Dekker OnDek Controller User manual

Page 1

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Dekker Controller Manual Rev: Feb 18 2016

Overview__________________________________ __ 2

Battery_______________________________________3

Controller Input/Output Layout___________________4

Current Input/Output Assignments__________ _____5

Entering Password____________________________ 6

Changing Vacuum Units______________________ _ 7

Changing Vac CutIn and CutOut_________________ 8

Multimachine Setup________________________ ___ 9

Temperature Warnings And Faults_______________10

Setting Date And Time_________________________11

Entering Keycodes____________________________13

Cooling Fan__________________________________15

Rotation_____________________________________16

Scavenger Output_____________________________17

Faults and Fault Logs__________________________18

Autostart____________________________________ 21

Maintenance Schedules________________________ 22

Reset Maintenance Schedule Hours_______________25

DPInlet_______________________________________26

Remote Start/Stop______________________________27

Network Options_______________________________28

Key Code List 28

Page 2

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

DEKKER CONTROLLER OVERVIEW

Dekker’s Controller is standard on the Vmax models. The Dekker Controller provides for system control

as well as monitoring of system status. Service functions include display of spare parts list, maintenance

schedules, and service history, along with logging of fault conditions.

The Dekker Controller includes a 4-line large-font liquid crystal display, a durable Lexan membrane

keypad, and multiple status LEDs. Communication between controllers is via RS-485 for multi-machine

systems. An Ethernet port provides for remote monitoring and control via TCP/IP protocols and can be

enhanced with the use of Dekker’s OnDek Software (optional and purchased separately). Input and

output (I/O) includes 9 digital (24VDC) inputs and 7 dry relay contact outputs. Analog I/O includes 2 RTD

(Resistance Temperature Detectors) inputs, four 0-10VDC/4-20mA inputs, one 0-10VDC output, and one

4-20mA output. Power input to the controller is 24VDC.

