules must be removed for individual programming.

LifeCheck symbol

DE H N r ec o r d

DRC LC M3

DE H N r ec o r d

DRC LC M3

RFID

signal

Note: During the programming there must not be any other unprogrammed SPD within a

distance of 50 cm from the LifeCheck sensor!

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 16 of 32 Date: 2013/01/16

Description Offline programming via DRC LC M3+ - Part 2 Handheld reader display

Snap the sensor of the DRC LC M3+ on the SPD to be programmed

before programming.

Do not remove the sensor from the SPD during the programming.

The programming result is indicated as LifeCheck OK or replace SPD.3)

If the programming fails again, it has to be checked, perhaps the SPD is

already programmed. Use the submenu „Check/Search“ to find it out.3)

Confirming the result automatically leads to the next consecutive num-

ber withing the group, which provides a quick progress, or a consecutive

number may also be set via the number keys. (Use the blue arrow keys

to change between device address and SPD number!)

Label programmed SPDs immediately! With the consecutive number

(1,2,...,9,10) or in connection with the group no./device address of the

DRC SCM XT (1.1,...,1.10)!

Programming can be checked by checking the SPDs in the submenu

“Check/Search”.

Enter device address and number of SPDs to be monitored.

Select submenu “Check SPD”

Snap the LifeCheck sensor on the

SPD and start checking

Do not remove the sensor from the SPD during the test!

The result of the LifeCheck test is shown as LifeCheck OK or replace

SPD.3)

Check the status of the removed SPD with the DRC LC M3+ handheld

reader, if testing fails repeatedly.3)

After successfully programming of all SPDs, the stationary DRC SCM XT

monitoring device can be started.

Note: Deviating scope of function and programming sequence when using the DRC LC M3 handheld reader,

observe Operating manual BA 1670/V.1.1.0.1 “Extension for the Stationary Monitoring Device

DRC MCM XT”!

3) See Operating Manual DRC LC M3+. /1/

ADR=01 SPD=01:

SPD prog. --> OK

-Programming-

Please wait!

LifeCheck OK

ADR=01 SPD=01

ADR=01 SPD=02

SPD prog. -> OK

DRC MCM:

Check/Search

Configuration

ADR=01 SPD=10

Check SPD

ADR=01 10*SPD

ADR=01 SPD=01

Check SPD -> OK

-Checking-

Please wait!

LifeCheck OK

ADR=01 SPD=01

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 17 of 32 Date: 2013/01/16

10. Commissioning of DRC SCM XT

or 1 min.

LED

LED

21 22

21 22

e.g. SPD No. 2

1a

1

2

3

1b

3a

3b

21 22

21 22

!

21 22 21 22

3 min.

Checking the assigned SPDs

Status display

Display of the monitoring status

Note:

Ongoing tests (LED ) can be aborted by pressing the ctrl

button (see 13.1)!

Applying the supply voltage to the DRC SCM XT or plugging the module into the

connected base part starts the device with the

Boot up

Checking the configuration (DIP switch see 8.1)

DRC SCM XT automatically loads the last valid monitoring status

Monitoring status FM

All SPDs OK

Replace at least one SPD

Note: When delivered, the monitoring status is set to “Replace all SPDs”

DRC SCM XT automatically starts the test cycle

Configuration OK Configuration not OK

LED

Start sequence (6 Sek.) Faulty configuration

FM LED

Status

OK

LifeCheck faulty,

replace SPD

FM

⇒ Configuration see 8

FM

Monitoring of the SPDs by the DRC SCM XT is automatically started as soon as the testing for ad-

missible configuration and the start sequence is terminated.

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 18 of 32 Date: 2013/01/16

Commissioning is successful and can be terminated, if the assigned SPDs are checked

and DRC SCM XT shows that the monitoring status of all SPDs is OK.

Attention! If the configured number of SPDs wrongly is lower than the existing SPDs to be monitored, this can

not be recognised by the device, this means SPDs with No. n> than the configured number are not

checked!

11. Monitoring Status

The status of the monitoring group is redetermined with every complete checking

and visually indicated by LED and remote signalling contact (FM).

Two states may be shown:

LED FM 21-22, nc

All SPDs OK

Replace at least one SPD

First SPD No., (here e.g. SPD No. 2)

The updating rate of a DRC SCM XT monitoring status mainly depends on the number of SPDs

which are determined for replacement.

For a DRC SCM XT with 10 assigned SPDs which are all OK, it is typically 15 seconds.

Another 75 seconds are necessary for every single faulty SPD. In the worst case, checking in case

of 10 faulty SPDs would last approx. 13 minutes.

