Delavan PowerFLO 7800 Series Use and care manual

PowerFLO™7800 Series

Installation • Operation • Repair • Parts

12 Volt DC Motor-Driven Diaphragm Pumps

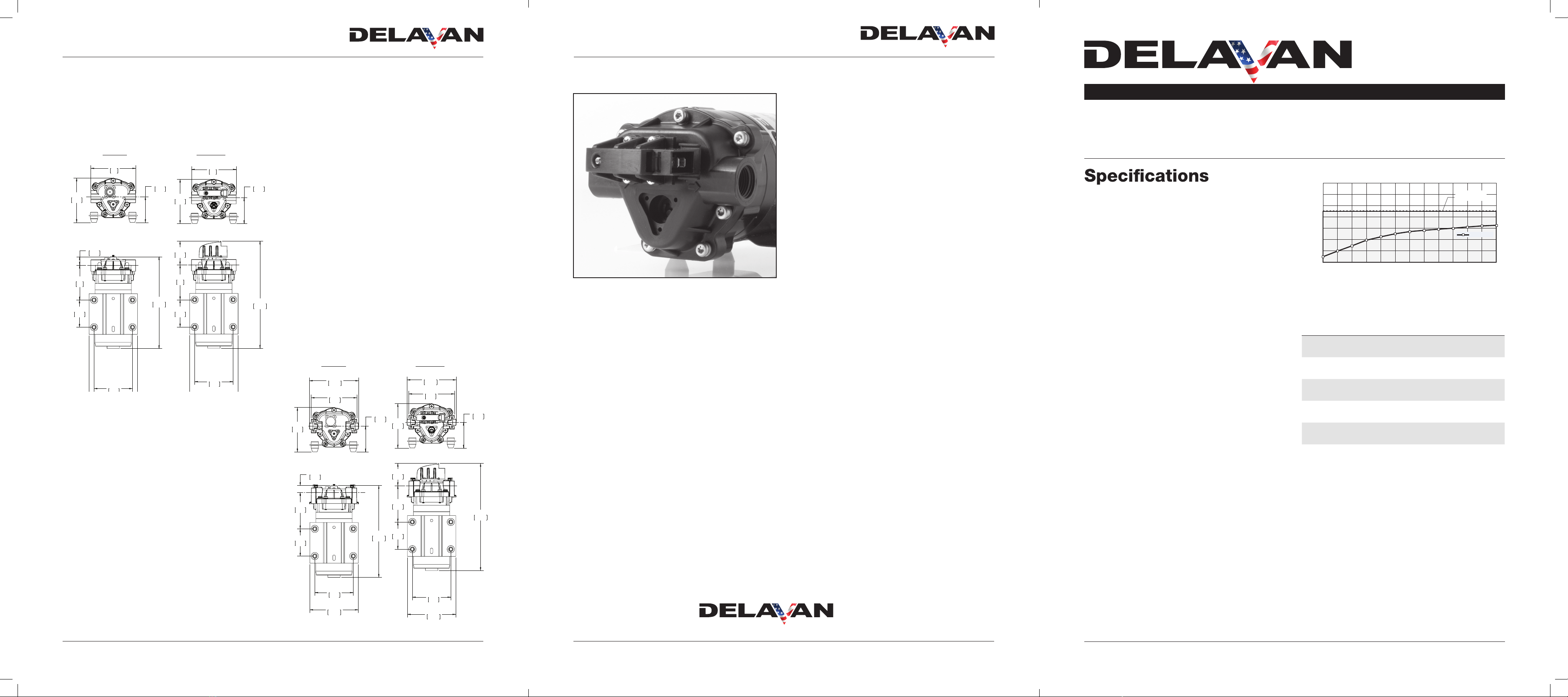

3.70

94

3.67

93.2

2.13

54.1

3.17

80.5

4.00

101.6

2.25

57.2

7.58

192.5

2.87

73

.70

17.8

3.70

94

3.67

93.2

2.13

54.1

2.25

57.2

3.17

80.5

4.00

101.6

8.84

224.5

2.87

73

1.96

49.8

3.77

95.8

3.67

93.2

2.13

54.1

4.07

103.4

7.58

192.5

3.17

80.5

4.00

101.6

2.25

57.2

3.00

76.2

.58

14.6

3.77

95.8

3.67

93.2

2.13

54.1

4.07

103.4

2.25

57.2

3.17

80.5

4.00

101.6

8.84

224.5

3.00

76.2

1.83

46.6

Motor

Type: 12 VDC, permanent magnet, totallyenclosed,

non-ventilated

Leads: 16 AWG, 6” long

Duty Cycle: See Heat Rise graph

Temperature Limits: Motor is not equipped with thermal

protection. For user safety, optimal performance, and maximum

motor life, the motor surface temperature should not exceed

150°F (66°C) (See Heat Rise graphs).

