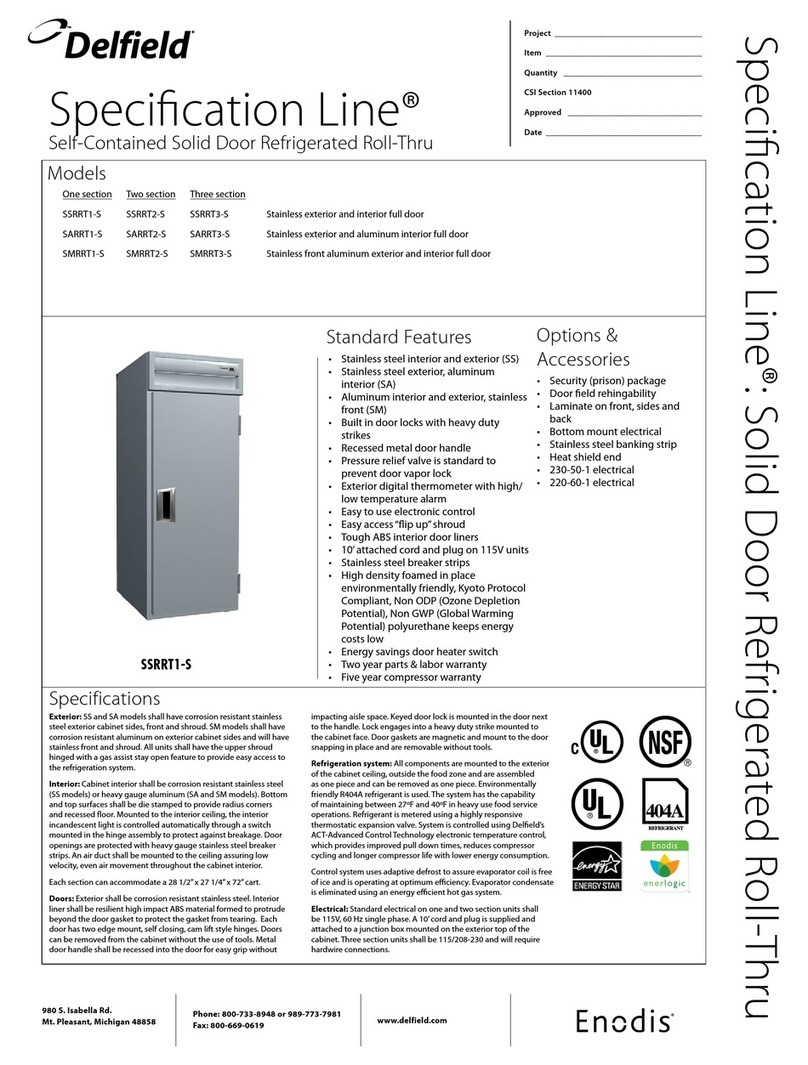

6000XL Reach-In Refrigeration

The 6000XL series reach-in refrigeration is specifically

designed to serve the commercial foodservice market.

Well thought out features like efficient and space saving

top mount refrigeration systems, stay open doors

that make loading and unloading easy, very cleanable

seamless interior liners and the capability to

accommodate 18”x26” sheet pans

make the 6000XL series a perfect fit

for enhancing productivity in your

foodservice operation.

Real Value

The initial investment in Delfield’s

6000XL series is more than justified

by the benefits your operation

will derive from its’ use in your

kitchen. The product is standard

with features, designed to bolster

your bottom line increasing your

opportunities to generate revenues.

Realize:

6000XL provides a great environment

for storing your food products.

Fresh, safe, appealing food attracts

customers and allows you to set

menu prices at a level that reflects

the quality of the product your

putting on the table.

Reliable, solid state electronic control

Out performs conventional electromechanical controls with more precise

performance and longer life.

Our refrigeration systems on both refrigerators and freezers are designed to defrost

on demand, assuring continuous performance in any work environment. Hot humid

kitchens, heavy use, lots of door openings and closings? No problem. Adaptive

defrost senses conditions and assures a clean, ice free evaporator all the time. And

adaptive defrost lowers energy usage, saving you money.

