Dekker DVW Series User manual

Operation

Manual

DEKKER Controller

Programmable Logic Controller (PLC)

Part No. 9983-0000-E02 September 2019

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

2

DEKKER

C

ONTROLLER

OPERATION MANUAL

TABLE OF CONTENTS

CUSTOMER SERVICE 4

C

ONTACT INFORMATION

4

O

RDER

I

NFORMATION

4

INTRODUCTION 5

DEKKER CONTROLLER KEYPAD 5

BATTERY 6

CONTROLER INPUT/OUTPUT LAYOUT 7

CURRENT INPUT/OUTPUT ASSI NMENTS 8

I

NPUTS

8

O

UTPUTS

8

ENTERIN PASSWORD 9

CHAN IN VACUUM UNITS 10

CHAN IN VACUUM CUTIN AND CUTOUT 12

MULTIMACHINE SETUP 13

TEMPERATURE WARNIN S AND FAULTS 13

SETTIN DATE AND TIME 14

ENTERIN KEYCODES 15

COOLIN FAN 16

ROTATION 17

MANUAL ROTATION 17

SCAVEN ER OUTPUT 18

FAULTS AND FAULT LO 19

AUTOSTART 20

MAINTENANCE SCHEDULES 21

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

3

RESETTIN MAINTENANCE SCHEDULE HOURS 24

DP INLET 25

REMOTE START STOP 25

NETWORK OPTIONS 26

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

4

CUSTOMER SERVICE

Contact information

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 – FAX: 219-861-0662 – TOLL-FREE: 888-925-5444

Bus. Hours: 7:30 a.m. – 4:30 p.m. CST

Website: www.DEKKERvacuum.com

Order Information

When calling for service, parts or system information always have the pump or system model number and

serial number(s) ready. Refer to the bill of lading, the gold-colored system information plate attached to the

system (see image below), or the white label on the inner door of the control panel (see image below).

Control panel nameplate label

Parts should be purchased from the nearest authorized DEKKER Vacuum Technologies, Inc. (hereafter

referred to as DEKKER) representative (visit www.dekkervacuum.com to find a distributor near you via the

Distributor Locator) or from the vacuum pump system supplier. If, for any reason parts, cannot be obtained in

this manner, contact the factory directly.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

5

INTRODUCTION

The Dekker Controller provides for system control as well as monitoring of system status. Service functions

include display of spare parts list, maintenance schedules, service history, and logging of fault conditions.

The Dekker Controller includes a 4-line large-font LCD (Liquid Crystal Display), a durable Lexan membrane

keypad, and multiple status LEDs. Communication between controllers is via RS-485 for multimachine systems.

An Ethernet port provides for remote monitoring and control via TCP IP protocols and can be enhanced with

the use of Dekker’s OnDek Software (optional and purchased separately as Item# 9985-2000-000).

Input Output (I O) includes 9 digital (24VDC) inputs and 7 dry relay contact outputs. Analog I O includes 2

RTD (Resistance Temperature Detectors) inputs, four 0-10VDC 4-20mA inputs, one 0-10VDC output, and

one 4-20mA output. Power input to the controller is 24VDC.

