Quick Start - Software Version 1.1x & 2.x

004R-625-110 Page 1

Table of Contents

1. INTRODUCTION ....................................................................... 2

1.1. Manuals ............................................................................ 2

1.2. Shipping Contents ............................................................ 2

2. SPECIFICATIONS .................................................................... 3

3. WARNINGS............................................................................... 4

3.1. General............................................................................. 4

3.2. Configuration Issues......................................................... 4

4. INSTALLATION ........................................................................ 5

4.1. Electrical Safety................................................................ 5

4.2. Panel Mount Template...................................................... 5

4.3. Function Keys................................................................... 5

4.4. Optical Communications................................................... 6

5. CONNECTIONS ........................................................................ 7

5.1. Cable Connections ........................................................... 7

5.2. DC Power (DC PWR +, DC PWR –)................................. 7

5.3. Summing Slave Serial Connection ................................... 7

5.4. Auxiliary Connections ....................................................... 8

5.5. Connecting Shields......................................................... 10

5.6. Regulatory Sealing Requirements .................................. 11

6. INSTRUMENT SETUP ............................................................ 12

6.1. Calibration Counter......................................................... 12

6.2. Access Full Setup........................................................... 12

6.3. Access Safe Setup ......................................................... 12

6.4. Exit Full or Safe Setup .................................................... 13

6.5. Slave Indicator Configuration.......................................... 13

6.6. K481 Summing Indicator Configuration .......................... 14

6.7. Using Menus................................................................... 16

6.8. Settings........................................................................... 17

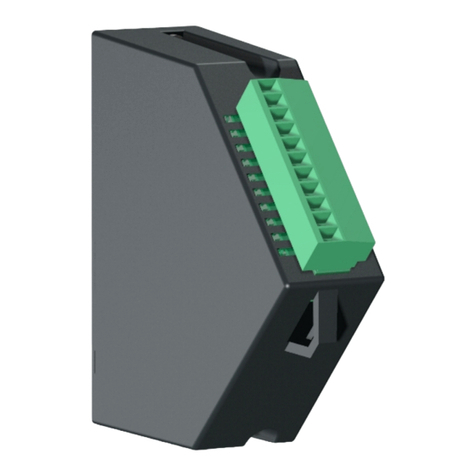

7. ACCESSORY MODULES ....................................................... 26

7.1. General........................................................................... 26

7.2. Inputs.............................................................................. 27

7.3. Outputs ........................................................................... 28

7.4. Analog Output................................................................. 29

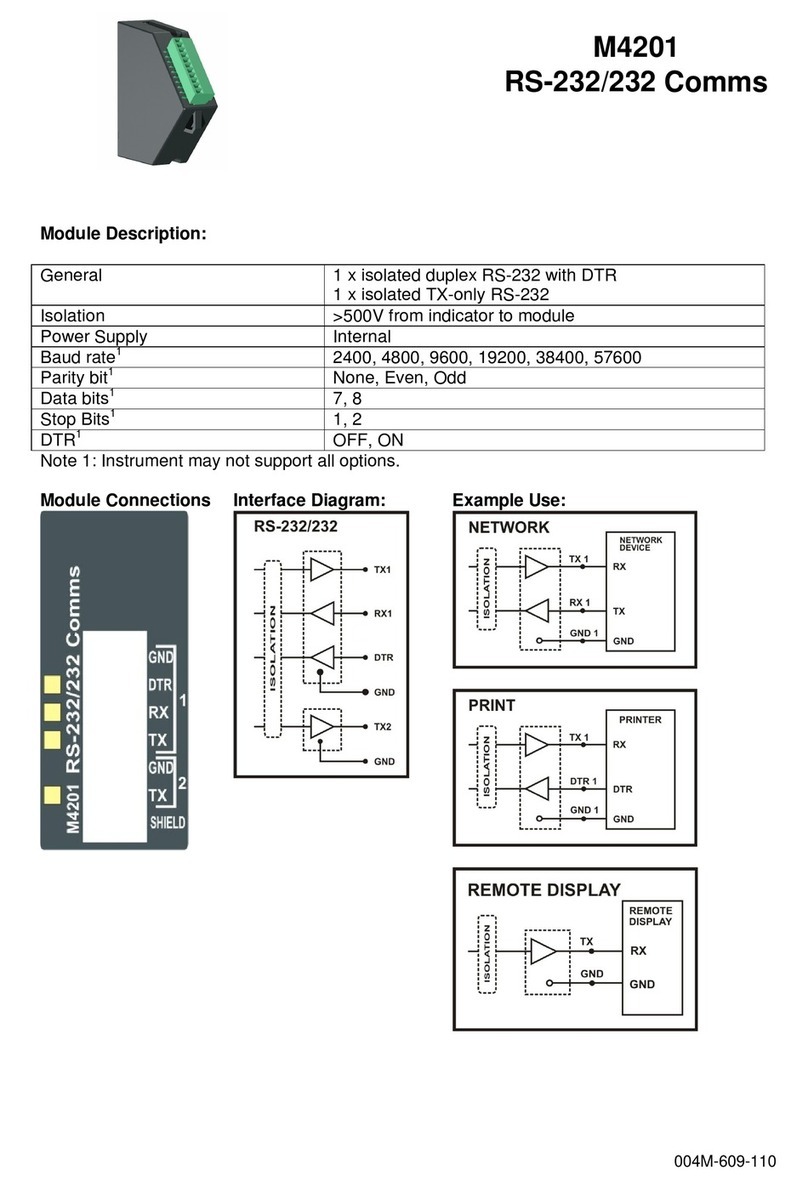

7.5. Communications............................................................. 29

7.6. Ethernet Module ............................................................. 30

8. ERROR MESSAGES .............................................................. 32

8.1. Weighing Errors.............................................................. 32

8.2. Setup Errors ................................................................... 34

8.3. Diagnostic Errors ............................................................ 34