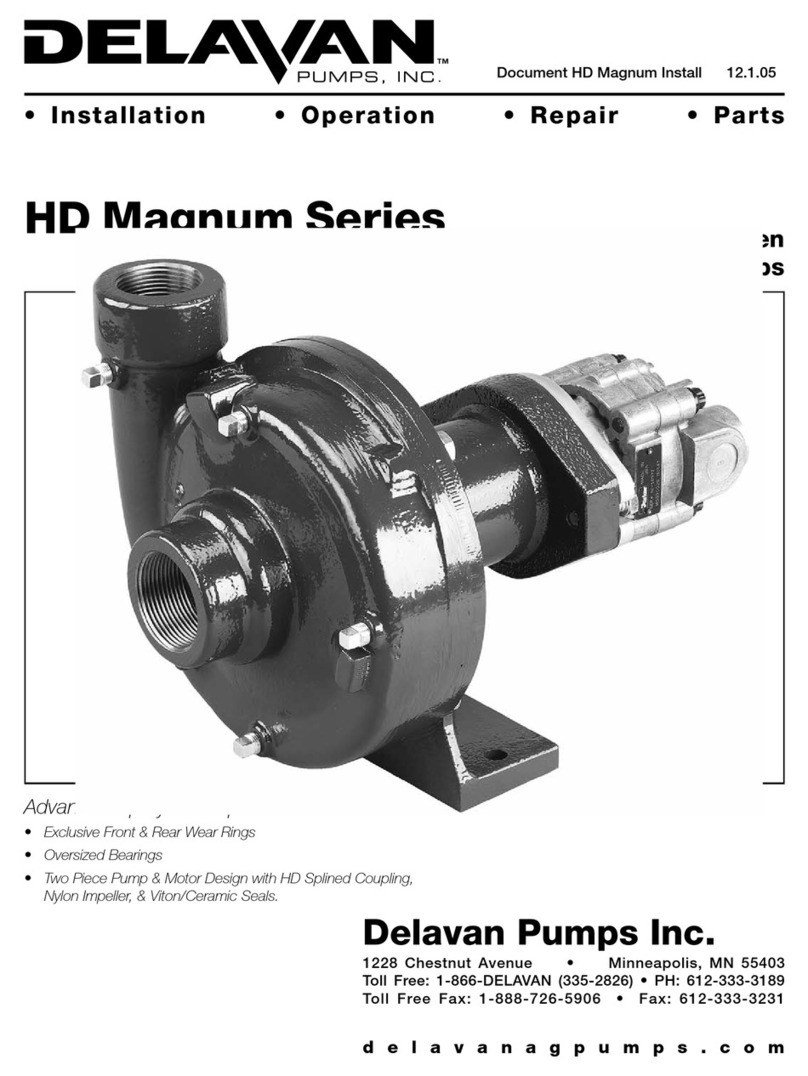

Delavan 4400 Series User manual

4-, 5-, 6-, 7-,

8-Roller Pump

Instruction

Manual

01509-MN

GENERAL

Delavan roller pumps are available with a variety of options, such as a choice of roller numbers (4-roller, 5-roller, 6-roller, 7-roller,

8-roller), seal materials (Viton-A or Teflon), and a direction of rotation. Also, Ni-Resist and Diamond Cast pump bodies are available on

all Delavan roller pumps. Stainless steel shaft is standard on all models.

(Read carefully before installation and operation)

FEATURES:

•Max. flow: 9.2 gpm at 2600 rpm

•Max. fluid temperature: 140ºF/60ºC

•Port size: 3/4” NPT

•Shaft size: 5/8” Solid or 1/2” Hollow

•Cast iron, Ni-Resist or Diamond Series housing

•Pump shaft rotation: CW Standard/CCW Optional

•Weight: 5 lbs.

•Rollers: Ultra Rollers standard

•Shaft Seals: Viton standard

•Available PTO adapters

FEATURES:

•Max. flow: 19.6 gpm at 1000 rpm

•Max. fluid temperature: 140ºF/60ºC

•Port size: 3/4” NPT

•Shaft size: 5/8” Solid

•Cast iron, Ni-Resist or Diamond Series housing

•Pump shaft rotation: CCW (CW available)

•Weight: 9 lbs.