Wide operating range

Our refrigeration systems allow for 27˚F to 40˚F operation on a refrigerator without

any special modifications. They have the range to meet the temperature needs of

your diverse menu.

Air moves through the coil more efficiently, creating better heat transfer, resulting in improved

temperature performance and faster recovery.

All models are standard with expansion valves. This provides variable refrigerant flow into the evaporator

for efficient operation, exceptional temperature performance and fast recovery.

Better energy efficiency with one fan motor rather than two. Fewer parts to wear out. Improved airflow

allows for better temperature maintenance and fast recovery.

More condensing surface allows for lower refrigerant pressures which result in better energy efficiency.

Larger coil surface also doesn’t clog as quickly from dirt and grease, requires less cleaning, provides more

efficient operation. Also optional condenser filter screen is available.

Controls are mounted integral to system base and are easy to access. Energy saver door heater on/off

switch placed next to the temperature mount. Wiring is concealed within the base of the system. The

condenser is easy to get at for cleaning.

Condensate removal extends all the way under the system base and has the capacity to handle

condensate in humid environments. The plastic pan will not corrode. Use energy efficient hot gas

refrigerant line to evaporate condensate.

Easy to read thermometer comes standard with visual high/low temp alarm.

Energy Efficient/Performance Capable

•All systems are built as one assembly offline, making for more exact assembly, raising quality, minimizing

the occurrence of refrigeration leaks. The new design averages a reduction of 10 joints/system over

the old.

• Only non-ozone depleting environmentally friendly refrigerants are used.

• One-piece system can be replaced in the field for service or for converting a refrigerator to a freezer or

vice-versa.

• All units are energy efficient, meeting Energy Star and California Energy Commission (CEC) standards.

Many meet CEE tier II standards and may have rebates to the end user through local utilities. Energy

numbers are available on specification sheets and on the Delfield website, www.delfield.com.

• Systems have the capacity to provide consistent temperatures in demanding conditions, with fast

recovery in periods of peak use.

• Systems are designed to be easy to service and maintain.

• Systems are designed to run quiet, putting less noise into the kitchen.

Saves space with all of the components

up and out of the storage area. Heat

is released up and away from the

refrigerated storage compartment.

Airflow circulates throughout the cabinet

with low velocities to ensure consistent,

safe food temperatures without drying

out the product.

Tough, thermal formed ABS material

won’t dent, ding or crack. Seamless one-

piece construction is a snap to clean,

saving labor. Material acts as a superior

insulator, helping keep cold in and heat

out to keep operating costs low. Plus it’s

backed by a limited lifetime warranty.

Depth and height let you roll thru

doorways without having to tilt or lay

units on their sides.

No clips to hassle with - shelf supports

are molded into the cabinet interior.

Tough, corrosion resistant, epoxy coated

shelves slide into 15 different locations.

Provides extra pliability for a tighter seal.

Removable without tools for cleaning or

replacement.

More efficient than previous generations.

Keep the cold in and the heat out for low

operational costs. Non-greenhouse gas

emitting blowing agents are used in the

foaming process.

Doors stay open past 90˚ for hassle free

loading and unloading. Close with a

slight push - cam lift system does all of

the work.

Everything’s ready to go - no drilling

required. 6000XL units are easily

adjustable to changing kitchen workflow

patterns, enabling you to keep your

efficiencies.

Lets you move the unit around easily for

cleaning. (2 and 3 section units)

Top mount design, coupled with no

refrigeration compartments inside the

cabinet, gives you approximately 15%

more usable storage capacity than

competition, all in a narrow footprint

that saves valuable kitchen space.

Lots of surface to grab, easy to grip even

with your hands full.

Resilient material won’t dent, ding

or crack, keeping surface smooth for

cleaning. It’s formed to protrude past

the door gasket, protecting it from being

torn, lowering potential service costs.

Durable and pleasing to the eye. The

6000XL stays looking good for a long

time.

Lets you secure your valuable inventory,

reducing shrink risk.

6000XL has the depth to handle all the

pan types used in foodservice operations,

including 18”x26” sheet pans.

6000XL is standard with a full one-year parts and labor warranty, with an

additional 4 year parts warranty on the compressor. A two year parts and

labor warranty is available for a small upcharge. This warranty is supported

by a nationwide network of service provides and parts depots.