Toll Free: 1-866-DELAVAN (335-2826) • PH: 612-333-3189 • Toll Free Fax: 1-888-726-5906 • Fax: 612-333-3231

Document HD Magnum Install 3.15.06

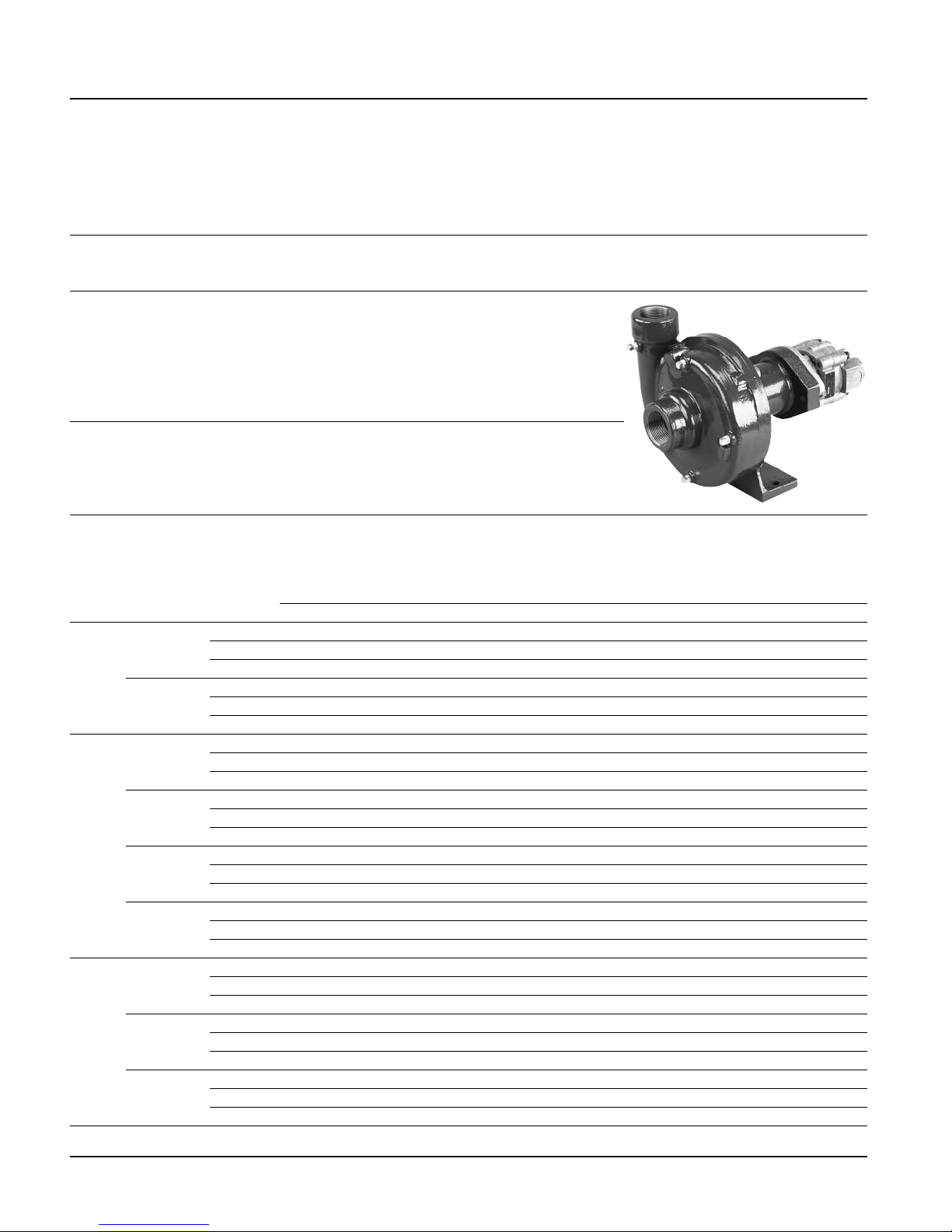

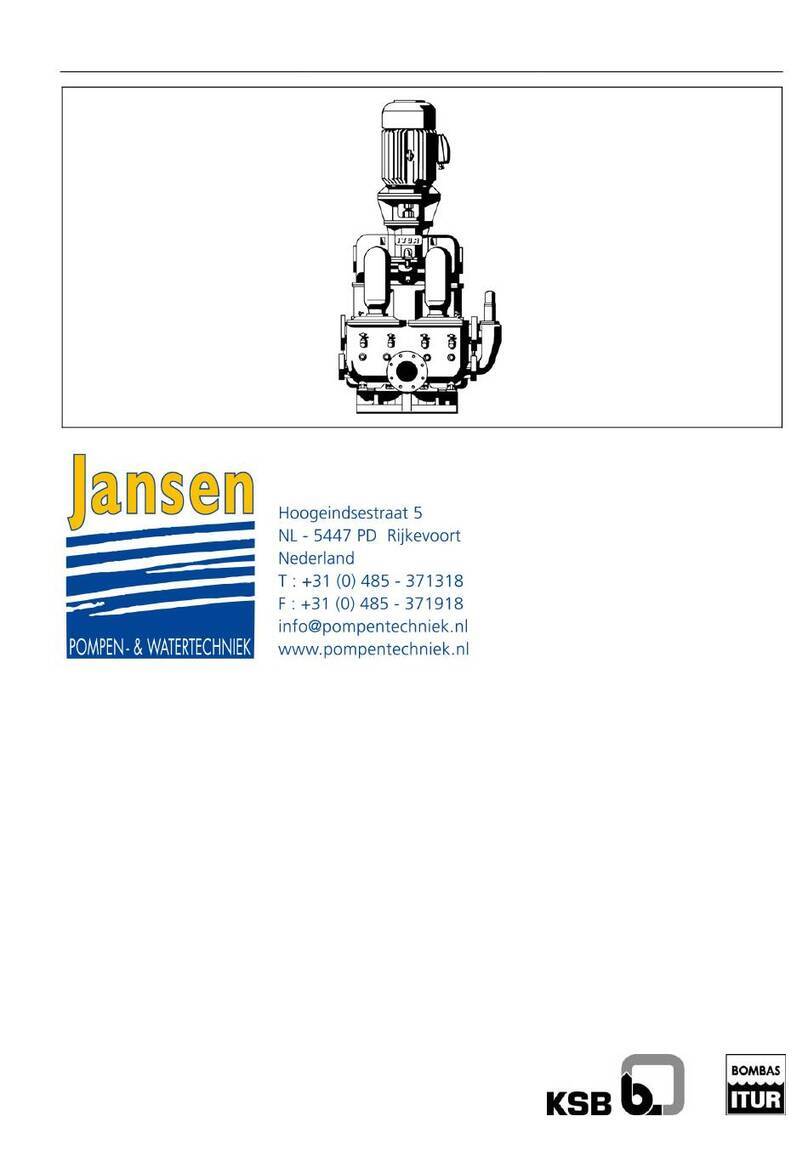

Hydraulically Driven Centrifugal Pumps

9

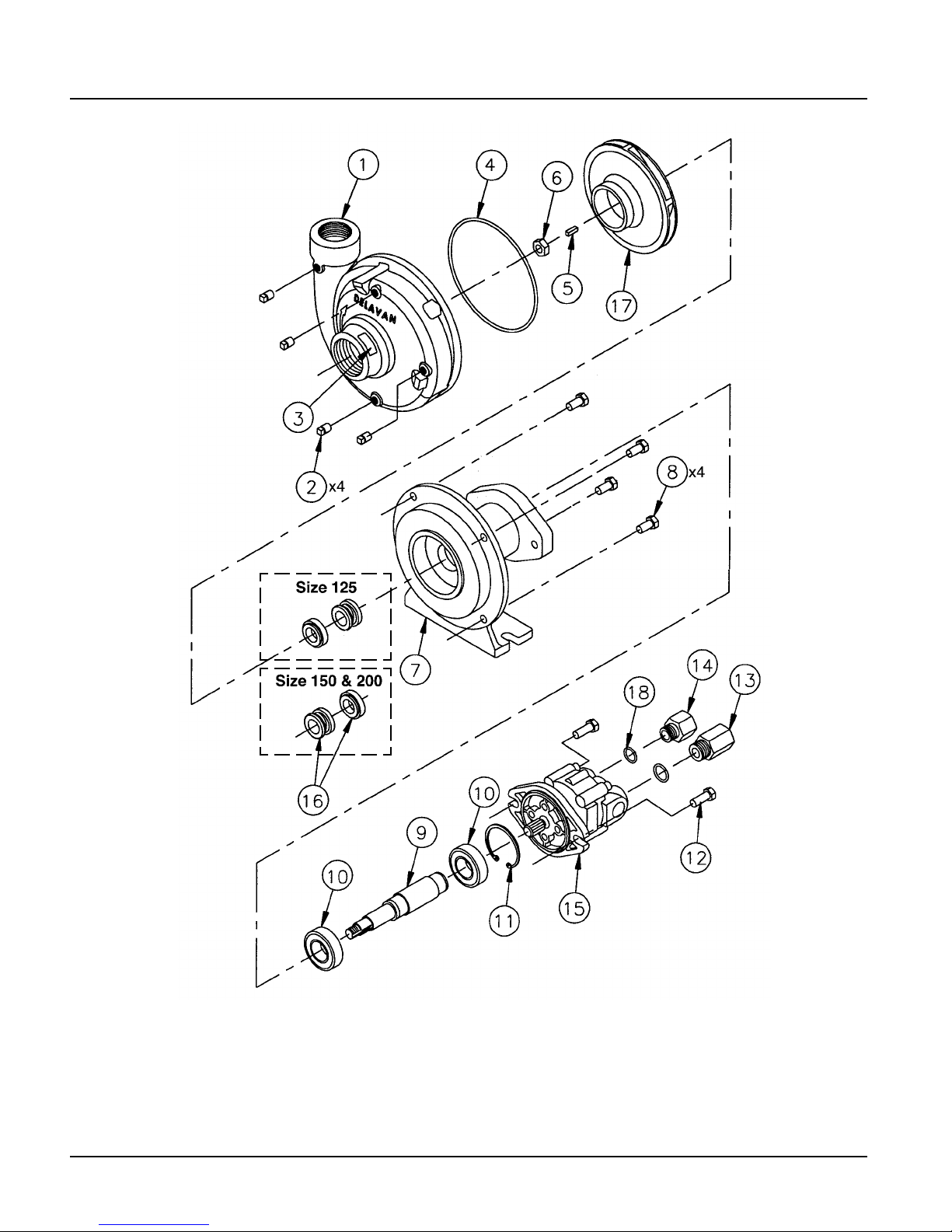

1 Volute Casing .......................................... 1

Size M125: 1-1/4”..................... I34-001

Size M150: 1-1/2”..................... I37-025

Size M200: 2” ........................... I39-025

2 1/8” NPT Pipe Plug ....................... 25785 4

3 Caution Label ................................. 35276 1

4 Frame O-ring Seal ....................... I34-003 1

5 3/16” Square Key......................... I34-005 1

6 Hex Nut ................................................... 1

Size M125: 3/8-24.................... I34-007