Pump

Type: 3 chamber positive displacement diaphragm pump, self

priming, capable of being run dry, demand or bypass model.

Liquid Temperature: 140°F (60°C) Max.

Priming Capabilities: 14 feet (4 m)

Max Pressure: 60 PSI

Inlet/Outlet Ports:

7801/7802/7822: Quick Attach (See chart on right)

7811/7812: 3/8” FNPT

Materials of Construction

Housing: Polypropylene Diaphragm: Santoprene

Valves: Viton Fasteners: Stainless steel

Weight

6 lbs (2.7 kg)

Quick Attach Nylon Inlet/Outlet Port Fittings

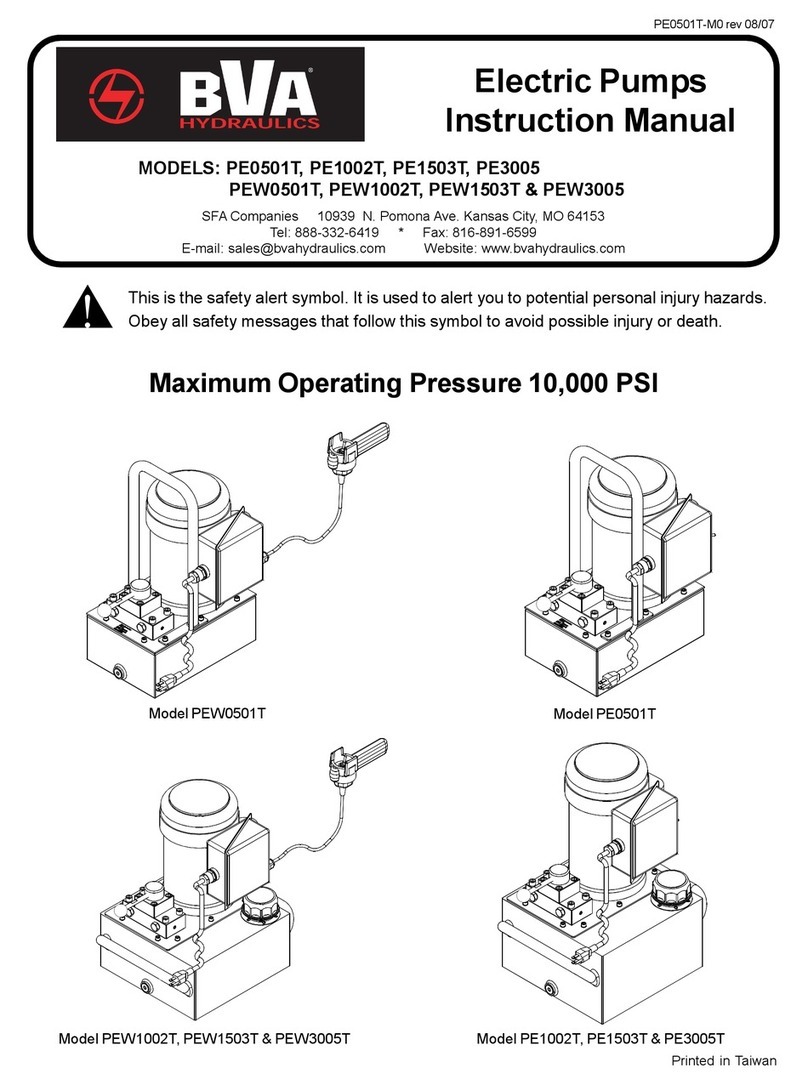

Heat Rise

Approximate values, actual values will vary with ambient temperature.