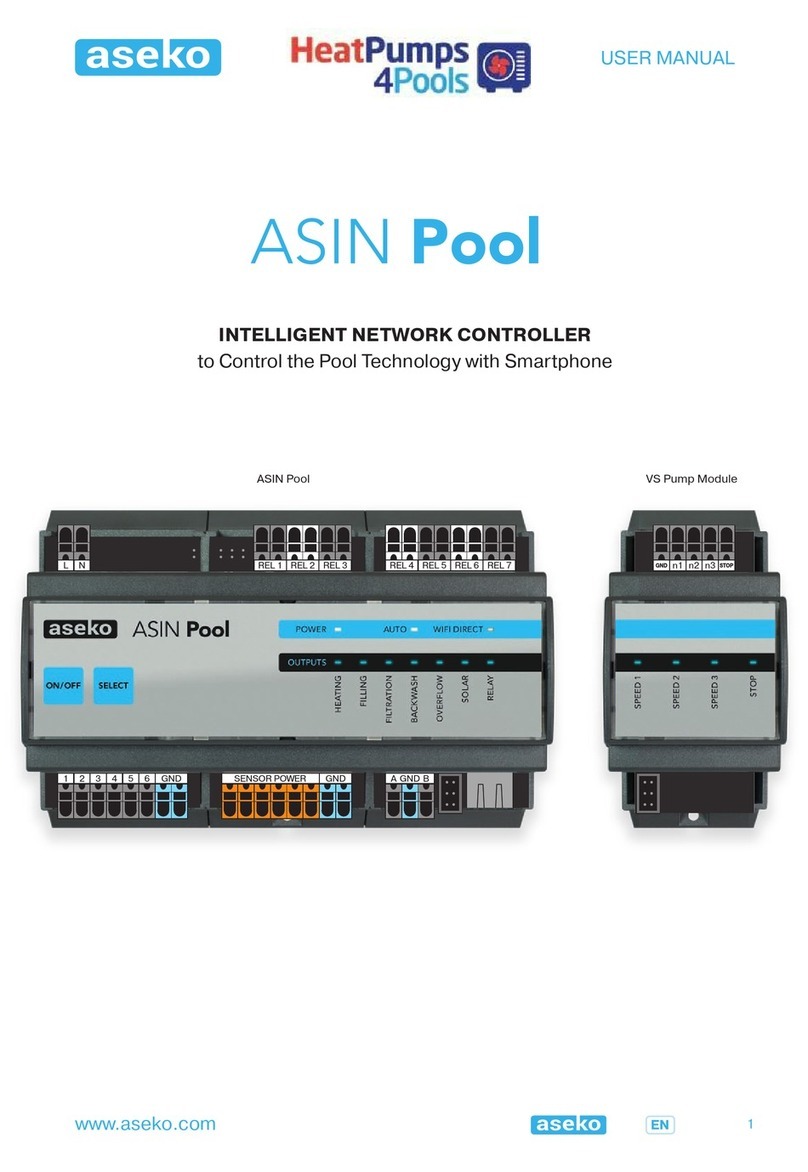

DEKKER CONTROLLER KEYPAD

The Dekker Controller text display, buttons, and LEDs are described below. Refer to the diagram below

that shows this information.

4 line LCD Display

ESCAPE BUTTON RETURNS TO

RUN/STANDBY/STOPPED SCREEN

PROGRAM BUTTON PROGRAM MENU

FOR SETPOINTS, CLOCK, UNITS

MAINT BUTTON MENU FOR: SPARE

PARTS LIST MAINTENANCE SCHEDULES

SERVICE HISTORY

LOG BUTTON FAULT HISTORY LOG

MENU

RESET BUTTON RESETS FAULTS

RUN STATUS LED GREEN = SYSTEM

RUNNING ORANGE = STANDBY/AUTO

MODE RED = SYSTEM STOPPED

OFF LED RED = SYSTEM STOPPED

OFF BUTTON STOPS SYSTEM

ON BUTTON STARTS SYSTEM

GREEN= SYSTEM RUNNING

OR IN STANDBY

POWER ON BUTTON

TURNS CONTROLLER ON

AND OFF

POWER ON LED

RED=CONTROLLER

RPOWER ON

HAND/AUTO

BUTTON

ALTERNATES

BETWEEN

HAND AND

AUTO

MODES

HAND/AUTO

LED

ORANGE=HAND

GREEN=AUTO

ENTER

BUTTON

SELECT

MENU ITEMS

MENUS AND

VALUES

UP / DOWN –ARROW/ - BUTTON

NAVIGATE MENUS AND CHANGE

VALUES

Page 3

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

The OnDek Dekker Controller

Battery

The Dekker Controller is shipped from supplier with a battery protector placed between the battery clip

and the surface of the battery, it may be a rubber sleeve around the clip or a small plastic insulator

between the clip and battery. This must be removed before applying power to the controller. If not

removed the controller will not retain Date, Time and other values that are written to the controller for

setup. The controller cannot be flashed with new firmware until this is removed. To remove use a pair of

needle nose pliers and pull from clip.

Battery

Page 4

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

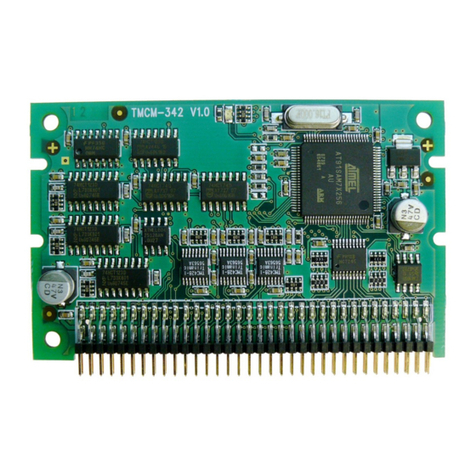

Controller Input/Output Layout

987654321

Digital Inputs

Relay Outputs C1 - C7

24 VDC

RTD1

RTD2

Analog In 4

Analog In 3

Analog In 2

Analog In 1

NC C7 NO | NC C6 NO

NC C5 NO | NC C4 NO

C3 NO | C2 NO | C1 NO

RS232 Port

4-20MA Calibration Switches

4-20MA Out

0-10 VDC Out

Ethernet Port

Page 5

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Current Input/Output Assignments

Digital Inputs Analog Inputs

1. E-Stop 1. Vacuum

2. Overloads 2. Backpressure

3. Aux Contact Vac Pump 3. Circ Pump Pressure

4. Low Fluid Level 4. Diff Pressure

5. High Fluid Level

6. Remote Start RTD Inputs

7. Remote Stop RTD1 –Aux Temp

8. Circ Pump Overload RTD2 –Discharge Temp

9. External Warning

(Note: External warning is used to give a warning on the screen from an external device.)