Size M150 & M200: 1/2-13 ...... I37-005

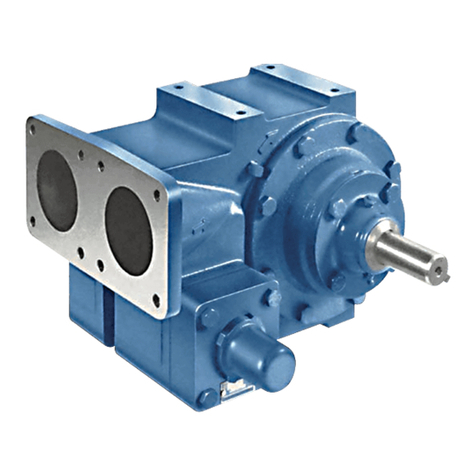

7 Frame .......................................... I34-012 1

8 3/8-16 X 3/4” Hex Head Screw ...... 34916 4

9 Shaft........................................................ 1

Size M125 ................................ I34-014

Size M150 & M200: .................. I37-014

10 Sealed Ball Bearing......................... 16228 2

11 Internal Retaining Ring..................... 26548 1

12 3/8-16 X 1” Heax Head Screw...... I34-017 2

13 Outlet NPT Adapter Assembly

with Check Valve 7/8-14 X 1/2” ... I34-060 1

14 Inlet NPT Adapter 3/4-16 X 1/2” ... I34-050 1

Item Part

# Description Number Qty

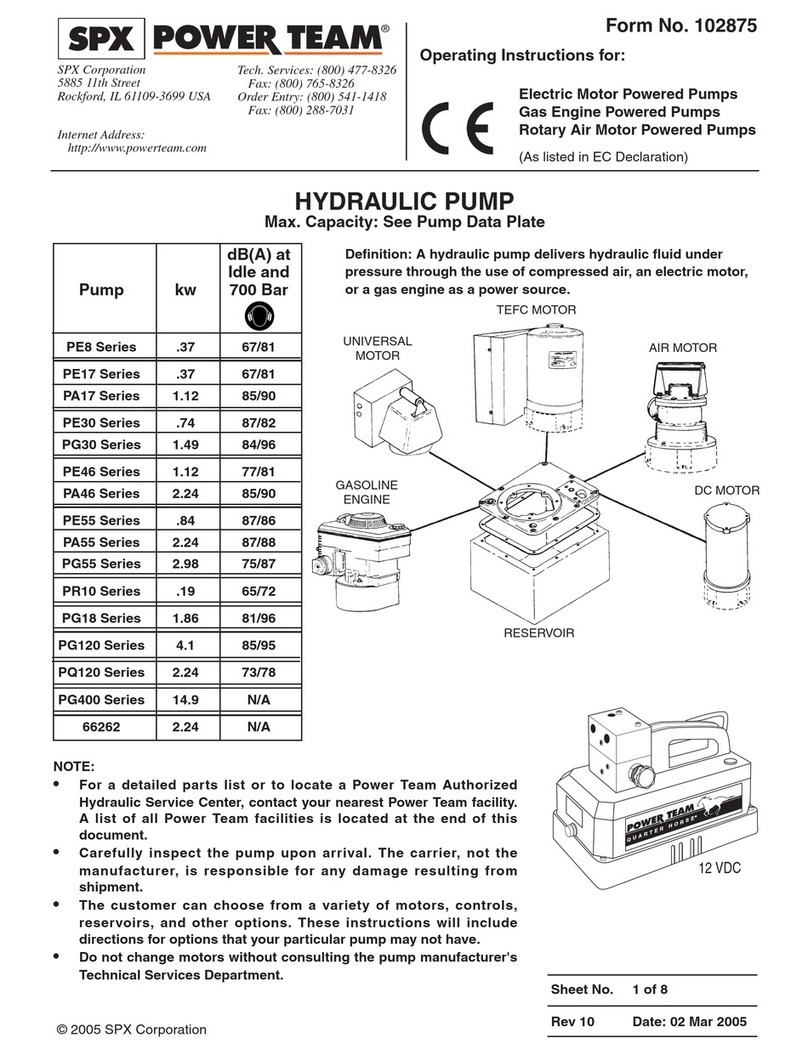

15 Hydraulic Motor ........................................ 1

With Rear Ports:

5-7 GPM PM21 Motor............... I34-029