•Rollers: Ultra Rollers standard

•Shaft Seals: Viton standard

•Available PTO adapters

FEATURES:

•Max. flow: 46.5 gpm at 1000 rpm

•Max. fluid temperature: 140ºF/60ºC

•Port size: 1” NPT

•Shaft size: 15/16” Solid Shaft

•Cast iron, Ni-Resist or Diamond Series housing

•Pump shaft rotation: CCW (CW available)

•Weight: 19 lbs.

•Rollers: Ultra Rollers standard

•Shaft Seals: Viton standard

•Available PTO adapters

FEATURES:

•Max. flow: 19.6 gpm at 1000 rpm

•Max. fluid temperature: 140ºF/60ºC

•Port size: 3/4” NPT

•Shaft size: 5/8” Solid

•Cast iron, Ni-Resist or Diamond Series housing

•Pump shaft rotation: CCW (CW available)

•Weight: 9 lbs.

•Rollers: Ultra Rollers standard

•Shaft Seals: Viton standard

•Available PTO adapters

•Rear Ports

4-ROLLER SIDE PORT PUMP 5-ROLLER SIDE PORT PUMP

6-ROLLER SIDE PORT PUMP 6-ROLLER BACK PORT PUMP

7-ROLLER SIDE PORT PUMP 8-ROLLER SIDE PORT PUMP

FEATURES:

•Max. flow: 22.5 gpm at 850 rpm max.

•Max. fluid temperature: 140ºF/60ºC

•Port size: 3/4” NPT

•Shaft size: 15/16” Solid

•Cast iron, Ni-Resist or Diamond Series housing

•Pump shaft rotation: CCW (CW available)

•Weight: 14 lbs.

•Rollers: Ultra Rollers standard

•Shaft Seals: Viton standard

•Available PTO adapters

FEATURES:

•Max. flow: 24 gpm at 1000 rpm

•Max. fluid temperature: 140ºF/60ºC

•Port size: 3/4” NPT

•Shaft size: 15/16” Solid

•Cast iron, Ni-Resist or Diamond Series housing

•Pump shaft rotation: CCW (CW available)

•Weight: 14 lbs.

•Rollers: Ultra Rollers standard

•Shaft Seals: Viton seals standard

•Available PTO adapters

Series 4400 Series 5500

Series 6600 Series 6601

Series 7000 Series 8800

Figure 2. Dimensional Drawings

2

1800 RPM 2200 RPM 2600 RPM

PRESSURE GPM (HP) GPM (HP) GPM (HP)

0 psig 6.5 (.12) 7.7 (.15) 9.2 (.19)

25 psig 5.4 (.24) 6.7 (.31) 8.4 (.36)

50 psig 4.7 (.35) 5.9 (.42) 7.7 (.54)

75 psig 4.0 (.43) 5.3 (.54) 7.1 (.70)

100 psig 3.5 (.50) 4.8 (.65) 6.7 (.84)

125 psig 3.0 (.55) 4.3 (.75) 6.3 (1.02)

150 psig 2.6 (.60) 3.9 (.85) 5.9 (1.17)

Flow Rates and Horsepower Requirements for

4-Roller Pump 4400 Series (44-5111)

Note:

Horsepower listed above is for electric motor drives.

For gas engine drives, follow gas engine manufacturers' rec-

ommendations. (As an estimate for gas engines, double the

horsepower requirements for electric motors listed above.)

PRESSURE 0psi 50psi 100psi 150psi 200psi

RPM GPM (HP) GPM (HP) GPM (HP) GPM (HP) GPM (HP)

450º 20.8 (.18) 16.4 (.98) 14.4 (1.74) 11.4 (2.31) 7.5 (2.71)

540º 25.1 (.27) 20.5 (1.16) 17.8 (2.03) 15.4 (2.74) 12.2 (3.44)

650º 30.4 (.39) 25.7 (1.45) 22.6 (2.41) 20.3 (3.42) 17.3 (4.26)

750º 34.7 (.49) 30.7 (1.68) 26.6 (2.73) 24.4 (4.00) 22.0 (5.11)

850º 39.7 (.79) 35.1 (1.93) 31.0 (3.00) 28.1 (4.60) 26.2 (5.95)

1000º 46.5 (1.62) 42.5 (2.93) 38.5 (4.11) 35.1 (5.42) —

Flow Rates and Horsepower Requirements for

5-Roller Pump 5500 Series (55-5110)

Note:

To achieve rated capacity 1" suction and pressure

hose should be used.