Recommended

Shell Temperature

Limit

Time (Minutes)

0

60

80

100

120

140

160

180

200

10 20 30 40 50 60 70 80 90 100 110 120

Temperature (ºF)

6.19 Amps

Item # Description

3DFA38 5/8” QA x 3/8” HB Straight Fitting

w/ O-Ring, Nylon

3DFA12 5/8” QA x 1/2” HB Straight Fitting

w/ O-Ring, Nylon

3DFE38 5/8” QA x 3/8” HB Elbow Fitting

w/ O-Ring, Nylon

3DFE12 5/8” QA x 1/2” HB Elbow Fitting

w/ O-Ring, Nylon

3DFF38 5/8” QA x 3/8” FNPT Straight Fitting

w/O-Ring, Black Nylon

3DFF12 5/8” QA x 1/2” FNPT Straight Fitting

w/ O-Ring, Black Nylon

Dimensions Inches (mm) Weight 6 lbs (2.7 kg)

The PowerFLO Series 7800 pump is controlled by a built-in

pressure sensing demand switch. When a faucet or valve

is opened down stream of the pump, line pressure drops

thus starting the pump automatically. Conversely, when the

valve shuts, the line pressure increases turning the pump off

automatically. The pressure switch actuates in response to the

pump outlet pressure at a predetermined and preset pressure.

The pump label indicates the predetermined ON and OFF

pressures. Typically, the OFF pressure is accurately set at the

Factory and the ON pressure is within an allowable range below

that value. In response to the characteristics of the system

in which the pump is installed, the flexibility and length of the

tubing, the faucet or valves and the duration that they are open;

these pressure settings may vary. Therefore, variation in pressure

setting is expected with use and over time.

Standard Warranty

Delavan warrants PowerFLO Series Pumps for a period of two

years from date of manufacture.

All products sold by Delavan are warranted only to purchasers

from Delavan for resale or for use in purchasers’ own business

or original equipment manufacture, against defects in

workmanship or materials under normal use, maintenance and

service (rental use excluded).

The sole and exclusive obligation of Delavan under this or any

implied warranty shall be to replace or, at its option, to repair,

without charge, any product which is determined by Delavan

to be defective in workmanship or materials after the product is

returned to the Delavan factory*, shipping costs prepaid.

In no event shall Delavan be liable to any person for indirect

or consequential damages or for injury or commercial loss

resulting from any use or inability to use any Delavan product.

Delavan expressly negates any other warranty, express or

implied, including any warranty of merchantability or fitness for

a particular purpose, or arising from any course of dealing or

custom or usage of trade.

No person, including any dealer or representative of Delavan,

is authorized to make any representation or warranty on behalf

of Delavan in addition to or inconsistent with these provisions.

Purchasers to whom these provisions apply agree to hold

Delavan harmless from claims by their customers in excess of

the obligations of Delavan expressly set forth herein

* Important return safety instructions:

When you return your pump for warranty or repair, you must

always do the following:

1. Flush chemical residue from the pump

(best done in the field).

2. Tag pump with type of chemicals having been sprayed

3. Include complete description of operation problem, such as

how pump was used, symptoms of malfunction, etc.

Since pumps can contain residues of toxic chemicals these

steps are necessary to protect all the people who handle return

shipments, and to help pinpoint the reason for the breakdown.

Pressure Sensing Demand Switch

www.delavanagpumps.com

Bypass Demand

PowerFLO™7800 Series PowerFLO™7800 Series

Toll Free: 1-866-DELAVAN (335-2826) •Toll Free Fax: 1-888-726-5906 •delavanagpumps.com

Toll Free: 1-866-DELAVAN (335-2826) •Toll Free Fax: 1-888-726-5906 •delavanagpumps.comToll Free: 1-866-DELAVAN (335-2826) •Toll Free Fax: 1-888-726-5906 •www.delavanagpumps.com

Threaded Port Pump

Quick Attach Port Pump

Bypass Demand

Toll Free: 1-866-DELAVAN (335-2826) •Toll Free Fax: 1-888-726-5906 •delavanagpumps.com

Mounting:

Determine the optimum location for your pump.

1. The pump should be mounted in a dry place and away

from any source of heat. If an enclosure is used, special

instructions for cooling the motor may be necessary. Consult

the Factory.

2. Do not subject the pump to extreme high or low (freezing)

temperatures while in operation. (Operating ambient

temperature range is 32° F to 115°F).

3. The pump may be mounted horizontally with the outlet port on

the right when viewed from the pump end or with the pump

above the mount, or vertically with the pump above or below

the motor.