7-10 GPM PM37 Motor............. I34-030

10-13 GPM PM45 Motor........... I34-031

12-15 GPM PM58 Motor........... I34-032

With Side Ports:

12-15 GPM PM58B Motor ........ I34-033

13-18 GPM PM70B Motor ........ I34-034

16 Seal Assembly.......................................... 1

Size M125: Viton/Silicon Carbide .. I34-010

Size M125: Viton/Ceramic ............ I34-011

Size M150 & M200: Viton/Silicon

Carbide........................................ I37-010

Size M150 & M200: Viton/

Ceramic ....................................... I37-011

17 Impeller Assembly..................................... 1

Size M125: 1-1/4” Nylon .............. I34-040

Size M125: 1-1/4” Polypropylene.. I34-043

Size M150: 1-1/2” Nylon .............. I37-040

Size M150: 1-1/2” Polypropylene with

SS Support Insert ........................ I37-043

Size M150: 1-1/2” Polypropylene.. I37-047

Size M200: 2” Nylon..................... I39-040

Size M200: 2” Polypropylene with

SS Support Insert ......................... I39-043

Size M200: 2” Polypropylene ........ I39-049

18 Adapter O-ring Seal .................................. 1

3/4” .......................................... 31351-15

7/8” .......................................... 31351-16

Item Part

# Description Number Qty

Repair Kits

Part Number Description

RK-M125VC Repair Kit with Viton/Ceramic Seals for M125

RK-M125VS Repair Kit with Viton/Silicon Carbide Seals for M125

RK-M215VC Repair Kit with Viton/Ceramic Seals for M150 & M200

RK-M215VS Repair Kit with Viton/Silicon Carbide Seals for M150 & M200

904003 Hydraulic Motor Bypass Valve Assembly

904804 Hydraulic Motor Seal Kit

904824 Hydraulic Motor Bearing Kit (includes bearings and seal kit) ......