SPEED

MODEL (RPM) 0 psig 25psig 50psig 100psig 150psig 200psig

6-Roller

Side & Back 540 10.8 9.6 8.5 6.9 5.6 4.6

(11/16" Rollers) 1000 19.5 18.6 17.8 16.3 15.0 13.8

7-Roller

Side-Port 540 15.0 14.0 13.2 12.0 10.8 9.9

(11/16" Rollers) 750 20.0 19.2 18.4 17.2 16.1 15.2

8-Roller

Side-Port 540 13.0 12.1 11.3 10.0 8.7 7.6

(11/16" Rollers) 1000 24.0 23.2 22.4 21.0 19.8 18.7

Flow Rates in GPM for 6-7-8-Roller Pumps -

6600, 6601, 7000 and 8800 Series (66-5110,

77-5110, 88-5110)

4-ROLLER SIDE-PORT

5-ROLLER SIDE-PORT

6-ROLLER BACK-PORT

6-ROLLER SIDE-PORT 7-ROLLER AND 8-ROLLER

SIDE-PORT

3

Tractor PTO Installation

1. Secure the PTO coupling to the pump shaft by sliding the cou-

pling as far forward as possible without touching the bearing

shield and tightening the set screws down on the key of the

pump shaft. Slide coupling onto PTO shaft and secure by

pulling collar back on PTO quick coupler, sliding onto PTO

shaft and locking into place.

2. Check pump rotation. An arrow on the pump indicates proper

rotation direction.

3. To keep the pump from rotating with the shaft, set a torque arm

and short length of chain. Bolt one end of the chain to the

torque arm and secure the other to a stationary part of the trac-

tor. Be sure the chain is at a point directly above or below the

torque arm. Fastening torque chain to a point forward or back-

ward from pump center will create a bending force on pump.

Do not fasten pump rigidly to the tractor.

4. With the pump in position, connect the suction hose to the "IN"

port and the discharge hose to the "OUT" port. Make sure the

suction hose connection is tight. A loose connection will permit

air to be sucked in and the pump will not prime itself. Use at

least a 3/4" diameter hose on the suction line.

5. Use a large suction strainer with a 40 mesh minimum screen.

Either a Delavan #1700-2 suction strainer or a Delavan

#39908-2 Y type line strainer is recommended.

Engine Installation

The pump base can be mounted on a frame and aligned for either

direct-drive or belt and pulley drive. When mounting for direct-

drive, be sure pump and engine shafts are in alignment. A flex-

ible drive coupling will compensate for fractional misalignment.

When mounting for pulley drive, be sure the engine and pump

shafts are parallel. Align pulleys and keep them as close to the

shaft bearings as possible. For gasoline engine requirements,

follow engine manufacturer's recommendation.

Operation

1. With a clear suction line and open discharge line, the pump

should displace liquid within 15 seconds. A squirt of oil in the

suction side of the pump before starting will accelerate priming

action.

2. Never run the pump dry. Excessive heat will damage rollers

and seals.

3. Do not pump abrasive white wash, paints or other abrasive liq-

uids.

4. Do not use rusty supply barrels or sandy water.

5. Do not close the discharge line of the pump while it is running

unless a means of bypassing the liquid has been installed. A

simple relief or bypass valve can be easily installed in the dis-

charge side. A Delavan #37562 or #13895 pressure relief

valve is recommended.

Maintenance

1. Your Delavan pump is equipped with permanently lubricated

ball bearings. They do not require further lubrication.

2. Do not inject oil or grease into the two weep holes on the

underside of the bearing housings. These holes are to reveal

seal leakage and to prevent the solution from forcing its way

into the bearings. The holes must be kept clean.

3.

AFTER SPRAYING —

Thoroughly flush the pump with clear

water or use a solution of approximately one cup of ammonia

in 10 gallons of water. This will dissolve most residue remain-

ing in the pump. Squirt a light oil in the pump and rotate to

cover the inner surfaces with a protective film.

4.

STORAGE.

If the pump is to be out of service for several days

or stored, flush pump with clear water or use a solution of one

cup of ammonia in 10 gallons of water. Then pump a 50 per-

cent permanent antifreeze solution through the pump. Plug ports.

Caution: Do not use gasoline, kerosene, or fuel oil.

Pump Disassembly

Note: The numbers in parentheses used in the following

text are reference numbers that are found in the

exploded views.