Plumbing:

1. Use suction hose on inlet of pump. We recommend use of

flexible tubing with proper pressure rating.

2. Pump will prime only if all pressure is relieved from outlet port.

3. It is recommended that pure water be pumped or an in-line

sediment filter (50 mesh) be installed at the inlet side to keep

foreign debris out of the system. If a check valve is installed

in the plumbing, it must have a cracking pressure of no more

than 2 psi (0.14 bar).

4. Avoid any sharp bends which may crimp tubing and restrict

flow. Use 90° elbow fittings if necessary.

5. The pump should always be mounted prior to any

components which could introduce particles to the water;

thus, preventing them from entering the pump chambers and

possibly causing clogging.

Electrical:

1. The 7800 series pumps are designed for intermittent duty.

Make sure that “OFF” periods are sufficient. Refer to Rapid

ON/OFF Operation. Consult the factory for particular data and

design criteria.

2. Be sure power supply used is adequate for the application.

3. Pump ratings are based off alternator charged battery which

supplies 13.7 volts.

4. Each single drop in voltage is a reduction in motor speed thus

reducing pump performance.

(1 volt decrease = 200-300 loss in RPM)

5. Higher operating flow and pressure increases amp draw.

Installation and Operation

Precautions:

1. The pump is equipped with a pressure sensing demand

switch that controls the maximum operating pressure.

2. In addition, never subject the pump to pressures above 125

PSI (8.5 bars).

3. As long as there is inlet water pressure, the pump will not stop

forward flow of water even if the motor is turned off. Be sure

the system has positive means of shutting off water supply.

4. Do not operate pump in an explosive environment. Arcing

from the motor brushes, switch or excessive heat from an

improperly cycled motor may cause an explosion.

5. Do not locate the pump motor near low temperature plastics

or combustible material. The surface temperature of the motor

may exceed 250°F (120°C).

6. Do not pump gasoline or other flammable liquids. Pump head

materials are designed for use with water only. Do not use

with petroleum products.

7. Do not assume fluid compatibility. If the fluid is improperly

matched to the pumps’ elastomers, a leak may occur.

8. To prevent electrical shock, disconnect power before initiating

any work. In the case of pump failure, the motor housing and/

or pump fluid may carry high voltage to components normally

considered safe. Therefore, always consider electrical shock

hazard when working with and handling electrical equipment.

If uncertain, consult an Electrician. Electrical wiring should only

be done by a qualified electrician per local and state electrical

codes.

Installation Recommendations Installation and Operation

1. Turn off water supply.

2. Cut flexible tubing in sufficient length to avoid any stress on

the tubing where it connects to the pump or the fitting on any

accessory.

3. Insert tubing into pump ports. If fittings are John Guest type,

be sure tubing is inserted past the resistance point until it

bottoms out against the port stop. If compression fittings

with threaded nuts are used, insert tubing until it bottoms out

in the port and hand tighten the compression nut until the

connection is tight. Then use a wrench to tighten the nut 1/2

turn clockwise or follow the wrench tightening instructions

provided by the fitting manufacturer.

4. The pump is now ready for operation. Turn on water supply to

allow water to flow to the pump.

5. If the power source is a transformer, plug the appropriate

supplied/approved transformer into the receptacle and

connect the pump to the transformer. If the power source is

not a transformer, connect the pump to the appropriate power

source. Open the discharge or dispensing valve. Allow water

to circulate, purging any entrapped air.

6. The pump will now start building pressure. Operating pressure

will vary with flow rate, flow valve, feed-water pressure and line

voltage. Check for fitting leaks.

7. If compression fittings with threaded nuts are used, observe

any leaks after pump has run for approximately 15 minutes.

Further tighten compression nuts approximately 1/8 to 1/4

of a turn on all fittings in the system. Wait 15 minutes and

repeat the leak check. Note: Further adjustments should

not be necessary although it may take several days of

operation before all the air has been purged and the system is

stabilized.

8. Adjusting the Pressure Switch. Should the pressure switch

OFF setting vary with use and time to an unsuitable value,

it may be adjusted for optimum performance. Turn the

setscrew clockwise to increase the OFF pressure setting

and counter clockwise to decrease. The screw should not

be adjusted more than one half turn without consulting the

Factory. Excessive adjustment of the pressure switch could

cause low system pressure, rapid cycling ON/OFF operation,

and reduced pump and motor life. Damage may occur. The

Warranty does not cover improper adjustment of the pressure

switch.