(Analog input 4 is a 0-15 psia transducer used in conjunction with Analog input 1 transducer to

measure the difference in vacuum across the inlet filter)

Relay Outputs

C1/NO = Vac Pump Motor Starter

C2/NO = Local Lag Light

C3/NO = Horn Output

C4/NO = Remote Lag Light

C5/NO = AllFault Out

C6/N0 = Scavender Valve Out

C7/NO = Cooling Fan

All inputs and outputs are 24VDC

Analog inputs are 0-10 Vdc by default, but configurable for 4-20ma

C5 Allfault output is used to for a remote indicator for any shutdown fault.

C6/NO Scavenger only10 Minute Run times were changed to a minium of 30 Minutes and adjustable to

90 Minutes in firmware version 1.12d all prior versions were 0 - 10 applies to firmware versions prior to

v 1.12d

Page 6

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Entering Password

Press and hold ESC button until Password 0 appears at bottom of screen.

Press MAINT button twice which enters the password 33 Then press ENTER

You now have access to change Controller settings.

ESC button

Password 0

MAINT

ENTER

Page 7

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Changing Vacuum Units

Enter Password

If current screen is STOPPED or RUNNING press PROG once to view Setpoints screen. If HgV is already

set for vacuum units you will see Vac CutIn and Vac CutOut in HgV units.

PROG

Page 8

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

To change to another Unit use DOWN arrow to scroll to Vacuum Unit Then press ENTER.

Once you press ENTER use UP arrow to change unit, you will have a choice of TORR, HgV or Millibars.

Once selection is made you must press ENTER again to save.

Changing Vac CutIn and CutOut

Enter Password

If current screen is STOPPED or RUNNING Press PROG once to view Setpoints screen.

Press UP or DOWN button if necessary to select Vac CutIn then press ENTER

DOWN

ENTER

Vacuum Unit

UP

PROG

Page 9

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Once ENTER is pressed use UP or DOWN arrows to change value then press ENTER to save. Using

UP/DOWN arrows repeat for Vac CutOut and save again by pressing ENTER

NOTE: When set up for multimachine, controller must be in STOPPED mode when changing Setpoints.

Multimachine Setup

Multimachine allows two or more Controllers to communicate and rotate Lead and Lag pumps based on

hours Run. When rotation occurs the pump with the least hours will rotate to Lead if the hours are

imbalanced. This keeps from putting all the run hours on one pump. To set up for multimachine CAT5

Ethernet cables are run from the RS485 jack mounted inside the panel. The cable is plugged into the jack

in the first panel, then routed to the second panel and plugged in. Each panel has two jacks so that you

can run cables to each machine if more than two. Cables must be run before setting the Controller up

for multimachine. Once cables are run go to first Controller and Enter Password.

Now press PROG button twice to view System Options Screen

Press DOWN arrow until Multimachine is selected.

Press ENTER.

Even though multimachine may already be set for 1 use UP button to move to 2 then back to 1

DOWN

ENTER

UP

Page 10

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

And press ENTER. Controller will reboot.

Go to second Controller Enter Password and follow same steps above only change multimachine to 2

and press ENTER.

If there are three controllers on the third set multimachine for 3. Do this for all Controllers each with a

different multimachine number starting with the first they should be, 1,2,3,4 etc.. When Controllers

power back up on each Controller it should show Units Found which will be the number of Units found

on the RS485 Bus. This should match the number of Controllers, if a Duplex 2, if a Triplex 3 etc..

Temperature Warnings And Faults

Temperature warnings and faults are factory set, It is not recommended to change these settings

without consulting with a Dekker Service Tech.

Page 11

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Setting Date And Time

Enter Password

Press PROG once to view Setpoints screen.

Using Down Arrow scroll to Date and Press ENTER key.

Use Up / Down arrows to change Date, press ENTER again to save.

Use Up / Down key to select Time.

Press Enter

PROG

UP

DOWN

ENTER

Page 12

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Use UP / DOWN key to change

Press ENTER to save.

UP

DOWN

ENTER

Page 13

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Entering Keycodes

Keycodes are used to enable available options. Keycodes are 7 digits. All keycodes are entered with 2 leading 0s.