1. With a screwdriver, remove snap ring (1). Lift out nameplate (2).

2. With a 9/16-inch wrench unscrew capscrews (3).

3. With cover plate down, cradle pump on "IN" and "OUT" ports

on fixture under an arbor press (Fig. 4). A cradle can be con-

structed of 2" x 4" lumber. Press the shaft and rotor assembly

(6) down through the pump body, bearing the seal. The shaft

and rotor assembly will remain in the end plate.

4. Lift off seal ring (4). Slide out rollers (5).

5. Check body for wear. File off any burrs that appear on rotor.

6. Make sure rollers (5) move freely in rotor slots. Replace rollers if

out-of-round, swollen or badly worn.

7. If further disassembly is required:

a. Press out shaft and rotor assembly (6) from end plate (7)

with an arbor press while supporting the end plate on a

cradle. Remove snap ring (1).

b. To remove bearing, use a small piece of brass rod and gen-

tly tap with hammer on the inner edges of the bearing. Drive

the seal out with a screwdriver and hammer. Discard seal.

4

Assembly

1. A repair kit including 4, 5, 6, 7 or 8 rollers, 2 seals, and a

seal ring is available (see parts list).

2. Position a new seal in seal housing with folded edge down.

Press seal down on outer edge until it "bottoms."

3. Position bearing (8) in bearing housing and press downward

until it "bottoms." Apply pressure to outer bearing race.

4. File off any burrs on the rotor faces and roller slots that may

have been caused by disassembly and handling.

5. Apply a light oil to shaft, end plate surface, and inside pump

body.

6. Press shaft and rotor into body, by easing the rotor shaft

through the seal; then press shaft with an arbor press while sup-

porting body bearing inner race.

7. Insert rollers (5), one in each slot.

8. Place seal ring (4) in groove.

9. Position end plate (7) for pressing down on pump body (10),

easing the shaft carefully through the seal. Carefully line up

matching holes of pump body and end plate.

10. Press pump together in an arbor press (Fig. 4), making sure the

pressing force is applied to the inner race of the ball bearing.

A sleeve with at least a 1 inch bore (that does not exceed 2

inches outside diameter) should be used.

11. Secure end plate with four capscrews (3).

12. After tightening capscrews, turn the shaft to make sure rotor is

not binding in pump. (It may be necessary to hold shaft in vise

when rotating body to check for binding.)

13. Tap shaft with a brass hammer. If this fails to center rotor, tap

the other end of the shaft lightly. The rotor should turn freely.

PROBLEM

1. NO PRESSURE OR NO CAPACITY

2. PUMP RUNS, BUT LOW PRESSURE AND

CAPACITY

3. PUMP PRESSURE GOOD, BUT LOW OUTPUT

THROUGH THE NOZZLES

4. EXCESSIVE NOISE OR VIBRATION

5. IMPOSSIBLE TO ROTATE SHAFT

TROUBLESHOOTING GUIDE

CAUSES AND REMEDIES

a. Inlet linenotfullyimmersedintank,or lowtanklevel.

b. Pumpnotproperlyprimed.

c. Cloggedinletstrainer.

d. Suctionlineairleaks.Useplumber'sjointcompoundorTeflontape.Tightenallconnections.Checkhosesforcracksorpinholes.

e. Suctionlineblockedorhosecollapsed.

f. Pumpisair-bound.Checkfordrytank,or"traps"in the line. Tryremovingonenozzleuntil pumpstartspriming.

g. Wornandleakingseals.Replace.

h. Pumpturningin wrongdirection.(Areversedirectionpumpwillnotwok onatractorPTO).

a. Suctionlineandfittingspartiallyblockedortoo small.Hosekinked.

b. Wornrollers. Replacewithnew(seepartslist).

c. Cloggedinletstrainer.

a. Nozzleorificestoosmall.Install largersizes.

b. Outletlinetoosmallorblocked.

c. Bypasspartiallyopen.Closeit.

a. Possibleloosecoupler...bentor damagedshaft.

b. ExcessivePTOspeed...1000rpm maximum.

c. Suctionlineleaks orcloggedstrainer(See1-dabove).

d. Wornrollers. Replacewithnew(seepartslist).

a. Improperassembly.Tapshaftwithbrasshammer(Refertoassemblyinstructions).

b. Corrosionorforeignobjectinpump.Disassembleandthoroughlycleanallparts.Replacewornparts.Seesectionon Maintenance.