Servicing:

Every Year: Check system against operating standards.

Every 2-3 Years: We recommend replacing the diaphragm

and checking against operating standards.

Troubleshooting Guide

Pump will not Start

Check:

•Correctvoltage (±10%) and electrical connections

•Fuseor breaker

•Pressureswitch operation and correct voltage at switch

or motor for open or grounded circuit

•Lockeddrive assembly

Pump will not Prime (No discharge with motor running)

Check:

•Debrisin strainer

•Restriction(kinks) in inlet/outlet tubes

•Debrisor swelling in inlet/outlet valves

Pump will not Shut Off (Output line closed and no leaks)

Check:

•Airtrapped in outlet line or pump head

•Correctvoltage to pump

•Debrisin pump inlet/outlet valves

•Loosedrive assembly or pump head screws

•Pressureswitch operations/adjustments

Leaks from Pump Head or Switch

Check:

•Loosescrews at switch or pump head

•Switchdiaphragm ruptured or pinched

•Punctureddiaphragm if is present

Replacement Parts

7801,7811,7802,7812,7822

1Lower Housing ............................................................................................................................................ 1

7801/7811 Demand or Bypass ....................................................................................... LHA-7801

7802/7812 Demand or Bypass ....................................................................................... LHA-7802

7822/7823 Demand or Bypass ....................................................................................... LHA-7822

2Valve Assembly ........................................................................................................................................... 1

7800 Series (all models) .................................................................................................. VHA-7800

3Upper Housing ............................................................................................................................................ 1

7801/7802/7822 Series w/Pressure Switch...............................................................UHA-7802-PS

7801/7802/7822 w/Bypass ........................................................................................ UHA-7802-B

7811/7812/7832 Series w/Pressure Switch...............................................................UHA-7812-PS

7811/7812/7832 Series w/Bypass.............................................................................. UHA-7812-B

4Mounting Screws .......................................................................................................................................

8-32 X 1”.......................................................................................................................... J78-051 4

10-32 X 1 1/2“.................................................................................................................. J78-050 3

5Complete Pump Head w/Threaded Ports.................................................................................................... 1

7811 w/Pressure Switch ............................................................................................. PH-7811-PS

7811 w/Bypass............................................................................................................. PH-7811-B

7812 w/Pressure Switch ............................................................................................. PH-7812-PS

7812 w/Bypass............................................................................................................. PH-7812-B

Complete Pump Head w/Quick Attach Ports .............................................................................................. 1

7801 w/Pressure Switch ............................................................................................. PH-7801-PS

7801 w/Bypass............................................................................................................. PH-7801-B

7802 w/Pressure Switch ............................................................................................. PH-7802-PS

7802 w/Bypass............................................................................................................. PH-7802-B

7822 w/Pressure Switch ............................................................................................. PH-7822-PS

7822 w/Bypass............................................................................................................. PH-7822-B

612 VDC Motor ............................................................................................................................................. 1

7800 Series w/Connector, No Switch, ............................................................................. M12-78B

7800 Series w/Switch and Connector............................................................................... M12-78C

7Pressure Switch .......................................................................................................................................... 1

7800 Series (all models) .................................................................................................7800-PSW

Item Description Part Number Qty

PowerFLO™7800 Series PowerFLO™7800 Series PowerFLO™7800 Series

Toll Free: 1-866-DELAVAN (335-2826) •Toll Free Fax: 1-888-726-5906 •delavanagpumps.com

Toll Free: 1-866-DELAVAN (335-2826) •Toll Free Fax: 1-888-726-5906 •delavanagpumps.com

This manual suits for next models

1

Other Delavan Water Pump manuals

Popular Water Pump manuals by other brands

BVA Hydraulics

BVA Hydraulics PE0501T instruction manual

EBARA

EBARA 3E Series Original instructions

Champion Power Equipment

Champion Power Equipment 100742 Operator's manual

SPIDO

SPIDO Subinox 6 instruction manual

SAMES KREMLIN

SAMES KREMLIN REXSON SH930 user manual

Tallas Pumps

Tallas Pumps P1 300 Instruction for installation and maintenance