Enter Password

Press DOWN key to find option needed

PROG

DOWN

From STOPPED or RUNNING screen press PROG

button once to get to SETPOINTSs Screen

Press PROG button once more to get to

SYSTEM OPTIONS Screen

PROG

Page 14

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

.

ENTER

ENTER

ENTER

Once selected press ENTER. Keycode will

appear with one 0

Once selected press ENTER. Keycode will

appear with two 0s

Press ENTER again then use UP/DOWN keys to enter

third digit of keycode

Press ENTER again then use UP/DOWN keys to enter

fourth digit of keycode

Press ENTER after each entry and continue until

all digits of keycode are entered

Then press ENTER one last time. The N/A will

change to Yes enabling the option chosen.

ENTER

ENTER

ENTER

Page 15

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Cooling Fan

The Dekker Controller is equipped with a temperature control to operate a cooling fan when applicable.

This feature requires a cooling fan keycode to be entered (see entering keycodes above). Once the

cooling fan keycode is entered press the PROG button until you see the SETPOINT screen.

Use DOWN arrow to scroll to Fan CutOn and Fan CutOff. These are the setpoints to turn the fan on and

off. They can be changed by entering password, scroll back to the settings. Press ENTER then use UP /

DOWN arrows to change values. You must press ENTER again to save. Normally Open Output C7 is used

for this purpose.

PROG

Page 16

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Rotation

When set up for multimachine the system will rotate pumps every 24 hours if needed. For rotation to

occur, the Lead pump must have the most run hours. When this condition is met and the time for

rotation occurs, the Lag pump will become the lead pump. If this condition is not met rotation will not

occur. If a triplex or higher system rotation for each pump will occur in order based on run hours of each

pump.

Manual Rotation

The pumps can be rotated manually, but the same condition above applies, the Lead must have the

most hours.

To rotate pumps manually, On the Lead pump, press and hold RESET button until you see the text

“Manual Transfer” appear on the screen, then release the button. Wait a few seconds and you will see

the upper text “LD” move to the opposite controller, the text “LG1” will move to where the “LD” was

previously.

RESET

RUN HOURS

Page 17

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Scavenger Output

Output 6 on the controller is used for a bleed valve. This output cycles on for 30 Secs and off for 9

minutes based on vacuum level. The vacuum level for cycling to occur is adjustable via the Setpoint

menu on the Dekker Controller.

Enter password

Press PROG until Setpoints screen is shown.

Using DOWN arrow scrool to Scav Lvl

Press ENTER

Use UP/DOWN arrows to change value

Press ENTER to save.

ENTER

Page 18

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Faults and Fault Log

If a fault occurs the fault will be displayed on the screen and recorded in the fault log. Faults include

Overload, Temperature and in some versions of firmware Back Pressure. The Temperature and Back

Pressure faults are adjustable from the setpoint screen, but it is not recommended to change these

without consulting with a Dekker Technician. Changing these values could result in pump damage.

Below is what is shown on the screen when a temperature fault occurs. The Run Status light will also

turn red and flash so you can see a fault has occurred from a distance. Faults are cleared using the Reset

button, but will not clear until the condition that caused the fault is cleared.

RESET

RUN STATUS LIGHT

Page 19

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

When the fault occurs it is recorded in the fault log. The fault log will record up to 10 faults. When this ir

reached the most recent fault is recorded at the top of the list and fault at the bottom of the list is

removed. To view the fault log press the Log button.

Each fault can be selected to view what values such as Vacuum, Back Pressure etc… were at the time of

the fault and up to 10 minutes prior to the fault.

To view this detail use UP or DOWN key to select the fault.

LOG

UP

DOWN

Page 20

935 SOUTH WOODLAND AVENUE, MICHIGAN CITY, IN 46360-5672

TEL.: 219-861-0661 - FAX: 219-861-0662 - TOLL-FREE: 888-925-5444 www.dekkervacuum.com

Then press ENTER. The first screen shows what was occurring at the time of the fault, use DOWN arrow

to view more information. Press ENTER again to view what was occurring 1 minute prior to fault. Press

again for 2 minutes prior. You can continue pressing ENTER to view up to 10 minutes prior to fault.

ENTER

Table of contents

Other Dekker Controllers manuals