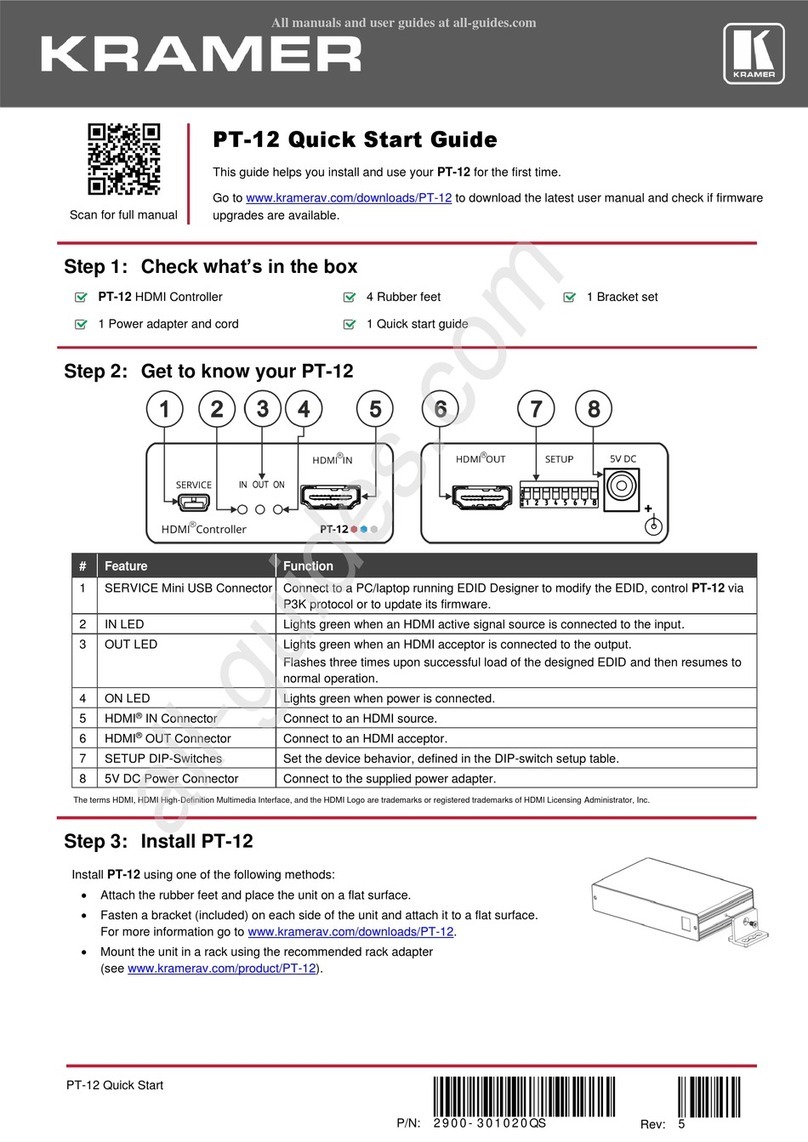

DEKKER CONTROLLER KEYPAD

The Dekker Controller text display, buttons, and LEDs are described below.

4 line LCD Display

UP/DOWN arrow button is used to navigate menus and change values for setpoints, real-time clock,

vacuum units, and temperature units.

ENTER button is used to select menu items, menus and values.

HAND/AUTO LED is used to identify the run status of the system. Orange = Hand (manual

operation). Green = Auto.

HAND/AUTO button is used to alternate between Hand (manual operation) and Auto mode.

POWER ON LED is used to indicate if the controller power is on. Red = Controller power is

on.

POWER button is used to turn the controller on and off.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

6

ON LED is used to display if the system is running or in standby mode. Green =

System is either running or in Standby mode.

ON button is used to start the system.

OFF button is used to stop the system.

OFF LED is used to display if the system is stopped. Red = System is stopped.

RUN STATUS LED is used to display the current run status. Green = System is

running. Orange = System is in Standby or Auto mode. Red = System is stopped.

RESET button is used to reset faults. Note: Fault condition must be cleared before the Reset

button will reset the fault.

LO button is used to access the Fault History Log menu.

MAINTENANCE button (MAIN) is used to access menu for the Spare Parts List, Maintenance

Schedule and Service History.

PRO RAM button (PROG) is used to access the Programming menu for Setpoints,

Clock, Vacuum Units, Temperature Units and other keycode options that are

purchased after the original sale (such as hi or low-level switches, backpressure, etc).

ESCAPE button (ESC) is used to return to the Run Standby Stopped screen.

BATTERY

The Dekker Controller may be shipped with a battery protector placed between the battery clip and the

surface of the battery, it may be a rubber sleeve around the clip or a small plastic insulator between the

clip and battery. This must be removed before applying power to the controller. If not removed the

controller will not retain Date, Time and other values that are written to the controller for setup. The

controller cannot be flashed with new firmware until this is removed. To remove, use a pair of needle

nose pliers and pull from clip.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

7

CONTROLER INPUT/OUTPUT LAYOUT

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

8

CURRENT INPUT/OUTPUT ASSI NMENTS

Inputs

Digital Inputs Analog Inputs RTD Inputs

E-Stop Vacuum RTD1 – Aux Temp

Overloads Backpressure RTD2 – Discharge Temp

Aux Contact Vac Pump Circ Pump Pressure

Low Fluid Level Diff Pressure

High Fluid Level

Remote Start

Remote Stop

Circ Pump Overload

External Warning

Note: Analog input 4 is a 0-15 psia transducer used in conjunction with Analog input 1 transducer to measure

the difference in vacuum across an inlet filter.