PART QUANTITY

NO. DESCRIPTION PER KIT

48234 Roller, Polypropylene, 1/2" diameter 4

20468 Lip Seal, Fluorocarbon (Viton) 4

31350-142 Seal Ring 2

5

Delavan Models 4400C, 4400N, 4400D, 4401C, 4401N, 4401D

REF. NO. QTY. PART NO. DESCRIPTION

1 2 15070 Snap Ring

2 1 48237 Nameplate 4400C

1 48237-1 Nameplate 4400N

1 48237-2 Nameplate 4400D

3 4 48236 Cap Screw

4 1 31350-142 Seal Ring

5 4 48234 Ultra Rollers 1/2"

6 1 31661-14 Shaft & Rotor Assy. Cast Iron

1 31661-14 Shaft & Rotor Assy. Ni-Resist

1 31661-17 Shaft & Rotor Assy. Diamond

1 31661-18 Hollow Shaft & Rotor Assy.

Cast Iron

1 31661-18 Hollow Shaft & Rotor Assy.

Ni-Resist

1 31661-23 Hollow Shaft & Rotor Assy.

Diamond

7 1 46231-1 Endplate Cast Iron

1 46231-2 Endplate Ni-Resist

1 46231-3 Endplate Diamond

8 2 15072 Bearing STD#6203ZZ

9 2 20468 Lip Seal Viton

10 1 48229-1 Pump Body Cast Iron

1 48229-2 Pump Body Ni-Resist

1 48229-3 Pump Body Diamond

Universal Repair Kit

44-4000 RK

4-Roller Pump Repair Kit for 4400 Pump

Note:

Repairs 44-XXXX

6

Delavan Models 5500C, 5500N, 5500D

REF. NO. QTY. PART NO. DESCRIPTION

1 2 15334 Snap Ring

2 1 48255 Nameplate 5500C

1 48255-1 Nameplate 5500N

1 48255-2 Nameplate 5500D

3 4 15341 Cap Screw

4 1 48252 Seal Ring

5 5 48253 Ultra Rollers 1"

6 1 31661-15 Shaft & Rotor Assy. Cast Iron

1 31661-15 Shaft & Rotor Assy. Ni-Resist

1 31661-20 Shaft & Rotor Assy. Diamond

7 1 48248-1 Endplate Cast Iron

1 48248-2 Endplate Ni-Resist

1 48248-3 Endplate Diamond

8 2 16228 Bearing STD#6705ZZ

9 2 47927 Lip Seal Viton

10 1 48246-1 Pump Body Cast Iron

1 48246-2 Pump Body Ni-Resist

1 48246-3 Pump Body Diamond

PART QUANTITY

NO. DESCRIPTION PER KIT

48253 Ultra Roller, 1” Diameter 5

47927 Lip Seal, Viton 2

48252 Seal Ring 2

Universal Repair Kit

55-1700 RK

5-Roller Pump Repair Kit for 5500 Pump

Note:

Repairs 55-XXXX

7

Delavan Models 6600C, 6600N, 6600D, 6601C, 6601N, 6601D

REF. NO. QTY. PART NO. DESCRIPTION

1 2 15070 Snap Ring

2 1 46210-2 Nameplate 6600C

1 46210-7 Nameplate 6600N

1 46210-3 Nameplate 6600D

1 46210-1 Nameplate 6601C

1 46210-8 Nameplate 6601N

1 46210-9 Nameplate 6601D

3 4 15077 Capscrew

4 1 24819 Seal Ring

5 6 19341 Ultra Rollers 11/16"

6 1 31661-8 Shaft & Rotor(Cast Iron/Ni-Resist)

1 31661-9 Shaft & Rotor (Diamond)

7 1 31664-1 End Plate Cast Iron

1 31664-2 End Plate Ni-Resist

1 31664-3 End Plate Diamond

8 2 15072 Bearing (STD#6203ZZ)

9 2 20468 Lip Seal Viton

10 1 50073-1 Pump Body Cast Iron Side

1 50073-2 Pump Body Ni-Resist Side

1 50073-3 Pump Body Diamond Side

1 24817-1 Pump Body Cast Iron Rear

1 24817-2 Pump Body Ni-Resist Rear

1 24817-3 Pump Body Diamond Rear

PART QUANTITY

NO. DESCRIPTION PER KIT

19341 Ultra Roller 11/16” Diameter 6

20468 Lip Seal, Viton 4

24819 Seal Ring 2

Universal Repair Kit

66-6500 RK

6-Roller Pump Repair Kit for 6600 & 6601 Pumps

Note:

Repairs 66-XXXX

Delavan Models 7000C, 7000N, 7000D

8

REF. NO. QTY. PART NO. DESCRIPTION

1 2 15334 Snap Ring

2 1 46209-3 Nameplate 7000C

1 46209-4 Nameplate 7000N

1 46209-7 Nameplate 7000D

3 4 15341 Capscrew

4 1 24829 Seal Ring

5 7 19341 Ultra Rollers, 11/16"

6 1 31661-10 Shaft & Rotor Assy.

(Cast Iron /Ni-Resist)

1 31661-11 Shaft & Rotor Assy. Diamond

7 1 31666-1 End Plate Cast Iron

1 31666-2 End Plate Ni-Resist

1 31666-3 End Plate Diamond

8 2 16228 Bearing (STD#6205ZZ)

9 2 47927 Lip Seal Viton

10 1 24842-1 Pump Body Cast Iron

1 24842-2 Pump Body Ni-Resist

1 24842-3 Pump Body Diamond

PART QUANTITY

NO. DESCRIPTION PER KIT

19341 Ultra Roller 11/16” Diameter 7

47927 Lip Seal, Viton 2

24829 Seal Ring 2

Universal Repair Kit

70-7700 RK

Pump Repair Kits

Note:

Repairs 77-XXXX

9

Delavan Models 8800C, 8800N, 8800D

REF. NO. QTY. PART NO. DESCRIPTION

1 2 15334 Snap Ring

2 1 46209-1 Nameplate 8800C

1 46209-2 Nameplate 8800N

1 46209-6 Nameplate 8800D

3 4 15341 Capscrew

4 1 24829 Seal Ring

5 8 19341 Ultra Rollers, 11/16"

6 1 31661-12 Shaft & Rotor Assy

(Cast Iron /Ni-Resist)

1 31661-24 Shaft & Rotor Assy Diamond

7 1 31666-1 End Plate Cast Iron

1 31666-2 End Plate Ni-Resist

1 31666-3 End Plate Diamond

8 2 16228 Bearing (STD#6205ZZ)

9 2 47927 Lip Seal Viton

10 1 24842-3 Pump Body Cast Iron

1 24842-4 Pump Body Ni-Resist

1 24842-6 Pump Body Diamond

PART QUANTITY

NO. DESCRIPTION PER KIT

19341 Ultra Roller 11/16” Diameter 8

47927 Lip Seal, Viton 2

24829 Seal Ring 2

Universal Repair Kit

88-7560 RK

Pump Repair Kits

Note:

Repairs 88-XXXX

10

PICTURE PART # FITS PUMPS RPM PUMP SHAFT SIZE PTO SHAFT DESCRIPTION

540 & 1 3/8”

46814-1 6600 Series 1000 5/8” Dual Speed

7/8” shaft 1 3/8” Dual Speed 540 & 1000 RPM,

Old Style & 540 & Corrosion Resistant,

46814-2 Competitive Pumps 1000 7/8” Dual Speed Cast Aluminum, Nylon Collar

7- and 8-Roller Pumps 540 & 1 3/8”

46814-3 7000 & 8800 Series 1000 15/16” Dual Speed

5500, 8800, & 7000* 540 RPM, Forged Steel Body

35735 Series (540 only) 540 15/16” 1 3/8” Nylon Collar

5500 & 8800Roller 1000 RPM, Forged Steel Body

35979 Pumps, Turbo 90 1000 15/16” 1 3/8” Nylon Collar, 1 3/4” PTO

5500 & 8800Roller 1000 RPM, Forged Steel Body

35992 Pumps, Turbo 90 1000 15/16” 1 3/4” Nylon Collar, 1 3/4” PTO

5500 & 8800 Roller

46935-1 Pumps, Turbo 90 1000 15/16” 1 3/8”

*Collar Coupler (see below)

1 3/4 1000 RPM PTO,

5500 & 8800 Roller

46647 Pumps, Turbo 90 1000 15/16” 1 3/4”

50101 4400 Series 2600 5/8” 5/8” Mild Steel Set Screw Coupler

*7000 Series Roller Pump Use on 540 RPM PTO Only

**Collar Coupler reduces possible vibration by clamping a full 360 degrees on the pump shaft & PTO. This better centers the pump shaft to the trac-

tor PTO, giving less chance of uneven wear. Both ends of the Coupler must be wrench-tightened onto the PTO & Pump shafts before operation.