If a running check has to be aborted, the test sequence may be interrupted by pressing the ctrl

button at the DRC SCM XT (until LED goes out for a short time) (see 13.1 Abort of an ongoing test

cycle).

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 19 of 32 Date: 2013/01/16

12. Maintenance at Monitoring Status Replace SPD

In order to avoid system downtimes, the SPD monitoring device

already generates the “Replace SPD” monitoring status in case

of an imminent fault due to inadmissible overload. Both thermal

(overheating) and electrical (impulse current) occurrences are re-

gistered.

The DRC SCM XT records the overload or a pre-damage at an assigned SPD and signalises the

“Replace SPD” monitoring status via LED and remote signalling contact.

The SPD to be replaced can be exactly located as follows:

12.1 On-site determination by pushbutton function at the

DRC SCM XT

The SHOW mode is used to indicate SPDs to be replaced/faulty on

site without any other auxiliaries.

It is called up automatically if the monitoring status shows “Replace at

least 1 SPD”. The SPD No. of the first SPD to be replaced is indicated. In

the following test cycle e.g. SPD No. 2 and SPD No. 4

are determined as faulty:

Checking

with faulty status

(SPD No. 2)

Show mode

SPD No. to be replaced is indicated for approx. 1 min

• • •

Next checking

Pressing the button long when the LED flashes orange leads on to the next SPD No.

to be replaced;

...

(SPD No. 2)

> 5 sec

(SPD No. 4)

Press button

Is indicated for 1 minute without pressing the button.

If no other SPD must be replaced, the Show mode is finished

and a new test cycle is automatically started.

(SPD No. 4)

> 5 sec Press button

Test cycle running

In addition to the indication function also programming of SPDs is possible in the Show mode (see 9.1

Direct programming at the monitoring device)

If, however, all assigned SPDs are OK, the status “All SPDs OK” is indicated for

3 min. . During this time the button provides no function.

push ctrl

DEHN + SÖHNE Operating Manual DEHN record DRC SCM XT

Protected by ISO 16016 20 of 32 Date: 2013/01/16

12.2 Offline determination by handheld reader DRC LC M3+

A documentation or labelling is not necessary for the on-site checking and identification of SPDs to

be replaced when using the handheld reader DRC LC M3 (version state > 1.1.02 dated 2008/05/28)

or the succeeding device DRC LC M3+ (version state > 1.2.00 dated 2009/08/04).

Prerequisite is the deactivation of the monitoring device for the group to be tested, i.e. it is just

locked out and removed from the base part.

Offline determination of SPDs to be replaced by DRC LC M3+ handheld reader:

Description Offline determination via DRC LC M3+ - Part 1 Handheld reader display

Under the menu item DRC MCM at the DRC LC M3+ , the checking of

SPDs and all other functions for the protective devices in connection with

the stationary reader are summarised:

3)

Before checking, the fixed device address /group no. (ADR=01)

and the number of SPDs in the group which is going to be tested must

be entered in the configuration, once when starting the DRC LC M3+ or

in case of changes.

Change between bus address and number of SPDs with

Whenever the configuration is called up, the status of the group,

available under DRC MCM Status is reset to untested.

There are three kinds of status: - untested

1SPD OK

0Replace SPD

Configuration of the display is increasing from left to right, starting with

the consecutive No. 1 up to the configured number.

Use the DRC LC M3+ menu item Check SPD for checking the Individual

SPDs

The device address/group No. (ADR=01) is automatically taken from the

configuration. Use the arrow keys for selecting the consecutive number

of the SPD to be tested. Both numbers are the necessary code for calling

up the SPD.

3) See operating manual DRC LC M3+. /1/

Mode <->

DRC MCM

Configuration

ADR=01 SPD=10

Check SPD

ADR=01 10*SPD

DRC MCM:

Check/Search

MCM status

ADR=01 10*SPD

MCM ADR=01

1 1 0 1 1 0 - - - -

Check SPD

ADR=01 10*SPD

ADR=01 SPD=01

Check SPD ---> OK

Table of contents

Other DEHN + SÖHNE Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Emerson

Emerson Rosemount 3410 Series Maintenance and troubleshooting manual

Reed Instruments

Reed Instruments R7700 instruction manual

Keller

Keller ADT1 operating manual

GREISINGER

GREISINGER GIA 2002 NS/DIF Series manual

Ankom

Ankom ANKOM200 FIBER ANALYZER Operator's manual

THORLABS

THORLABS LNR25 Series user guide