Outputs

Relay Outputs

C1 NO = Vac Pump Motor Starter

C2 NO = Local Lag Light

C3 NO = Horn Output

C4 NO = Remote Lag Light

C5 NO = All Fault Out

C6 NO = Scavenger Valve Out

C7 NO = Cooling Fan

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

9

ENTERIN PASSWORD

The Dekker Controller provides password protected settings and variables. To access these protected areas, a

password needs to be entered.

Press and hold the ESC button until Password 0 appears at the bottom of the screen.

Press the MAINT button twice, which enters the password 33, and then press ENTER. You now have access to

change the Controller settings.

To restore Basic Access, press and hold the ESCAPE (ESC) button for two seconds. The screen will display the

words Access Locked. Basic Access is also restored upon powering the controller off and on. If the DEKKER

Controller has no activity (no buttons pushed) for 5 minutes, it will default back to Basic Access.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

10

CHAN IN VACUUM UNITS

Enter Password

If the system is STOPPED or RUNNING press the PROG button once to view the Setpoints screen. If HgV is

already set for vacuum units, you will see VAC CUTIN and VAC CUTOUTt in HgV units.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

11

To change to another type of unit, use the DOWN arrow to scroll to Vacuum Unit then press ENTER.

Using the UP arrow to change unit, you will have a choice of TORR, HgV or Millibars. Once selection is made,

press ENTER to save.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

12

CHAN IN VACUUM CUTIN AND CUTOUT

Enter Password

If the system is STOPPED or RUNNING press the PROG button once to view the Setpoints screen.

Press the UP or DOWN button if necessary to select VAC CUTIN then press ENTER. Once ENTER is pressed,

use UP or DOWN arrows to change the value and then press ENTER to save. Repeat for VAC CUTOUT.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

13

MULTIMACHINE SETUP

Multimachine allows two or more Controllers to communicate and rotate Lead and Lag pumps based on hours

Run. When rotation occurs the pump with the least hours will rotate to Lead. This helps to keep the run hours

balanced amongst the networked pumps. To set up for multimachine CAT5 Ethernet cables are run from panel to

panel. Cables must be run before setting the Controller for multimachine operation. nce cables are run go to first

Controller and Enter Password.

•Enter the password on the first controller

•Press PR G button twice to view System ptions Screen

•Press D WN arrow until Multimachine is selected

•Press ENTER

•Even though multimachine may already be set for 1 use UP button to move to 2 then back to 1

•Press ENTER and the controller will reboot

•Enter the password on the second controller

•Follow the same steps as for the first controller but set the multimachine to 2

•Continue this process for all networked systems

After the controllers reboot they should show Units Found. The number of units found should match the number

of systems networked.

TEMPERATURE WARNIN S AND FAULTS

Temperature warnings and faults are factory set, It is not recommended to change these settings without

consulting with a Dekker Service Technician.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

14

SETTIN DATE AND TIME

Enter Password

Press PROG once to view Setpoints screen

Using the DOWN arrow to scroll to the Date and press ENTER

Use UP and DOWN arrows to change Date, press ENTER to save.

Use UP and DOWN arrows to scroll to the Time and press ENTER

Use UP and DOWN arrows to change Date, press ENTER to save.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

15

ENTERIN KEYCODES

Keycodes are used to enable available options. Keycodes are 7 digits. All keycodes are entered with 2 leading 0s.

Enter Password

Using the DOWN key, find the option needed and press ENTER. Keycode will appear with one 0. To

enter the keycode for this option use the UP DOWN keys to scroll to the required value for the digit

and press ENTER. Continue this process until the entire keycode is entered. Upon pressing ENTER for

the last digit, the option previously displaying N A will change to YES.