NOTE: Do not force Coupler too far onto the PTO. After Coupler is in position, 1/4” - 3/8” of PTO should be visible.

***Do not use series 46814 Couplers for 5-Roller or Turbo 90 Pumps.

ROLLER PUMP COUPLERS

UNIVERSAL REPAIR KITS

REPAIR FOLLOWING PUMP

NEW REPAIR KIT OLD REPAIR KIT DELAVAN OLD # DELAVAN NEW # HYPRO # DESCRIPTION

44-4000RK 48631-1 44-Cast Iron 4400 4001/4101 4 Ultra Rollers

Ni resist 4 Viton Shaft Seals

Diamond 2 Universal O-Rings

66-6500RK 48394-1 6/66-Cast Iron 6600 6500 6 Ultra Rollers

Ni resist 4 Viton Shaft Seals

Diamond 2 Universal O-Rings

70-7700RK 48394-2 77-Cast Iron 7000 7700 7 Ultra Rollers

Ni resist 2 Viton Shaft Seals

Diamond 2 Universal O-Rings

88-7560RK 48394-3 88-Cast Iron 8800 7560 8 Ultra Rollers

Ni resist 2 Viton Shaft Seals

Diamond 2 Universal O-Rings

55-1700RK 48632-1 55-Cast Iron 5500 1700 5 Ultra Rollers

Ni resist 2 Viton Shaft Seals

Diamond 2 Universal O-Rings

11

NOTES

Returns

All Delavan products are warranted against manufacturing defects

(see warranty, below). In the event you feel you have a warranty-

covered, returnable item, return the pump to your dealer, who will

replace a warrantable pump for you. Delavan's "No Hassle

Warranty" puts you back in the field sooner!

1228 Chestnut Avenue • Minneapolis, MN 55403

Toll Free: 1-866-DELAVAN (335-2826)

(612) 333-3189

Toll Free Fax: 1-888-726-5906

(612) 333-3231

Delavan Products Warranty

All products sold by Delavan are warranted only to purchasers from

Delavan for resale or for use in purchasers' own business or original

equipment manufacture, against defects in workmanship or materials

under normal use, maintenance and service (rental use excluded), if

notice of said defect is received by Delavan at the factory within 90

days after installation or one year from date of shipment from the

factory, whichever first occurs. The sole and exclusive obligation of

Delavan under this or any implied warranty shall be to replace or,

at its option, to repair, without charge, any product which is deter-

mined by Delavan to be defective in workmanship or materials after

the product is returned to the Delavan factory, shipping costs pre-

paid. In no event shall Delavan be liable to any person for indirect

or consequential damages or for injury or commercial loss resulting

from any use or inability to use and Delavan product. Delavan

expressly negates any other warranty, express or implied, including

any warranty of merchantability or fitness for a particular purpose,

or arising from any course of dealing or custom or usage of trade.

No person, including any dealer or representative of Delavan, is

authorized to make any representation or warranty on behalf of

Delavan in addition to or inconsistent with these provisions.

Purchasers to whom these provisions apply agree to hold Delavan

harmless from claims by their customers in excess of the obligations

of Delavan expressly set forth herein.

Important:

Whether you are returning your pump for warranty or for repair,

you must do the following:

1. Flush chemical residue from the pump (best done in the field).

2. Tag pump with type of chemicals having been sprayed.

3. Include complete description of operation problem, such as

how pump was used, symptoms of malfunction, etc.

Since pumps can contain residues of toxic chemicals these steps are

necessary to protect all the people who handle return shipments,

and to help pinpoint the reason for the breakdown.

This manual suits for next models

26

Table of contents

Other Delavan Water Pump manuals

Popular Water Pump manuals by other brands

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS PA6H60-4045H FT4-ESP Installation, operation and maintenance manual

Grundfos

Grundfos MIXIT instructions

VERTO

VERTO 52G441 instruction manual

vacuubrand

vacuubrand RC 6 Instructions for use

MULTIQUIP

MULTIQUIP MAYCO LS300P Operation manual

Mixtron

Mixtron MXO1.075.P110.00 Operating and maintenance manual