Option Description

Keycode

Hi Level Switch

001159823

Low Level Switch

001146833

Temperature Switch

001117934

Vacuum Switch

001134688

Auxiliary RTD Temperature

001182214

Differential Pressu

re Inlet Filter

001114236

Back Pressure Transducer

001196511

Multimachine

001127744

Remote Start Stop

001169856

Cooling Fan

001149877

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

16

COOLIN FAN

The Dekker Controller is equipped with a temperature control to operate a cooling fan when applicable. This

feature requires a cooling fan keycode to be entered (see entering keycodes above). Once the cooling fan keycode

is entered press the PROG button until you see the SETPOINT screen.

Use DOWN arrow to scroll to FAN CUTON and FAN CUTOFF. These are the setpoints to turn the fan on and

off. They can be changed by entering password, scroll back to the settings. Press ENTER then use UP DOWN

arrows to change values. You must press ENTER again to save. Normally Open Output C7 is used for this

purpose.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

17

ROTATION

When set up for multimachine the system will rotate pumps every 24 hours if needed. For rotation to occur, the

Lead pump must have the most run hours. When this condition is met and the time for rotation occurs, the Lag

pump will become the lead pump. If this condition is not met rotation will not occur. If a triplex or higher system

rotation for each pump will occur in order based on run hours of each pump.

MANUAL ROTATION

The pumps can be rotated manually, but the same condition above applies, the Lead must have the most hours.

To rotate pumps manually, on the Lead pump, press and hold RESET button until you see the text

“Manual Transfer” appear on the screen, then release the button. Wait a few seconds and you will see

the upper text “LD” move to the opposite controller, the text “LG1” will move to where the “LD” was

previously.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

18

SCAVEN ER OUTPUT

Output 6 on the controller is used for a bleed valve. This output cycles on for 30 Secs and off for 9 minutes based

on vacuum level. The vacuum level for cycling to occur is adjustable via the Setpoint menu on the Dekker

Controller.

•Enter password

•Press PROG until Setpoints screen is shown.

•Using DOWN arrow scroll to SCAV LVL

•Press ENTER

•Use UP DOWN arrows to change value

•Press ENTER to save.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

19

FAULTS AND FAULT LO

If a fault occurs the fault will be displayed on the screen and recorded in the fault log. Faults include Overload,

Temperature and in some versions of firmware Back Pressure. The Temperature and Back Pressure faults are

adjustable from the setpoint screen, but it is not recommended to change these without consulting with a Dekker

Technician. Changing these values could result in pump damage. Below is what is shown on the screen when a

temperature fault occurs. The Run Status light will also turn red and flash so you can see a fault has occurred from

a distance. Faults are cleared using the Reset button, but will not clear until the condition that caused the fault is

cleared.

When the fault occurs, it is recorded in the fault log. The fault log will record up to 10 faults. When this is reached

the most recent fault is recorded at the top of the list and fault at the bottom of the list is removed. To view the

fault log press the Log button.

Each fault can be selected to view what values such as Vacuum, Back Pressure etc… were at the time of the fault

and up to 10 minutes prior to the fault.

To view this detail use UP or DOWN key to select the fault.

Then press ENTER. The first screen shows what was occurring at the time of the fault, use DOWN arrow to view

more information. Press ENTER again to view what was occurring 1 minute prior to fault. Press again for 2

minutes prior. You can continue pressing ENTER to view up to 10 minutes prior to fault.

DEKKER Vacuum Technologies, Inc. Part No. 9983-0000-E02 September 2019

20

AUTOSTART

The Dekker controller is equipped with Autostart. This feature allows automatic restart of system when power

returns from a power loss. To enable this feature press PROG button to show SETPOINTS screen. Use DOWN

arrow to select Autostart. Press ENTER. Use UP arrow to change to ON. Press ENTER to save. If system is

multimachine, this must be set on all controllers.

This manual suits for next models

1

Table of contents

Other Dekker Controllers manuals

Popular Controllers manuals by other brands

Kutzner + Weber

Kutzner + Weber H100 installation instructions

Ponast

Ponast Sigmatek Instructions for use and installation

KOHSEL ELEPHANT

KOHSEL ELEPHANT M40 installation guide

Stahl

Stahl 8264 operating instructions

YASKAWA

YASKAWA 264IF-01 user manual

Titan Controls

Titan Controls Helios 3 instruction manual